Study on microscopic deformation fractal characteristics of methane adsorbed by coal based on CT images

-

摘要:

为了定量化研究煤吸附甲烷过程细观变形的各向异性特征,通过ACTIS-CT扫描实验系统,开展了恒定温度下方型无烟煤吸附甲烷过程的吸附变形CT扫描实验;根据CT图像,采用质点追踪应变计算算法定量计算了吸附过程中煤内部细观结构的应变变形,讨论了其变化规律。在此基础上,提出了一种基于CT技术煤吸附气体细观变形的非均质性定量化研究方法,应用盒计数维数法计算了分形维数,定量评价了煤细观变形的非均质性,并基于分形几何和细观应变变形分布的物理描述,讨论了分形维数和甲烷吸附各向异性变形特性的关系。研究结果表明:煤吸附气体膨胀变形首先挤压孔隙或裂缝以获得更大的膨胀空间;煤吸附甲烷后引起的细观变形,其非均质性符合分形特征;分形维数与煤吸附甲烷后的膨胀变形率呈负相关性关系,膨胀变形率值越高,分形维数越低,即煤吸附甲烷后越膨胀,煤整体的非均质应变变形的不规则程度越低;相反,膨胀变形率值越低,则分形维数越高,煤整体的非均质应变变形的不规则程度越高。

Abstract:In order to quantify the anisotropic characteristics of mesoscopic deformation during the process of coal adsorbing methane, the CT scanning experiment of adsorption deformation was conducted during the methane adsorption process of anthracite coal under constant temperature using the ACTIS-CT scanning experimental system, the strain deformation of meso-structure of coal was quantitatively calculated during the adsorption process based on the particle tracking strain calculation algorithm of CT image, and the change regulation was discussed. On this basis, a quantitative research method for the heterogeneity of micro deformation of coal adsorbing methane based on CT technology was proposed, and the fractal dimension D was calculated using the fractal dimension method to quantitatively evaluate the heterogeneity of micro deformation of coal. Based on the physical description of fractal geometry and micro-strain deformation distribution, the relationship between fractal dimension D and anisotropic deformation characteristics of methane adsorption was also discussed. The results indicate that: the expansion deformation of coal adsorbing gas first compresses pores or cracks to obtain a larger expansion space; the heterogeneity of microscopic deformation caused by coal adsorbing methane conforms to the fractal characteristics; the fractal dimension is negatively correlated with the expansion and deformation rate of coal after methane adsorption; the higher the expansion and deformation rate is, the lower the fractal dimension is. In other words, the larger the expansion of coal after methane adsorption is, the lower the irregularity of the overall heterogeneous strain deformation of coal is. On the contrary, the lower the value of expansion deformation rate, the higher the fractal dimension, and the higher the irregularity of the whole heterogeneous strain deformation of coal.

-

在“碳达峰、碳中和”的双碳目标下,煤炭作为我国的重要能源,在能源体系结构中仍起着安全兜底的作用,其发展的可持续性直接影响着我国经济发展的稳定性[1-4]。但是随着煤炭开采逐步转向深部,由于开采技术的限制,以及煤与瓦斯突出等煤矿安全问题一直制约着我国煤炭工业健康可持续发展[5-6]。

煤吸附瓦斯变形改变了煤的力学性质,是引起煤岩瓦斯动力灾害重要因素之一[7]。许多研究学者认为煤吸附瓦斯引起的膨胀变形是测定煤岩瓦斯动力灾害危险性的辅助指标之一[8-11]。研究表明,煤体在吸附瓦斯后会膨胀,解吸会收缩,这些特征已在宏观实验中得到证实[12-14]。近年来,国内外学者对煤吸附气体后的细观变形进行了大量研究。BERGEN等[15]采用自行研制的显微测量实验装置,在10 MPa的流体压力和约40 °C的温度下,研究了限制和无限制力场条件下煤吸附CH4、水、氩气和CO2时的膨胀变形;曹树刚等[16]通过煤岩气固耦合细观力学试验装置,将显微图像观测系统引入到含瓦斯煤力学实验,得到了含瓦斯煤受力过程细观图像;KARACAN[17-18]利用CT和扫描电子显微镜(SEM)对煤吸附CO2后的细观变形进行了研究,研究认为煤的显微组分的不同使得煤吸附CO2后的细观膨胀和收缩变形具有差异性,并且发现镜质组的膨胀变形能力较强;王江芳等[19]、FENG等[20]、周动等[21-22]通过CT和扫描电子显微镜(SEM)技术,研究了煤细观结构类型与其变形的关系,并且从多个尺度研究了煤吸附瓦斯后引起的细观变形特征;MAO等[23]基于CT图像,采用数字体积三维应变图技术定量计算了煤吸附CO2后引起的细观变形,研究认为煤吸附CO2后引起的细观膨胀和收缩的差异性是由煤岩组分及微观孔隙结构引起;NIE等[24]基于CT图像的像素灰度矩阵,采用煤粒跟踪方法定量计算了煤吸附甲烷后引起的细观应变,研究得出膨胀变形倾向于首先挤压原始孔隙或孔隙内部的裂缝,以获得更多的膨胀空间;HAO等[25]利用CT扫描和高分辨率三维X射线显微分析仪,从微观角度研究了烟煤吸附水分后对孔隙率的影响,并采用阈值分割方法对煤样扫描切片进行分割,计算了不同含水量煤样中不同介质的扫描体积和实际体积比,定量描述了煤体的非均质性;刘勇等[26]通过CT技术研究了不同变质煤体吸附SC-CO2后引起的吸附膨胀及溶解萃取作用对煤体裂隙的影响,并通过CT二维扫描图像的灰度值分布函数,定量表征了煤吸附膨胀及裂隙的演化。

煤作为一种天然的吸附介质,具有复杂的微孔隙和裂隙结构,由于这种结构的无序分布,很难用传统的欧氏几何理论定量研究其非均质性[27-28]。大量的研究表明[29-33],煤的无序分布结构符合分形几何规律,分形维数可以定量表征结构的非均质性及其与其他影响因素的相互关系。综上所述,前人的研究多集中于煤吸附气体后引起细观变形的定量表征以及煤孔隙结构本身分形特征的研究。目前,针对煤吸附气体后引起的细观膨胀变形是否具有分形特征的研究相对较少。

为此,通过ACTIS工业CT扫描实验系统,开展了恒定温度下方型无烟煤吸附CH4过程的CT扫描实验,在CT扫描图上采用质点追踪方法定量了计算细观膨胀变形,并利用盒计数维数法对细观膨胀变形的非均质性进行了分形维数研究,得出了煤吸附甲烷的膨胀变形过程中的分形维数变化规律,为煤吸附气体细观膨胀变形的非均质研究提供一定的实验和理论参考。

1. 实验设计与方法

1)实验系统。采用的ACTIS实验系统主要是由CT扫描系统、非金属密封加载系统和数据采集分析处理系统组成。CT扫描系统是由GEIT 320 KV X射线系统、FeinFocus FXE-225.48 微焦点X射线系统、空间分辨率为7.0 /6.2/5.6 l p/mm的图像增强器、2个独立的转台和切片定位轴构成,非金属密封加载系统是由轴向加载器、上下加载部分、应变传递、记录设备、轴向加载活塞、液压泵和真空泵组成。加载器由壁厚为10 mm的非金属聚合物制成,内径38 mm,可装载ϕ25 mm×50 mm的圆柱形煤岩样品和25 mm×25 mm×50 mm长方体煤岩样品。系统最大轴向压力为30 MPa,最大围压为20 MPa,最大气压可达5 MPa。

2)煤样制备。实验煤样取自山西省阳泉市固庄煤矿15号煤层,在现场工作面钻取无烟煤样品,并密封在密封罐中,然后运到实验室。将这些样品沿垂直于层理的方向切割成长25 mm、宽25 mm、高50 mm的正方体样品,两端不平行度误差±0.05 mm,两端表面粗糙度误差±0.02 mm。在每个样品中平行于层理方向安装了1个应变片,实验样品的CT扫描层位及应变片位置如图1所示。

3)实验方法。首先在没有任何加载力的状态下,将煤样品放置在加载气缸中,密封好后对系统进行抽真空。然后对抽真空后的煤样品,在顶部、中间和底部横截面进行初始CT扫描。初始扫描完成后,甲烷气体被充填到系统中。当气体压力达到4.5 MPa时,关闭系统阀门,扫描煤样的顶部、中部和底部横截面(A1B1C1D1、A2B2C2D2、A3B3C3D3)。随着煤样品开始吸附甲烷气体,室内的气体压力开始不断降低,并在不同的气体压力下对选定的同一截面进行CT扫描。最后,当系统中吸附气体压力稳定在3.929 MPa时,吸附达到平衡,然后完成CT扫描。

2. 实验结果

2.1 基于CT图像的质点追踪应变计算分析

基于CT灰度图像,采用质点追踪应变计算算法[34],定量计算煤吸附瓦斯后引起的细观膨胀变形量,其基本假设为当煤吸附气体时,对于同一台CT扫描仪,在其扫描的时间间隔内,煤样上任一质点小范围内灰度变化不大,且由于实验用的固体煤样,在吸附作用下移动范围不会很大,同等情况下以连续2张CT图片上2点移动距离最小作为判断,是否是下一张图上某点要追踪的点。

对于煤吸附甲烷后的连续2张CT图片,在其平面上形成的膨胀应变变形以三角形微分单元的应变变化来表示,而三角形微分单元的应变变化则以该三角形的中心质点的变化来表示。在连续的CT图像中,可以得到这些变形质点的变化坐标。同时每一个质点在吸附前后坐标的矢量增量、方向变化及质点的移动距离可以根据式(1)得出,进而可得到其对应的三角形的变形,从而求出其应变[34-35]。

$$ \left\{\begin{array}{c}\Delta x={x}_{{\mathrm{scan2}}}-{x}_{{\mathrm{scan1}}}\\ \Delta y={y}_{{\mathrm{scan2}}}-{y}_{{\mathrm{scan1}}}\\ D=\sqrt{{\Delta x}^{2}+{\Delta y}^{2}}\end{array}\right. $$ (1) 式中:$ D $为煤粒质点的位移矢量;$ \Delta x $、$ \Delta y $分别为x方向、y方向的矢量增量。

煤粒任一质点的位移状态$ {L}_{i} $可以用在x、y方向上的2个位移矢量$ \tau $、$ \omega $来表示,而应变的计算依赖于该煤粒质点以及最接近它的周围3个点。即1个坐标(x,y)用来表示的平面三角形微分单元,其中三角形3个点分别用i、m、n来表示。用多组这样的三角形微分单元来计算煤样在吸附前后的应变。

在CT扫描灰度图上,煤粒任一质点位移状态$ {L}_{i} $可表示如下:

$$ {L}_{i}=\left\{\begin{array}{c}{\tau }_{i}\\ {\omega }_{i}\end{array}\right. $$ (2) 根据Zienkiewicz and Taylor(1989)[34]的研究,每一点的位移可用2个变量x,y线性表示:

$$ \left\{\begin{array}{c}\tau ={\alpha }_{1}+{\alpha }_{2}x+{\alpha }_{3}y\\ \omega ={\alpha }_{4}+{\alpha }_{5}x+{\alpha }_{6}y\end{array}\right. $$ (3) 3个点共9个$ \alpha $分量可以通过解2组3个未知量的联立方程组来解得。得到3个煤粒质点的坐标和位移,其方程组具体可以表示为:

$$ \left\{ \begin{array}{c}{\tau }_{i}={\alpha }_{1}+{\alpha }_{2}{x}_{i}+{\alpha }_{3}{y}_{i}\\ {\tau }_{m}={\alpha }_{1}+{\alpha }_{2}{x}_{m}+{\alpha }_{3}{y}_{m}\\ {\tau }_{n}={\alpha }_{1}+{\alpha }_{2}{x}_{n}+{\alpha }_{3}{y}_{n}\end{array}\right. \left\{ \begin{array}{c}{\omega }_{i}={\alpha }_{4}+{\alpha }_{5}{x}_{i}+{\alpha }_{6}{y}_{i}\\ {\omega }_{m}={\alpha }_{4}+{\alpha }_{5}{x}_{m}+{\alpha }_{6}{y}_{m}\\ {\omega }_{n}={\alpha }_{4}+{\alpha }_{5}{x}_{n}+{\alpha }_{6}{y}_{n}\end{array}\right. $$ (4) 由上述方程组可以解得$ {\alpha }_{i} $系数,根据Zienkiewicz and Taylor(1989)[34]的研究,该系统方程组的解可以表示为更一般的形式如下:

$$ \left\{\begin{array}{c}\tau =\dfrac{1}{2S}\left[\begin{array}{c}\left({a}_{i}+{b}_{i}x+{c}_{i}y\right){\tau }_{i}+\left({a}_{m}+{b}_{m}x+{c}_{m}y\right){\tau }_{m}+\\ \left({a}_{n}+{b}_{n}x+{c}_{n}y\right){\tau }_{n}\end{array}\right]\\ \omega =\dfrac{1}{2S}\left[\begin{array}{c}\left({a}_{i}+{b}_{i}x+{c}_{i}y\right){\omega }_{i}+\left({a}_{m}+{b}_{m}x+{c}_{m}y\right){\omega }_{m}+\\ \left({a}_{n}+{b}_{n}x+{c}_{n}y\right){\omega }_{n}\end{array}\right]\end{array}\right. $$ (5) 式中:S为三角形微元的面积;$ {a}_{i} $、$ {b}_{i} $、$ {c}_{i} $为$ {\alpha }_{i} $系数。

$$ {S}=\dfrac{1}{2}{\mathrm{det}}\left[\begin{array}{ccc}1& {x}_{i}& {y}_{i}\\ 1& {x}_{m}& {y}_{m}\\ 1& {x}_{n}& {y}_{n}\end{array}\right] $$ (6) 其它变量中的参数可按照i、m、n的顺序循环,可表示为:

$$ \left\{\begin{array}{c}{a}_{i}={\mathrm{det}}\left[\begin{array}{cc}{x}_{i}& {y}_{i}\\ {x}_{n}& {y}_{n}\end{array}\right]\\ {b}_{i}=\left[\begin{array}{cc}1& {y}_{m}\\ 1& {y}_{n}\end{array}\right]\\ {c}_{i}=\left[\begin{array}{cc}{x}_{m}& 1\\ {x}_{n}& 1\end{array}\right]\end{array}\right. $$ (7) x、y方向的应变变化可表示为:

$$ \left\{\begin{array}{c}{\varepsilon }_{x}=\dfrac{\partial \tau }{\partial x}\\ {\varepsilon }_{y}=\dfrac{\partial \tau }{\partial y}\end{array}\right. $$ (8) 因此,平面上的应变$ {\varepsilon }_{{\mathrm{L}}} $可计算为:

$$ {\varepsilon }_{{\mathrm{L}}}={\varepsilon }_{x}+{\varepsilon }_{y} $$ (9) 综上所述,CT灰度图像平面中的其他质点也依照上述算法进行计算,可得到整个煤样吸附膨胀过程中在CT平面的应变情况。基于以上质点追踪应变计算算法开发了CT图像处理Matlab程序,对煤吸附甲烷(气体压力p为4.513~3.929 MPa)膨胀变形过程的细观应变进行了计算。煤样吸附甲烷过程中,A1B1C1D1、A2B2C2D2、A3B3C3D3应变计算结果如图2~图4所示。

由图2~图4的上、中、下3个不同层位的CT灰度图像来看:CT扫描图大致分为白色、灰、和黑色3个部分,其灰度值分布范围为0~255;白色部分的灰度值最低,密度最高,其主要是煤的全岩无机矿物结构部分;灰色部分的灰度值介于白色和黑色部分之间,其主要是煤基质结构;黑色部分的灰度值最高,密度最低,其主要分布着微孔或不规则裂纹的填充介质。

由图2~图4的应变结果分布图(x轴和y轴分别为CT像素横、纵坐标,图中不同的颜色代表不同应变值,靠近红色越深,膨胀变形越大,蓝色越深收缩变形越大)来看:在煤吸附甲烷后,煤样的整体形状几乎没有变化,但是在不同的细观局部区域存在明显的正、负应变值,正、负应变分别代表膨胀和收缩变形;对于CT灰度图中的白色(高密度)区域,在吸附平衡之前主要是以膨胀为主,仅有少量收缩变形,这主要是因为该区域为全岩无机矿物相带,能够非常迅速地吸收大量气体,很少形成收缩变形,这一点与前人的研究相一致[17-18,36-38]。对于CT图中灰色和黑色(低密度)区域,除了有正应变值即膨胀变形以外,还存在大量的负应变值即收缩变形,由于这一部分区域属于煤基质和孔隙、微裂纹存在的区域,大量研究表明煤吸附气体膨胀变形首先挤压孔隙或微裂纹以获得更大的膨胀空间,这一点与已有研究成果较为一致[17-20,23,38]。

2.2 煤吸附甲烷细观变形分形特征

已有的大量研究已经证明,任一孔隙材料从晶粒尺寸到原子尺度,材料的孔隙几何和粒子几何均会出现分形特征。分形理论被广泛引入定量描述多孔介质的非均质性和复杂性[29,39-41]。分形几何中计算分形维数的方法包括相似维数、容量维数、关联维数及盒计数维数等方法,为了更准确地定量描述在CT图像中煤吸附甲烷引起变形的非均质性,采用盒计数维数法,以“像素覆盖”来计算其分形维数。将1幅L×L像素的二值化图设定为R2空间的任一非空有界子集$ \theta $,对于任一$ \tau > 0 $,使得$ {N}_{\tau }\left(\theta \right) $为覆盖$ \theta $所需边长为$ \tau $的立方体盒子的最小数目,当$ \tau \to 0 $时,则分形维数D[28,42]可表示为:

$$ D=-\underset{\tau \to 0}{\mathrm{lim}}\dfrac{\mathrm{lg}\;{N}_{\tau }\left(\theta \right)}{\mathrm{lg}\;\tau } $$ (10) 对式(10)在双对数坐标系中用最小二乘法对数据点(−$ \mathrm{lg}\;\tau $,$ \mathrm{lg}\;{N}_{\tau }\left(\theta \right) $)进行线性拟合求直线方程:

$$ \mathrm{lg}\;{N}_{\tau }\left(\theta \right)=A \left(-\mathrm{lg}\;\tau \right)+\mathrm{lg}\;B $$ (11) 式中:A为煤吸附气体变形的分形维数;$ B $为煤吸附气体变形应变分布初值。

根据以上模型与算法,对3个CT扫描层面应变结果分布图进行了分形维数的计算,吸附过程中不同层位膨胀变形率与应变图分形维数结果见表1,A1B1C1D1层面应变图分形维数计算结果如图5所示。

表 1 吸附过程中不同层位膨胀变形率与应变图分形维数结果Table 1. Calculation results of expansion deformation rate and fractal dimension of strain map at different layers during the process of adsorptionCT扫描层位 气体压力/MPa 膨胀变形率

(像素统计)/%分形维数 A1B1C1D1 4.513~4.492 47.35 1.471 4.492~4.476 46.72 1.522 4.476~4.256 46.92 1.484 4.256~4.112 47.02 1.473 4.112~3.929 44.49 1.495 A2B2C2D2 4.513~4.492 44.89 1.625 4.492~4.476 44.75 1.652 4.476~4.256 43.39 1.688 4.256~4.112 43.49 1.683 4.112~3.929 44.00 1.636 A3B3C3D3 4.513~4.492 42.69 1.651 4.492~4.476 42.12 1.705 4.476~4.256 43.09 1.686 4.256~4.112 42.32 1.695 4.112~3.929 42.57 1.675 从表1和图5分形维数的计算结果来看,分形维数线性拟合的相关系数R2都在0.97以上,充分说明计算得出的分形维数是有效的,也证明了煤吸附甲烷膨胀过程产生的非均质应变变化具有分形特性,这种非均质特性可以通过分形维数来进行定量描述表征。

研究表明,对于二维平面下的孔隙结构,从分形几何理论中计算出的分形维数位于1~2之间,分形维数值越小,煤孔隙结构复杂程度越低,孔隙形态越均一,孔隙分布相对简单;分形维数值越大,煤孔隙结构复杂程度越高,孔隙形态及分布越复杂[28,43]。

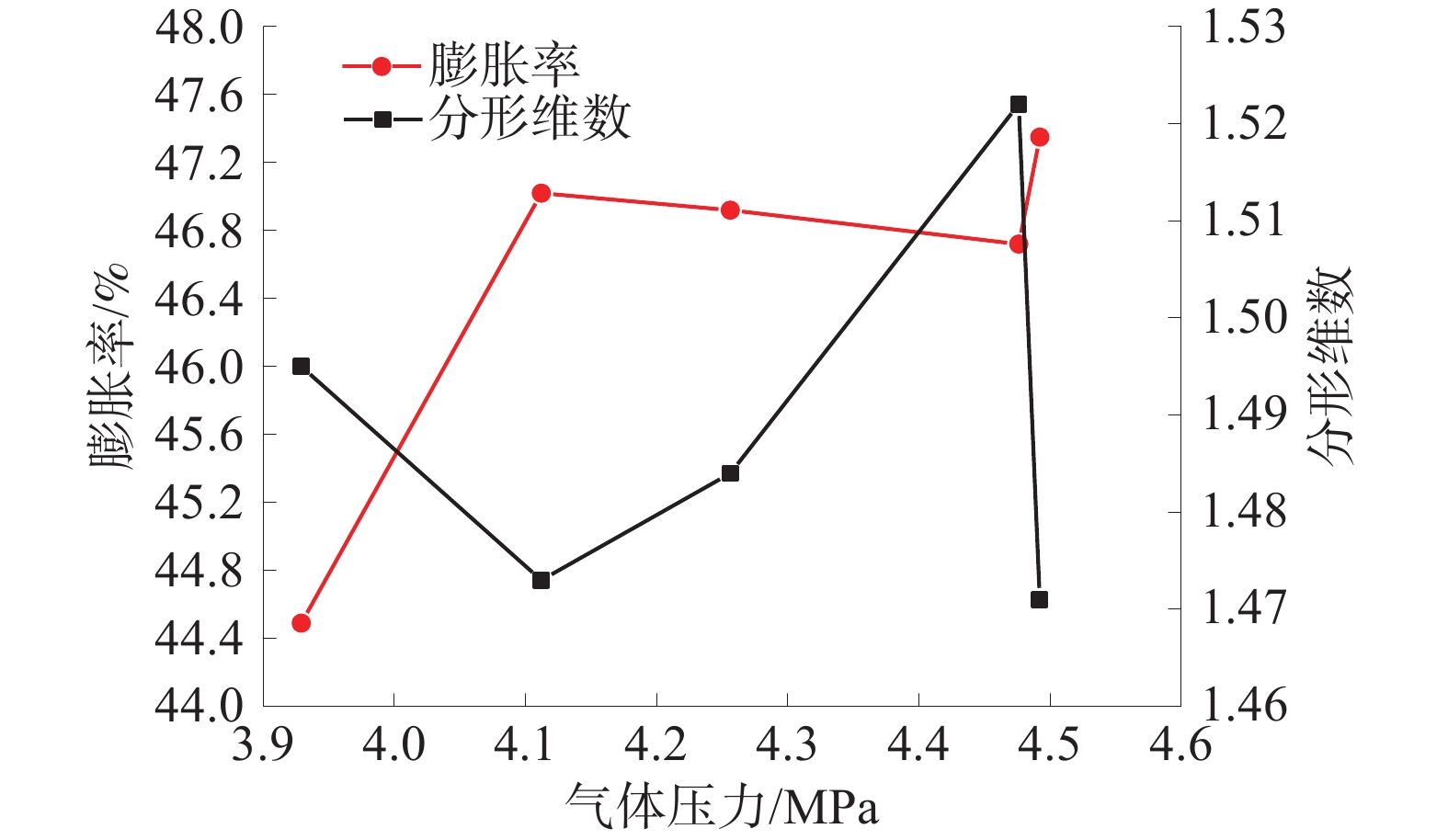

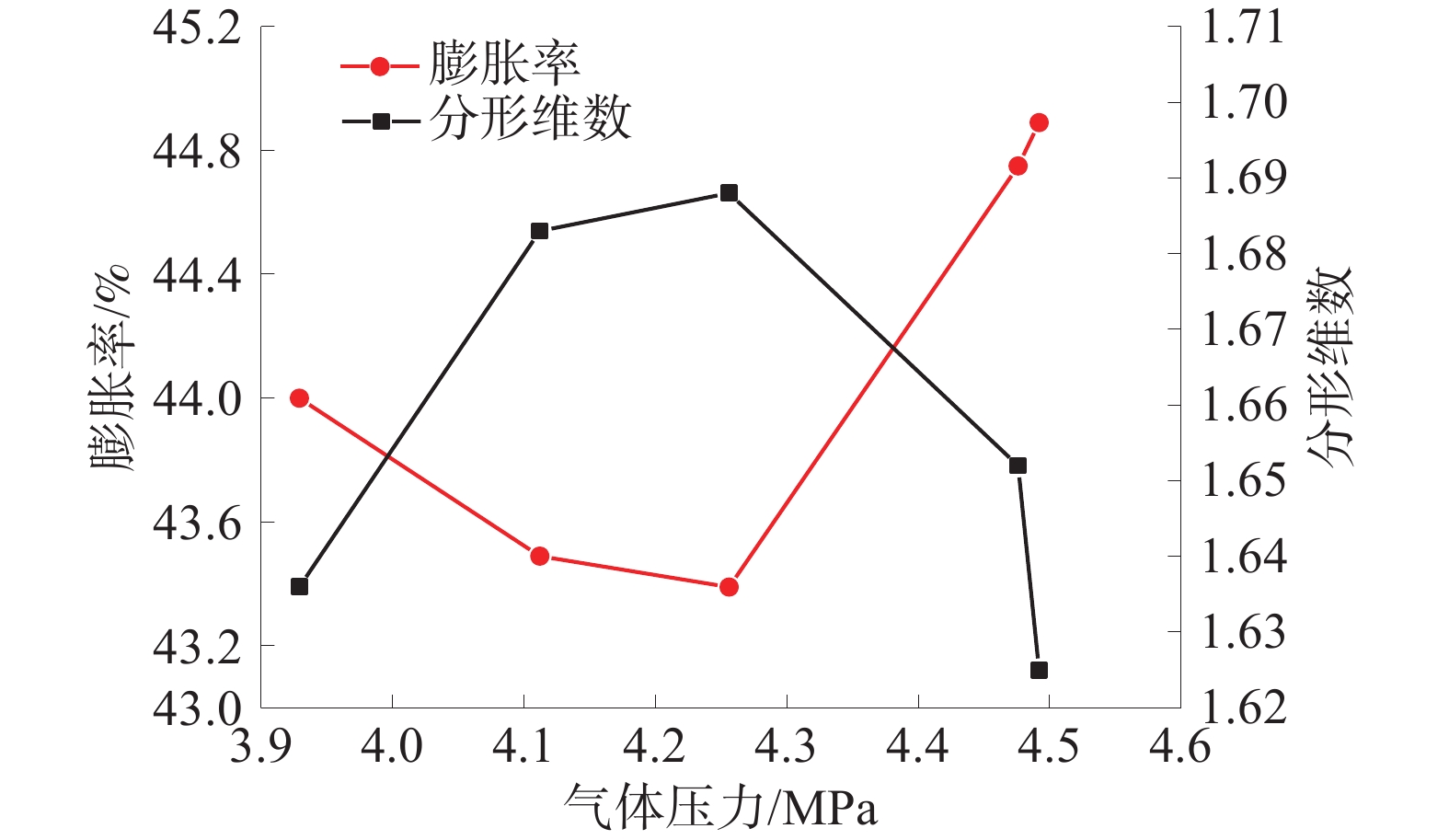

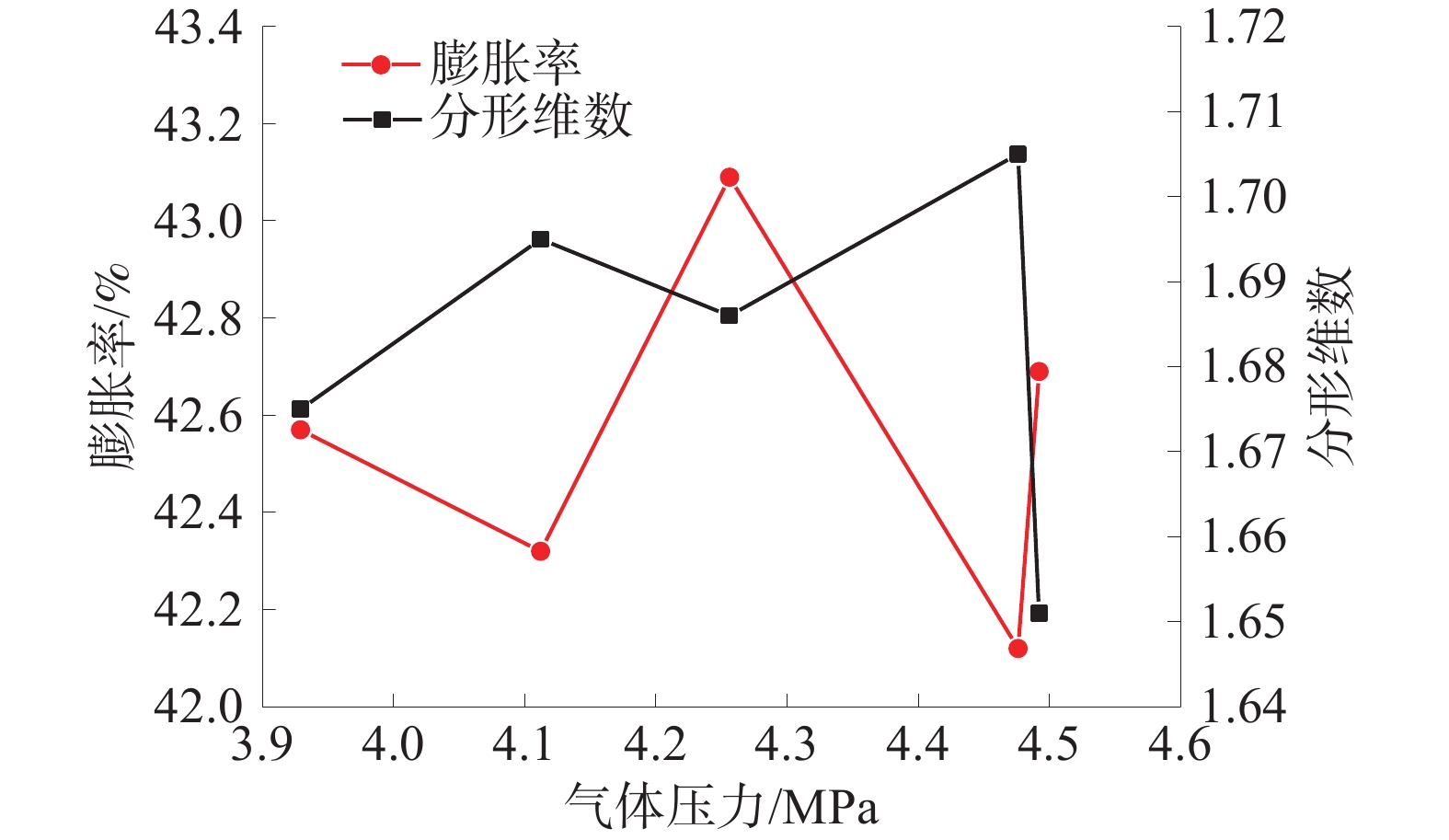

吸附过程中,A1B1C1D1、A2B2C2D2、A3B3C3D3膨胀变形率和分形维数变化曲线如图6~图8所示。

由图6~图8可以看出,二维平面下煤吸附甲烷膨胀后产生的非均质应变变化,其分形维数也是位于1~2之间,并且煤吸附甲烷后的膨胀变形率与分形维数呈负相关性关系,膨胀变形率值越高,分形维数越低,即煤吸附甲烷后越膨胀,煤整体的非均质应变变形的不规则程度越低;相反,膨胀变形率值越低,分形维数越高,煤吸附甲烷后膨胀越小,煤整体的非均质应变变形的不规则程度越高,分形维数可定量表征煤吸附甲烷后非均质变形的不规则程度。

3. 结 语

1)采用基于CT图像的质点追踪应变计算算法,对煤吸附甲烷过程的细观应变进行了定量计算。从应变计算结果看,煤吸附甲烷后,煤样的整体形状几乎没有变化,但是在不同的细观局部区域存在明显的正、负应变值,即煤吸附甲烷后在细观的各个局部区域上呈现出较多的膨胀和收缩的非均质变形;对于煤中的全岩无机矿物相带,由于其良好的吸附性,表现出大量的膨胀变形和几乎很少的压缩变形;对于煤基质和孔隙、微裂纹存在的区域,同时表现出大量的膨胀和收缩变形,表明煤吸附气体膨胀变形首先挤压孔隙或微裂纹以获得更大的膨胀空间。

2)根据分形维数的计算方法,提出了一种基于CT图像,定量化研究煤吸附气体后非均质变形的方法,并通过维数定量表征了煤吸附甲烷后非均质变形的不规则程度。同时,揭示了分形维数与煤吸附甲烷后的膨胀变形率呈负相关性关系,膨胀变形率值越高,分形维数越低,即煤吸附甲烷后越膨胀,煤整体的非均质应变变形的不规则程度越低;相反,膨胀变形率值越低,则分形维数越高,煤整体的非均质应变变形的不规则程度越高。

-

表 1 吸附过程中不同层位膨胀变形率与应变图分形维数结果

Table 1 Calculation results of expansion deformation rate and fractal dimension of strain map at different layers during the process of adsorption

CT扫描层位 气体压力/MPa 膨胀变形率

(像素统计)/%分形维数 A1B1C1D1 4.513~4.492 47.35 1.471 4.492~4.476 46.72 1.522 4.476~4.256 46.92 1.484 4.256~4.112 47.02 1.473 4.112~3.929 44.49 1.495 A2B2C2D2 4.513~4.492 44.89 1.625 4.492~4.476 44.75 1.652 4.476~4.256 43.39 1.688 4.256~4.112 43.49 1.683 4.112~3.929 44.00 1.636 A3B3C3D3 4.513~4.492 42.69 1.651 4.492~4.476 42.12 1.705 4.476~4.256 43.09 1.686 4.256~4.112 42.32 1.695 4.112~3.929 42.57 1.675 -

[1] 彭苏萍. 我国煤矿安全高效开采地质保障系统研究现状及展望[J]. 煤炭学报,2020,45(7):2331−2345. PENG Suping. Current status and prospects of research on geological assurance system for coal mine safe and high efficient mining[J]. Journal of China Coal Society, 2020, 45(7): 2331−2345.

[2] 袁亮. 深部采动响应与灾害防控研究进展[J]. 煤炭学报,2021,46(3):716−725. YUAN Liang. Research progress of mining response and disaster prevention and control in deep coal mines[J]. Journal of China Coal Society, 2021, 46(3): 716−725.

[3] 袁亮,王恩元,马衍坤,等. 我国煤岩动力灾害研究进展及面临的科技难题[J]. 煤炭学报,2023,48(5):1825−1845. YUAN Liang, WANG Enyuan, MA Yankun, et al. Research progress of coal and rock dynamic disasters and scientific and technological problems in China[J]. Journal of China Coal Society, 2023, 48(5): 1825−1845.

[4] 唐珏,王俊. “双碳”目标下煤炭发展及对策建议[J]. 中国矿业,2023,32(9):22−31. doi: 10.12075/j.issn.1004-4051.20230483 TANG Jue, WANG Jun. Coal development and countermeasures under the carbon peaking and carbon neutrality goals[J]. China Mining Magazine, 2023, 32(9): 22−31. doi: 10.12075/j.issn.1004-4051.20230483

[5] 李鹏. 我国煤炭工业的现状及可持续发展观[J]. 决策探索(中),2018(8):16−17. [6] 刘峰,郭林峰,张建明,等. 煤炭工业数字智能绿色三化协同模式与新质生产力建设路径[J]. 煤炭学报,2024,49(1):1−15. LIU Feng, GUO Linfeng, ZHANG Jianming, et al. Synergistic mode of digitalization-intelligentization-greeniation of the coal industry and it’s path of building new coal productivity[J]. Journal of China Coal Society, 2024, 49(1): 1−15.

[7] 祝捷,张敏,传李京,等. 煤吸附/解吸瓦斯变形特征及孔隙性影响实验研究[J]. 岩石力学与工程学报,2018,35(S1):2620−2626. ZHU Jie, ZHANG Min, CHUAN Lijing, etal. Experimental study on coal strain induced by methane sorption/desorption and effect of pore features[J]. Chinese Journal of Rock Mechanics and Engineering, 2018, 35(S1): 2620−2626.

[8] 林柏泉,周世宁. 含瓦斯煤体变形规律的实验研究[J]. 中国矿业学院学报,1986(3):9−16. [9] 程波,颜文学,孙炳兴,等. 含瓦斯煤的吸附量与孔隙率及变形的映射规律研究[J]. 煤矿安全,2021,52(1):25−29. CHENG Bo, YAN Wenxue, SUN Bingxing, et al. Study on the mapping law of adsorption, porosity and deformation of gas bearing coal[J]. Safety in Coal Mines, 2021, 52(1): 25−29.

[10] 曹树刚,张遵国,李毅,等. 突出危险煤吸附、解吸瓦斯变形特性试验研究[J]. 煤炭学报,2013,32(10):1792−1799. CAO Shugang, ZHANG Zunguo, LI Yi, et al. Experimental study of deformation properties of outburst-prone coal induced by gas adsorption and desorption[J]. Journal of China Coal Society, 2013, 32(10): 1792−1799.

[11] 刘延保. 极松软煤体高压吸附过程中变形特性试验研究[J]. 矿业安全与环保,2016,43(5):1−4. doi: 10.3969/j.issn.1008-4495.2016.05.001 LIU Yanbao. Test study on deformation characteristics of extra-soft coal in high-pressure absorption process[J]. Mining Safety & Environmental Protection, 2016, 43(5): 1−4. doi: 10.3969/j.issn.1008-4495.2016.05.001

[12] 李祥春,聂百胜,何学秋,等. 瓦斯吸附对煤体的影响分析[J]. 煤炭学报,2011,36(12):2035−2038. LI Xiangchun, NIE Baisheng, HE Xueqiu, et al. Influence of gas adsorption on coal body[J]. Journal of China Coal Society, 2011, 36(12): 2035−2038.

[13] 张遵国,赵丹,陈毅. 不同含水率条件下软煤等温吸附特性及膨胀变形特性[J]. 煤炭学报,2020,45(11):3817−3824. ZHANG Zunguo, ZHAO Dan, CHEN Yi. Isothermal adsorption and swelling deformation characteristics of soft coal under different moisture content[J]. Journal of China Coal Society, 2020, 45(11): 3817−3824.

[14] 林海飞,季鹏飞,孔祥国,等. 三轴应力下原煤吸附CH4/N2变形时空特性[J]. 中国矿业大学学报,2023,52(2):314−328. LIN Haifei, JI Pengfei, KONG Xiangguo, et al. Temporal and spatial characteristics of raw coal deformation during the adsorption of CH4/N2 under triaxial stress[J]. Journal of China University of Mining & Technology, 2023, 52(2): 314−328.

[15] BERGEN F V, HOL S, SPIERS C. Stress–strain response of pre-compacted granular coal samples exposed to CO2, CH4, He and Ar[J]. International Journal of Coal Geology, 2011, 86(2−3): 241−253.

[16] 曹树刚,刘延保,李勇,等. 煤岩固-气耦合细观力学试验装置的研制[J]. 岩石力学与工程学报,2009,28(8):1681−1690. doi: 10.3321/j.issn:1000-6915.2009.08.020 CAO Shugang, LIU Yanbao, LI Yong, et al. Research and development of testing apparatus of coal solid-gas coupled meso-mechanics[J]. Chinese Journal of Rock Mechanics and Engineering, 2009, 28(8): 1681−1690. doi: 10.3321/j.issn:1000-6915.2009.08.020

[17] KARACAN C Ö. Swelling-induced volumetric strains internal to a stressed coal associated with CO2 sorption[J]. International Journal of Coal Geology, 2007, 72(3−4): 209−220.

[18] KARACAN C Ö. Heterogeneous sorption and swelling in a confined and stressed coal during CO2 injection[J]. Energy & Fuels, 2003, 17(6): 1595−1608.

[19] 王江芳,王辰,冯增朝. 天然煤体吸附甲烷的非均匀特征研究[J]. 煤矿安全,2021,52(7):15−20. WANG Jiangfang, WANG Chen, FENG Zengzhao. Study on heterogeneous characteristics of methane adsorption by natural coal[J]. Safety in Coal Mines, 2021, 52(7): 15−20.

[20] FENG Z C, CAI T T, ZHOU D, et al. Temperature and deformation changes in anthracite coal after methane adsorption[J]. Fuel, 2017, 192: 27−34. doi: 10.1016/j.fuel.2016.12.005

[21] 周动,冯增朝,赵东,等. 煤吸附瓦斯细观特性研究[J]. 煤炭学报,2015,40(1):98−102. ZHOU Dong, FENG Zengzhao, ZHAO Dong, et al. Study on mesoscopic characteristics of methane adsorption by coal[J]. Journal of China Coal Society, 2015, 40(1): 98−102.

[22] 周动,冯增朝,王辰,等. 煤吸附甲烷结构变形的多尺度特征[J]. 煤炭学报,2019,44(7):2159−2166. ZHOU Dong, FENG Zengzhao, WANG Chen, et al. Multi-scale characteristics of coal structure deformation during methane adsorption[J]. Journal of China Coal Society, 2019, 44(7): 2159−2166.

[23] MAO L T, HAO N, AN L Q, et al. 3D mapping of carbon dioxide-induced strain in coal using digital volumetric speckle photography technique and X-ray computer tomography[J]. International Journal of Coal Geology, 2015, 147: 115−125.

[24] NIE B S, FAN P H, LI X C. Quantitative investigation of anisotropic characteristics of methane-induced strain in coal based on coal particle tracking method with X-ray computer tomography[J]. Fuel, 2018, 214: 272−284. doi: 10.1016/j.fuel.2017.10.084

[25] HAO D Y, TU S H, ZHANG C. Experimental study on the effect of moisture content on bituminous coal porosity based on 3D reconstruction of computerized tomography[J]. Natural Resources Research, 2020, 29(3): 1657−1673. doi: 10.1007/s11053-019-09528-y

[26] 刘勇,李海超,魏建平,等. 超临界二氧化碳短时作用煤体裂隙演化CT/XDR实验研究[J/OL]. 煤炭学报, 2024. [2024-05-20]. https://doi.org/10.13225/j.cnki.jccs.xr23.1086. LIU Yong, LI Haichao, WEI Jianping, et al. CT experimental study on the fracture evolution of supercritical CO2 short duration action coal body[J/OL]. Journal of China Coal Society, 2024. [2024-05-20]. https://doi.org/10.13225/j.cnki.jccs.xr23.1086.

[27] 任少魁,秦玉金,贾宗凯,等. 不同煤阶煤孔隙结构分形表征及其对甲烷吸附特性的影响[J]. 煤矿安全,2023,54(5):175−181. REN Shaokui, QIN Yujin, JIA Zongkai, et al. Fractal characterization of pore structure of coal with different ranks and its effect on methane adsorption characteristics[J]. Safety in Coal Mines, 2023, 54(5): 175−181.

[28] 阎纪伟,要惠芳,李伟,等. μCT技术研究煤的孔隙结构和分形特征[J]. 中国矿业,2015,24(6):151−156. doi: 10.3969/j.issn.1004-4051.2015.06.035 YAN Jiwei, YAO Huifang, LI Wei, et al. Pore structure and fractal characteristics of coals by μCT technology[J]. China Mining Magazine, 2015, 24(6): 151−156. doi: 10.3969/j.issn.1004-4051.2015.06.035

[29] 张昆,孟召平,金毅,等. 不同煤体结构煤的孔隙结构分形特征及其研究意义[J]. 煤炭科学技术,2023,51(10):198−206. ZHANG Kun, MENG Zhaoping, JIN Yi, et al. Fractal characteristics of pore structures on different coal structures and its research significance[J]. Coal Science and Technology, 2023, 51(10): 198−206.

[30] 金毅,李娅妮,宋慧波,等. 分形界面吸附行为初探[J]. 煤田地质与勘探,2024,52(5):1−11. doi: 10.12363/issn.1001-1986.24.01.0035 JIN Yi, LI Yani, SONG Huibo, et al. A preliminary study of coalbed methane adsorption at fractal interfaces[J]. Coal Geology & Exploration, 2024, 52(5): 1−11. doi: 10.12363/issn.1001-1986.24.01.0035

[31] 李树刚,周雨璇,胡彪,等. 低阶煤吸附孔结构特征及其对甲烷吸附性能影响[J]. 煤田地质与勘探,2023,51(2):127−136. doi: 10.12363/issn.1001-1986.22.09.0743 LI Shugang, ZHOU Yuxuan, HU Biao, et al. Structural characteristics of adsorption pores in low-rank coals and their effects on methane adsorption performance[J]. Coal Geology & Exploration, 2023, 51(2): 127−136. doi: 10.12363/issn.1001-1986.22.09.0743

[32] 刘怀谦,王磊,谢广祥,等. 煤体孔隙结构综合表征及全孔径分形特征[J]. 采矿与安全工程学报,2022,39(3):458−469. LIU Huaiqian, WANG Lei, XIE Guangxiang, et al. Comprehensive characterization and full pore size fractal characteristics of coal pore structure[J]. Journal of Mining & Safety Engineering, 2022, 39(3): 458−469.

[33] 黄赞,孙斌,杨青,等. 鸡西盆地煤储层吸附孔特征及分形表征研究[J]. 煤炭科学技术,2021,49(5):218−226. HUANG Zan, SUN Bin, YANG Qing, et al. Study on characterization and fractal features of adsorption pores of coal reservoirs in Jixi Basin[J]. Coal Science and Technology, 2021, 49(5): 218−226.

[34] JDNS Pone. Carbon dioxide sequestration in coal: Characterization of matrix deformation, sorption capacity and dynamic permeability at in-situ stress conditions [D]. Pennsylvania State: Pennsylvania State University, 2009.

[35] ZIENKIEWICZ O C, TAYLOR R L. The finite element patch test revisited a computer test for convergence, validation and error estimates[J]. Computer Methods in Applied Mechanics and Engineering, 1997, 149(1−4): 223−254.

[36] 赵楷棣,傅雪海. 无烟煤各向异性吸附膨胀动态响应实验研究[J]. 煤矿安全,2022,53(4):1−6. ZHAO Kaidi, FU Xuehai. Experimental study on dynamic response of anisotropic adsorption swelling of anthracite[J]. Safety in Coal Mines, 2022, 53(4): 1−6.

[37] CHEN T Y, FENG X T, PAN Z J. Experimental study of swelling of organic rich shale in methane[J]. International Journal of Coal Geology, 2015, 150: 64−73.

[38] ZHANG Y H, LEBEDEV M, SARMADIVALEH M, et al. Swelling effect on coal micro structure and associated permeability reduction[J]. Fuel, 2016, 182: 568−576. doi: 10.1016/j.fuel.2016.06.026

[39] 李祥春,高佳星,张爽,等. 基于扫描电镜、孔隙-裂隙分析系统和气体吸附的煤孔隙结构联合表征[J]. 地球科学,2022,47(5):1876−1889. doi: 10.3321/j.issn.1000-2383.2022.5.dqkx202205024 LI Xiangchun, GAO Jiaxing, ZHANG Shuang, et al. Combined characterization of scanning electron microscopy, pore and crack analysis system, and gas adsorption on pore structure of coal with different volatilization[J]. Earth Science, 2022, 47(5): 1876−1889. doi: 10.3321/j.issn.1000-2383.2022.5.dqkx202205024

[40] 傅雪海,秦勇,张万红,等. 基于煤层气运移的煤孔隙分形分类及自然分类研究[J]. 科学通报,2005,50(S1):51−55. [41] 王聪,江成发,储伟. 煤的分形维数及其影响因素分析[J]. 中国矿业大学学报,2013,42(6):1009−1014. doi: 10.3969/j.issn.1000-1964.2013.06.019 WANG Cong, JIANG Chengfa, CHU Wei. Fractal dimension of coals and analysis of its influencing factors[J]. Journal of China University of Mining & Technology, 2013, 42(6): 1009−1014. doi: 10.3969/j.issn.1000-1964.2013.06.019

[42] 汪学清,赵云猛,冯莹,等. 含孔洞多裂隙复合岩层裂纹扩展和分形特性模拟研究[J]. 煤矿安全,2024,55(1):42−49. WANG Xueqing, ZHAO Yunmeng, FENG Ying, et al. Simulation of cracks propagation and fractal characteristics of composite rock strata with holes and fractures[J]. Safety in Coal Mines, 2024, 55(1): 42−49.

[43] 宫伟力,张艳松,安里千. 基于图像分割的煤岩孔隙多尺度分形特征[J]. 煤炭科学技术,2008,36(6):28−32. GONG Weili, ZHANG Yansong, AN Liqian. Multiple-scale fractal features of coal and rock porosity based on miage segmentation[J]. Coal Science and Technology, 2008, 36(6): 28−32.

下载:

下载: