Designing and dust control performance of internal and external dual swirl air curtain in fully mechanized excavation face

-

摘要:

针对煤矿综掘工作面粉尘浓度超限的问题,设计了一种新型内外双旋流风幕发生装置,通过数值模拟和相似试验分析了装置应用前后综掘工作面的风流流场特性和粉尘扩散规律。结果表明:司机位置粉尘质量浓度随风幕发生装置射流出口风速的增大呈先降低后增大的变化趋势,有效控尘临界风速为35 m/s;风幕发生装置可以形成阻挡粉尘向外扩散的漏斗状旋流风幕,并将综掘工作面分成粉尘控制区和工作区2部分;旋流风幕将粉尘颗粒的扩散速度降低了84%,且对5 μm以下呼吸性粉尘控尘效率更优;新型风幕发生装置应用后司机位置处的粉尘质量浓度由337 mg/m3降到38 mg/m3,控尘效率为88.7%。

Abstract:In response to the problem of excessive dust concentration at the coal mine heading face, a new type of internal and external dual swirl air curtain generator was designed. Numerical simulations and similar tests were carried out to investigate the characteristics of the wind flow field and the dust dispersion pattern at the heading face before and after the application of the device. The results show that the dust concentration at the driver’s position decreases first and then increases with the increase of the jet outlet airflow velocity of air curtain generator, and the empirical relationship between the dust concentration at the driver’s position and the jet outlet airflow velocity is proposed, and a critical wind speed of 35 m/s was determined for effective dust control. The wind curtain generator can form a funnel-shaped swirling air curtain to prevent dust from spreading outwards, and divide the working face into two parts of dust control area and work area. The swirl air curtain reduces the diffusion speed of dust particles by 84% and has a better dust control effect for respirable dust below 5 μm; after the installation of the new swirl air curtain generator, the dust concentration at the driver’s position of the road header is reduced from 337 mg/m3 to 38 mg/m3.

-

随着矿井智能化、机械化水平的提高以及开采强度的加大,综掘工作面高浓度粉尘污染问题日益突出[1]。据现场实测,综掘工作面无防尘措施情况下,人员主要作业区域的时间加权总尘质量浓度可达2 000~3 000 mg/m3,其中呼尘质量浓度高达300~500 mg/m3,严重超出《煤矿安全规程》相关标准,这不仅影响企业的高效安全生产,也对工人的职业卫生健康造成严重威胁[2]。

近年来,国内外学者在综掘工作面粉尘防治方面进行了深入细致的研究。基于通风控尘系统在煤矿综掘工作面的应用,丁翠[3]总结了不同通风方式下掘进巷道内粉尘的扩散规律,验证了通风排尘的有效性;周智勇等[4]对比分析了综掘工作面不同通风布置参数下的排尘效果。随着学者们的研究重点由排尘向阻尘控尘转移,如何控制风流阻控粉尘并集中抽出成为综掘工作面粉尘控制技术研究的热点和难点。刘雅俊等[5]提出短路流场理论并研制了风幕集尘风机;程卫民等[6]设计了附壁风筒及抽尘净化装置组成的综掘工作面旋流气幕抽吸控尘系统,探究了该系统的流场特点及降尘效果;李雨成[7]提出利用风幕集尘并通过风筒抽出净化的粉尘防治方法,确定了平面风幕集尘的原理和条件;荆德吉等[8]提出闭环回旋控尘技术能有效控制粉尘扩散;聂文等[9]提出了多径向涡形气幕,并对比分析了风幕应用前后综掘工作面净化控尘效果;YIN等[10]进一步阐释了多径向涡旋气幕径轴向风量比、风筒布置参数等条件对综掘工作面通风控尘的影响;刘荣华等[11]提出了双径向旋流屏蔽通风控尘方式,并通过数值模拟与试验测试分析了该方式下综掘工作面风流流场和粉尘浓度分布。

尽管诸多学者在综掘工作面气幕控尘方面已开展了系列研究,且成果丰硕,但这些成果主要集中在如何利用轴向或径向等平面气幕将掘进产尘阻控在迎头区域,而对于空间螺旋气幕阻尘的研究却鲜有报道。为此,设计了一种新型内外双旋流风幕发生装置,通过数值模拟和相似试验研究了该旋流风幕应用后的空间流场特性及粉尘运移规律。

1. 控尘原理与系统结构

1.1 内外双旋流风幕控尘原理

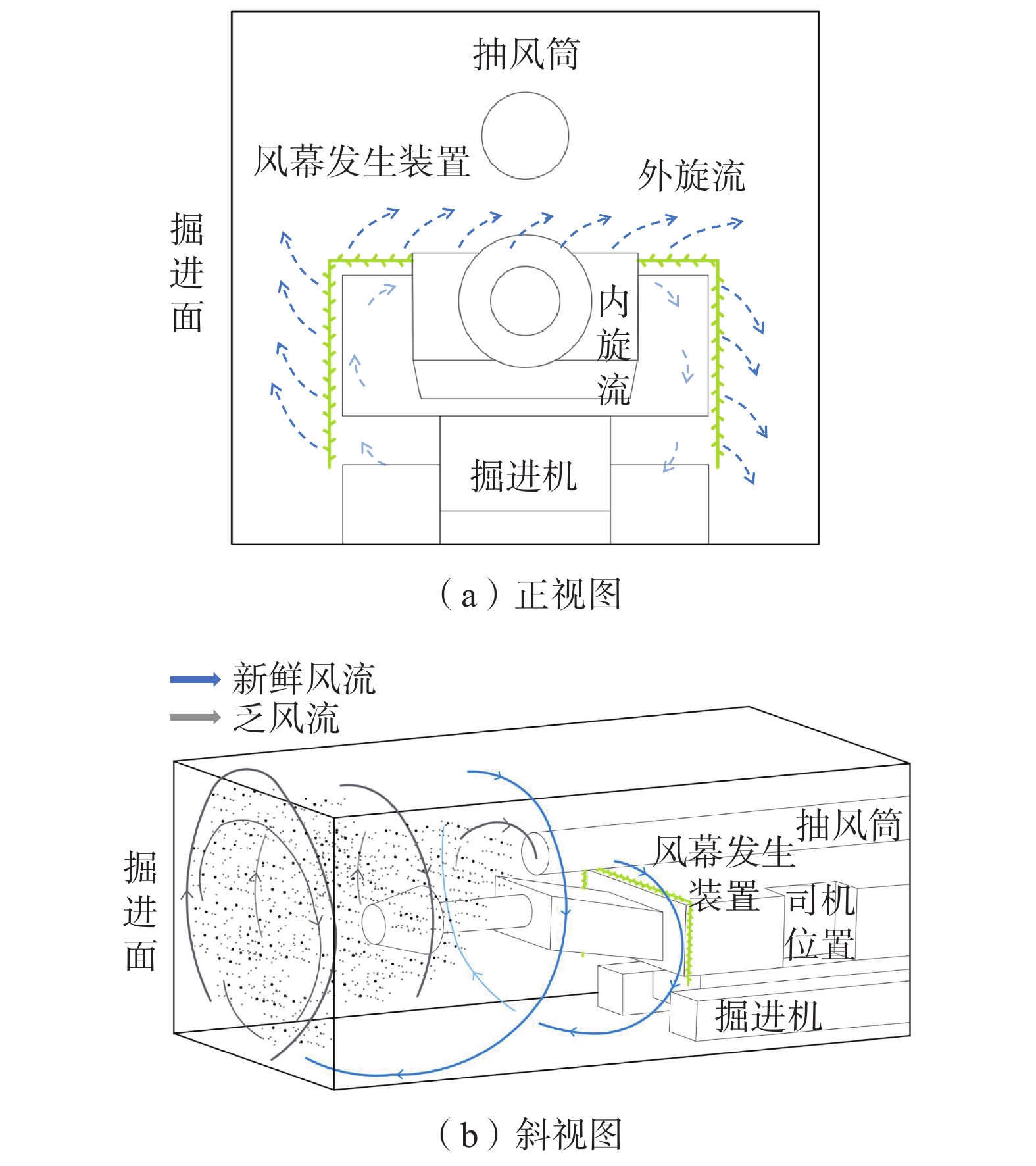

综掘工作面旋流风幕控尘技术示意如图1。

综掘工作面旋流风幕控尘是以高压风管提供的气源作为动力,通过内外双旋流风幕发生装置在司机位置前方汇成内外2道旋转气幕屏障的一种新型通风控尘技术。经内外双旋流风幕发生装置射出的高压空气通过卷吸效应将动量传递给靠近掘进迎头段受限区域的空气,使空气以巷道轴线为中心向掘进迎头旋转移动,在抽出式风筒的共同作用下,形成一股覆盖整个截面的螺旋状气流,使掘进时产生的粉尘随着射流旋转,并将高浓度粉尘聚集在负压旋涡内,经抽出式风筒排出。

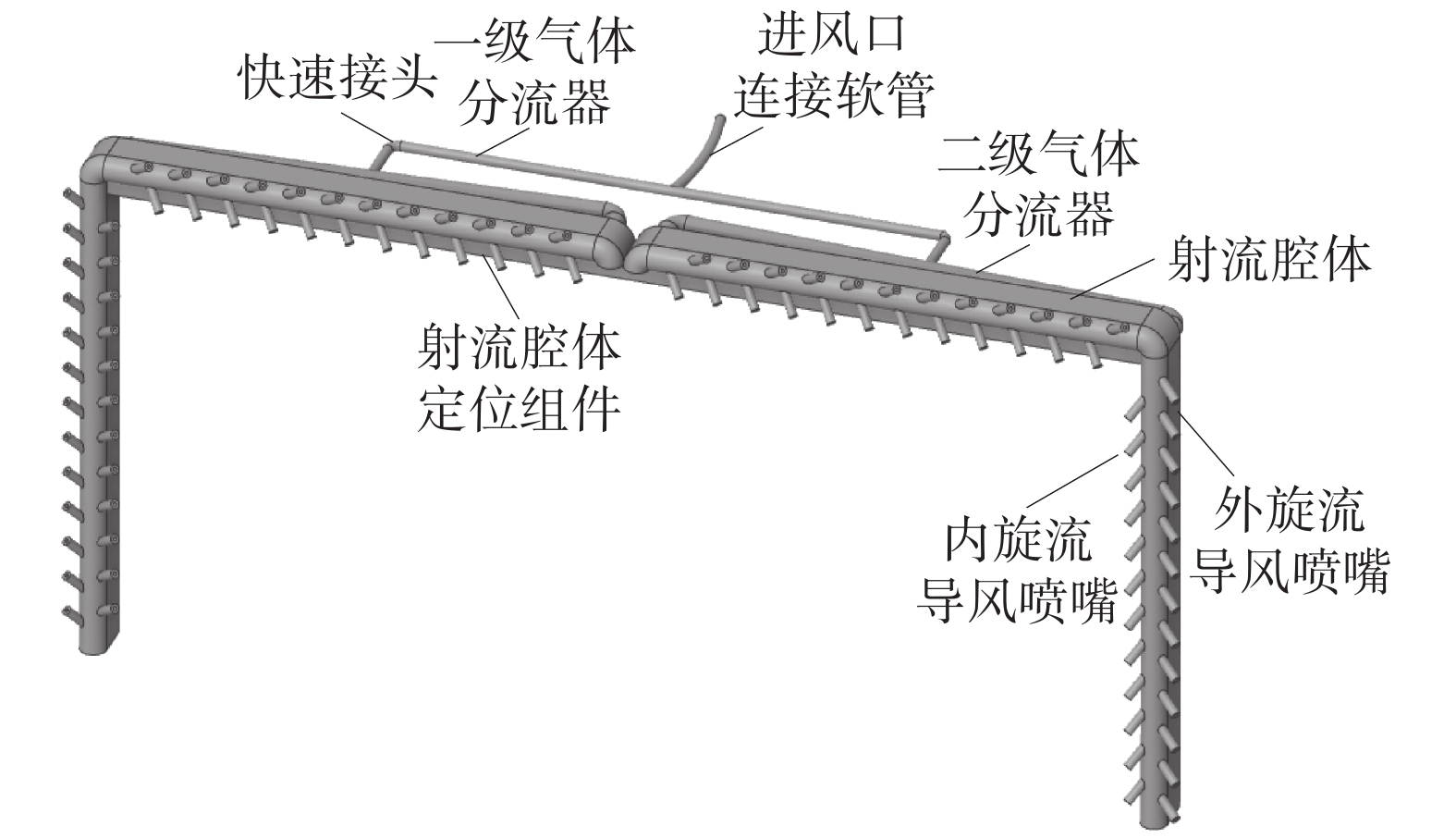

1.2 系统组成与旋流风幕装置

综掘工作面旋流风幕发生装置结构如图2。综掘工作面旋流风幕控尘系统由压入式风筒、抽出式风筒、井下高压风管、内外双旋流风幕发生装置等部分组成。

设计的内外双旋流风幕发生装置架设EBZ260掘进机上,保证射流出口处于司机前方,并且要求安装此装置后对司机的操作和正常生产不产生任何影响[12]。依据掘进机尺寸和风幕控尘装置设计原则,确定装置的尺寸为:宽2.7 m,高1.3 m。内外双旋流风幕发生装置由4个完全相同且可拆卸的射流腔体以及布置在腔体上的射流喷嘴组成,射流腔上的喷嘴包括形成外旋流的导风喷嘴和形成内旋流的导风喷嘴,每个腔体独立供风并由定位组件固定。经过多次模拟测试,确定装置结构参数如下:①导风喷嘴与腔体轴线所在直线夹角为45°;②导风喷嘴与装置所在径向平面夹角为45°;③射流喷嘴孔径为16 mm;④相邻喷嘴间距为100 mm。为了保证旋流喷嘴的出口风速一致,根据均匀送风理论[13]对射流腔体内部风道进行变截面处理,通过内置楔形阻体使腔体内的空气流动截面积沿其流动方向逐渐减小,维持内部风道全长上的静压稳定。内置的楔形阻体长为1.3 m,两端高度差为80 mm。

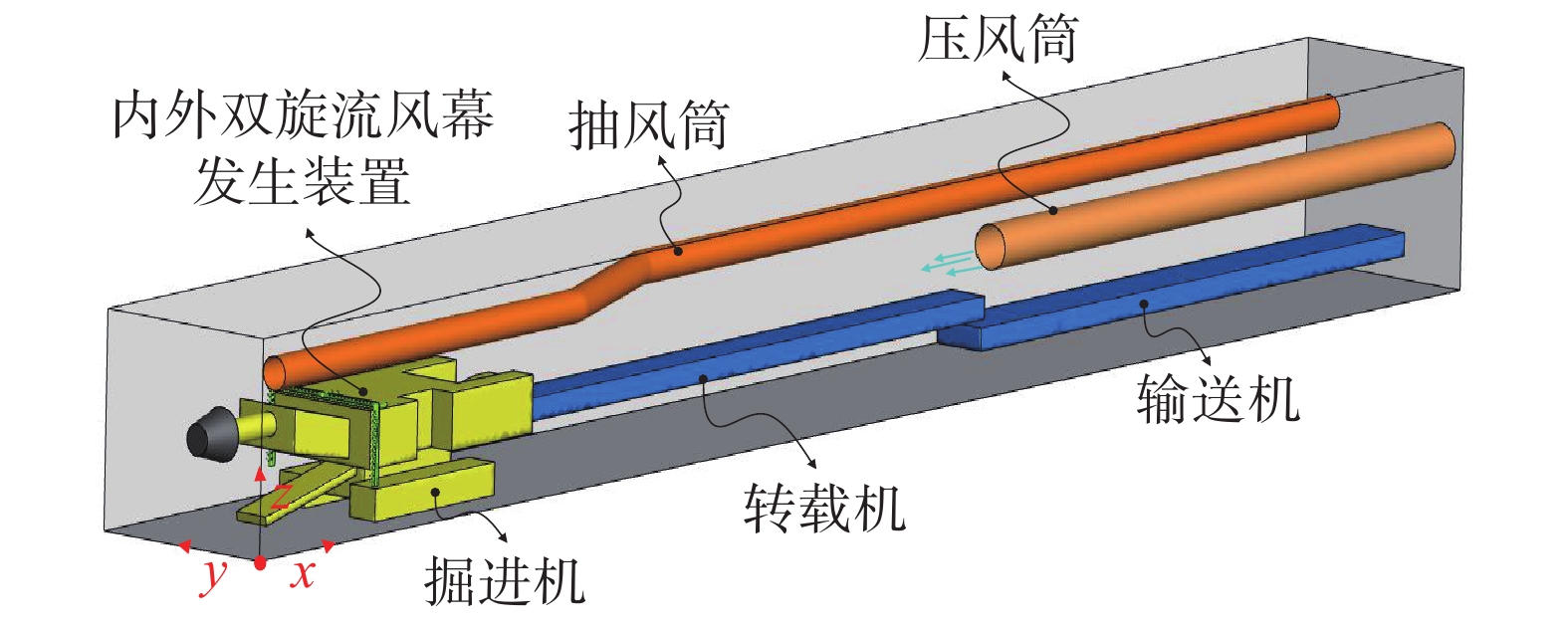

2. 模型建立及参数设置

以山西晋能控股集团某矿3101综掘工作面前端40 m巷道为研究对象,利用SpaceClaim软件等比例建立工作面巷道尺寸长、宽、高分别为40、4.2、3.8 m的几何模型。综掘工作面采用长压短抽混合式通风方式,数值计算物理模型如图3。

其中,压入式风筒直径0.8 m,压风口距掘进迎头25 m,中轴线距底板2.4 m;抽出式风筒直径0.6 m,抽风口距掘进迎头3 m,中轴线距底板2.6 m;风幕发生装置架设于掘进机长轴线位置处,距掘进迎头4.7 m。图3中,将综掘工作面至巷道出口方向设定为x正方向,将巷道短轴线方向设定为y方向,将巷道底板至顶部的方向设定为z正方向,行人呼吸带位置距近侧煤壁0.6 m,距底板1.6 m,司机呼吸位置坐标为(x=7 m,y=1.2 m,z=2.2 m)。

针对长压短抽通风方式(方案Ⅰ)和添加旋流风幕发生装置后的长压短抽通风方式(方案Ⅱ)2种方案开展研究,根据矿井巷道风量的相关规定,将压风量设置为300 m3/min,压抽风量比选择常用数值1.2。针对方案Ⅰ,将压入式风筒出口、抽出式风筒入口设置为速度入口边界条件,将巷道出口设置为压力出口边界条件,将掘进机、转载机、输送机等外表面以及巷道均定义为无滑移壁面。对于方案Ⅱ,将风幕发生装置的内、外旋流导风喷嘴均设置为速度入口,其他边界条件均以方案Ⅰ中的边界类型设定。

将风流视为连续相,尘粒视为离散相,考虑到综掘工作面旋流风幕运移属于贴壁射流与强旋流形成的复合流场,故选用Realizable$k - \varepsilon $模型开展连续相运移模拟,采用DPM模型开展离散相运移模拟。根据CCHZ-1000全自动粉尘测定仪现场实测的掘进迎头粉尘质量浓度和激光粒度分析仪获得的粉尘粒度分布实验结果。设置数值计算DPM尘源参数为:最小粒径Dmin=1 μm,中间粒径Dmean=35 μm,最大粒径Dmax=100 μm;粉尘粒径遵循Rosin-Rammler分布,分散系数1.78;初始粉尘质量流率为0.005 kg/s,由工作面喷射进入流体域。数值模拟采用的气-固耦合模拟控制方程参见文献[14-16]。

3. 结果与分析

3.1 临界风速

临界风速VL代表旋流风幕控尘效果最优时,内外双旋流风幕发生装置的射流出口风速V。当V<VL时风幕发生装置形成的旋流风幕强度较低,无法实现对综掘工作面粉尘颗粒的有效屏蔽;当V>VL时,空间流场扰动增强,导致控制区内粉尘逃逸到工作区并引起二次扬尘。

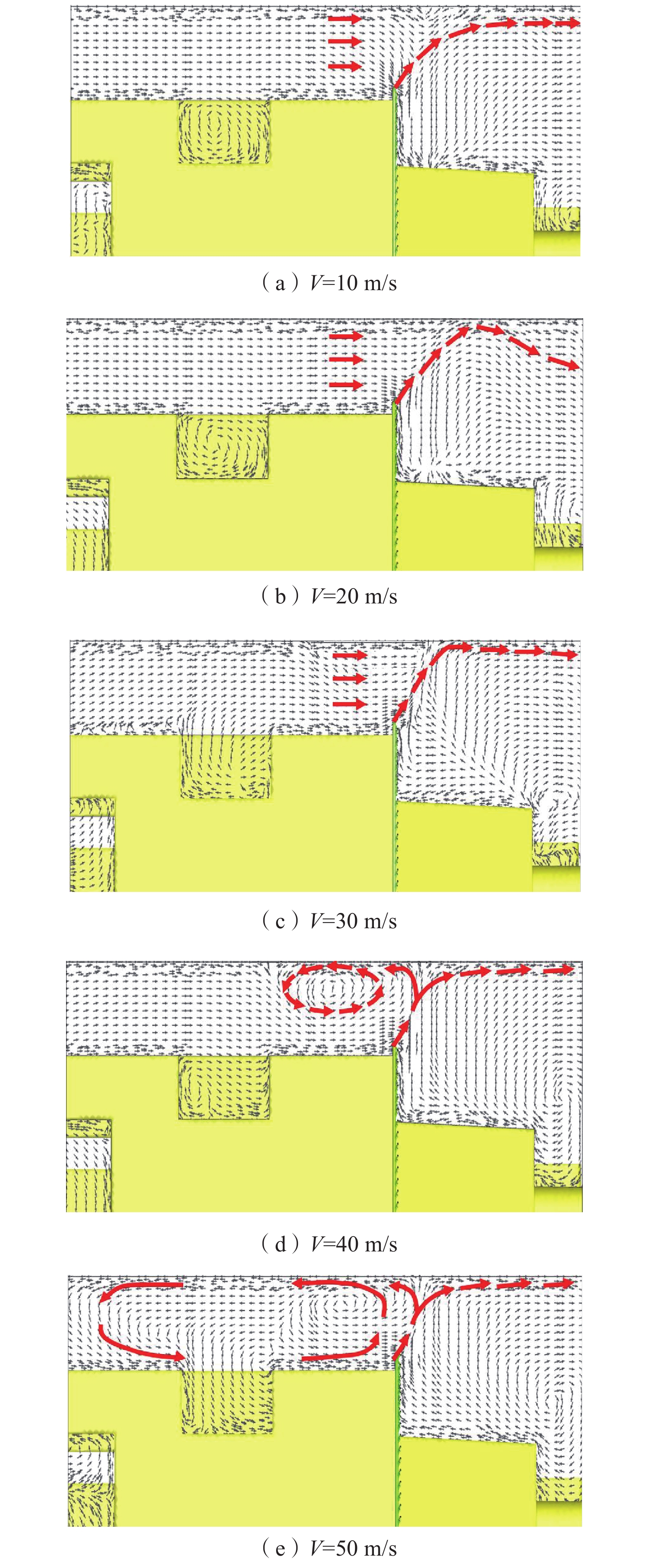

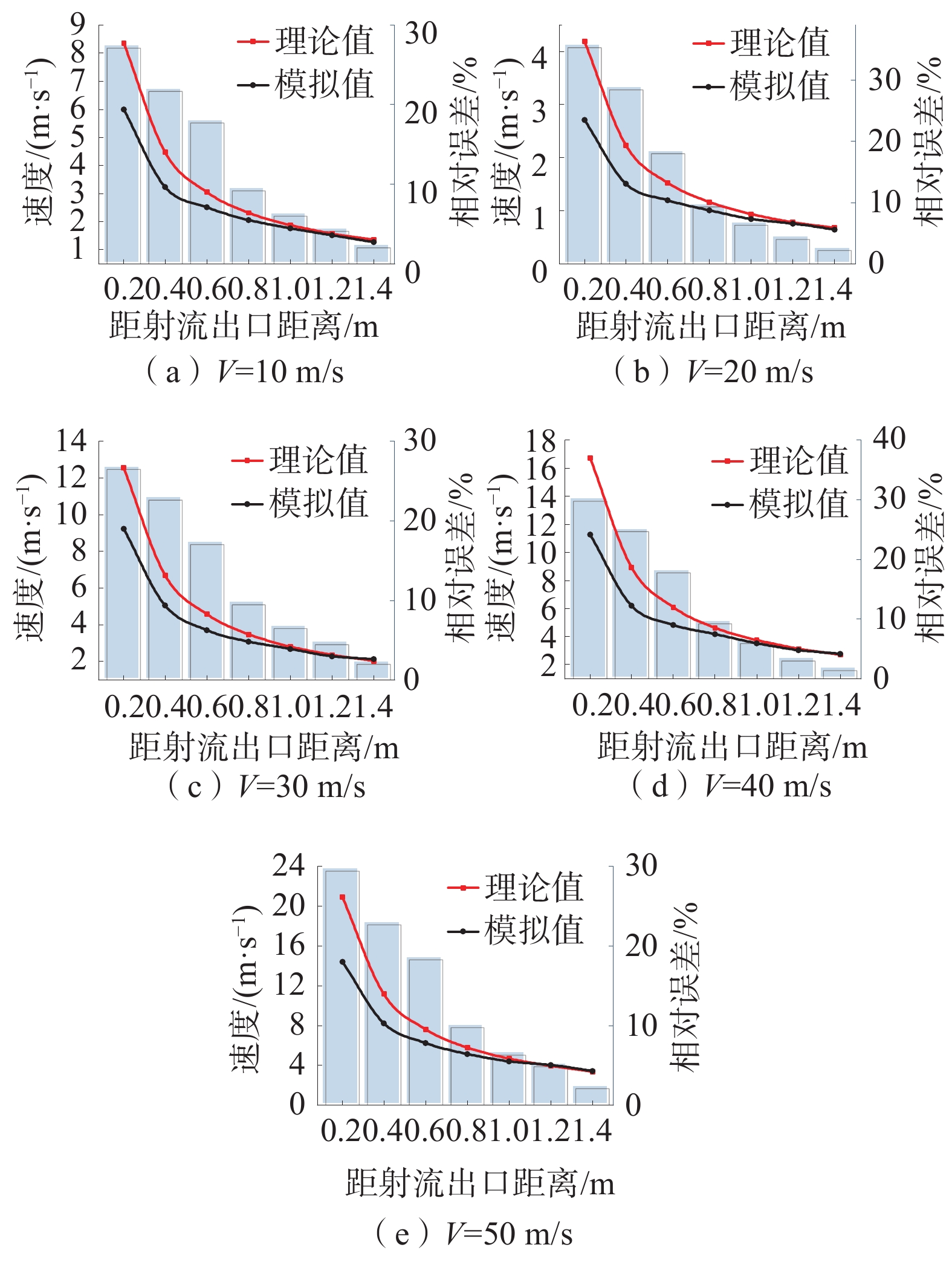

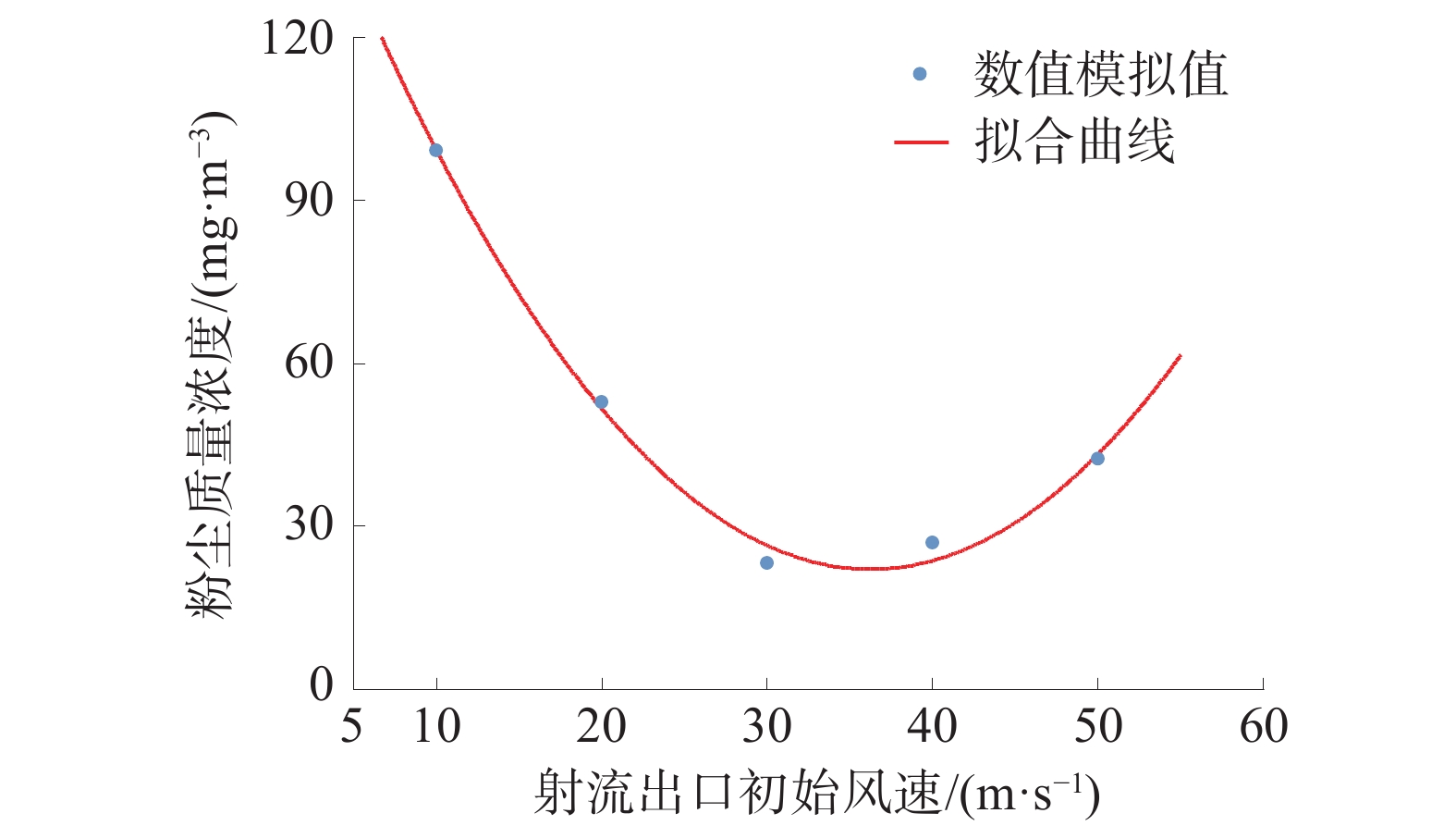

不同射流出口风速条件下巷道局部速度分布如图4,不同射流出口风速条件下测点速度模拟值与理论计算值对比如图5[17],司机位置粉尘质量浓度随射流出口风速的变化如图6。

由图4可知:当V较小时,受后方来流及抽出式风筒影响,风幕收缩效应显著,无法完成对整个巷道截面的封堵;当V=30 m/s时,射流抗干扰强度增大,能够到达巷道壁面并贴壁向迎头旋转运动,初步形成具有一定强度的旋转风幕;随着V的进一步增大,射流冲击壁面效应逐渐增强,导致部分气流与巷道周壁碰撞后流向风幕发生装置后侧并形成回流旋涡,可导致控制区的粉尘随旋涡逸散到掘进机司机区域,且该回流旋涡面积随着V的增大而逐渐增大。

由图5可知:当射流出口风速一定时,测点速度的模拟值与理论值随测点至射流出口距离的增加均呈反比例型下降;在距射流出口0.8 m范围内,测点速度的模拟值明显低于理论值,这是因为相邻两喷嘴间圆孔射流汇合,相互干扰导致的结果;在距射流出口0.8~1.4 m时,测点速度的模拟值与理论值相对误差低于10%,说明经内外双旋流风幕发生装置射出的高压射流到达壁面的末端风速仍可用圆形紊动射流轴心速度理论值表征。此外,文献[7]通过实验测试发现风幕射流到达壁面的末端风速达到2 m/s以上时,可以对综掘作业产尘起到很好地控制效果,由此可得风幕发生装置射流出口风速在30~40 m/s之间较为合理。

由图6可以看出:司机位置处的粉尘浓度随射流出口风速的增大呈先降低后增大的变化趋势,说明射流初始风速对高浓度粉尘扩散规律影响显著。为定量化这种影响作用,针对射流出口风速V,提出司机位置粉尘质量浓度C随射流出口风速V的变化的表达式:

$$ C{\text{ = }}a{V_0}^2 - b{V_0} + c $$ (1) 式中:a、b、c为拟合参数。

根据Levenberg-Marquartd拟合算法,拟合参数a、b、c分别为0.11、−8.12、169.23,决定系数R2为0.9939,说明该模型较好地描述射流出口风速和司机位置粉尘质量浓度的关系。结合风幕射流末端风速的合理性,由式(1)可知,射流出口风速V=35 m/s时,旋流风幕发生装置控尘效果最佳,即临界风速VL=35 m/s。

3.2 旋流风幕对风流流场特性的影响

为进一步了解临界风速下,旋流风幕对综掘工作面空间流场特性的影响,对内外双旋流风幕发生装置开启前后,综掘工作面的风流流场分布进行分析,并结合流场中压力分布分析风幕发生装置周围空间流场流动特性。巷道内风流流场特性如图7,不同截面上速度和压力分布如图8。

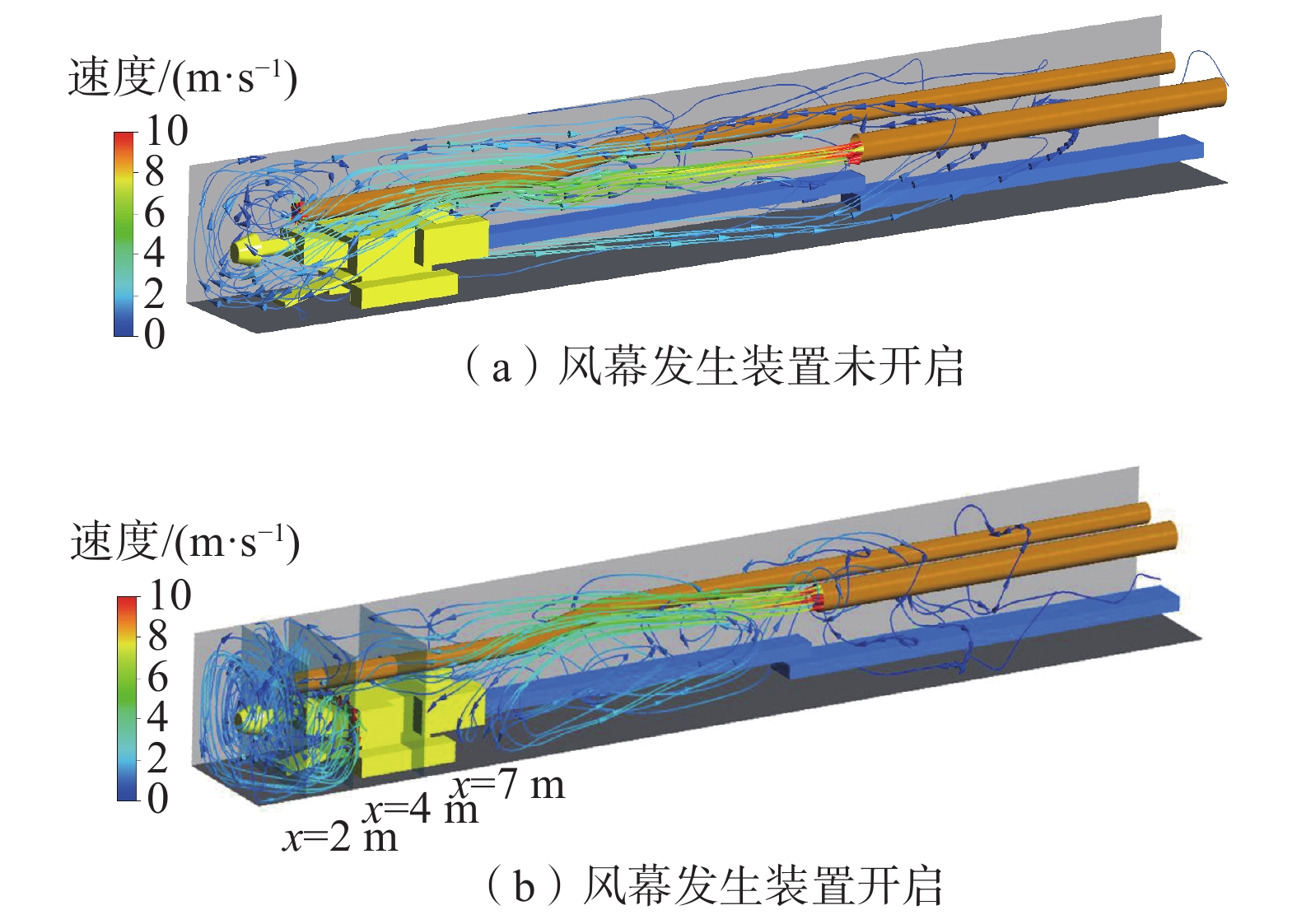

由图7(a)可知:风幕发生装置未开启时,由压风筒流出的风流分为2部分,一部分风流受掘进机尾部的阻挡返回巷道;其余风流越过掘进机并与迎头发生碰撞,受掘进机阻滞作用的影响,风流以折返流动的形式发生冲击、掺混,导致x=0~5 m范围内流场紊乱;且有少量未被抽风筒捕吸的风流因惯性作用沿右侧煤壁向巷道后方运动。

由图7(b)可知:内外双旋流风幕发生装置开启后,经外旋流喷嘴射出的多束径向高速气流汇成指向左右侧帮与顶板的斜冲击射流流场,在与巷道壁面碰撞后向掘进迎头发生偏转并沿周壁环绕流动;同时,附壁射流的旋转运动通过黏性剪应力和湍流剪应力向内部传递,并与经内旋流喷嘴射出的高速气流相互卷吸,带动周围空气呈顺时针向掘进迎头旋转运动;到达掘进迎头后的风流仍保留较强的旋转惯性,在抽风负压的影响下反向螺旋运动形成旋涡,其旋转半径在向心力主导下逐渐减小,并向吸风口收缩,最终风幕发生装置前方的风流按顺时针呈漏斗状螺旋运动。

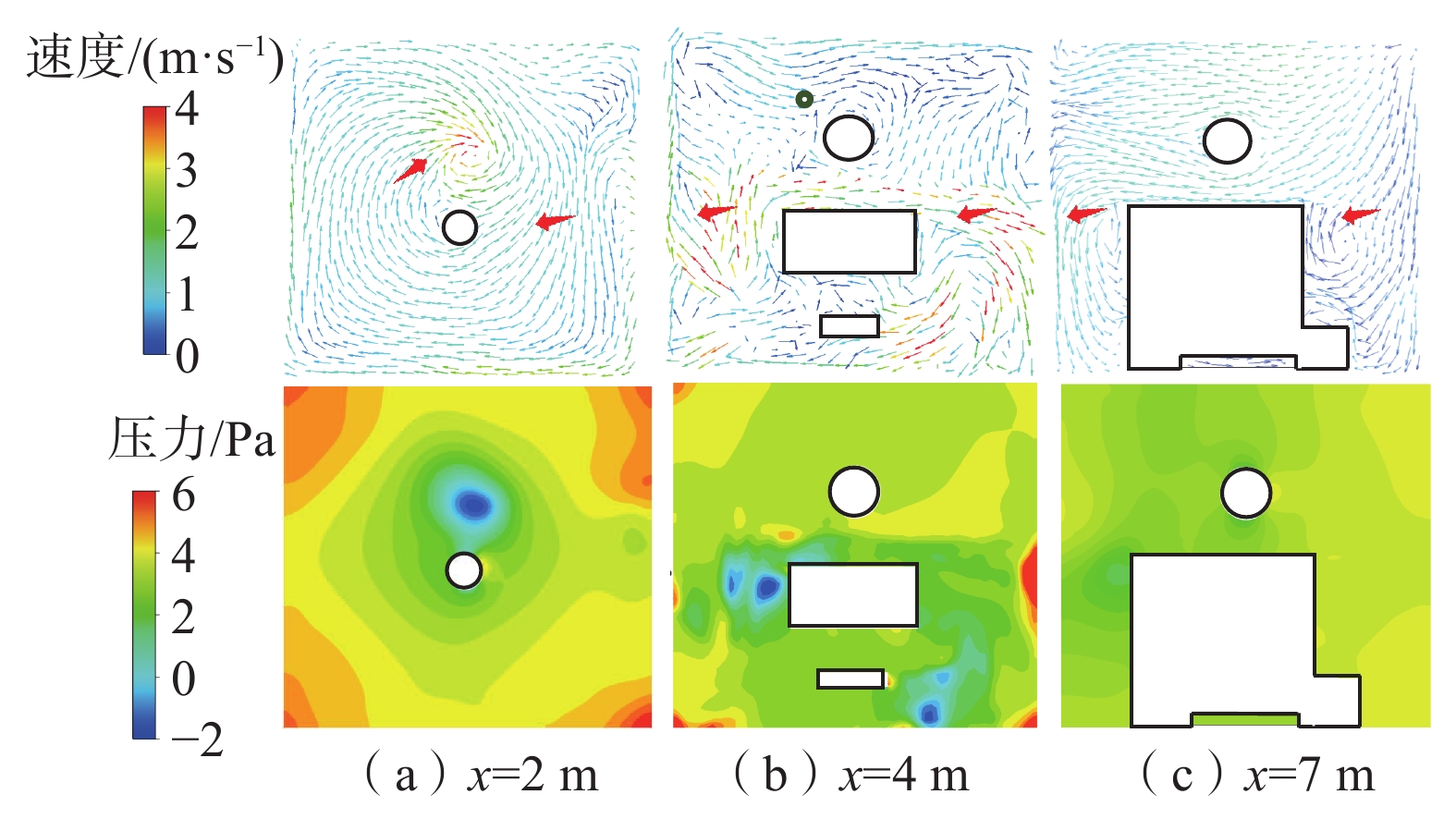

由图8可知:在x=7 m截面处,风流速度矢量箭头均指向掘进迎头,风流速度分布范围及压力梯度较小;在x=4 m截面处,高速射流速度矢量呈与风幕发生装置形状一致的倒“U”形,经风幕发生装置射出的高速气流造成附近区域压力降低,压力差反作用于风流流动;因此,在x=4~7 m空间内,风流越过掘进机汇成均匀压向掘进迎头的单向流场;随着距综掘迎头距离的减小,风流轴向速度发生变化,贴壁射流向迎头运动,中央气流向吸风口汇集;截面压力逐渐呈外高内低的分布规律,压力梯度逐渐增大,风流向吸风口收缩。说明内外双旋流风幕发生装置在掘进机司机工作区前方形成了可阻挡粉尘向外扩散的漏斗状旋流风幕,并将综掘工作面分成粉尘控制区和工作区2部分,从而为掘进机司机提供一个清洁的作业环境。

3.3 旋流风幕对粉尘扩散规律的影响

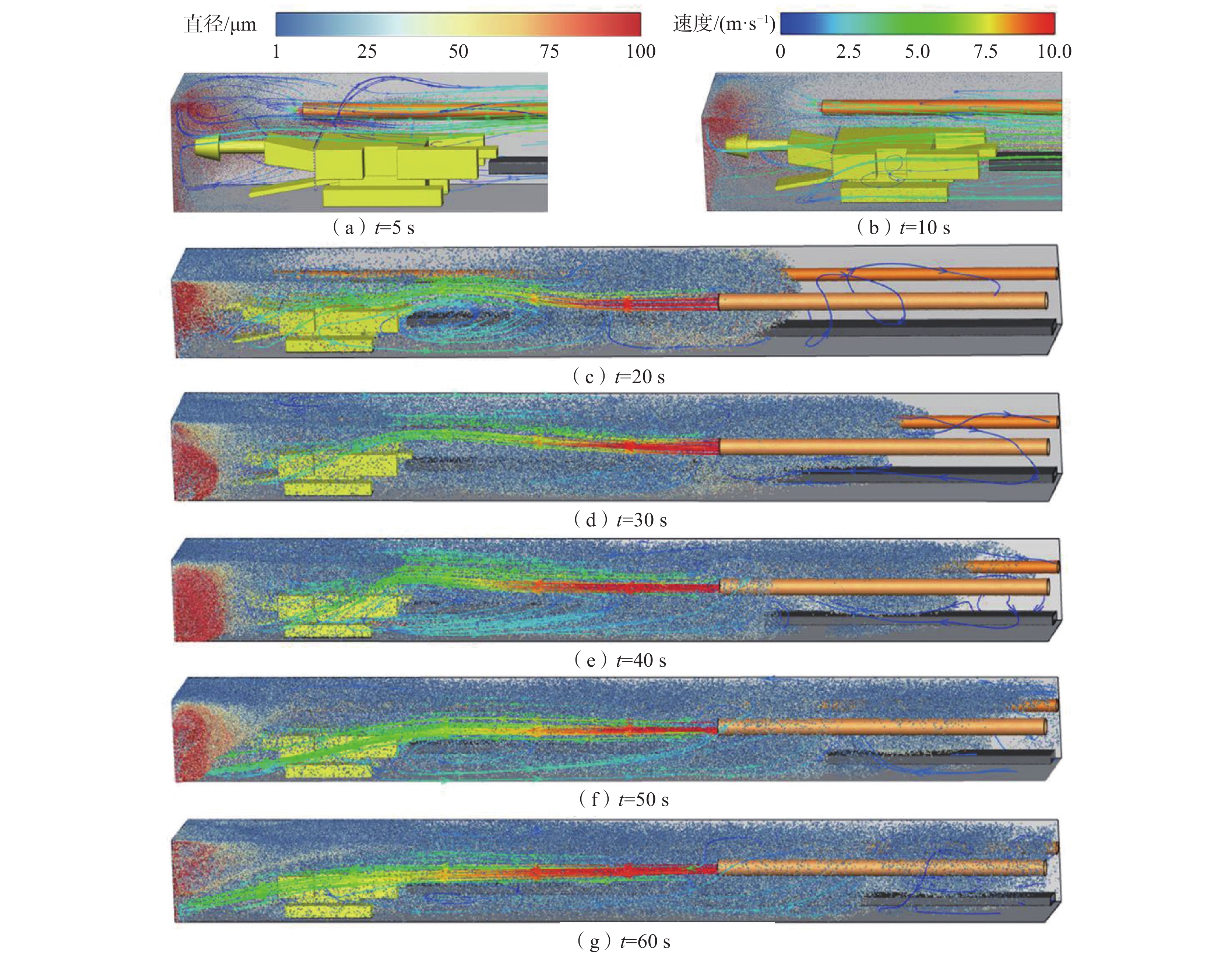

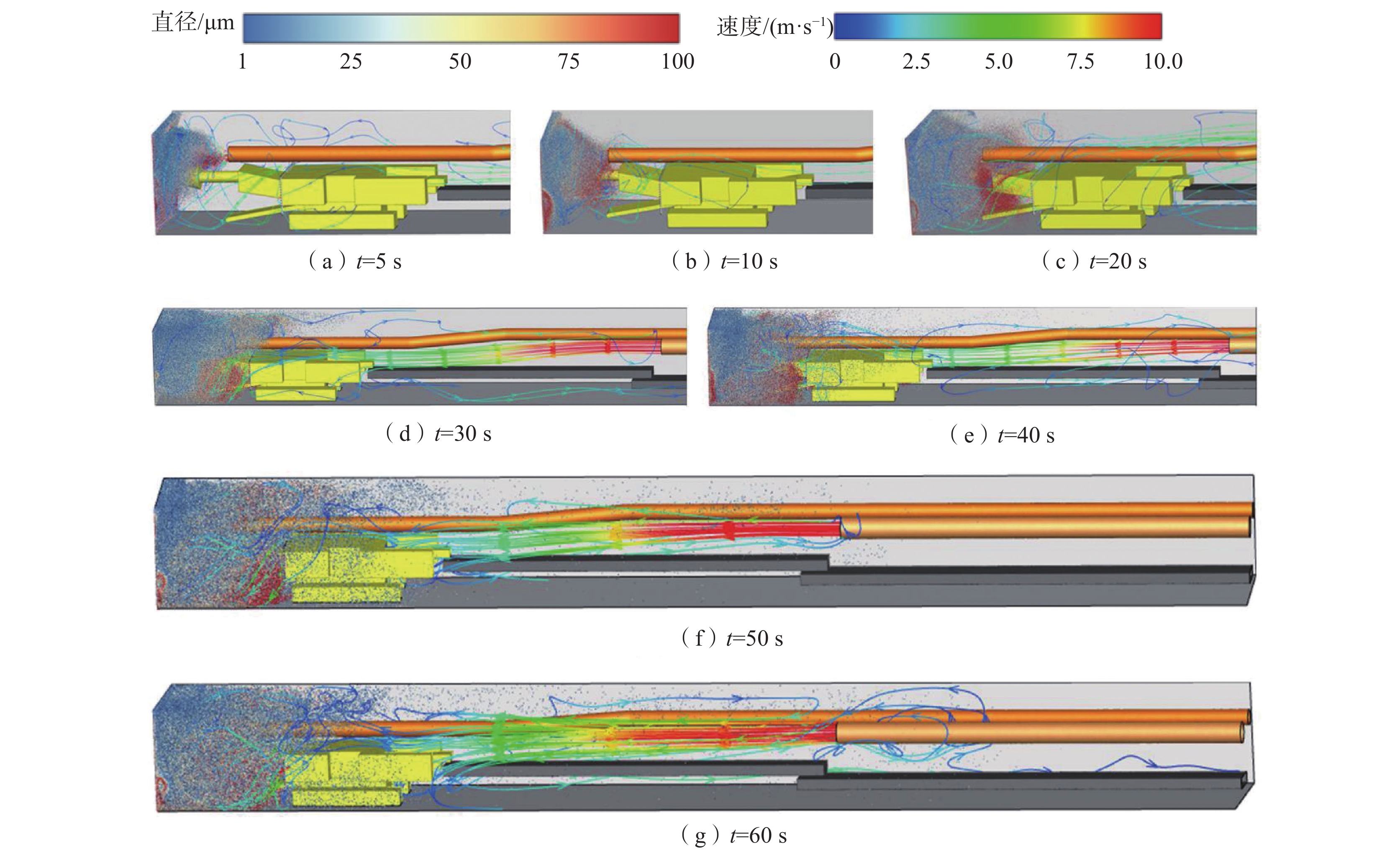

为了更清楚地了解旋流风幕的控尘效果,选取了7个时间点,即5、10、20、30、40、50、60 s,对比分析内外双旋流风幕发生装置开启前后,综掘工作面不同时刻风流和粉尘颗粒的耦合扩散过程。不同时刻风流-粉尘耦合分布(装置未开启)如图9,不同时刻风流-粉尘耦合分布(装置开启)如图10。

由图9可知:风幕发生装置未开启时,巷道空间内的粉尘颗粒在紊乱的风流场中无序扩散,部分尘粒在负压作用下被吸进抽出式风筒,其余尘粒则受风流裹挟继续沿回风侧壁面向巷道后方运移并逐渐充满整个巷道。此时,掘进机司机受高浓度粉尘的影响严重,该通风方式下整体降尘效果不理想。

由图10可知:风幕发生装置开启后,粉尘扩散范围呈漏斗状集中于抽出式风筒吸风口;受旋流风幕屏蔽作用的影响,粉尘颗粒的扩散速度降低了84%,具体表现为20 s时,旋流风幕发生装置开启后,粉尘集中于距迎头面4 m范围内,而风幕发生装置未开启时,粉尘分布于距迎头面25 m范围内;此外,在30 s后,粉尘颗粒几乎没有向风幕发生装置后方再扩散,说明经风幕发生装置产生的旋转射流和抽风汇流结合可以在掘进机司机前方形成一股高动能的螺旋气流,有效地防止了粉尘扩散,显著改善了综掘工作面作业环境质量。

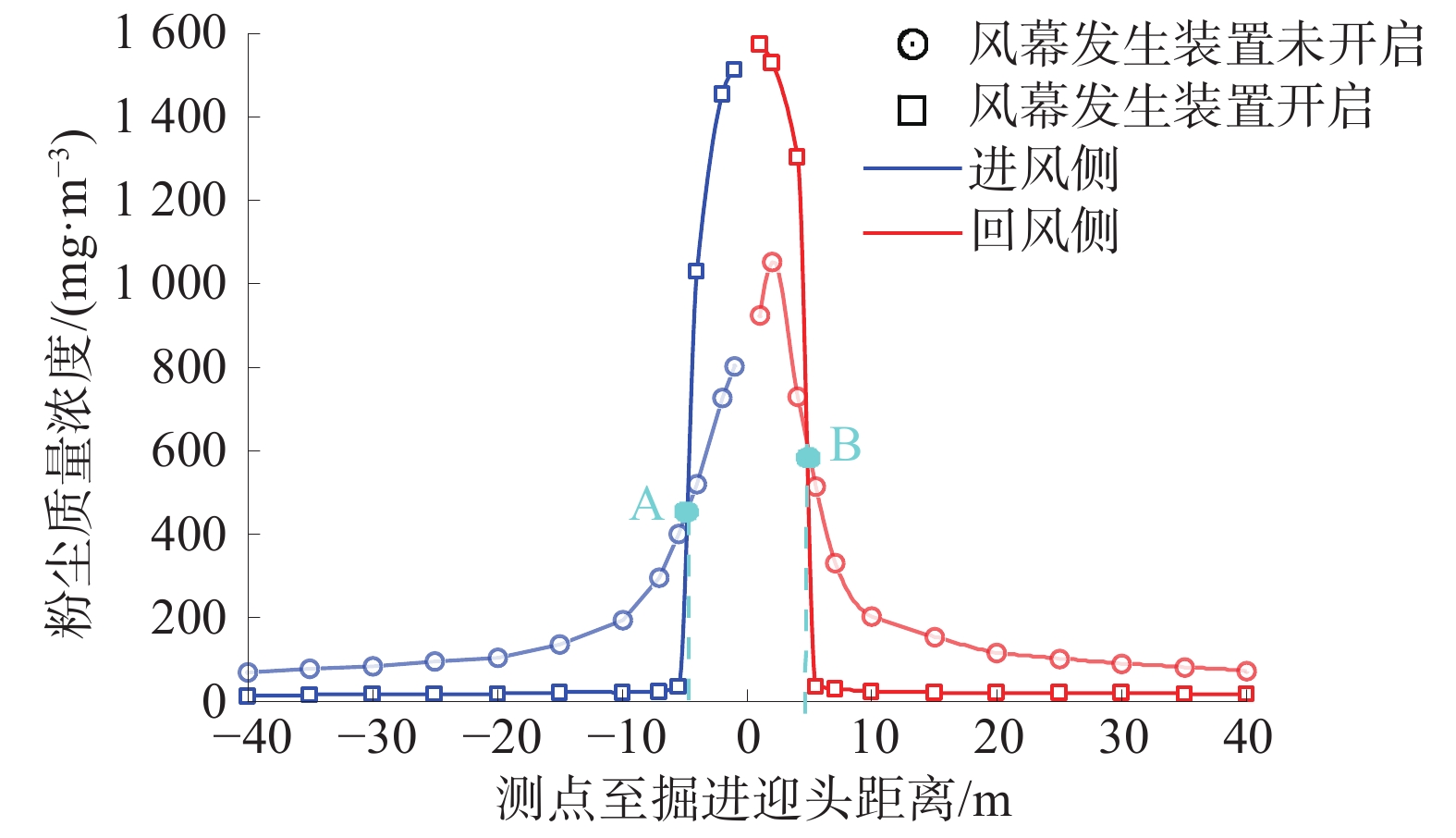

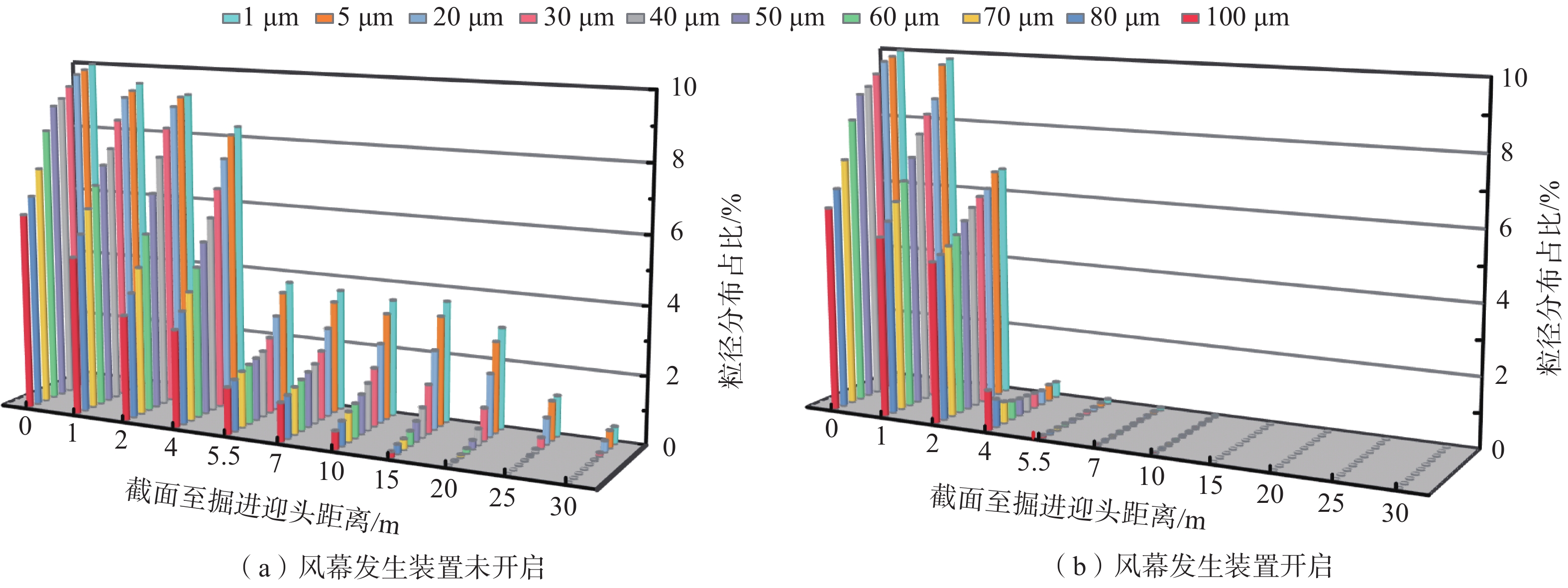

综掘工作面测点布置及粉尘质量浓度如图11,其中水平轴的正负代表综掘工作面的进风侧和回风侧,A、B 2点的横坐标分别对应内外双旋流风幕发生装置安设位置。综掘工作面不同位置颗粒粒径分布如图12。

由图11可知:风幕未开启时,在距掘进迎头10 m范围内粉尘浓度较高,且峰值位于回风侧2 m位置处;当风幕发生装置开启后,粉尘主要集中在距掘进迎头4 m范围内,粉尘质量浓度峰值点显著增大且峰值位置向进风侧发生偏移;风幕发生装置后方,粉尘质量浓度骤减,且随着距掘进迎头距离的增加逐渐降低,在10 m后维持在20 mg/m3以下的较低水平。

由图12可知:风幕未开启时,粉尘颗粒粒径在距掘进迎头20 m内分布范围较广,这是因为大颗粒粉尘受自身重力影响逐渐沉降,而小颗粒粉尘在湍流脉动作用下悬浮于空气中,并随风流向巷道后方扩散;旋流风幕开启后,粉尘粒径分布占比发生了显著变化;在距离迎头2~4 m范围内,各粒径粉尘颗粒数目均大幅下降;与距综掘迎头4 m前各截面粒径分布相比,x=4 m位置处的粒径分布由小粒径粉尘占比最大转变为大粒径粉尘占比最大,说明旋流风幕对5 μm以下呼吸性粉尘的控尘效率明显优于对大颗粒的粉尘的控尘效率;结合图11,在风幕发生装置后方,大颗粒粉尘受自身重力和动能损失的影响快速沉降,粉尘粒径分布主要以悬浮于空气中小颗粒粉尘为主。

4. 旋流风幕控尘相似试验

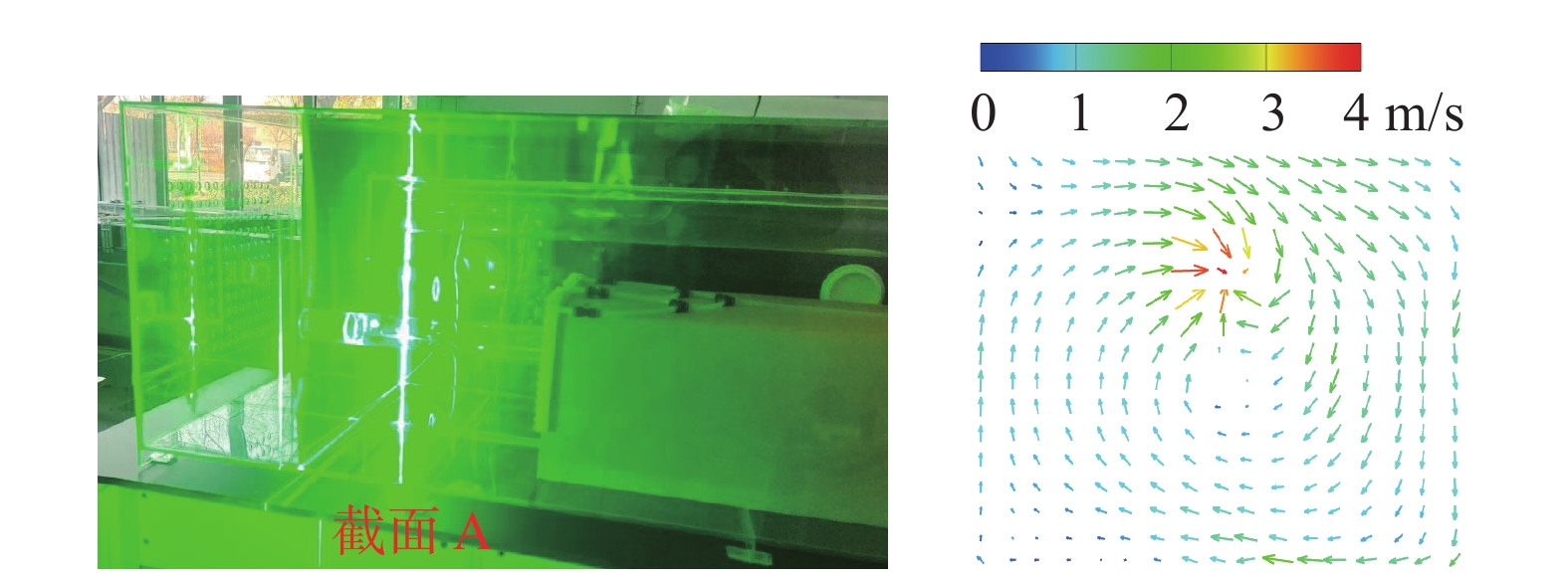

依据图3选取几何相似比1∶7搭建模化相似试验平台,相似试验平台如图13。

其中,模型外框主体由透明有机玻璃组成,长5.7 m,宽0.6 m,高0.54 m;内外双旋流风幕发生装置以树脂作为材料,借助3D打印技术制作完成,并架设于距掘进迎头0.67m的位置。同时,试验参数满足流动相似准则[18]。在空间流场试验分析中,以橄榄油滴作为示踪粒子,待试验平台运行1 min至流场稳定后,利用PIV粒子图像测试系统分析空间流场特性。在粉尘浓度测试验中,采用粉尘发生器产尘,产尘速率为6 g/min,使用CCHZ-1000全自动粉尘测定仪读取测点位置的粉尘质量浓度,其中采样时间为3 min,采样流量为15 L/min。PIV试验结果如图14,粉尘质量浓度见表1。

表 1 粉尘质量浓度Table 1. Dust mass concentration数值 粉尘质量浓度/(mg·m−3) 控尘效率/% 风幕发生装置

开启前风幕发生装置开启后 实测值 337 38 88.7 模拟值 297 24 91.9 平均误差/% 3.6 由图14利用PIV粒子图像测速系统实测截面A(对应x=2 m)的速度矢量图可以看出:截面A的风流按顺时针方向旋转,旋涡均位于截面中心偏上位置处,这与图8(a)中x=2 m截面的速度矢量分布数值模拟结果基本一致,说明内外双旋流风幕发生装置可以形成阻挡粉尘向外扩散的旋流风幕。

由表1可知:相似试验中,安设新型旋流风幕发生装置后掘进司机位置处的粉尘浓度由337 mg/m3降到38 mg/m3,控尘效率为88.7%,与数值模拟的进行比较,平均误差小于5%。说明内外双旋流风幕发生装置起到了良好的控尘效果。

5. 结 语

1)随着内外双旋流风幕发生装置射流出口风速的增大,射流冲击壁面效应逐渐增强,部分气流与巷道周壁碰撞后流向旋流风幕发生装置后侧形成回流旋涡,且回流旋涡面积随着初始风速的增大而逐渐增大;司机位置粉尘浓度随射流出口风速的增大呈先降低后增大的趋势;给出了关于司机位置处粉尘质量浓度与射流出口风速的经验关系式,并确定了有效控尘临界风速为35 m/s。

2)内外双旋流风幕发生装置射出的高压空气受卷吸及附壁效应影响,并在抽风筒负压吸风的联合作用下,在掘进机司机前方可以形成阻挡粉尘向外扩散呈漏斗状的旋流风幕,并将综掘工作面分成粉尘控制区和工作区两部分,从而为掘进机司机提供一个清洁的作业环境。

3)旋流风幕发生装置开启后,粉尘颗粒扩散速度降低了84%,粉尘颗粒主要集中在距掘进迎头4 m范围内;旋流风幕对5 μm以下呼吸性粉尘的控尘效率更优。

4)相似试验表明,安设新型旋流风幕发生装置后掘进司机位置处的粉尘浓度由337 mg/m3降到38 mg/m3,控尘效率为88.7%。

-

表 1 粉尘质量浓度

Table 1 Dust mass concentration

数值 粉尘质量浓度/(mg·m−3) 控尘效率/% 风幕发生装置

开启前风幕发生装置开启后 实测值 337 38 88.7 模拟值 297 24 91.9 平均误差/% 3.6 -

[1] 程卫民,周刚,陈连军,等. 我国煤矿粉尘防治理论与技术20年研究进展及展望[J]. 煤炭科学技术,2020,48(2):1−20. CHENG Weimin, ZHOU Gang, CHEN Lianjun, et al. Research progress and prospect of dust control theory and technology in China's coal mines in the past 20 years[J]. Coal Science and Technology, 2020, 48(2): 1−20.

[2] 王杰,郑林江. 煤矿粉尘职业危害监测技术及其发展趋势[J]. 煤炭科学技术,2017,45(11):119−125. WANG Jie, ZHENG Linjiang. Development tendency and monitoring technology of dust occupational hazard in coal mine[J]. Coal Science and Technology, 2017, 45(11): 119−125.

[3] 丁翠. 掘进巷道粉尘运移扩散规律研究进展[J]. 煤矿安全,2018,49(9):219−222. DING Cui. Research progress of dust movement and diffusion laws in excavation roadway[J]. Safety in Coal Mines, 2018, 49(9): 219−222.

[4] 周智勇,胡培,韩章程,等. 综掘工作面通风布置对粉尘分布规律的影响[J]. 中南大学学报(自然科学版),2018,49(9):2264−2271. ZHOU Zhiyong, HU Pei, HAN Zhangcheng, et al. Effect of heading face ventilation arrangement on regulation of dust distribution[J]. Journal of Central South University(Science and Technology), 2018, 49(9): 2264−2271.

[5] 刘雅俊,葛少成,刘剑. 风幕集尘风机及其短路流场的数学模型研究[J]. 中国安全科学学报,2002(1):69−72. LIU Yajun, GE Shaocheng, LIU Jian. Windscreen dust-collecting ventilator and study on mathematical model for short circuit flow field[J]. China Safety Science Journal, 2002(1): 69−72.

[6] 程卫民,聂文,姚玉静,等. 综掘工作面旋流气幕抽吸控尘流场的数值模拟[J]. 煤炭学报,2011,36(8):1342−1348. CHEN Weiming, NIE Wen, YAO Yujing, et al. Numerical simulation on the flow field of swirling flow air curtain aspiration control dust in fully mechanized workface[J]. Journal of China Coal Society, 2011, 36(8): 1342−1348.

[7] 李雨成. 基于风幕技术的综掘面粉尘防治研究[D]. 阜新: 辽宁工程技术大学, 2010: 21-54. [8] 荆德吉,葛少成. 闭环回旋控尘技术的三维数值模拟研究[J]. 中国安全生产科学技术,2015,11(3):79−84. JING Deji, GE Shaocheng. Study on 3D numerical simulation of closed-loop dust control technology[J]. Journal of Safety Science and Technology, 2015, 11(3): 79−84.

[9] 聂文,魏文乐,华赟,等. 多径向涡形风控制岩巷综掘面粉尘污染分析[J]. 应用基础与工程科学学报,2017,25(1):65−77. NIE Wen, WEI Wenle, HUA Yun, et al. Analysis on the dust pollution in fully mechanized rock headings controlled by the multi-radial vortex wind[J]. Journal of Basic Science and Engineering, 2017, 25(1): 65−77.

[10] YIN S, NIE W, GUO L, et al. CFD simulations of air curtain dust removal effect by ventilation parameters during tunneling[J]. Advanced Powder Technology, 2020, 31(6): 2456−2468. doi: 10.1016/j.apt.2020.04.008

[11] 刘荣华,朱必勇,王鹏飞,等. 综掘工作面双径向旋流屏蔽通风控尘机理[J]. 煤炭学报,2021,46(12):3902−3911. LIU Ronghua, ZHU Biyong, WANG Pengfei, et al. Dust control mechanism of double radial swirl shielding ventilation in fully mechanized heading face[J]. Journal of China Coal Society, 2021, 46(12): 3902−3911.

[12] 李雨成,刘宗桃,刘蓉蒸,等. 综掘工作面风幕控尘装置设计及试验研究[J]. 煤炭科学技术,2017,45(10):66−71. LI Yucheng, LIU Zongtao, LIU Rongzheng, et al. Design and experiment study on air curtain dust control device of mine fully-mechanized heading face[J]. Coal Science and Technology, 2017, 45(10): 66−71.

[13] 何叶从,黄腾进,刘怀灿,等. 隧道等截面通风系统均匀送风特性研究[J]. 地下空间与工程学报,2020,16(6):1841−1848. HE Yecong, HUANG Tengjin, LIU Huaican, et al. Research on uniform air supply characteristics of equal cross-section ventilation system in tunnel[J]. Chinese Journal of Underground Space and Engineering, 2020, 16(6): 1841−1848.

[14] 荆德吉,徐放,葛少成,等. 多层螺旋雾幕技术的喷雾模拟及降尘试验研究[J]. 中国安全生产科学技术,2019,15(8):70−76. JING Deji, XU Fang, GE Shaocheng, et al. Study on spray simulation and dust removal experiments of multi-layer spiral fog curtain technology[J]. Journal of Safety Science and Technology, 2019, 15(8): 70−76.

[15] 王昊,撒占友,王春源,等. 综掘工作面通风条件对径向旋流风幕阻尘效果的影响[J]. 煤矿安全,2022,53(3):186−192. WANG Hao, SA Zhanyou, WANG Chunyuan, et al. Influences of ventilation conditions of fully mechanized excavation face on dust-resistance effect of radial swirling air curtain[J]. Safety in Coal Mines, 2022, 53(3): 186−192.

[16] 胡胜勇,廖奇,王和堂,等. 高瓦斯煤层综掘工作面风流-粉尘两相流动特性[J]. 煤炭学报,2019,44(12):3921−3930. doi: 10.13225/j.cnki.jccs.2019.1008 HU Shengyong, LIAO Qi, WANG Hetang, et al. Gas-solids two-phase flow at high-gassy fully mechanized within high gassy coal seam[J]. Journal of China Coal Society, 2019, 44(12): 3921−3930. doi: 10.13225/j.cnki.jccs.2019.1008

[17] 董志勇. 射流力学[M]. 北京: 科学出版社, 2005. [18] 陈景序,荆德吉,葛少成,等. 掘进机外气动涡旋雾幕控尘装置的研制与实验[J]. 煤炭学报,2019,44(10):3233−3240. doi: 10.13225/j.cnki.jccs.2018.1370 CHEN Jingxu, JING Deji, GE Shaocheng, et al. Research and experiment on dust control device with external pneumatic vortex mist curtain for road-header[J]. Journal of China Coal Society, 2019, 44(10): 3233−3240. doi: 10.13225/j.cnki.jccs.2018.1370

-

期刊类型引用(3)

1. 王成,彦鹏,代振华,陆斌,葛少成,赵伟智. 微米活性液滴场致荷电效果及煤尘润湿性能研究. 煤矿安全. 2024(10): 46-52 .  本站查看

本站查看

2. 宋明明. 矿井大断面岩巷综掘快速掘进技术研究. 矿业装备. 2024(09): 10-12 .  百度学术

百度学术

3. 葛宇,周骥平,倪厚强,徐钟林. 实验废液抽吸柜滑移窗嵌入式移动风幕机设计与应用. 实验技术与管理. 2023(12): 207-211 .  百度学术

百度学术

其他类型引用(0)

下载:

下载: