Stick-slip vibration characteristic of PDC bit cutting composite strata based on discrete element method

-

摘要:

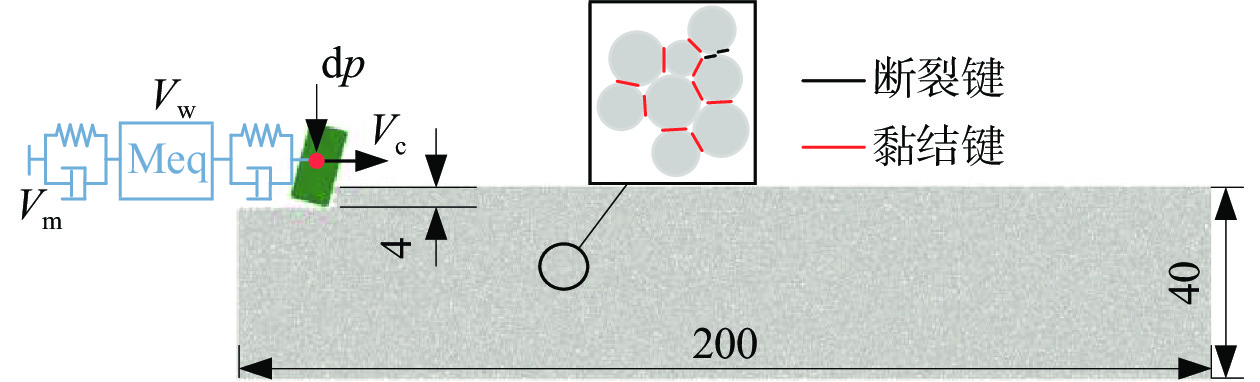

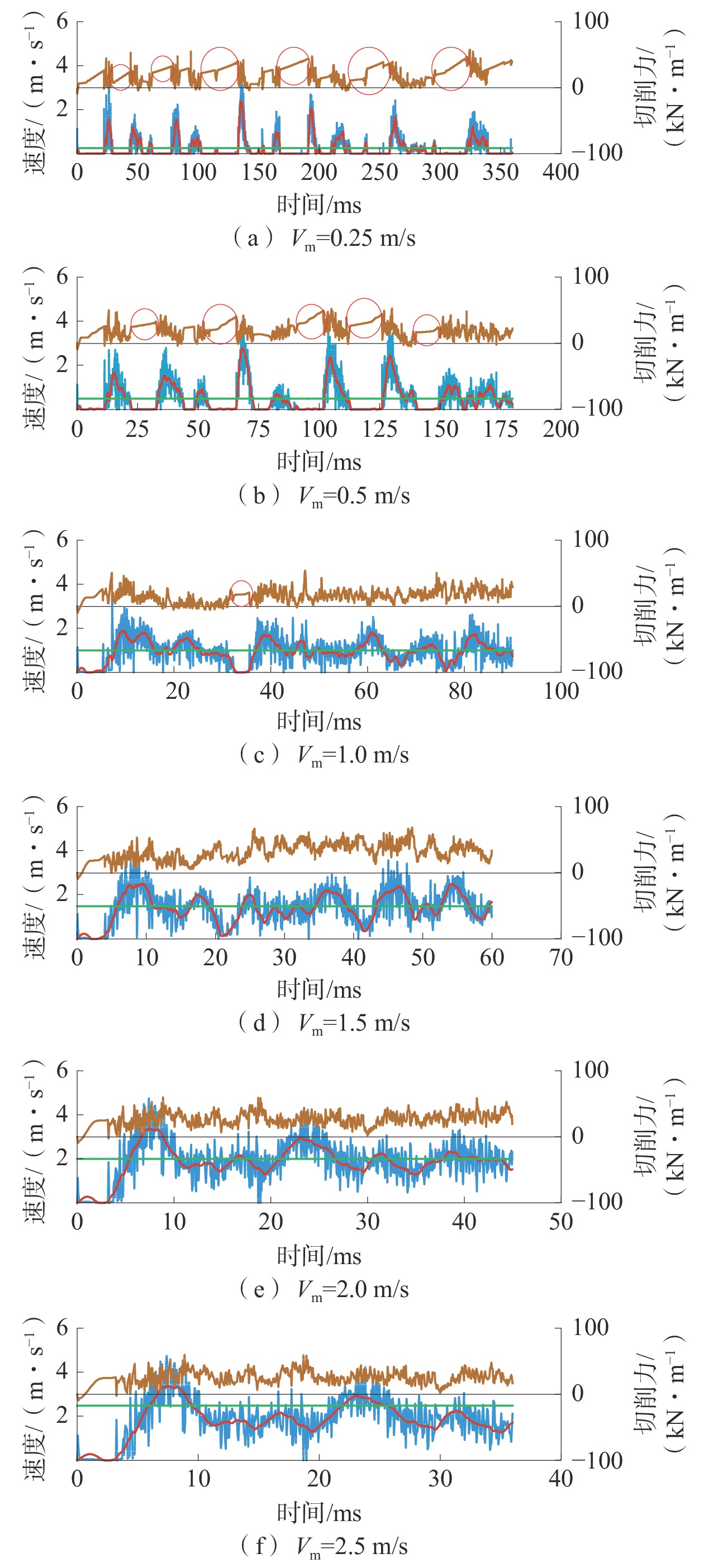

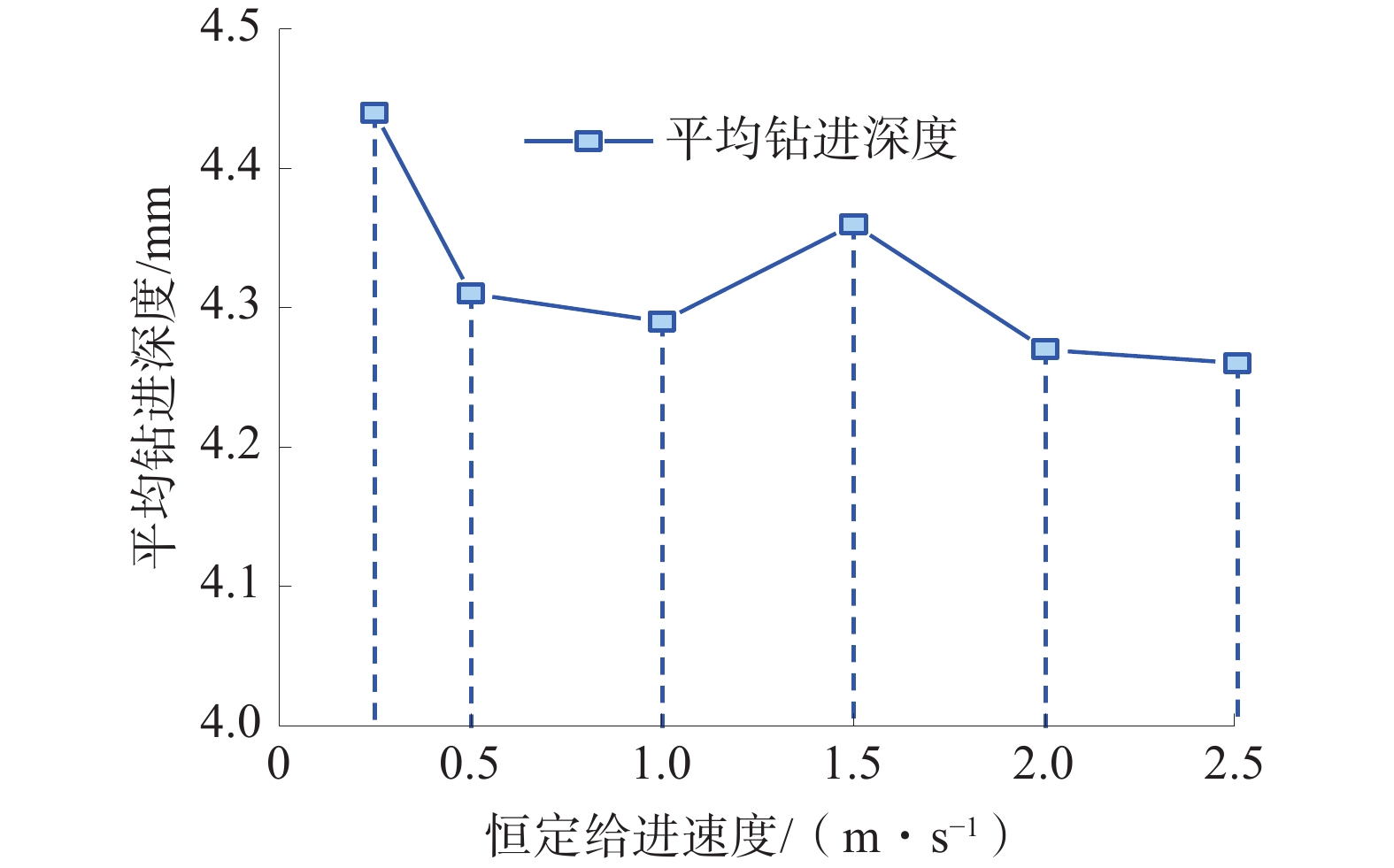

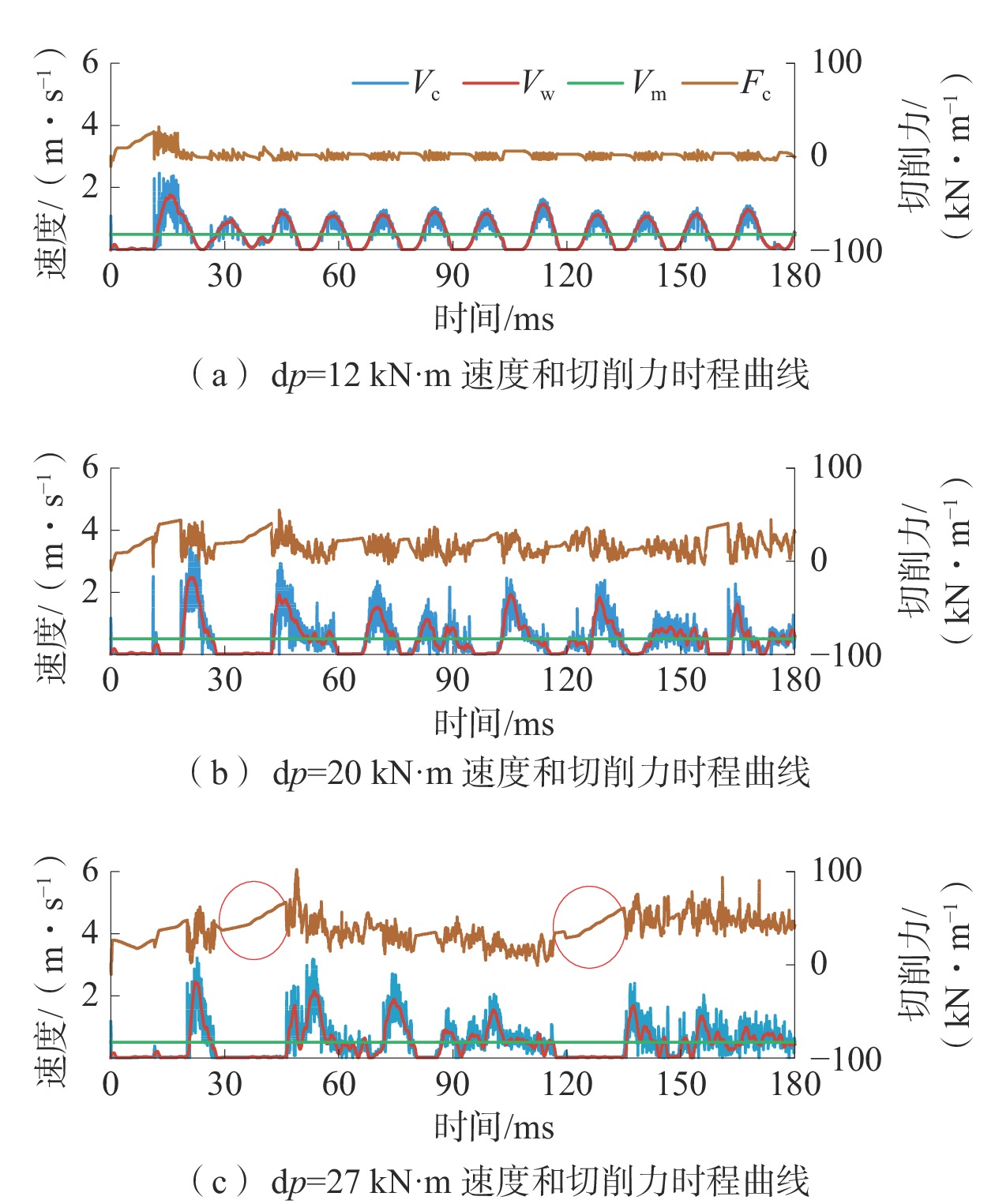

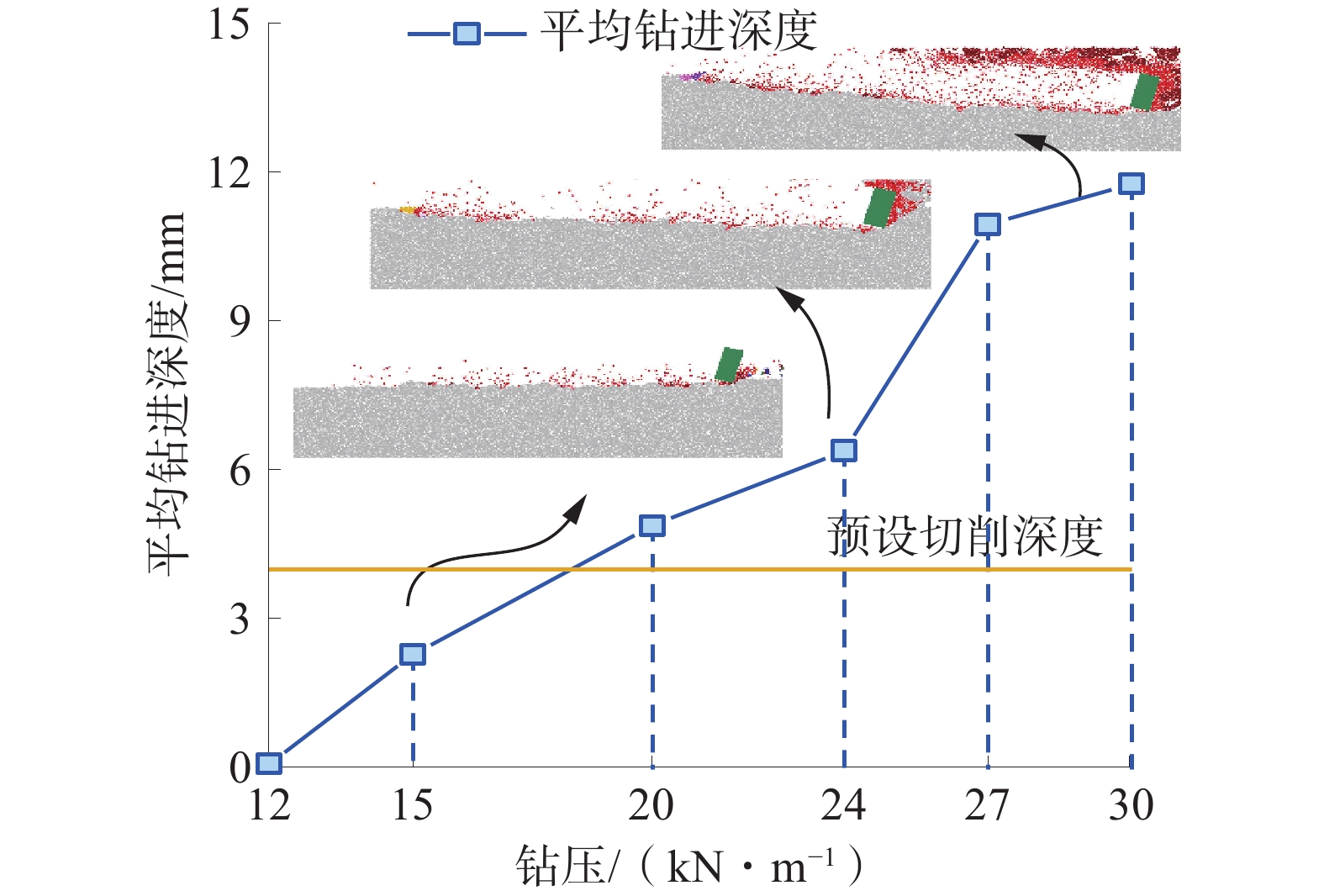

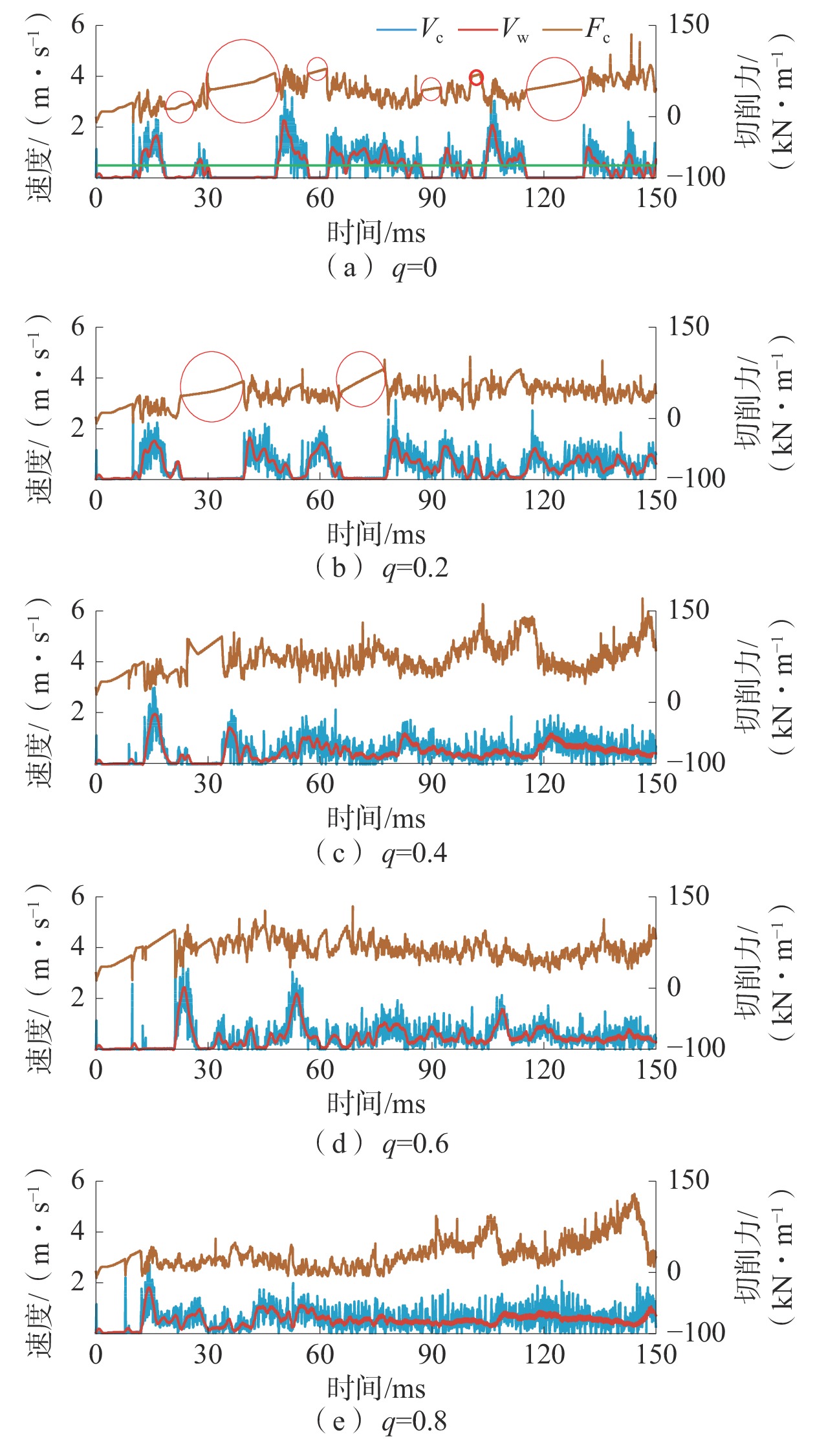

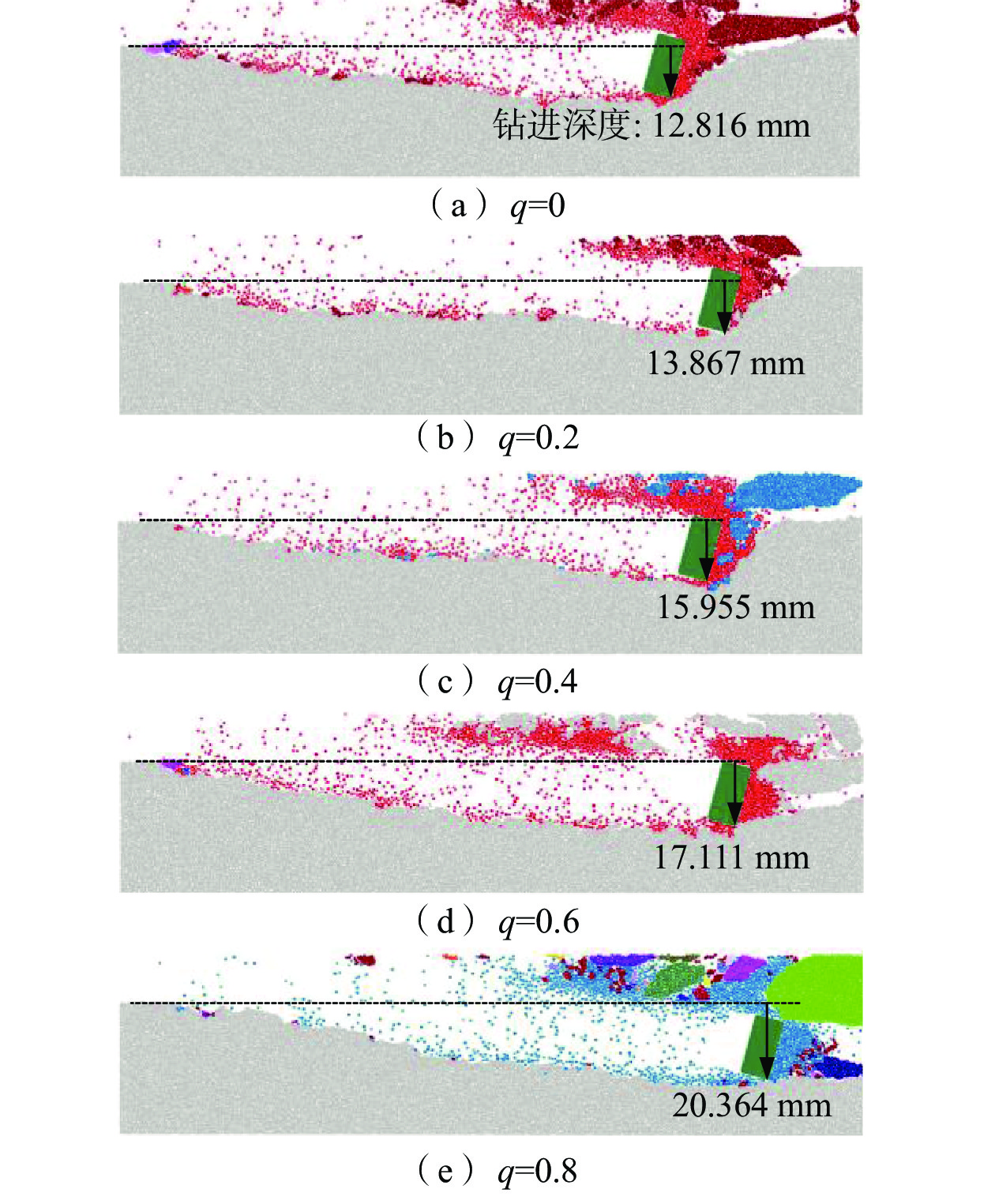

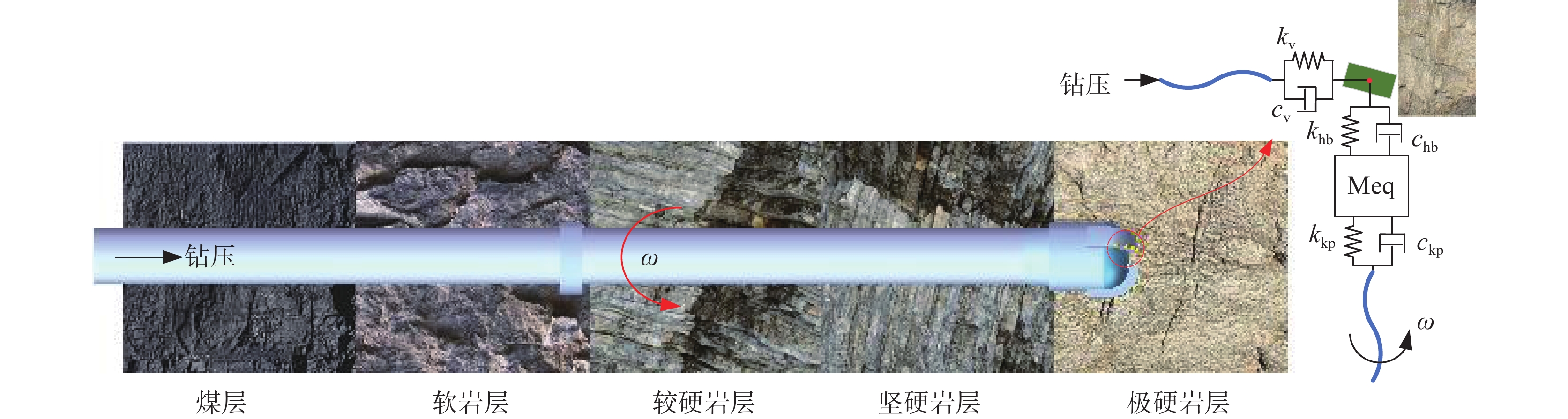

针对煤矿井下钻孔时钻头穿层钻进过程中遇到坚硬岩层而发生黏滑振动的问题,借助离散元数值模拟技术开展了PDC齿在5种典型硬度地层中切削破岩性能及黏滑振动特性研究。结果表明:钻头黏滑现象随着地层硬度的增加愈发明显,PDC齿切削极硬岩层时在岩石表面滑移而无法有效钻进;提高钻头转速在一定程度上能够减弱黏滑振动,但对提高钻进性能无明显增益效果;增加钻压能够显著提高钻头钻进效率,但同时会导致更严重的黏滑振动;采用扭转冲击方法能够有效减弱甚至抑制钻头的黏滑振动且能够提高钻头的钻进性能,但过大的扭转冲击会导致钻头所受冲击载荷增加。

Abstract:For the problem of stick-slip vibration caused by hard rock formation in the process of drill bit penetrating in coal mine, and the discrete element method (DEM) was employed to study the rock cutting performance and stick-slip vibration behavior of PDC bit drilling in five typical different hardness rock strata. The result shows that the stick-slip phenomenon of the bit is more obvious with the increasing of the formation hardness, and in the ultra-hard rock layer, it slips on the rock surface and cannot be effectively drilled. The approach of increasing the rotational speed of the bit can weaken the stick-slip behavior to an extent, but it has no obvious effect on improving the drilling efficiency. The drilling performance of the bit can be improved by increasing drilling pressure, but it will also lead to more serious stick-slip vibration. The torsional impact method can effectively weaken or even inhibit the stick-slip vibration of the bit and improve the drilling performance. However, excessive torsional impact force will lead to an increase in the impact load on the bit.

-

-

表 1 仿真中复合地层中颗粒力学参数

Table 1 Physical and mechanical parameters of particles of composite strata in simulation

岩层 ν E/GPa UCS/MPa Emod/GPa Krat Pb-coh/MPa Pb-ten/MPa 煤 0.14 3.73 15.1 3.84 3.06 9.76 6.93 软岩 0.17 7.96 29.3 8.06 3.15 11.24 9.68 较硬岩 0.23 14.7 72.0 13.5 3.34 19.6 13.1 硬岩 0.24 22.9 100.4 24.3 3.32 25.6 19.3 极硬岩 0.29 48.0 156.0 48.0 3.66 32.0 24.2 注:ν为颗粒泊松比;E为颗粒弹性模量;UCS为单轴抗压强度;Emod为颗粒黏结键有效模量;Krat为颗粒黏结键法向和切向刚度比;Pb-coh为颗粒黏结强度;Pb-ten为颗粒拉伸强度。 -

[1] 彭旭,郝世俊. 全尺寸PDC钻头复合冲击破岩机理的有限元分析[J]. 煤田地质与勘探,2021,49(2):240−246. PENG Xu, HAO Shijun. Rock breaking mechanism of composite impact of full-size PDC bit based on finite element analysis[J]. Coal Geology & Exploration, 2021, 49(2): 240−246.

[2] 李子丰,杨海滨,许春田,等. 定向井滑动钻进送钻原理与技术[J]. 天然气工业,2013,33(12):94−98. LI Zifeng, YANG Haibin, XU Chuntian, et al. Bit feed principles and technologies in slide-drilling directional wells[J]. Natural Gas Industry, 2013, 33(12): 94−98.

[3] 李思琪,毕福庆,李玮,等. 扭转冲击钻井稳态钻进动力学特性及现场应用[J]. 中国石油大学学报(自然科学版),2019,43(2):97−104. LI Siqi, BI Fuqing, LI Wei, et al. Dynamic characteristics of steady torsional impact drilling and its field application[J]. Journal of China University of Petroleum (Edition of Natural Science), 2019, 43(2): 97−104.

[4] 黄志强,范永涛,魏振强,等. 冲旋钻头破岩机理仿真研究[J]. 西南石油大学学报(自然科学版),2010,32(1):148−150. HUANG Zhiqing, FAN Yongtao, WEI Zhenqiang, et al. Emulation study on rock-breaking mechanism of percussion-rotary bit[J]. Journal of Southwest Petroleum University (Science & Technology Edition), 2010, 32(1): 148−150.

[5] 李思琪,闫铁,李玮,等. 高频谐波振动冲击破岩机制及试验分析[J]. 中国石油大学学报(自然科学版),2015,39(4):85−91. LI Siqi, YAN Tie, LI Wei, et al. Mechanism experimental study of rock breaking assisted with high frequency harmonic vibration and impaction[J]. Journal of China University of Petroleum(Edition of Natural Science), 2015, 39(4): 85−91.

[6] 汪伟,柳贡慧,李军,等. 复合冲击钻井工具结构设计与运动特性分析[J]. 石油机械,2019,47(7):24−29. WANG Wei, LIU Gonghui, LI Jun, et al. Structural design and motion behavior analysis of composite percussion drilling tool[J]. China Petroleum Machinery, 2019, 47(7): 24−29.

[7] 闫炎,管志川,玄令超,等. 复合冲击条件下PDC钻头破岩效率试验研究[J]. 石油钻探技术,2017,45(6):24−30. YAN Yan, GUAN Zhichuan, XUAN Lingchao, et al. Experimental study on rock breaking efficiency with a PDC bit under conditions of composite percussion[J]. Petroleum Drilling Techniques, 2017, 45(6): 24−30.

[8] 田家林,胡志超,张昕,等. 纵扭复合冲击工具动力学特性研究[J]. 机械工程学报,2022,58(7):141−151. TIAN Jialin, HU Zhichao, ZHANG Xin, et al. Study on dynamic characteristics of longitudinal torsional composite impactor[J]. Journal of Mechanical Engineering, 2022, 58(7): 141−151.

[9] HAN Xiaoming, LI Peibo, XUE Liubing, et al. Stick-slip vibration characteristics of drilling tool during drilling in coal seam with gangue[J]. Science Progress, 2022, 105(1): 1−14.

[10] 王皓琰. 岩性及切削深度对PDC钻头粘滑振动的影响研究[D]. 青岛: 中国石油大学, 2020. [11] 张冯豆. 典型复合地层钻进过程仿真及钻柱动态特性仿真[D]. 武汉: 中国地质大学, 2022. [12] ZHANG Heng, NI Hongjian, HUANG Bin, et al. Research on discrete element modeling and numerical simulation of cutting rock behavior under impact load[J]. Energy Science & Engineering, 2022, 10(7): 2420−2436.

[13] 孟凡海. 基于离散元的PDC齿冲击破岩规律研究[D]. 大庆: 东北石油大学, 2017. [14] ZHANG Heng, NI Hongjian, WANG Zizhen, et al. Discrete element modeling and simulation study on cutting rock behavior under spring-mass-damper system loading[J]. Journal of Petroleum Science and Engineering, 2022, 209: 1−14.

[15] 豆旭谦. 煤矿井下穿层钻孔高效钻进方法[J]. 煤矿安全,2020,51(5):126−129. DOU Xuqian. High efficiency drilling methods for penetration boreholes in coal mine underground[J]. Safety in Coal Mines, 2020, 51(5): 126−129.

-

期刊类型引用(15)

1. 张铎,孙伟,郭曦蔓,岑孝鑫,代爱萍. 煤制油气化灰渣防灭火凝胶的制备及性能. 材料导报. 2024(03): 255-261 .  百度学术

百度学术

2. 姜小龙,孙明,常建平,董红娟. 矿井煤自燃防灭火材料阻燃机理综述. 内蒙古科技大学学报. 2024(03): 226-229 .  百度学术

百度学术

3. 李洋,戴广龙,杨苗苗. 高保水矿用凝胶阻化材料的制备和性能研究. 煤炭技术. 2023(03): 173-177 .  百度学术

百度学术

4. 段西凯,周睿,何勇军. 矿用超吸水防灭火凝胶制备及性能研究. 煤矿安全. 2023(02): 71-76 .  本站查看

本站查看

5. 谢军,卞兆庆,解恒星,王怡,王法铨. 基于CiteSpace的矿用凝胶研究趋势分析. 煤矿安全. 2023(02): 54-60 .  本站查看

本站查看

6. 王海军,吴艳,马良,陈崇枫,孙保平,王相业,吴敏杰,刘善德. 陕北浅埋煤层一体化漏风通道探查技术. 煤矿安全. 2023(04): 83-90 .  本站查看

本站查看

7. 陈鹏燕,周春山,程熙宇. CMC/AlCit/GDL防灭火凝胶的流变性能及本构方程研究. 应用化工. 2023(04): 1010-1014 .  百度学术

百度学术

8. 唐金召,范利丹,张纪云,徐峰,余雳伟,杨杰,赵伟. 我国煤矿巷道锚杆支护理论及技术研究进展. 煤矿安全. 2023(06): 131-143 .  本站查看

本站查看

9. 王毅泽,董凯丽,张玉龙,董智宇,王俊峰. CMC/ZrCit/GDL防灭火凝胶泡沫的制备及特性研究. 煤炭科学技术. 2023(06): 122-129 .  百度学术

百度学术

10. 陈鹏燕,周春山. 矿用双网络凝胶防灭火特性研究. 煤矿安全. 2023(11): 84-91 .  本站查看

本站查看

11. 杨苗苗,戴广龙. 矿用煤自燃防治高吸水高保水性水凝胶的制备及性能研究. 煤矿安全. 2022(02): 40-45 .  本站查看

本站查看

12. 卜祝龙,张铎,吕英英,王慧,王泓皓,杨娟娟. 煤渣填充防火凝胶配比实验研究. 粘接. 2022(01): 12-18 .  百度学术

百度学术

13. 韩福志,邵和,司俊鸿,张俊. 矿用堵漏无机触变防灭火凝胶的流变特性研究. 矿业安全与环保. 2022(01): 1-7 .  百度学术

百度学术

14. 刘东. 基于程序升温实验的煤低温氧化特性数值模拟研究. 煤矿安全. 2022(05): 40-45 .  本站查看

本站查看

15. 秦存利,刘袁昊,李军. 新型高分子材料防灭火技术研究与安全评估. 山东煤炭科技. 2021(10): 212-215+218+225 .  百度学术

百度学术

其他类型引用(10)

下载:

下载: