Study on reinforcement support for close coal seam dynamic pressure roadway

-

摘要:

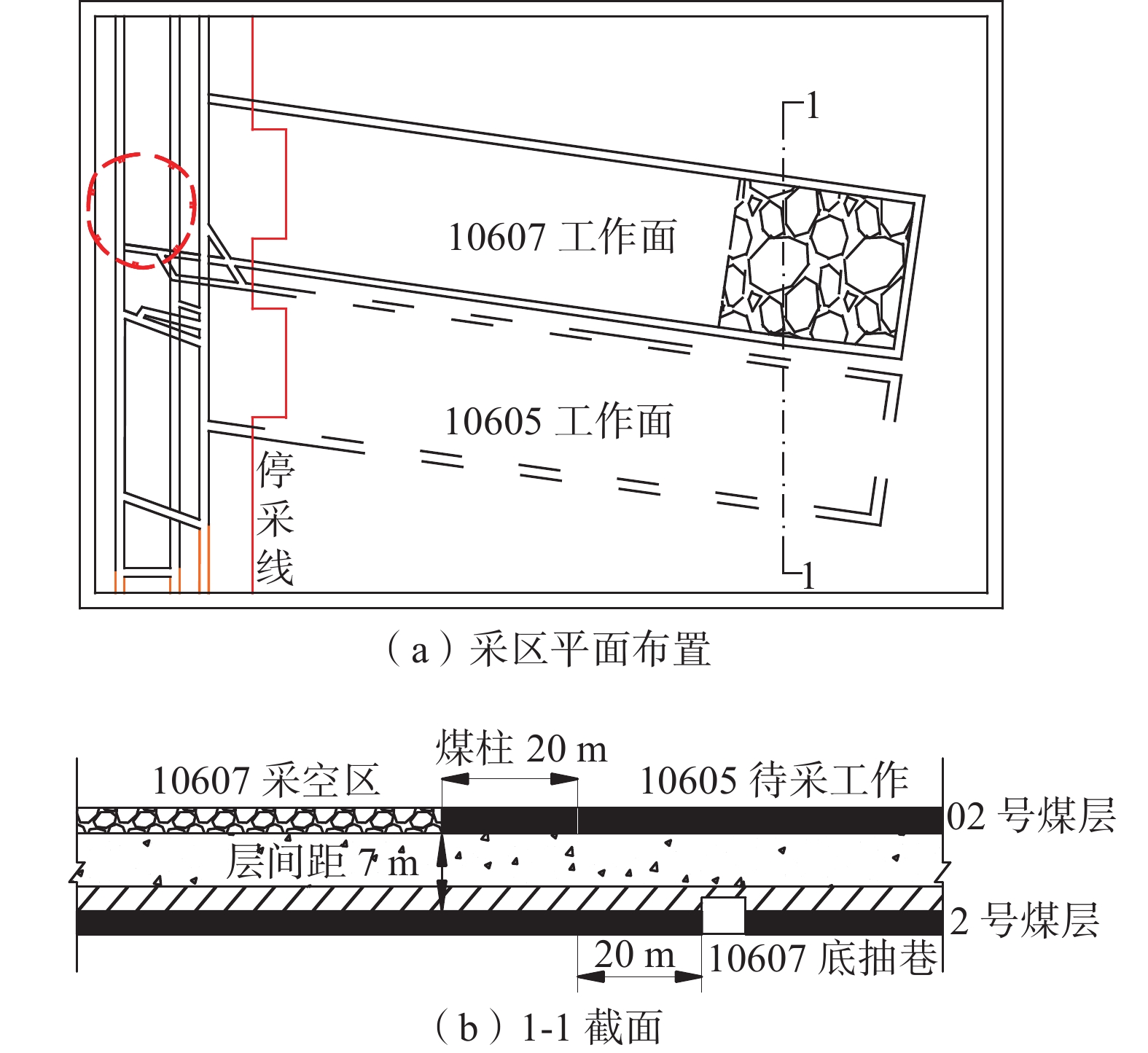

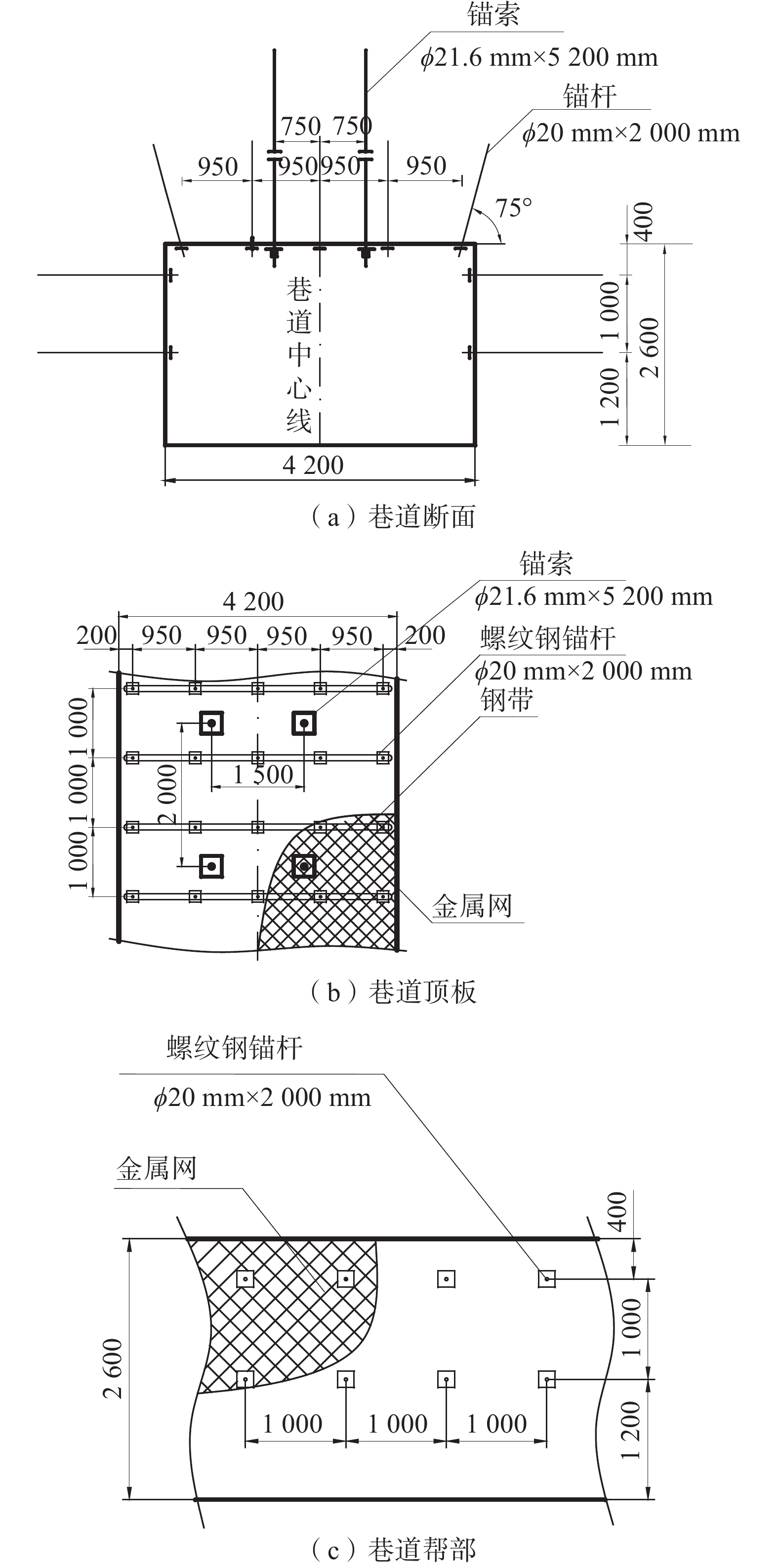

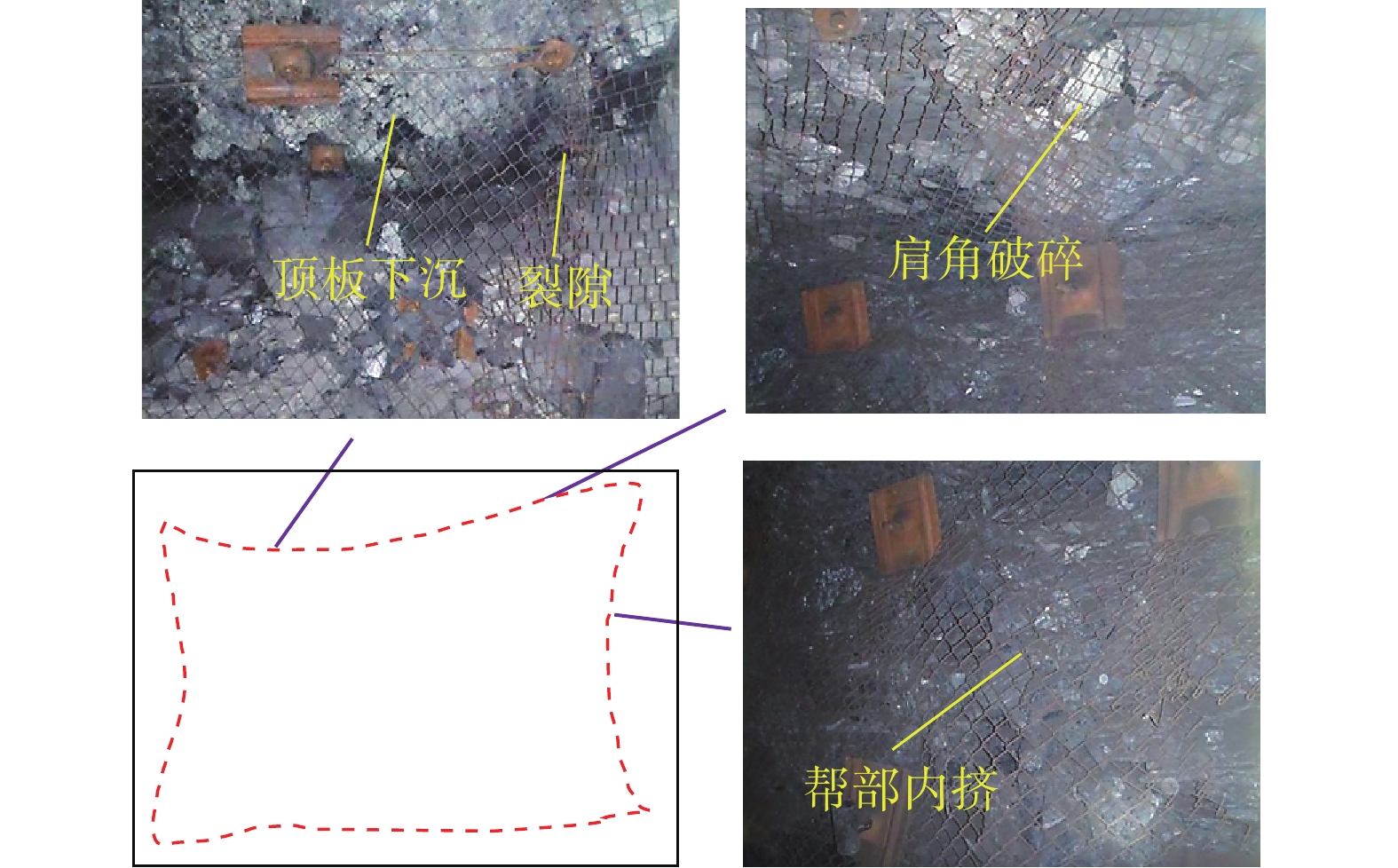

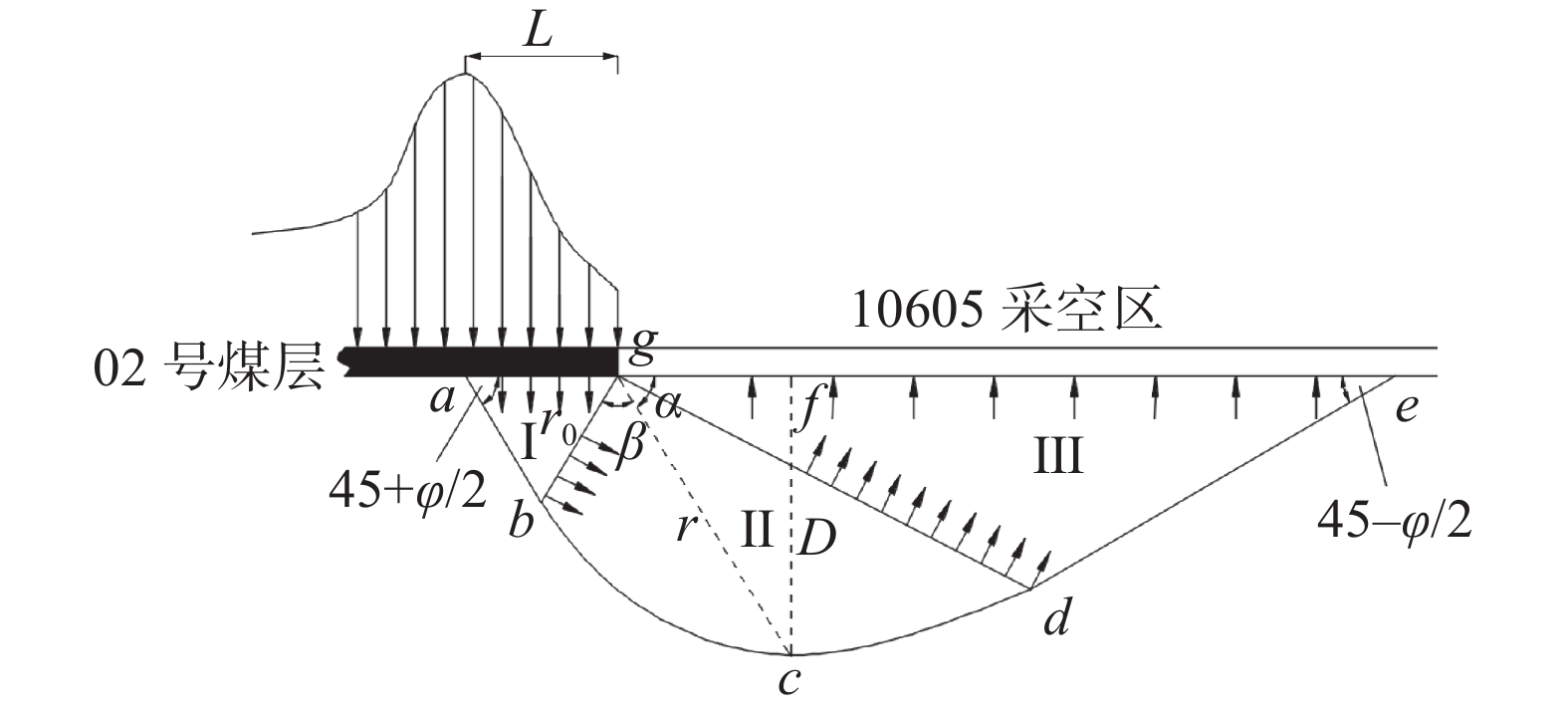

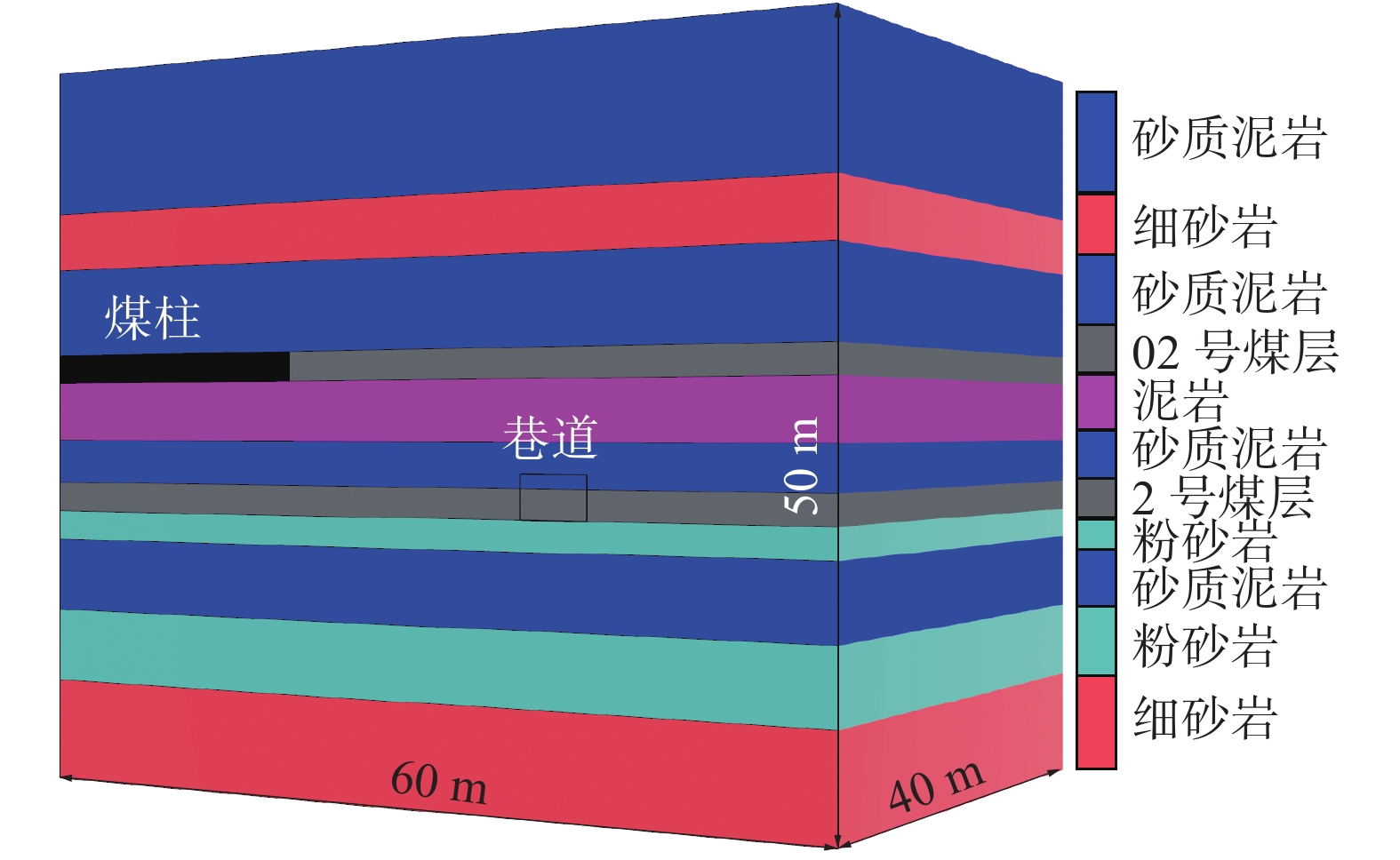

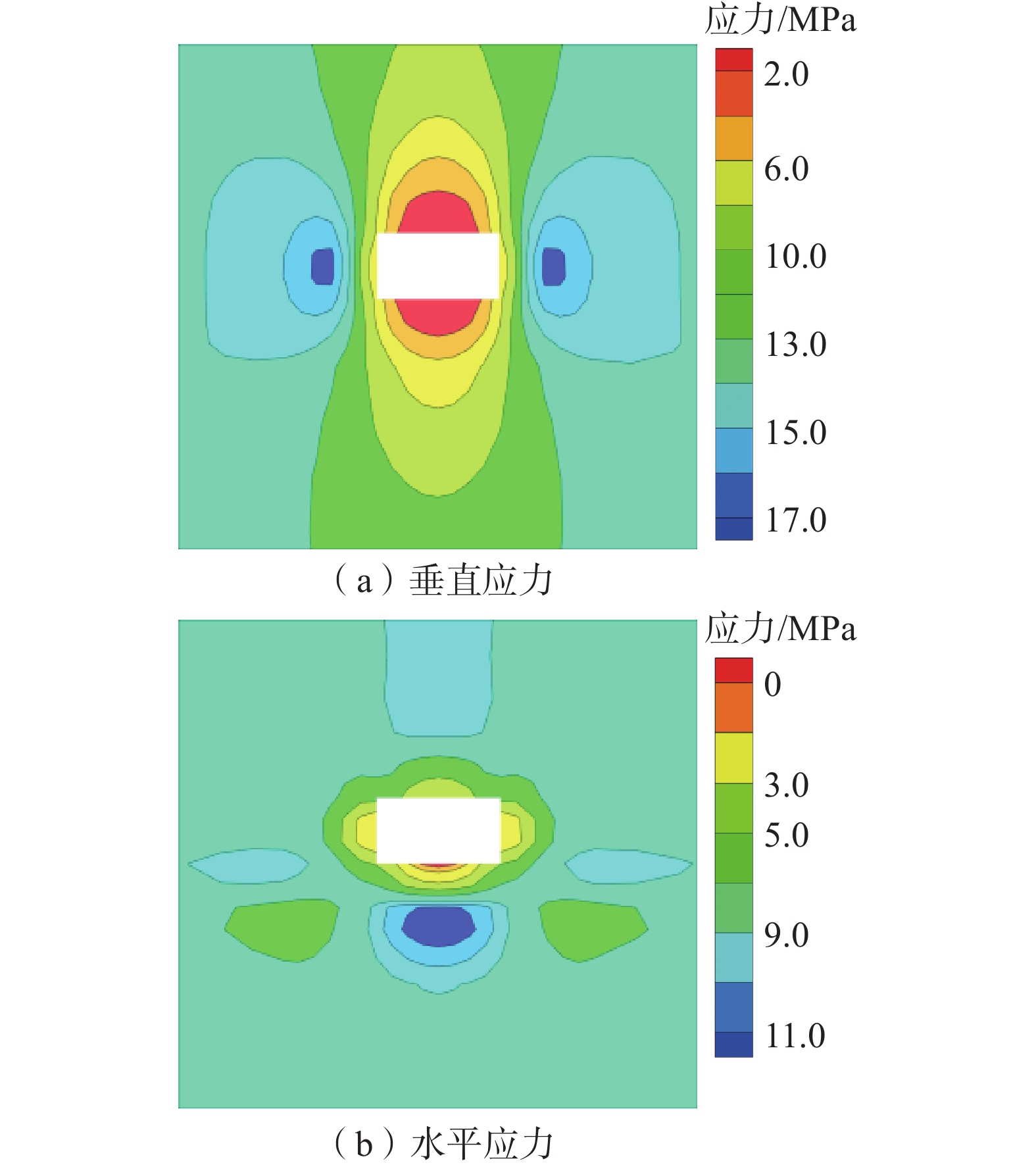

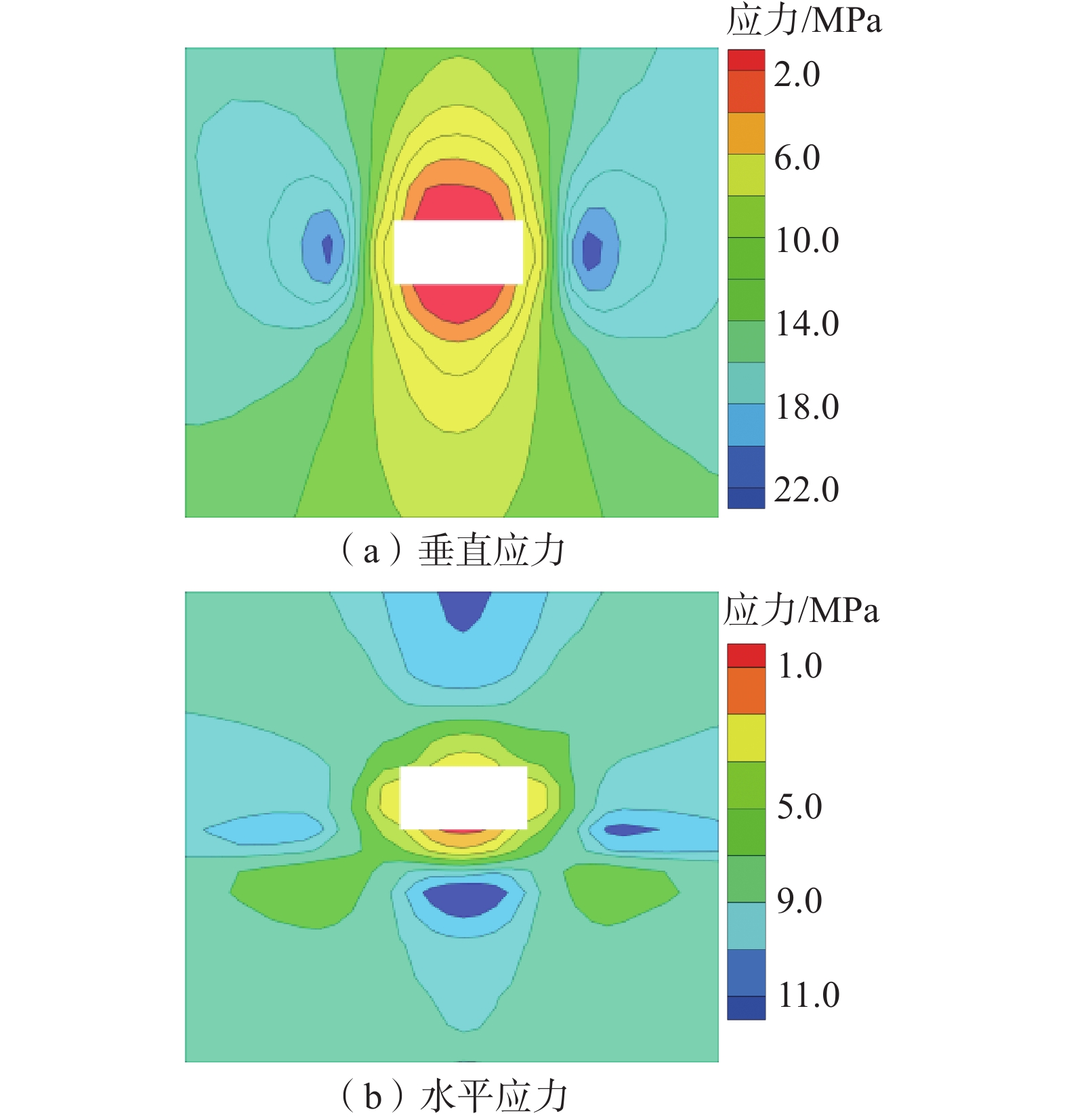

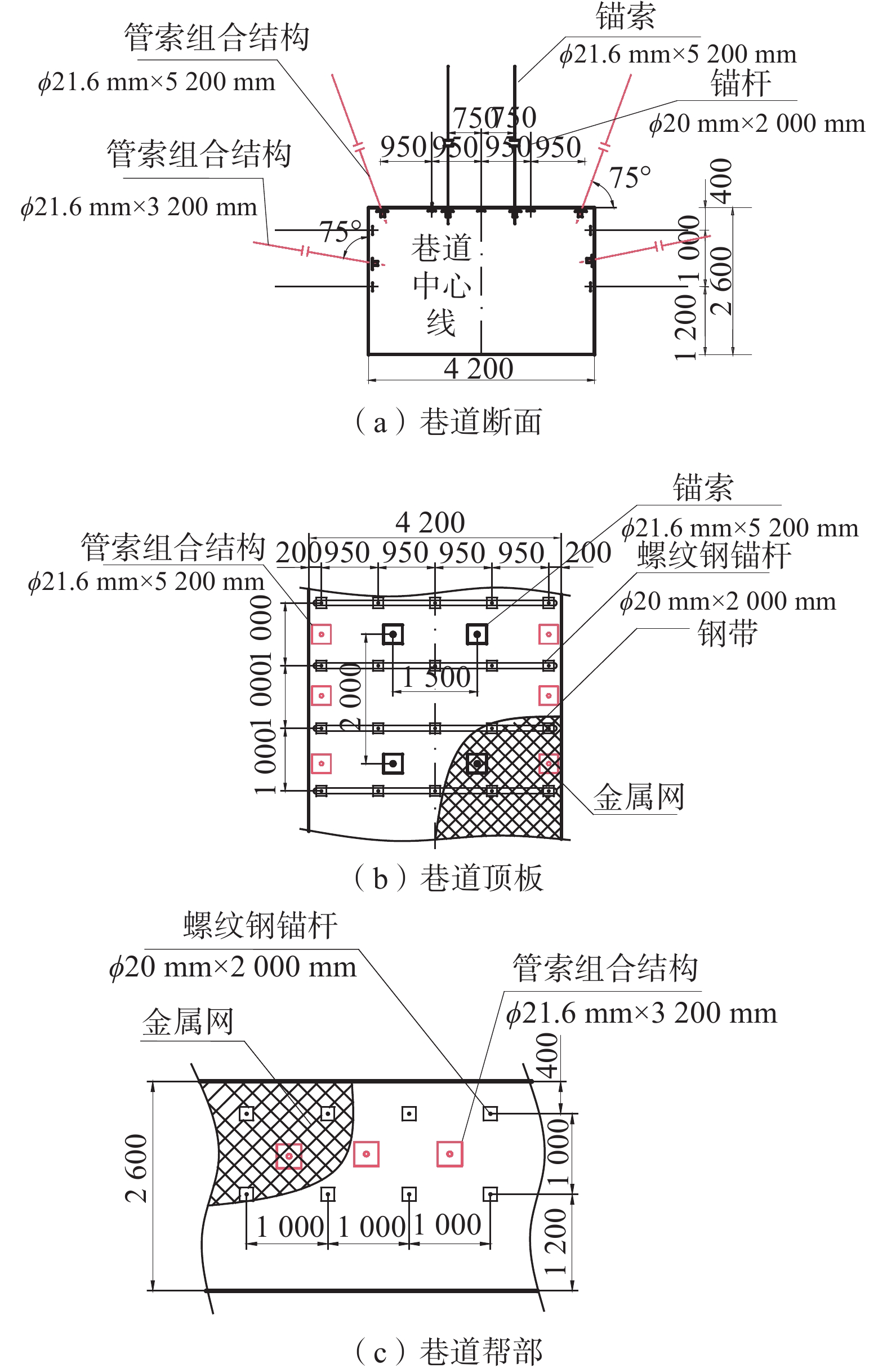

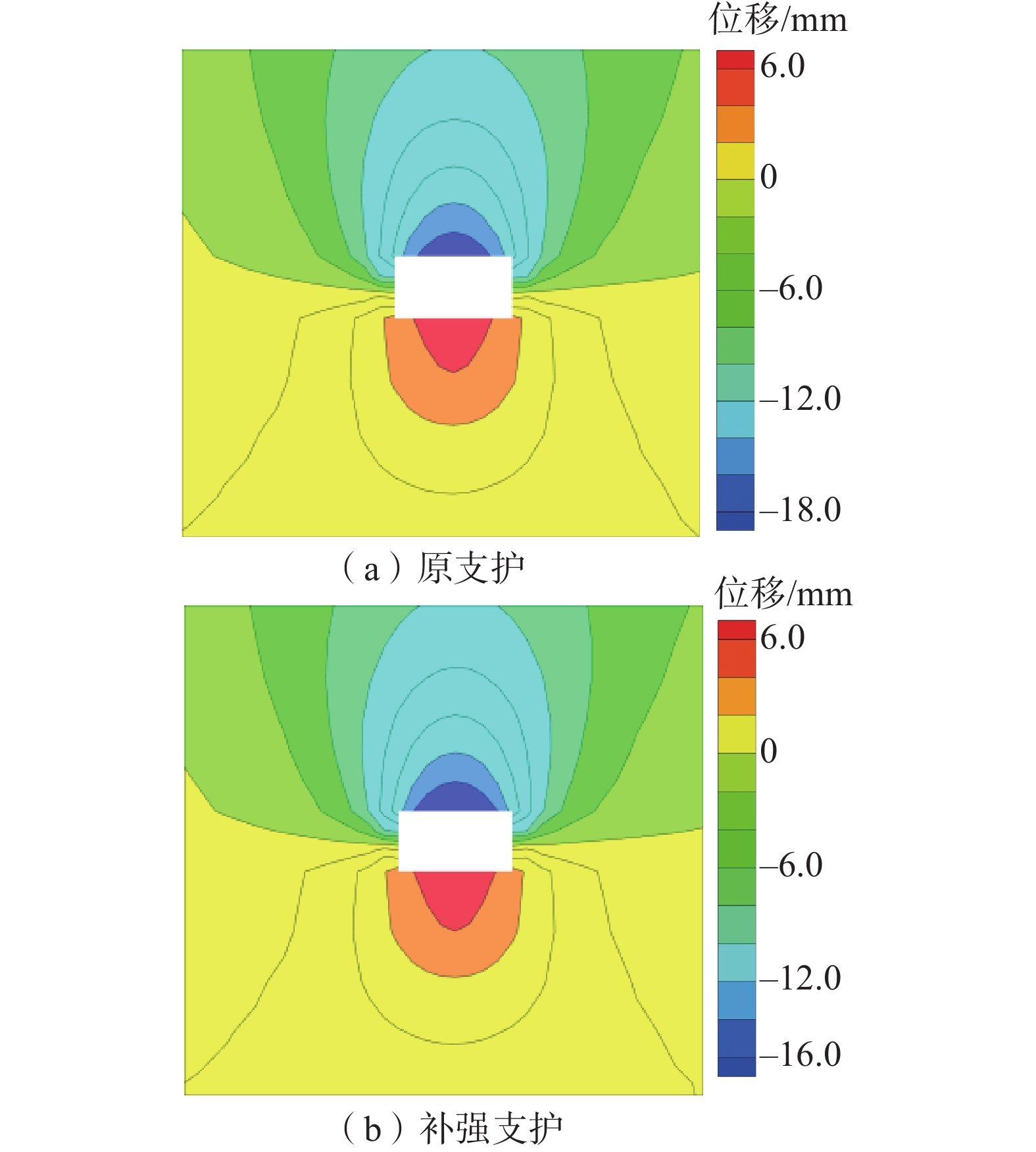

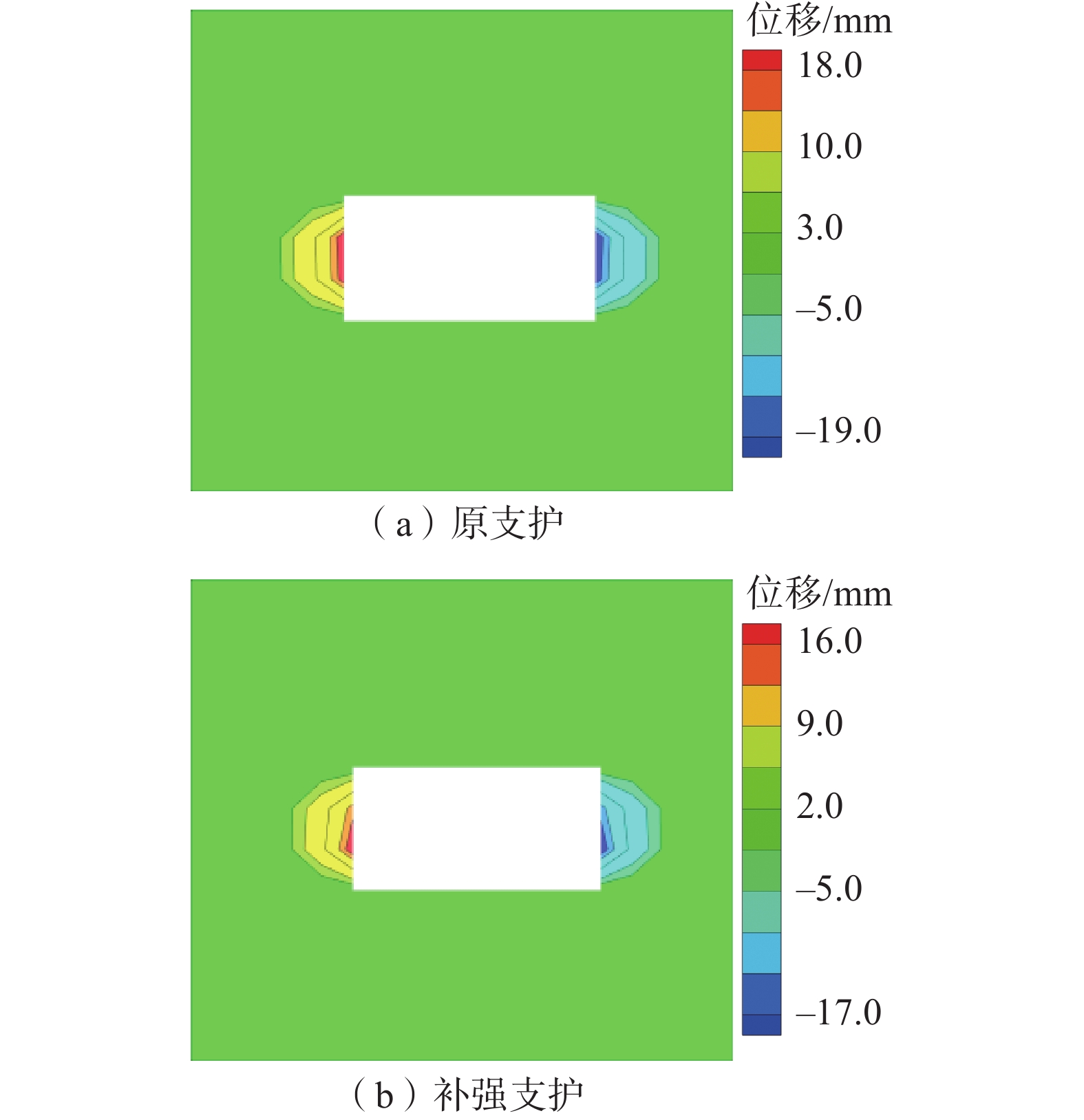

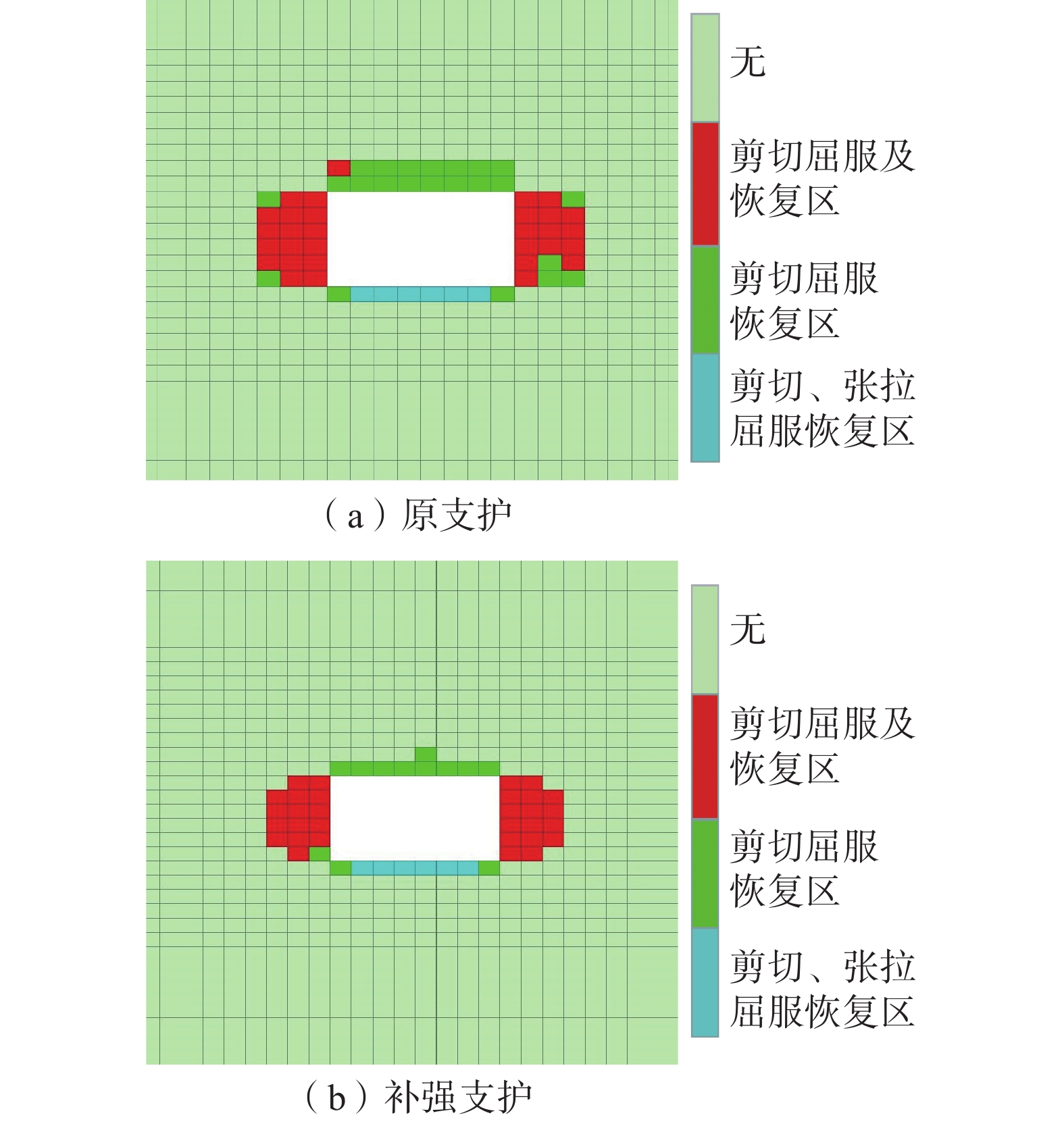

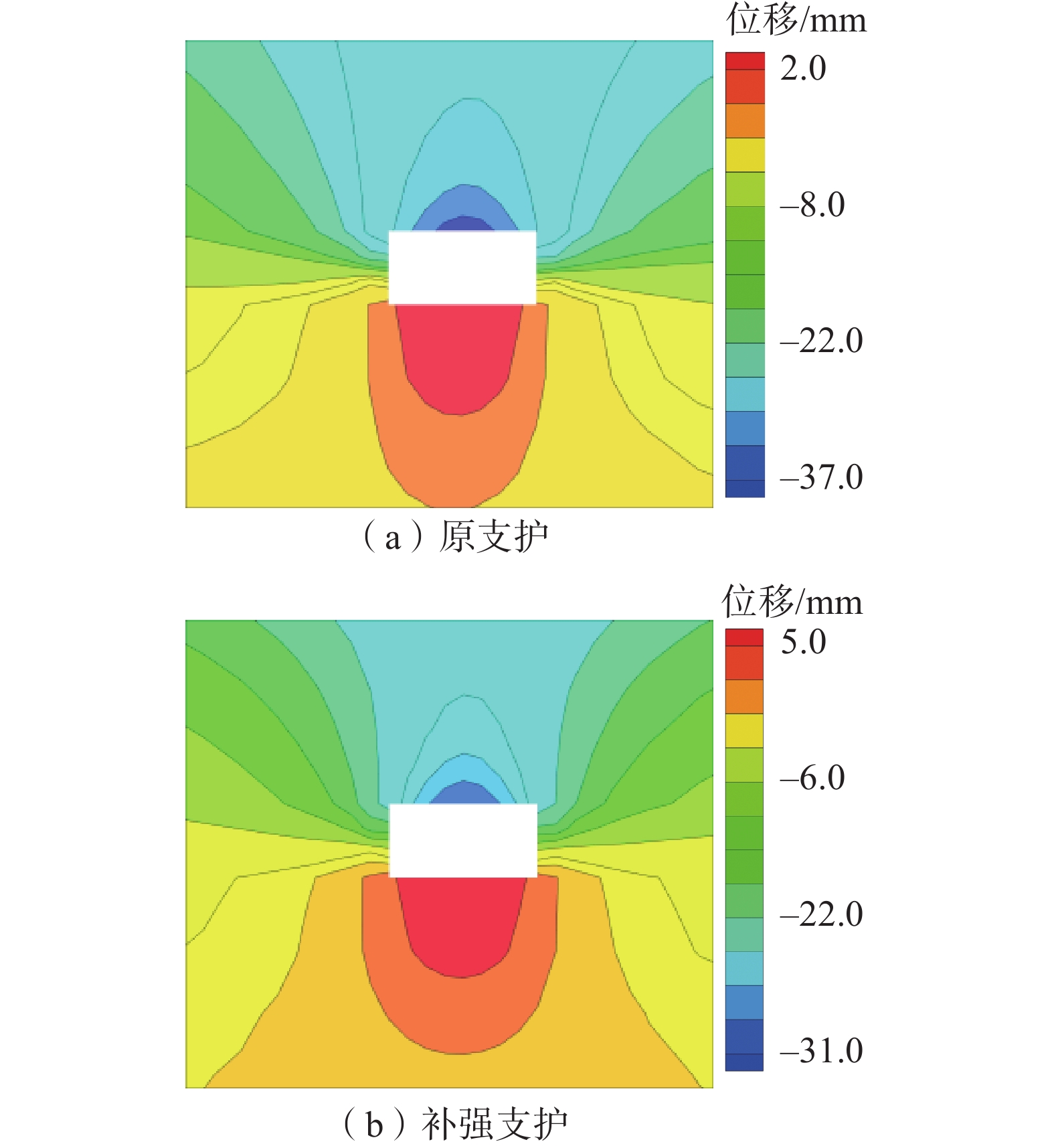

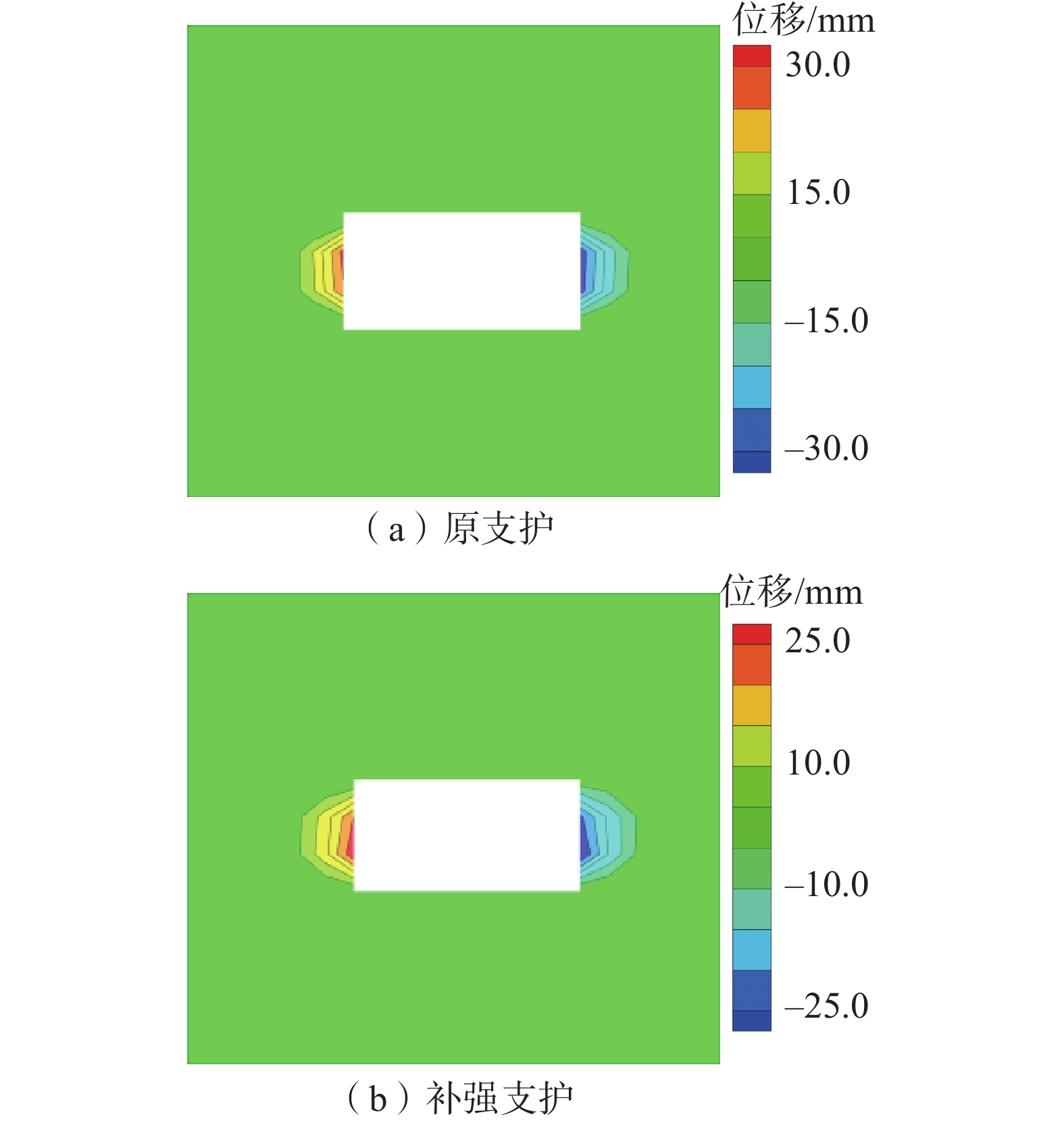

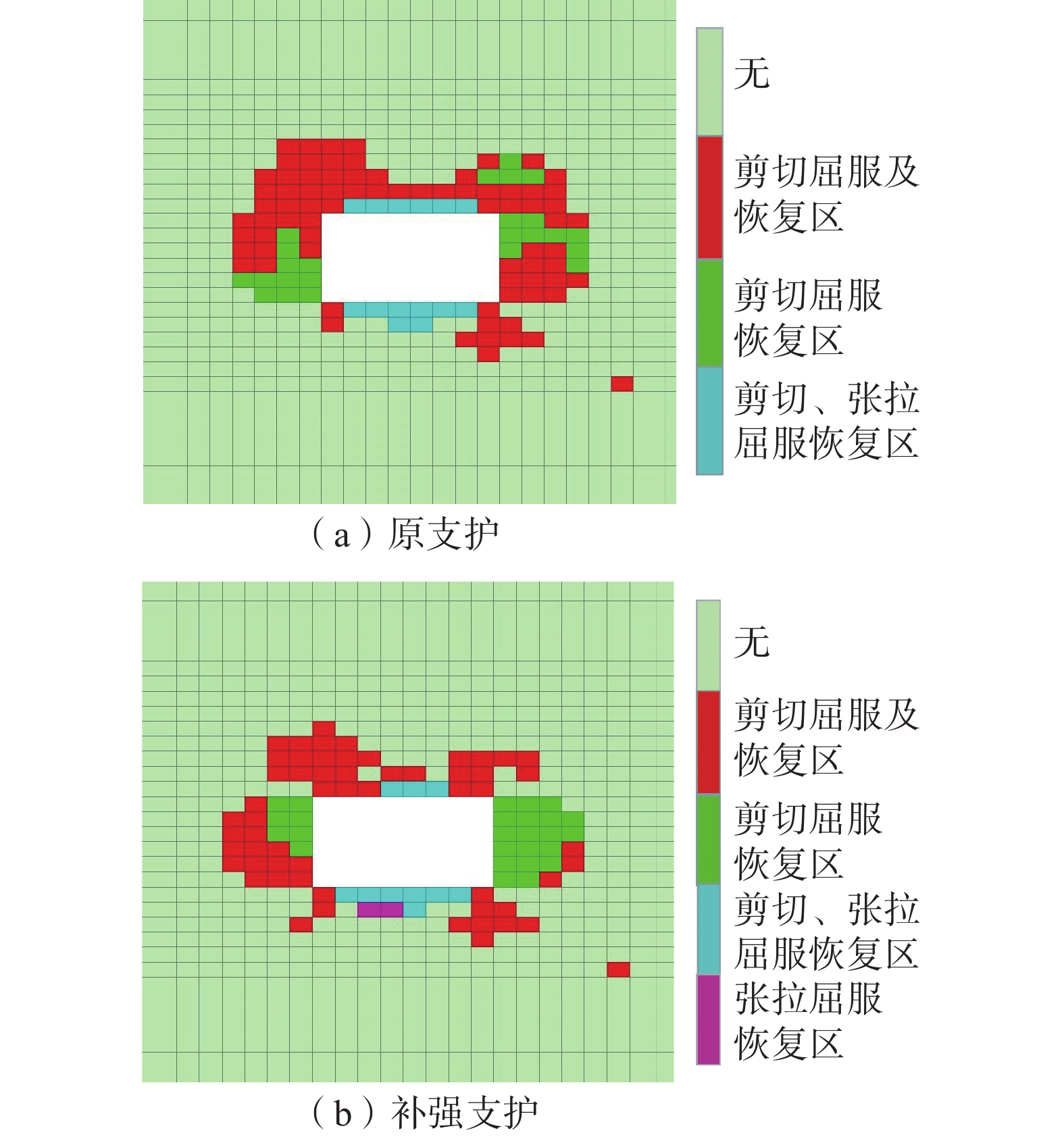

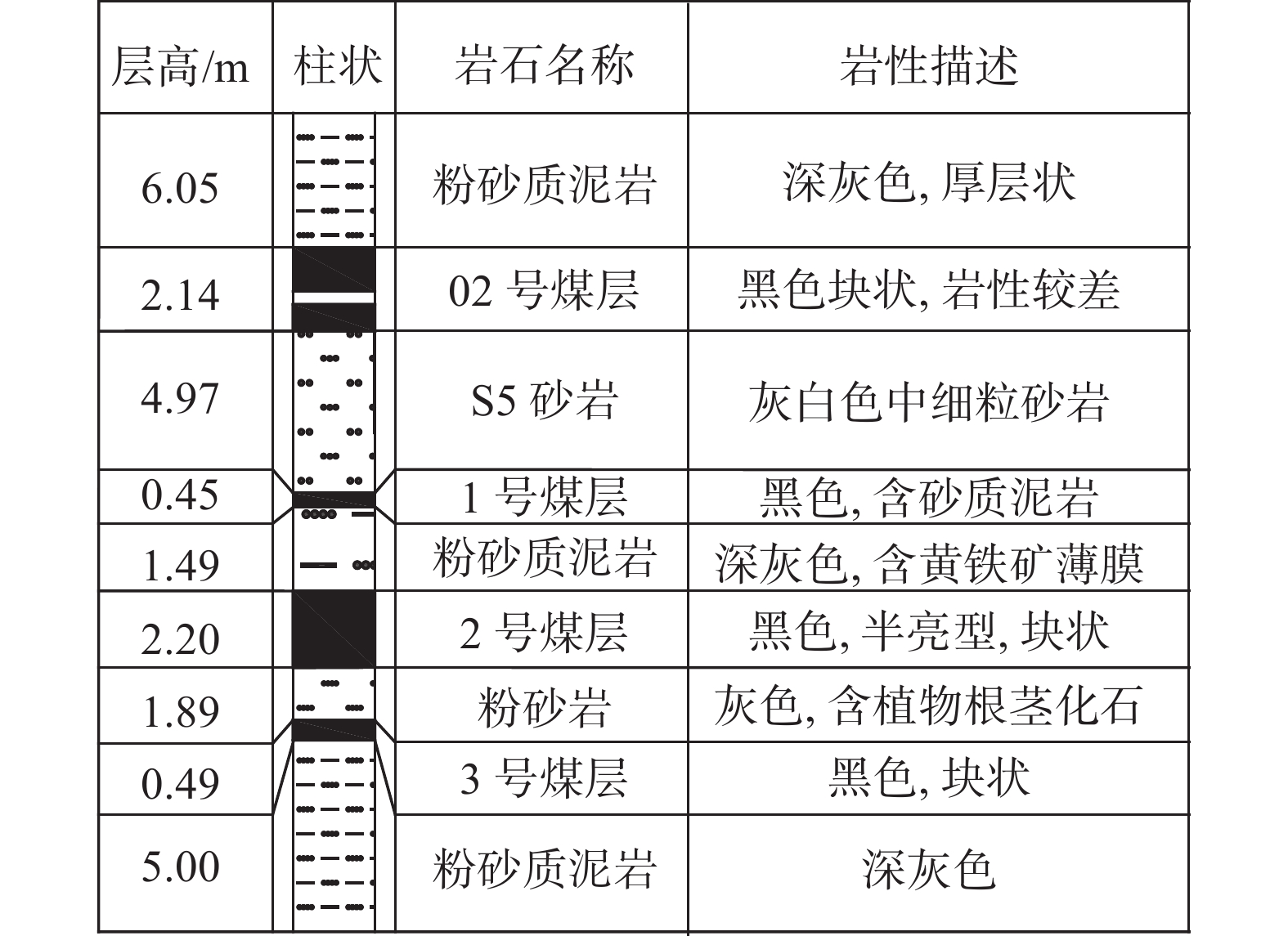

为了解决马兰矿近距离煤层上组煤采动影响下的下组煤巷道破坏严重、难于支护的问题,通过现场调研、数值模拟及理论分析,对巷道掘进后及上组煤回采期间的巷道围岩应力环境进行了分析;并基于此分析,提出原方案+管索组合结构的补强支护方案,对比了原支护方案及补强支护方案的塑性区发育和围岩变形情况。结果表明:补强支护方案下的巷道在掘进、采动影响下围岩的垂直、水平位移分别减少了12.76%、11.09%,17.06%、16.63%,塑性区发育的情况较原支护时也得到了明显改善;管索组合结构补强支护方案具有良好的支护效果,可以有效控制巷道围岩发育。

Abstract:In order to solve the severe damage and difficult support of lower group coal roadways under the influence of mining in upper group coal seams near Malan Mine, a field survey, numerical simulation, and theoretical analysis were conducted to analyze the stress environment of roadway surrounding rock during tunnel excavation and upper group coal mining. Based on this analysis, a strengthening support plan with combination structure of original plan and pipe cable was proposed, comparing the development of plastic zones and surrounding rock deformation between the original support plan and the strengthening support plan. The results showed that under the strengthening support plan, the vertical displacement and horizontal displacement of roadway surrounding rock reduced by 12.76%, 11.09%, and 17.06%, 16.63% respectively under tunnel excavation and mining influence, and the development of plastic zones was also significantly improved compared to the original support; the combination structure of pipe cable strengthening support plan has good supporting effect and can effectively control roadway surrounding rock development.

-

Keywords:

- close coal seam /

- mining impact /

- bottom plate damage /

- roadway support /

- numerical simulation

-

-

表 1 岩层力学参数

Table 1 Mechanical parameters of rock strata

岩层 体积模量/

GPa剪切模量/

GPa密度/

(kg·m−3)内摩擦角

/(˚)黏聚力/

MPa抗拉强度/

MPa砂质泥岩 3.8 2.6 2 350 32 3.3 2.40 细砂岩 11.3 6.8 2 500 32 3.1 2.70 粉砂岩 13.3 10.8 2 600 35 4.9 2.90 煤层 1.3 1.1 1 600 26 1.1 0.75 泥岩 3.6 2.1 2 300 32 2.3 2.20 -

[1] 杨昊睿,宁树正,丁恋,等. 新时期我国煤炭产业现状及对策研究[J]. 中国煤炭地质,2021,33(S1):44−48. YANG Haorui, NING Shuzheng, DING Lian, et al. Chinese coal industry status quo in new period and countermeasures study[J]. Coal Geology of China, 2021, 33(S1): 44−48.

[2] 康红普. 我国煤矿巷道围岩控制技术发展70年及展望[J]. 岩石力学与工程学报,2021,40(1):1−30. KANG Hongpu. Seventy years development and prospects of strata control technologies for coal mine roadways in China[J]. Chinese Journal of Rock Mechanics and Engineering, 2021, 40(1): 1−30.

[3] 陈炎光, 陆士良. 中国煤矿巷道围岩控制[M]. 徐州: 中国矿业大学出版社, 1994. [4] 单仁亮,黄博,郑赟,等. 竖向动载下巷道支护相似模拟试验装置的研制[J]. 岩土工程学报,2019,41(2):294−302. SHAN Renliang, HUANG Bo, ZHENG Yun, et al. Development of similar simulation equipment for roadway support subjected to vertical dynamic loads[J]. Chinese Journal of Geotechnical Engineering, 2019, 41(2): 294−302.

[5] 单仁亮,黄博,燕发源,等. 中兴矿沿空留巷工作面矿压显现规律研究[J]. 煤炭工程,2015,47(12):74−77. SHAN Renliang, HUANG Bo, YAN Fayuan, et al. Study on mine pressure behaviors of gob-side entry retaining working face in Zhongxing Mine[J]. Coal Engineering, 2015, 47(12): 74−77.

[6] 方新秋,何杰,何加省. 深部高应力软岩动压巷道加固技术研究[J]. 岩土力学,2009,30(6):1693−1698. FANG Xinqiu, HE Jie, HE Jiasheng. Research on reinforced technology for deep soft rock and dynamic pressurized roadway under high stress[J]. Rock and Soil Mechanics, 2009, 30(6): 1693−1698.

[7] 李昂,纪丙楠,牟谦,等. 深部煤岩层复合结构底板破坏机制及应用研究[J]. 岩石力学与工程学报,2022,41(3):559−572. LI Ang, JI Bingnan, MOU Qian, et al. Research on damage mechanism and application of composite structure footing of deep coal rock seam[J]. Chinese Journal of Rock Mechanics and Engineering, 2022, 41(3): 559−572.

[8] 袁越,王卫军,袁超,等. 深部矿井动压回采巷道围岩大变形破坏机理[J]. 煤炭学报,2016,41(12):2940−2950. YUAN Yue, WANG Weijun, YUAN Chao, et al. Large deformation failure mechanism of surrounding rock for gateroad under dynamic pressure in deep coal mine[J]. Journal of China Coal Society, 2016, 41(12): 2940−2950.

[9] 张向阳,常聚才,王磊. 深井动压巷道群围岩应力分析及煤柱留设研究[J]. 采矿与安全工程学报,2010,27(1):72−76. ZHANG Xiangyang, CHANG Jucai, WANG Lei. Study on surrounding rock stress and reasonable pillar of mining induced roadway groups in deep well[J]. Journal of Mining & Safety Engineering, 2010, 27(1): 72−76.

[10] 张向阳,常聚才. 上下采空极近距离煤层开采围岩应力及破坏特征研究[J]. 采矿与安全工程学报,2014,31(4):506−511. ZHANG Xiangyang, CHANG Jucai. Stress and failure characteristics of surrounding rock in the extremely close distance coal seams group mining after the upper and lower coal seam mining[J]. Journal of Mining & Safety Engineering, 2014, 31(4): 506−511.

[11] 武传伟. 高动压巷道分次联合支护及快速掘进技术研究[J]. 山东煤炭科技,2022,40(1):62−64. WU Chuanwei. Research on graded combined support and fast tunneling technology of high dynamic pressure roadway[J]. Shandong Coal Science and Technology, 2022, 40(1): 62−64.

[12] 任硕,周逸群,王鹏飞. 软弱夹层复合顶板动压巷道支护技术研究[J]. 煤炭技术,2021,40(8):32−36. REN Shuo, ZHOU Yiqun, WANG Pengfei. Study on support technology of dynamic pressure roadway support in soft and weak interlayer composite roof[J]. Coal Technology, 2021, 40(8): 32−36.

[13] 张洪清,汪占领,万峰,等. 动压巷道锚固失效机理及支护结构优化研究[J]. 煤矿机械,2021,42(7):129−134. ZHANG Hongqing, WANG Zhanling, WAN Feng, et al. Study on the mechanism of anchorage failure and optimization of support structure in dynamic pressure roadway[J]. Coal Mine Machinery, 2021, 42(7): 129−134.

[14] 姚顺. 采空区下掘进巷道围岩控制技术研究[J]. 煤,2019,28(5):20−21. YAO Shun. Research on rock control technology of tunneling roadway under mining area[J]. Coal, 2019, 28(5): 20−21.

[15] 王凯,薛兴伟. 大采高煤层回采对邻近巷道变形及控制研究[J]. 山西煤炭,2022,42(1):58−62. WANG Kai, XUE Xingwei. Study on the deformation and control of adjacent roadway by large mining height coal seam retrieval[J]. Shanxi Coal, 2022, 42(1): 58−62.

[16] 王济宇. 台头煤矿3206回风平巷深井动压巷道支护技术[D]. 徐州: 中国矿业大学, 2020. [17] 张佳文. 动压影响巷道顶帮底互控高强补强支护技术研究[J]. 煤炭工程,2019,51(S1):122−127. ZHANG Jiawen. Research on dynamic pressure affected roadway top and bottom mutual control high strength reinforcement support technology[J]. Coal Engineering, 2019, 51(S1): 122−127.

[18] 何富连,张广超. 大断面采动剧烈影响煤巷变形破坏机制与控制技术[J]. 采矿与安全工程学报,2016,33(3):423−430. HE Fulian, ZHANG Guangchao. Deformation and failure mechanism and control technology of large section coal roadway subjected to severe mining dynamic load[J]. Journal of Mining & Safety Engineering, 2016, 33(3): 423−430.

[19] 张清清. 断层破碎区动压巷道稳定性分析及支护参数优化[J]. 煤炭技术,2022,41(4):49−52. ZHANG Qingqing. Analysis of dynamic pressure roadway stability and optimization of support parameters in fracture zone[J]. Coal Technology, 2022, 41(4): 49−52.

[20] 单仁亮,仝潇,黄鹏程,等. 管索组合结构及其力学性能研究[J]. 岩土力学,2022,43(3):602−614. SHAN Renliang, TONG Xiao, HUANG Pengcheng, et al. Research on tube and cable combination structure and its mechanical properties[J]. Rock and Soil Mechanics, 2022, 43(3): 602−614.

[21] 单仁亮,孔祥松,燕发源,等. 煤巷强帮强角支护技术模型试验研究与应用[J]. 岩石力学与工程学报,2015,34(11):2336−2345. SHAN Renliang, KONG Xiangsong, YAN Fayuan, et al. Research on sidewall and corner strengthened support for coal roadway by modeling experiments[J]. Chinese Journal of Rock Mechanics and Engineering, 2015, 34(11): 2336−2345.

[22] 张后全,石浩,李明,等. 基于锚杆轴力实测的综采工作面区段煤柱稳定性分析[J]. 煤炭学报,2017,42(2):429−435. ZHANG Houquan, SHI Hao, LI Ming, et al. Stability analysis of section coal pillar at a fully-mechanized working face based on axial bolt load tests[J]. Journal of China Coal Society, 2017, 42(2): 429−435.

[23] 杨征,丁彦雄,高晓君. 基于切顶卸压技术的动压巷道力学响应破坏机制试验研究[J]. 煤矿安全,2021,52(7):47−53. YANG Zheng, DING Yanxiong, GAO Xiaojun. Experimental study on mechanical response failure mechanism of dynamic pressure roadway based on roof cutting and pressure releasing technology[J]. Safety in Coal Mines, 2021, 52(7): 47−53.

[24] 冯廷灿,邹德均,周诗建. 动压影响下留窄煤柱沿空掘巷围岩控制技术[J]. 煤矿安全,2018,49(3):87−90. doi: 10.13347/j.cnki.mkaq.2018.03.023 FENG Tingchan, ZOU Dejun, ZHOU Shijian. Surrounding rock control technology of narrow coal pillar gob-side entry driving under dynamic pressure[J]. Safety in Coal Mines, 2018, 49(3): 87−90. doi: 10.13347/j.cnki.mkaq.2018.03.023

[25] 马振通. 回采工作面动压区U型钢支护托棚加固技术[J]. 煤矿安全,2017,48(9):89−91. MA Zhentong. Reinforcement technology of U type steel support shed in mining face of dynamic pressure area[J]. Safety in Coal Mines, 2017, 48(9): 89−91.

[26] 钱鸣高, 石平五, 许家林. 矿山压力与岩层控制[M]. 徐州: 中国矿业大学出版社, 2010. [27] 张金才, 张玉卓, 刘天泉. 岩体渗流与煤层底板突水[M]. 北京: 地质出版社, 1997. [28] 石浩. 采动岩体强度演化及锚-岩相互作用研究[D]. 徐州: 中国矿业大学, 2021. -

期刊类型引用(15)

1. 张铎,孙伟,郭曦蔓,岑孝鑫,代爱萍. 煤制油气化灰渣防灭火凝胶的制备及性能. 材料导报. 2024(03): 255-261 .  百度学术

百度学术

2. 姜小龙,孙明,常建平,董红娟. 矿井煤自燃防灭火材料阻燃机理综述. 内蒙古科技大学学报. 2024(03): 226-229 .  百度学术

百度学术

3. 李洋,戴广龙,杨苗苗. 高保水矿用凝胶阻化材料的制备和性能研究. 煤炭技术. 2023(03): 173-177 .  百度学术

百度学术

4. 段西凯,周睿,何勇军. 矿用超吸水防灭火凝胶制备及性能研究. 煤矿安全. 2023(02): 71-76 .  本站查看

本站查看

5. 谢军,卞兆庆,解恒星,王怡,王法铨. 基于CiteSpace的矿用凝胶研究趋势分析. 煤矿安全. 2023(02): 54-60 .  本站查看

本站查看

6. 王海军,吴艳,马良,陈崇枫,孙保平,王相业,吴敏杰,刘善德. 陕北浅埋煤层一体化漏风通道探查技术. 煤矿安全. 2023(04): 83-90 .  本站查看

本站查看

7. 陈鹏燕,周春山,程熙宇. CMC/AlCit/GDL防灭火凝胶的流变性能及本构方程研究. 应用化工. 2023(04): 1010-1014 .  百度学术

百度学术

8. 唐金召,范利丹,张纪云,徐峰,余雳伟,杨杰,赵伟. 我国煤矿巷道锚杆支护理论及技术研究进展. 煤矿安全. 2023(06): 131-143 .  本站查看

本站查看

9. 王毅泽,董凯丽,张玉龙,董智宇,王俊峰. CMC/ZrCit/GDL防灭火凝胶泡沫的制备及特性研究. 煤炭科学技术. 2023(06): 122-129 .  百度学术

百度学术

10. 陈鹏燕,周春山. 矿用双网络凝胶防灭火特性研究. 煤矿安全. 2023(11): 84-91 .  本站查看

本站查看

11. 杨苗苗,戴广龙. 矿用煤自燃防治高吸水高保水性水凝胶的制备及性能研究. 煤矿安全. 2022(02): 40-45 .  本站查看

本站查看

12. 卜祝龙,张铎,吕英英,王慧,王泓皓,杨娟娟. 煤渣填充防火凝胶配比实验研究. 粘接. 2022(01): 12-18 .  百度学术

百度学术

13. 韩福志,邵和,司俊鸿,张俊. 矿用堵漏无机触变防灭火凝胶的流变特性研究. 矿业安全与环保. 2022(01): 1-7 .  百度学术

百度学术

14. 刘东. 基于程序升温实验的煤低温氧化特性数值模拟研究. 煤矿安全. 2022(05): 40-45 .  本站查看

本站查看

15. 秦存利,刘袁昊,李军. 新型高分子材料防灭火技术研究与安全评估. 山东煤炭科技. 2021(10): 212-215+218+225 .  百度学术

百度学术

其他类型引用(10)

下载:

下载: