Energy and damage analysis of fractured sandstone under true triaxial cyclic loading

-

摘要:

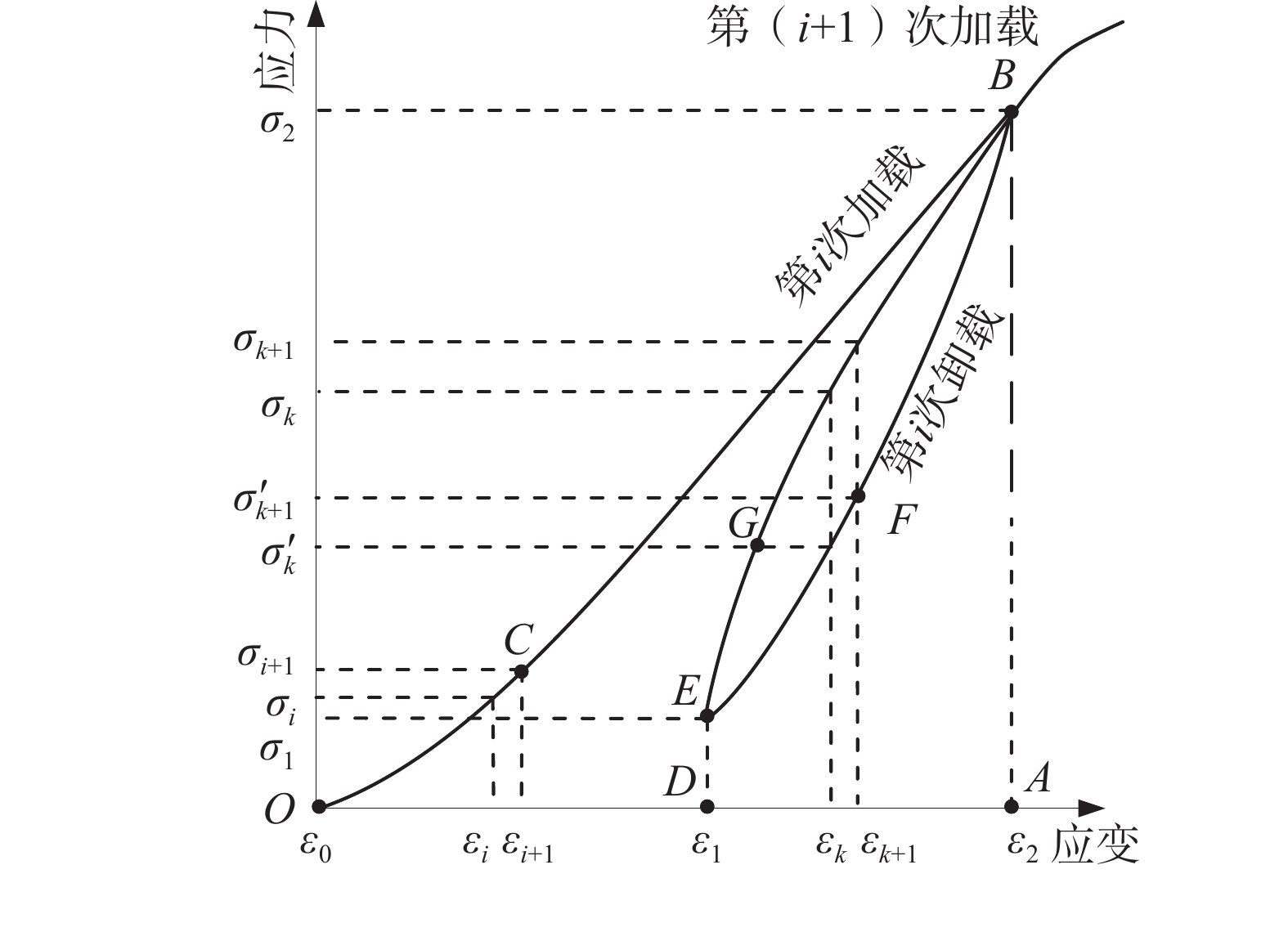

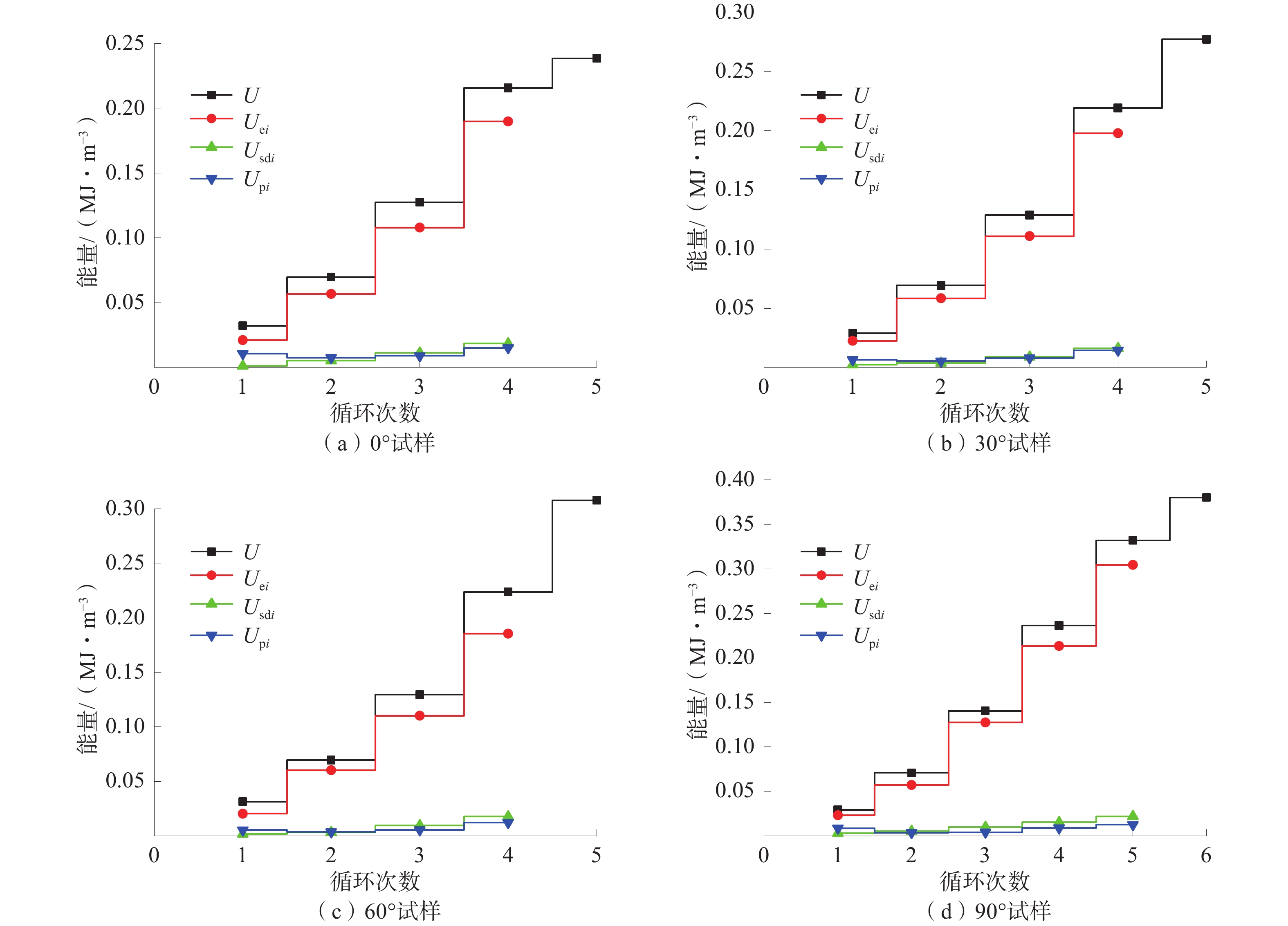

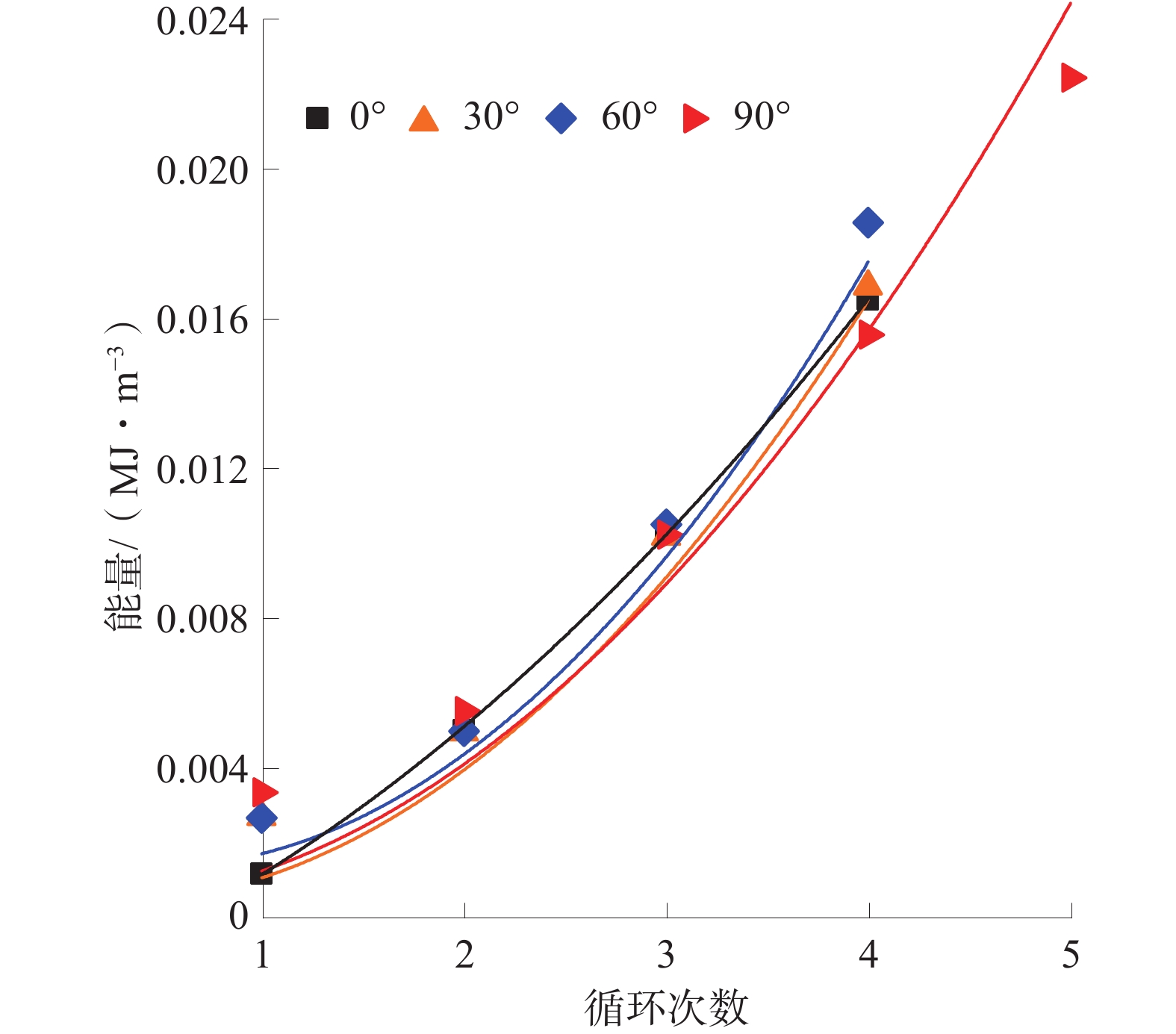

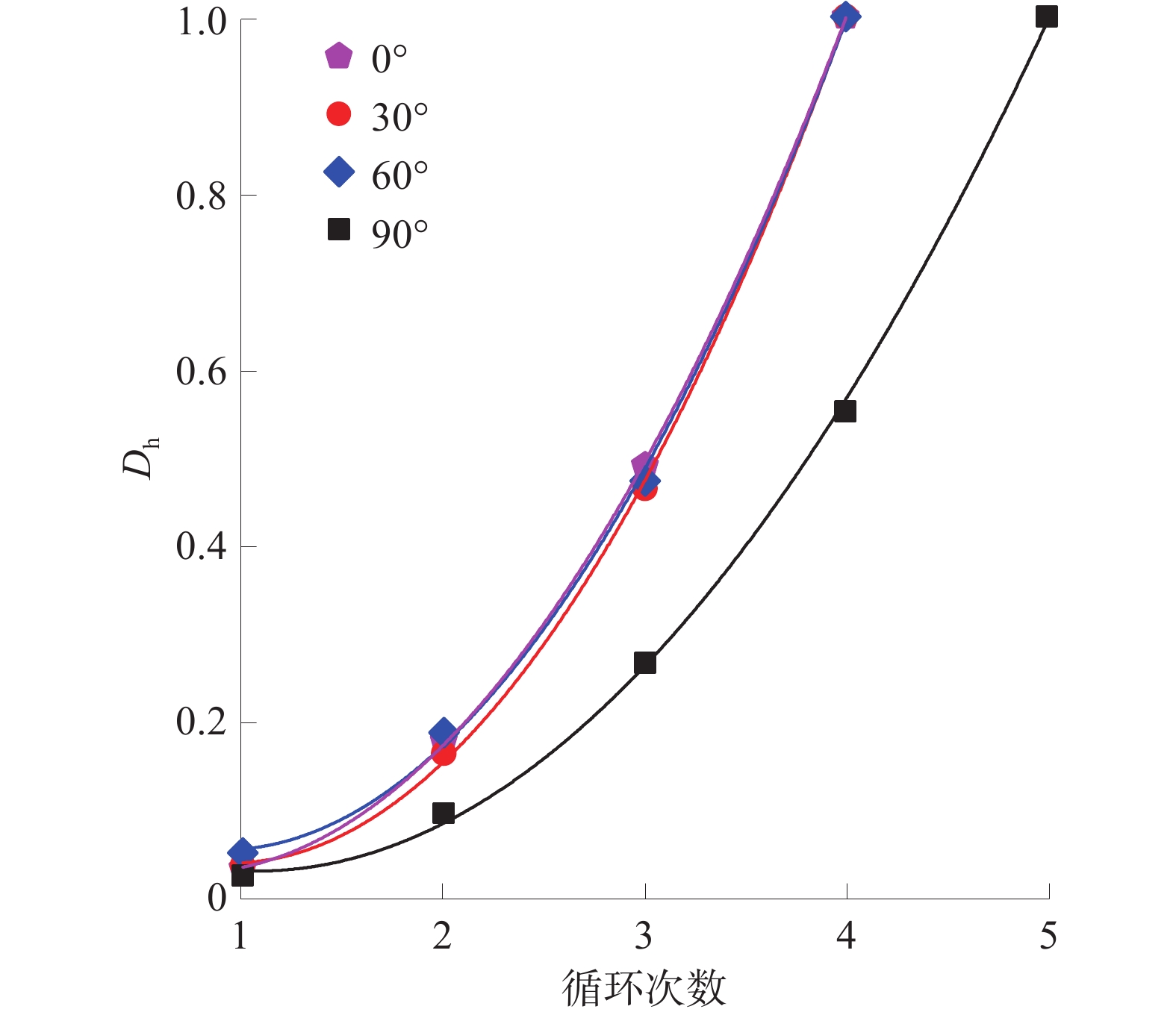

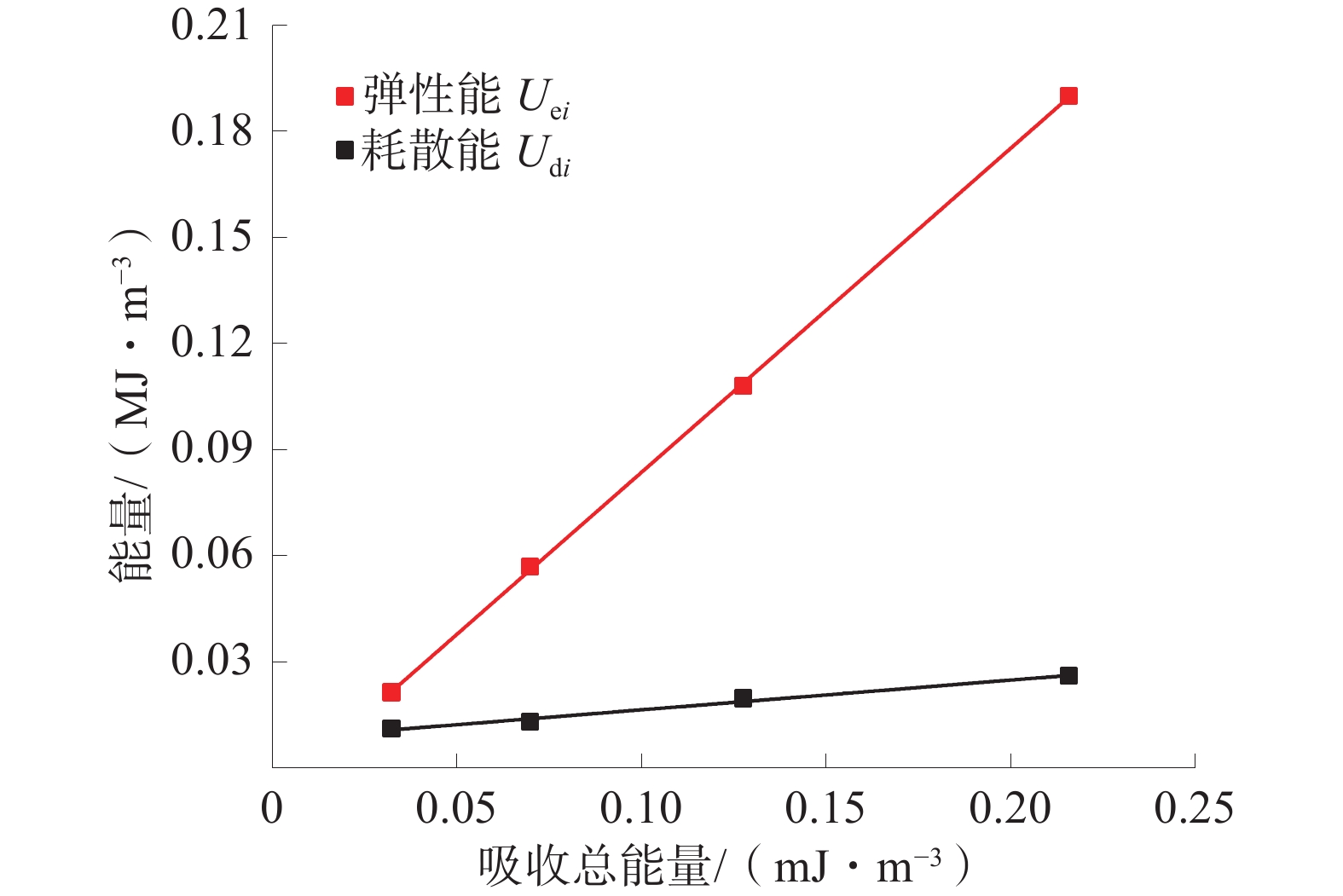

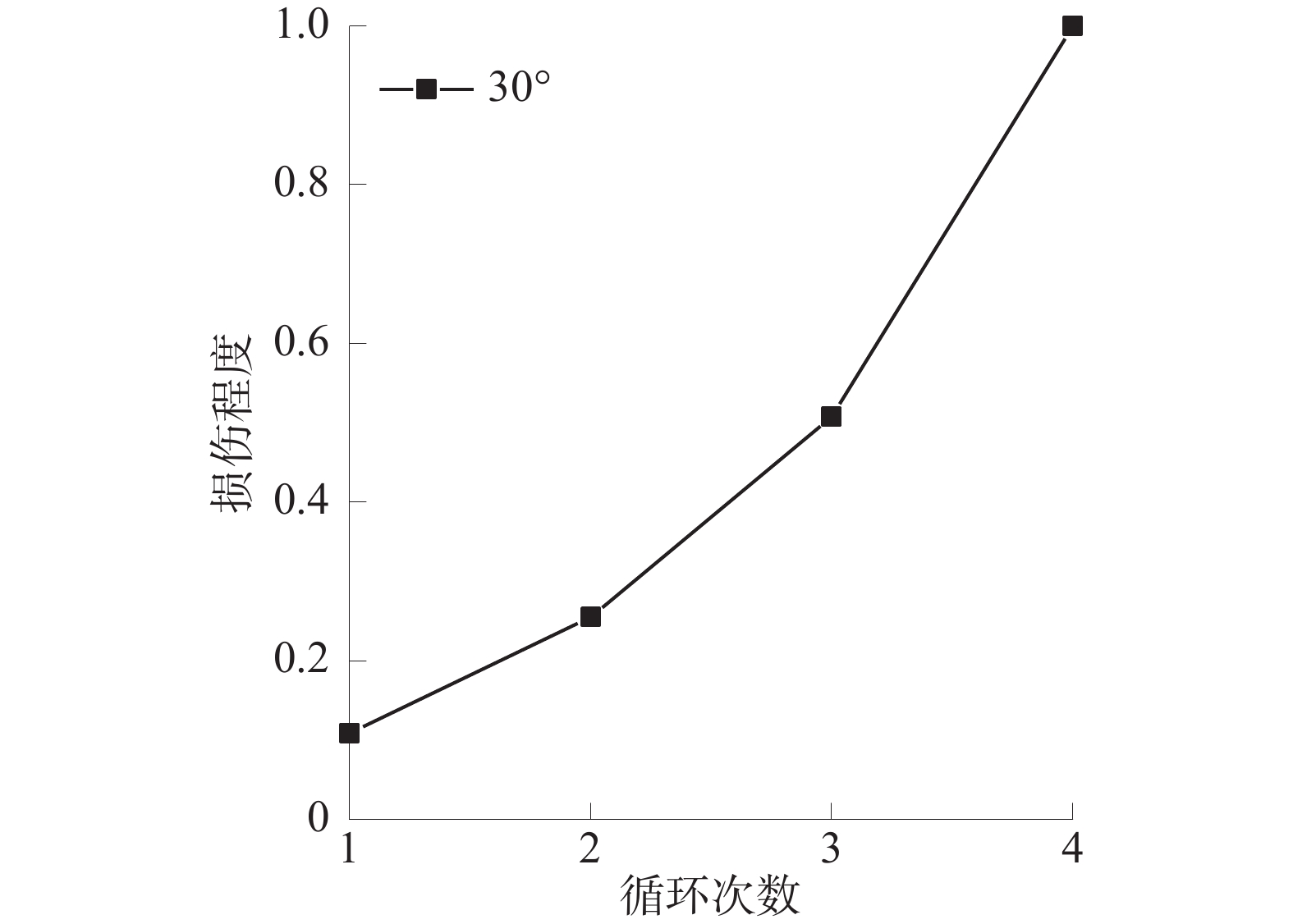

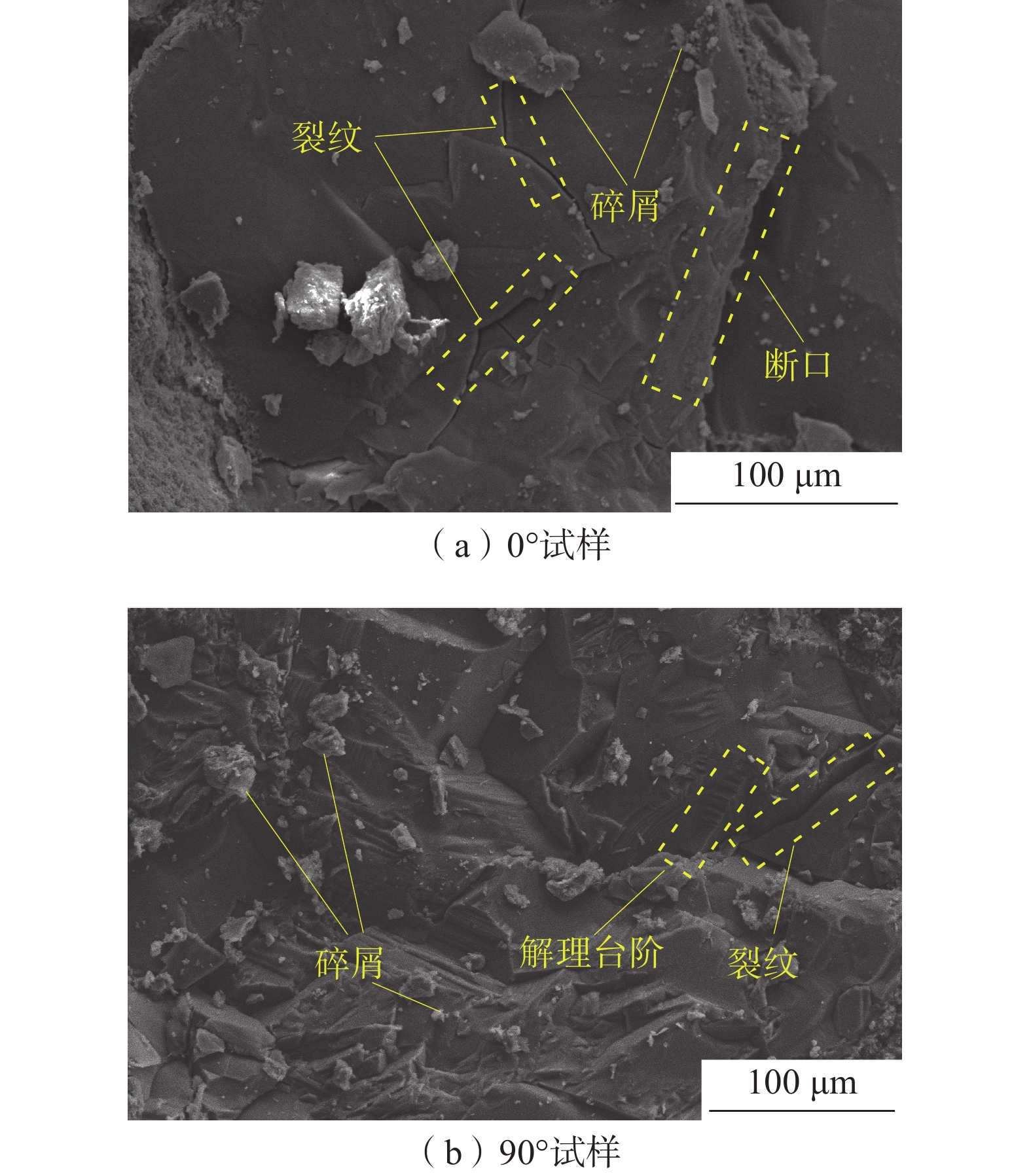

探究真三轴循环荷载作用下含裂缝砂岩能量演化有助于明确岩石损伤破坏规律。开展了真三轴循环加卸载试验,分析了吸收总能量、弹性能、耗散能和塑性变形能的演化特征,并建立岩石损伤评价模型,结合断裂面细观损伤特征,探讨了岩石损伤破坏规律。结果表明:随着裂缝角度增大,试样强度越大,破坏时吸收总能量越大,分别为0.238、0.276、0.307、0.332 MJ/m3;试验时吸收总能量、弹性能、耗散能均逐渐增加,塑性变形能先减小后增大;通过滞回环能量和总耗散能量,建立岩石损伤破坏评价指标,两者评价结果一致,岩石损伤程度随加卸载进行呈非线性变化;试样破坏时经历循环加卸载次数越多,受挤压摩擦程度越高,断裂面细观形貌越复杂。

Abstract:Exploring the energy evolution of fractured sandstone under true triaxial cyclic loading is helpful to clarify the law of rock damage and failure. The evolution characteristics of total absorbed energy, elastic energy, dissipated energy and plastic deformation energy during the test were systematically analyzed. A rock damage evaluation model was established, and the rock damage failure law was discussed in combination with the mesoscopic damage characteristics of the fracture surface. The results show as follows: with the increase of crack angle, the greater the peak strength of the sample during failure, the greater the total absorbed energy, they were 0.238, 0.276, 0.307 and 0.332 MJ/m3, respectively; the total absorbed energy, elastic energy and dissipated energy increase gradually during the whole test process, while the plastic deformation energy decreases first and then increases; based on hysteretic loop energy and total dissipated energy, an evaluation index was established to describe rock damage, and the results of the two evaluation methods are consistent, and it is found that the rock damage degree changes nonlinear with loading and unloading during the test; the number of cyclic loading and unloading during the failure of the sample has a significant influence on the internal damage of the sample. The more times of cyclic loading and unloading, the higher the degree of extrusion friction and the more complex the micromorphology of the fracture surface.

-

煤是一种由类聚合物分子组成的复杂材料,其内表面包含许多分子间孔隙,煤大分子与分子间孔隙组合形成复杂的结构[1]。煤的成分组成和结构性质都取决于生物化学作用和地质构造运动[2-3]。作为世界上分布最广的化石能源,煤是世界电力供应的支柱,在炼钢、混凝土制造等工业环节中提供了必要的能量供给,支撑着人类的生存和发展[4]。煤炭是我国现代化建设过程中不可缺少的资源[5],但因其储存环境相对复杂、埋藏深度大、瓦斯含量高、渗透性低等特点,煤炭在开采过程中,很容易出现煤矿瓦斯爆炸、煤炭自燃、煤与瓦斯突出等灾害[6]。研究煤的微观结构有助于查明这些灾害出现的根本原因,如氧气在煤炭表面的吸附、在煤孔隙中的扩散,导致煤的低温氧化引发煤炭自燃[7-8]等,有助于找到预防煤矿灾害的有效措施。此外,从分子水平了解煤的微观结构和微观性质有助于研究与煤相关的物理化学过程和反应机理,如煤进行脱灰处理后的煤结构变化[9]、煤孔隙湿润过程[10]、煤尘润湿性变化、不同变质程度煤热解过程和热解机理[11-12]以及煤层气吸附行为等[13],这对于煤层气开采和煤化工的发展有重要价值。

煤结构的研究方法大致上分为以下几种:物理表征法、化学实验法、物理化学法和分子模拟。前3种方法都是以物理仪器和实验设计为基础探究煤结构的方法,能够准确得出煤的成分组成和结构参数,为煤大分子结构模型的构建提供了必要的数据。然而,煤炭特性的实验室测试通常需要精密的实验设备和复杂的实验程序,既昂贵又费时,因此,煤的分子结构领域需要新手段对其相关研究进行技术支持[13]。近年来,随着理论化学和计算化学的发展,分子模拟也取得了较大进步,因其在研究煤分子结构中具有成本低、安全性高、精确度高、效率高等优点,逐渐成为研究煤大分子结构的有力工具,并收获了一系列研究成果,为煤大分子结构模型的构建和优化提供了新的思路[14]。

分子模拟不仅能对煤大分子提供定性的描述,还能模拟出煤分子体系中一些结构与性能的定量结果,从而缩短煤大分子结构模型优化的周期,提高煤结构模型的准确性。此外,还可以基于分子模拟以及优化后的煤大分子结构模型研究煤与煤层气进行化学反应的路径、过渡态、反应机理等关键问题。为此,总结了分子模拟构在煤大分子结构模型构建、优化、验证方面的研究进展,讨论了分子模拟在煤分子结构研究中存在的不足。

1. 煤大分子结构经典模型

随着研究手段的不断进步,煤大分子结构模型也得到了不断地改进和发展,其合理性和准确性也越来越高。因为煤结构特有的复杂性,不同的变质程度也代表着煤结构间存在着一定的差异,在20世纪,通过前人不断的探索,煤分子结构模型依次经历了Fuchs模型、Krevelen模型、Given模型、Wiser模型、Shinn模型、Faulon模型等阶段[15-20]。煤大分子结构经典模型如图1所示。

近年来,学者们利用仪器分析技术、分子模拟技术和计算机辅助技术,基于分子结构模型构建流程,从分子水平上构建了许多煤结构模型,涵盖了低煤阶、中煤阶和高煤阶。XU等[21]、张殿凯等[22]分别构建了霍林河褐煤模型、峨山褐煤模型;GAO等[23]、QIAN等[24]分别构建了府谷次烟煤模型、准东次烟煤模型;JING等[25]、LEI等[26]分别构建了豹子沟烟煤模型、神府烟煤模型;CUI等[27]、JIA等[28]分别构建了GBW(E)110031无烟煤模型、阳泉无烟煤模型;这些煤大分子结构模型得到了广泛认可。分子结构模型构建流程如图2所示,不同煤阶煤的3D结构模型如图3所示,近年来构建的煤大分子结构模型见表1[21-28]。

表 1 近年来构建的煤大分子结构模型Table 1. Structural models of coal macromolecules constructed in recent years煤结构模型 分子式 结构信息 意义 霍林河褐煤模型 C200H195N3S1O32 霍林河褐煤模型以噻吩、吡啶、吡咯、苯、萘、苯酚和醚为代表性结构单元 用主共价键浓度对分子模型进行了调整和检验,可以解决在建立模型时选择有代表性异构体的问题,且考虑了化学反应的本质。为褐煤热反应过程的分子尺度研究开辟了途径 峨山褐煤模型 C153H137O35N2 芳香碳结构以苯和萘为主,且芳碳率为39.20%;脂肪碳结构以亚甲基,季碳和氧接脂碳为主;羟基、醚氧、羰基和羧基结构是氧原子主要赋存地;含氮结构则以吡啶为主 可在热解、液化和气化等领域研究中提供理论参考 府谷次烟煤模型 C 11995 H10363 N159O1366 N15由具有20种不同平均结构的75个大分子和29种不同的小分子组成 为基于有限的常规特征数据,构建合理的大型次烟煤模型提供了一种可行的方法 准东次烟煤模型 C179H124O21N4 将脂肪链和官能团引入到芳香族碳环框架结构中 为从微观尺度上理解准东煤结构特征和热解反应机理提供了参考 豹子沟烟煤模型 C169H128O10N2S 单个模型主要为二环和三环结构,脂肪族结构主要为甲基、乙基侧链和环烷烃类 使用了20个烟煤大分子模型来构建聚合结构模型,为优选表面活性剂提供了理论模型依据 神府烟煤模型 C 3198 H3261 O513S33揭示轻质焦油的反应机制是自由基加成反应,自由基主要来自C—O化学键的裂解 为研究烟煤热解过程中轻焦油的生成机制提供了技术手段与理论指导 GBW(E)110031

无烟煤模型C202H104O21N2S2 苯和萘结构占芳香族化合物质量的70%,脂肪族结构以侧链和环的形式存在;氧原子中羰基占85%,其余以羧基和羟基形式存在;氮原子出现在吡啶和吡咯的结构中,硫原子出现在噻吩的结构中 为系统性、多手段构建无烟煤模型提供了科学理论指导 阳泉无烟煤模型 C 3120 H2430 O180N60氮主要以吡啶和吡咯的形式存在,桥碳与周碳之比为0.38,芳香结构中缩合程度较高 为深入了解无烟煤的结构特征,建立无烟煤结构模型提供了一种有效方法 2. 煤大分子结构模型的优化

模型结构优化在整个煤分子结构模型的构建过程中扮演着至关重要的角色。早期构建的煤分子结构模型与21世纪研究者们所建立的模型之间存在显著差异,主要根源在于结构模型的优化方法和技术的不足。随着分子模拟技术的日益发展,对煤分子结构模型的优化也变得更加精细和精确。目前,分子模拟主要通过3种关键方法对煤的初级结构模型进行优化,旨在将其调整至能量最低状态,以更好地反映实际煤样的性质和结构。这些方法包括分子力学模拟、分子动力学模拟、量子力学方法。

2.1 分子力学模拟和分子动力学模拟

分子力学模拟(MM)又被称为分子力场方法,是以COMPASS、PCFF、CVFF、UFF以及Dreiding等分子力场作为基础来实现函数计算的一种分子模拟方法,也是一种使用经典模型来预测分子能量作为其构象的函数。这正是分子力学模拟可以对构象异构体之间或不同分子之间的平衡几何结构和过渡态相对能量进行预测的主要原因[29]。

分子动力学模拟(MD)又被称为分子动态模拟法,是以经典力学和牛顿运动定律为基础,利用体系中各原子的位置及相互作用计算体系的总势能,通过应用统计力学中正则系综、微正则系综和巨正则系综等不同系综的模拟方法分析体系中原子的坐标和速度信息,进而得到体系的一系列宏观性质[30]。分子动力学方法以能够有效跟踪粒子运动轨迹、模拟结果准确和能够考虑真实分子的构象等特性而备受关注,是一种研究模拟煤大分子结构及其演化过程的有效方法。常用的分子动力学模拟方法包括淬火模拟法、模拟退火法、推动动力学法、Langevin推动动力学法、随机边界动力学法等[31]。

自然界中的分子均处于最低能量状态,所以分子模型只有处于最低能量状态时才能代表煤的真实性质,因此必须优化分子模型使能量最小化。Forcite模块是MS软件中的重要组成模块,它将分子力学和分子动力学模拟结合为一体,包括煤分子等任何的高分子材料或者系统都可以根据与自身相关的物化参数在该模块里进行能量最低优化[32]。前人根据元素组成、官能团类型和分布、低分子量化合物含量(LMWCs)等煤分子结构信息,结合ACD/Chemsketch等软件绘制煤大分子2D结构和官能团片段,通过一系列MM和MD模拟平衡和松弛初始结构,执行退火动力学以搜索规范系综(NVT)下的全局最小能量配置,对其进行几何优化,分子构型发生弯曲和扭曲,总能量大大降低;在Dreiding力场或COMPASS II力场中建立了煤的稳定三维分子结构和理化结构模型,从分子水平上揭示了煤的理化性质[33-38]。分子力学模拟和分子动力学模拟在煤大分子结构模型研究中有极为重要的作用,可以对利用物理表征和化学实验结果构建的煤大分子初级结构模型进行几何结构模型优化,使模型的能量处于最低状态,提高模型的准确性和真实性。

2.2 量子力学法

相较于MM与MD这2种以经典力学为基础对煤大分子初级结构模型进行几何结构模型优化的模拟方法,量子力学模拟(QM)方法可以从更为微观的角度,利用更为准确的理论对其进行能量优化。QM是基于量子力学的基本概念和原理,而非经典力学的思想和方法,它认为分子的能量和其他的性质可以通过求解Schrödinger方程获得,但是求精确解的难度极大,一般都采用近似解进行研究。量子力学方法以3个近似为出发点:①相对论的量子理论,即从Schrödinger方程出发;②Born-Oppenheimer近似(B-O近似),即将核运动和电子运动分离开来;③轨道近似,即单粒子函数的近似[39]。QM模拟具有即时反应性,可以描述煤大分子之间的复杂键合模式、极化效应和电荷转移过程[40]。基于QM的模拟计算可用于获得大量材料特性,例如晶体结构的稳定性、弹性常数和传递现象。除了能量和力之外,还可以通过QM模拟直接计算其他可观测值,例如偶极矩、极化率、化学位移、声子频率,用于分子和材料系统的光谱表征[41]。相关学者经常利用傅里叶红外光谱(FTIR)、X射线光电子能谱(XPS)、碳-13固体核磁共振(13C-NMR)等表征方法获取煤大分子模型的结构参数,通过QM计算来定义MD模拟所需力场中长程非键合相互作用势能参数以及键长、键角、二面角和静电荷分布等微观结构参数,使用具有色散校正的密度泛函理论来获得单元素固体系统的状态方程,并在M06-2X基组、B3LYP/3-21G基组中对其进行结构优化,使其三维立体效果更加明显[42-47]。QM模拟结合MM和MD模拟,从分子层面上为煤分子结构优化提供了精确技术手段,构建更为真实的煤大分子优化构型,为研究煤的气化、液化和热解等化学反应过程中的反应路径、反应状态以及反应机理提供了基础。

3. 煤大分子结构模型的验证

煤样分子经过二维结构绘制、三维结构构建、能量最低结构优化这一系列流程后,所获得的模型并不能被视为代表实际煤分子结构的最终模型。为了保证模型构建的准确性,使其与实际煤样相匹配,必须对处于最低能量状态的模型进行验证。目前,受到广泛认可的验证方法主要包括光谱模拟验证法与密度模拟验证法。同时,鉴于煤样的复杂性,也存在其他高度准确的验证方法,这些方法包括验证化学键的断裂顺序、热失重趋势、等温吸附曲线、孔隙率、比表面积、元素含量等。这些验证方法有助于更全面地评估模型的准确度和可信度。

3.1 光谱模拟验证法

密度泛函理论(DFT)彻底改变了量子化学,特别是它的计算部分。目前,DFT是化学领域中探索分子、聚合物和固体的结构、稳定性、电子特性、反应性的重要理论,因其包含了相对论效应,研究范围几乎涵盖了整个元素周期表[48]。DFT以近似的方式解释了电子相关性,在计算精度和计算成本之间提供了一个很好的折中方案,能够有效计算FTIR光谱和13C-NMR化学位移,是验证煤大分子结构模型准确性的重要方法之一[49]。

1)13C-NMR化学位移模拟验证。13C-NMR能够很好表征煤大分子的碳骨架结构,利用13C-NMR化学位移模拟图谱与实验图谱进行对比分析可以有效验证煤大分子结构模型的准确性。目前,计算13C-NMR化学位移的方法已经有了很大的进步,包括量子化学计算法,ACD/NMR Predictors软件计算和MestReNova软件计算等。量子化学计算法因其独特的计算速度和准确度,成为最具有研究前景的13C-NMR化学位移计算方法。ACD/NMR Predictors软件是目前最常用的13C-NMR化学位移模拟软件,具有非常强大的13C-NMR化学位移计算功能,其核心是庞大的光谱信息数据库,通过该软件可以得出非常准确的核磁共振谱计算结果[50]。前人基于多次模型修正、退火计算和几何构型优化获得的煤大分子几何构型,利用全电子量子化学计算、密度泛函理论方法、ACD/NMR Predictors软件以及MestReNova软件等给出13C-NMR模拟谱图与煤实验谱图在峰形和峰强度上均表现出良好的对应关系,以此验证所构建的煤大分子模型的准确性与合理性[36, 51-55]。13C-NMR化学位移模拟验证法以脂肪族碳和芳香族碳的结构组成和参数信息以及煤大分子结构的基本连接单元为基础,为验证煤大分子结构模型的准确性提供了支撑。

2)FTIR模拟验证。FTIR是一种强大的物理表征手段,可对材料的化学成分和化学结构等分子信息进行详细的分析[56]。因此,利用红外模拟图谱与实验图谱进行对比分析可以有效验证煤大分子结构模型的准确性。与13C-NMR化学位移模拟不同的是,除了以煤分子结构最低能量模型为基础,利用全电子量子化学计算和密度泛函理论框架下的全电子M06-2X/3-21G基组之外,还可运用MS中VAMP计算模块和Gaussian09W软件中HF/3-21G基组对模型进行红外光谱模拟;通过振动频率计算可模拟出红外光谱,从峰形和峰强度上与实验光谱进行对比,验证模型的合理性和准确性[22, 57-61]。FTIR模拟验证法以煤分子结构中芳香族、脂肪族和杂原子的结构分布和官能团类型组成以及官能团与碳骨架之间的相互作用方式和成键类型等参数信息为基础,为验证煤大分子结构模型的准确性提供了有效的方法。

3.2 密度模拟验证

光谱模拟验证法是以煤样自身的化学成分和化学结构为验证对象,通过分析实际光谱与模拟光谱之间的对应关系来确定构建的煤分子结构模型的准确性;同理,密度验证法也能准确地验证煤分子结构模型的可靠性。虽然验证方法上存在一定差异,但密度作为煤大分子结构的重要参数,模型结构的密度也被视为评价模型结构有效性的重要依据。

目前,密度模拟包括2种方法:①利用MS软件,为煤结构模型添加周期性边界条件,并通过MM和MD模拟寻找势能与密度关系曲线中第2个能量密度曲线最低点,选取此时的模拟密度作为周期性边界条件中的能量最小化几何构型的密度,以此与煤分子的实验密度想对比,验证煤分子结构模型的准确性[62-63];②利用MS软件,对构建的煤分子模型进行退火动力学模拟,并采用NPT系综在不同压力下进行压缩和解压缩,最后通过MD模拟计算,得出煤分子几何最优构型,选取此时的模拟密度作为煤分子结构模型的密度[32]。

基于这2种密度模拟验证方法,HAN等[64]通过几何优化和退火动力学对褐煤、烟煤、无烟煤模型进行优化,以最小化全局能量,3种对应于体系最低能量的密度分别为1.19、1.27、1.81 g/cm3,数值接近现有的研究结果,优化后的煤分子结构模型是合理的;相建华等[62]将密度为1.475 g/cm3的成庄煤结构模型的构象作为成庄煤在周期性边界条件中的能量最小化几何构型,与煤的密度实测值(1.60 g/cm3)相比,计算的密度偏小,但也在误差范围内,证明了模型的准确性;SONG等[63]利用退火处理后的模型进行密度模拟,模拟过程中总能量随着密度的增加先减小后增加,以模拟曲线第1次抖动后能量最小点的密度(1.24 g/cm3)作为真实密度,与测量的煤样密度(1.25 g/cm3)呈现出良好一致性,验证了模型的准确性。密度测量是检验煤大分子结构模型与真实煤样一致性的重要手段,利用分子模拟得到的模拟密度值与实验测量所得的真实密度值进行分析对比,可以有效验证煤大分子结构模型的准确性。

3.3 其他验证方法

煤特有的复杂性意味着除了上述主流验证方法外,还有其他方法可以验证煤大分子结构模型的真实性,包括验证化学键断裂顺序、热失重趋势、等温吸附曲线、孔隙率、比表面积和元素含量等。BIAN等[65]利用量子化学半经验计算方法,将得到的键长和成键值用于估计煤的大分子结构中键的断裂顺序,并与热失重微分曲线(DTG)进行对比分析,以此进一步验证模型的准确性;WANG等[66]基于反应分子动力学(ReaxFF-MD)方法对煤的真实聚集体结构模型的热行为进行了模拟,并与TG实验数据进行了对比验证,结果显示ReaxFF-MD模拟出的热失重和累积释放总分子的趋势与TG-MS实验数据基本一致,验证了煤真实聚集体结构模型的准确性;孙致学等[67]通过MS软件对煤分子结构模型的孔隙率、比表面积、Langmuir体积和Langmuir压力进行了模拟,并与相应实验测量进行相互验证,进一步地证明了模型的真实性,结果表明CO2的吸附等温线高于CH4,其模拟结果与前人的结论一致,与实验进行对比分析也呈现出良好的一致性,验证了模型的真实性;LEI等[33]对最终的优化构型进行分子模拟计算,以获取模型的元素含量,将其与实验测量所获的元素含量进行对比分析,估算结果与实验结果一致,证明构建的煤大分子结构模型是合理的。

4. 分子模拟在煤研究领域存在的不足

1)基于煤样物理表征和化学结构,利用ACD/Chemsketch等软件绘制煤大分子二维结构和官能团片段,再通过MS软件进行三维结构建模的模型构建流程已然成为主流;但将不同方法和不同软件处理后得到的分子数据和表征数据放入ACD/Chemsketch等软件构建出来的二维模型结构并非最为准确的结果,还存在着一定的经验性,再将其导入MS软件后所构建的三维结构模型也更加粗糙,同时还会导致模型构建流程过长,模型构建方法复杂等问题。

2)在运用分子模拟技术构建并优化煤大分子结构模型方面,虽然如今的模型构建以及优化流程已较成熟,但在理论上还是需要进一步创新。例如,在构建模型时,可以采取更多的表征方法获取更全面的煤分子结构参数;在模型优化时,将MM、MD和DFT进行优势结合,或是运用更为先进的理论方法进行模型优化和验证,使煤大分子结构理论体系更为完善。模型构建上也需要技术性创新。以往在运用分子模拟技术优化煤大分子结构模型时,所选用的力场几乎都是Dreiding力场,虽然该力场确实对煤大分子结构系统计算精度较高,但适用范围较小。相比于Dreiding力场,虽然UFF和COMPASS力场在计算上的误差更大,但是这2种力场的适用范围以及研究深度明显高于Dreiding力场。如何降低UFF和COMPASS力场在计算上的误差,或建立计算精度更高、适用范围更广、研究层次更深的分子力场,使其能够更好地适用于煤大分子结构模型的优化,确保建模的流程更为简便、构建的模型更加精确,值得深入思考。

3)在运用分子模拟进行模型准确度验证时,通常仅依赖一种验证方法的结果可能会导致说服力不足。此外,模型准确度的评判标准在实践中确实存在一定的差异性,这一标准通常是1个范围值,其内的光谱峰值、密度值等参数被认为是准确的。然而,这些参数相对于实际值仍然可能存在一定误差。这种差异性和误差的存在使得模型验证变得更为复杂,需要综合考虑多种因素来确定模型的准确性。

4)现今构建的煤大分子结构模型仍然存在成熟度不足、普适性差等问题。对于不同煤阶的煤大分子结构模型,只有少部分模型得到了广泛认可,例如表1中涵盖的褐煤、次烟煤、烟煤、无烟煤这4种不同煤阶的煤大分子结构模型。虽然上述8种模型获得了广泛认可,但是对其进行深入的研究后发现模型中存在着不足。例如,XU等[21]构建的霍林河褐煤模型,虽然建模过程中用主共价键浓度对分子模型进行了调整和检验,能解决在建立模型时选择有代表性异构体的问题,还考虑了化学反应的本质,为褐煤热反应过程的分子尺度研究开辟了途径,但该模型并没有考虑到煤分子结构中小分子化合物的赋存形式。

5)由于煤的特殊复杂性,当前构建的大分子结构模型通常是高度特异的,仅适用于特定煤阶和地域。这意味着无法将不同煤阶和地区的煤分子结构模型通用于所有情况。

6)目前,基于模型理论和先进技术以及真实的煤分子结构参数所成功构建的煤大分子结构模型,其模拟密度普遍低于实验密度,这主要源于对结构中的小分子化合物和金属离子存在方式的研究不足。因此,应当充分考虑微量元素与小分子化合物的存在方式,考虑结构中各类化学键和分子间作用力的作用方式,构建更为真实的煤大分子结构体系。

目前,分子模拟技术主要用于获取煤大分子的优化构型、研究煤的结构特性。然而,在煤热解、煤石墨化、煤分子湿润性以及煤分子结构压裂变形等反应过程中,煤分子结构演变规律和反应机理方面的深入研究仍然相对有限。

5. 分子模拟的深入研究和发展趋势

5.1 深入研究

1)开发专用于构建煤分子结构模型的软件,以MS等分子模拟软件作为核心,将构建煤分子结构模型所需要的物理表征和化学结构表征等参数整合到一个系统中,从模型构建到优化均在一个软件系统中进行。简化模型构建流程,减少多环节带来的失误,提高结构模型的准确性。

2)力场是分子模拟的核心,在计算上需要更加精确,所研究的层面也应该更为深入,例如通过引入多极矩和偶极极化以及更为精确的函数表达式(贝叶斯方法等),从原子层面探究煤分子基本能量与高阶多极矩是如何随着相邻原子的精确位置而变化的,使所有的结构现象都可以作为原子内能、交换离域能、静电能和动态相关能的相互作用而被快速地计算,在亚原子、原子、超原子或超分子水平上描述分子作用过程中结构-能量-功能之间的关系并揭示电子和质子转移之间的耦合关系。

3)几何优化是确保煤分子模型处于最低能量状态的核心方法,但该方法在理论的量子水平上不够先进,特别是DTF这些量子化学计算法,在计算上非常复杂,限制了模型优化算法的速度。如何加速这一计算过程极具研究前景,因此提出一种基于神经网络集成的主动学习方法来加速多个煤分子结构的局部几何优化。

4)模型验证也是获取煤大分子最终结构模型的关键环节之一,在此提出一种定量分子模拟法来进行模型验证,这种模拟的“定量”性质最终是通过与实验的比较来判断的,将来自实验和模拟所涉及的不确定性和实际评估相结合,有利于实现对复杂系统的全面描述和理解,在这方面,基于机器学习技术将有助于能量函数和分子模拟本身的表示,以及潜在不确定性的量化。同时,机器学习技术所提供的自动化、可重复性和客观性是复杂系统分析中非常需要的特征,已迅速成为所有科学学科中分析和组织大规模数据的关键方法。结合分子模拟技术和机器学习技术,根据不同年代、不同地区和不同变质程度,构建不同的煤分子结构模型,增添煤大分子结构模型数量,对煤大分子结构模型数据库进行完善,使煤化工领域相关研究更为系统化和规范化。

5.2 发展趋势

1)明确定义极化近似和新的多极静电公式。进一步改进极化模型,以更准确地描述煤分子中电子云的极化行为。新的多极静电公式和精确的极化近似有望提高模拟准确性。

2)求解互极化方程和提高MD时间步长。煤分子模拟中的互极化效应是复杂而耗时的计算,研究提高数值方法,以更高效地求解互极化方程,并提高MD时间步长,从而减少计算时间。

3)结合线性标度电子结构方法与新的QM/MM系统和QM/MD系统。将线性标度电子结构方法与更精确的QM/MM系统和QM/MD系统相结合,可以提高煤分子结构模拟的准确性,尤其是在研究复杂反应过程时。

4)改良和优化分子模拟程序。利用Python等编程软件对现有分子模拟程序进行改良和优化,或者针对特定研究目标开发新的煤分子结构模拟程序。这可以提供更高的灵活性和效率,以满足不同煤阶和反应的需要。

5)硬件平台的改进和软件部署。进一步利用GPU和CPU硬件平台,以加速分子模拟计算。此外,实现合理的软件部署和分布式计算,以提高计算资源的利用率。

6. 结 语

基于对分子模拟技术在煤分子结构研究中的应用及其前沿进展的梳理,提出未来发展的若干展望。针对煤分子模型的构建、优化和验证,亟需开发集成化的软件系统,提升力场计算精度,引入神经网络加速几何优化,并采用定量分子模拟法进行验证,以确保模型的可靠性。同时,进一步改进极化模型、提高MD时间步长、整合先进的QM/MM方法,并通过硬件优化和分布式计算提升效率,将推动煤分子研究的精准化和高效化。这些进展将为煤炭开采、转化及其热解机理研究提供重要支持,助力煤化工领域的持续创新与发展。

-

表 1 不同试样破坏时变形对比

Table 1 Deformation comparison of different samples during failure

裂缝角度/(°) $ {\varepsilon _1} $/% $ {\varepsilon _2} $/% $ {\varepsilon _3} $/% 0 1.384 0.0487 0.126 30 1.395 0.0468 0.124 60 1.461 0.0451 0.138 90 1.701 0.0395 0.0837 -

[1] 王泽鹏. 温度-瓦斯-压裂液作用下深部煤岩微观结构演化及力学特性研究[D]. 重庆:重庆大学,2022. [2] 詹可亮,薛俊华,刘之喜. 岩石循环加卸载作用下能量的演化规律[J]. 煤矿安全,2019,50(3):49−52. ZHAN Keliang, XUE Junhua, LIU Zhixi. Evolution laws of dissipated energy under rock cyclic loading and unloading[J]. Safety in Coal Mines, 2019, 50(3): 49−52.

[3] 李东文,赵光明,刘之喜,等. 单轴压缩下岩石全应力应变过程中能量演化特征[J]. 煤矿安全,2023,54(2):135−144. LI Dongwen, ZHAO Guangming, LIU Zhixi, et al. Characteristics of energy evolution during total stress-strain in rocks under uniaxial compression[J]. Safety in Coal Mines, 2023, 54(2): 135−144.

[4] 王泽鹏. 粒度对砂岩力学及声发射特性影响的研究[D]. 重庆:重庆大学,2018. [5] 王宁,李树刚,王世斌,等. 煤体破碎过程中分形特征与能量耗散规律研究[J]. 煤矿安全,2021,52(4):1−6. WANG Ning, LI Shugang, WANG Shibin, et al. Research on fractal characteristics and energy dissipation law in the process of coal fragmentation[J]. Safety in Coal Mines, 2021, 52(4): 1−6.

[6] 谢和平,鞠杨,黎立云. 基于能量耗散与释放原理的岩石强度与整体破坏准则[J]. 岩石力学与工程学报,2005(17):3003−3010. XIE Heping, JU Yang, LI Liyun. Criteria for strength and structural failure of rocks based on energy dissipation and energy release principles[J]. Chinese Journal of Rock Mechanics and Engineering, 2005(17): 3003−3010.

[7] XIE Heping, LI Liyun, JU Yang, et al. Energy analysis for damage and catastrophic failure of rocks[J]. Science China Technological Sciences, 2011, 54(1): 199−209.

[8] 郭连军,马昊阳,徐景龙,等. 循环冲击作用下岩石能量耗散特征及损伤研究[J]. 矿业研究与开发,2023,43(5):106−112. GUO Lianjun, MA Haoyang, XU Jinglong, et al. Study on energy dissipation characteristics and damage of rock under cyclic impacts[J]. Mining Research and Development, 2023, 43(5): 106−112.

[9] 张风达. 深部煤层底板岩体能量演化特征及卸荷劣化破坏机制研究[J]. 采矿与安全工程学报,2023,40(2):346−353. ZHANG Fengda. Study on energy evolution characteristics and unloading degradation failure mechanism of deep coal seam floor rock mass[J]. Journal of Mining & Safety Engineering, 2023, 40(2): 346−353.

[10] 李泓颖,刘晓辉,郑钰,等. 深埋锦屏大理岩渐进破坏过程中的特征能量分析[J]. 岩石力学与工程学报,2022,41(S2):3229−3239. LI Hongying, LIU Xiaohui, ZHENG Yu, et al. Analysis of characteristic energy during the progressive failure of deep-buried marble in Jinping[J]. Chinese Journal of Rock Mechanics and Engineering, 2022, 41(S2): 3229−3239.

[11] 赵光明,刘之喜,孟祥瑞,等. 高径比对砂岩能量积聚与耗散试验及分析方法[J]. 煤炭学报,2022,47(3):1110−1121. ZHAO Guangming, LIU Zhixi, MENG Xiangrui, et al. Energy accumulation and dissipation test and analysis method of height-diameter ratio sandstone[J]. Journal of China Coal Society, 2022, 47(3): 1110−1121.

[12] 马秋峰,刘志河,秦跃平,等. 基于能量耗散理论的岩石塑性-损伤本构模型[J]. 岩土力学,2021,42(5):1210−1220. MA Qiufeng, LIU Zhihe, QIN Yueping, et al. Rock plastic-damage constitutive model based on energy dissipation[J]. Rock and Soil Mechanics, 2021, 42(5): 1210−1220.

[13] 刘之喜,赵光明,孟祥瑞,等. 基于线性储能规律的红砂岩蠕变能量演化分析方法[J]. 中南大学学报(自然科学版),2021,52(8):2748−2760. LIU Zhixi, ZHAO Guangming, MENG Xiangrui, et al. Analysis of creep energy evolution of red sandstone based on linear energy storage law[J]. Journal of Central South University (Science and Technology), 2021, 52(8): 2748−2760.

[14] 唐胡丹,朱明礼,朱珍德. 不等幅循环荷载下石灰岩局部微裂隙三维扩展及劣变非线性机制[J]. 岩石力学与工程学报,2021,40(6):1170−1185. TANG Hudan, ZHU Mingli, ZHU Zhende. Three-dimensional propagation of local micro-cracks and non-linear deterioration mechanism of limestone under variable amplitude cyclic loading[J]. Chinese Journal of Rock Mechanics and Engineering, 2021, 40(6): 1170−1185.

[15] 孟庆彬,王从凯,黄炳香,等. 三轴循环加卸载条件下岩石能量演化及分配规律[J]. 岩石力学与工程学报,2020,39(10):2047−2059. MENG Qingbin, WANG Congkai, HUANG Bingxiang, et al. Rock energy evolution and distribution law under triaxial cyclic loading and unloading conditions[J]. Chinese Journal of Rock Mechanics and Engineering, 2020, 39(10): 2047−2059.

[16] 李树刚,陈高峰,双海清,等. 加载速率和初始损伤对砂岩能量演化影响的试验研究[J]. 采矿与安全工程学报,2019,36(2):373−380. LI Shugang, CHEN Gaofeng, SHUANG Haiqing, et al. Experimental study on effect of loading rate and initial damage on energy evolution of sandstone[J]. Journal of Mining & Safety Engineering, 2019, 36(2): 373−380.

[17] 刘婕,张黎明,丛宇,等. 真三轴应力路径花岗岩卸荷破坏力学特性研究[J]. 岩土力学,2021,42(8):2069−2077. LIU Jie, ZHANG Liming, CONG Yu, et al. Research on the mechanical characteristics of granite failure process under true triaxial stress path[J]. Rock and Soil Mechanics, 2021, 42(8): 2069−2077.

[18] 刘之喜,孟祥瑞,赵光明,等. 真三轴压缩下砂岩的能量和损伤分析[J]. 岩石力学与工程学报,2023,42(2):327−341. LIU Zhixi, MENG Xiangrui, ZHAO Guangming, et al. Energy and damage analysis of sandstone under true triaxialcompression[J]. Chinese Journal of Rock Mechanics and Engineering, 2023, 42(2): 327−341.

[19] 谢和平,鞠杨,黎立云,等. 岩体变形破坏过程的能量机制[J]. 岩石力学与工程学报,2008,27(9):1729−1740. XIE Heping, JU Yang, LI Liyun, et al. Energy mechanism of deformation and failure of rock masses[J]. Chinese Journal of Rock Mechanics and Engineering, 2008, 27(9): 1729−1740.

[20] 秦涛,段燕伟,孙洪茹,等. 砂岩三轴加载过程中力学特征与能量耗散特征[J]. 煤炭学报,2020,45(S1):255−262. QIN Tao, DUAN Yanwei, SUN Hongru, et al. Mechanical characteristics and energy dissipation characteristics of sandstone under triaxial stress conditions[J]. Journal of China Coal Society, 2020, 45(S1): 255−262.

[21] 张黎明,高速,任明远,等. 岩石加荷破坏弹性能和耗散能演化特性[J]. 煤炭学报,2014,39(7):1238−1242. ZHANG Liming, GAO Su, REN Mingyuan, et al. Rock elastic strain energy and dissipation strain energy evolution characteristics under conventional triaxial compression[J]. Journal of China Coal Society, 2014, 39(7): 1238−1242.

[22] 张东明,白鑫,尹光志,等. 含层理岩石单轴损伤破坏声发射参数及能量耗散规律[J]. 煤炭学报,2018,43(3):646−656. ZHANG Dongming, BAI Xin, YIN Guangzhi, et al. Analysis of acoustic emission parameters and energy dissipation characteristics and damage evolution of bedding rock failure process under uniaxial compression[J]. Journal of China Coal Society, 2018, 43(3): 646−656.

[23] 张志镇,高峰. 3种岩石能量演化特征的试验研究[J]. 中国矿业大学学报,2015,44(3):416−422. ZHANG Zhizhen, GAO Feng. Experimental investigations on energy evolution characteristics of coal, sandstone and granite during loading process[J]. Journal of China University of Mining & Technology, 2015, 44(3): 416−422.

[24] LI C, GAO C, XIE H, et al. Experimental investigation of anisotropic fatigue characteristics of shale under uniaxial cyclic loading[J]. International Journal of Rock Mechanics and Mining, 2020, 130: 104314.

[25] 高阳,郭鹏,李晓,等. 不同类型储层岩石三轴压缩变形破裂与声发射特征研究[J]. 工程地质学报,2022,30(4):1169−1178. GAO Yang, GUO Peng, LI Xiao, et al. Investigation of triaxial compression failure and acoustic emission characteristics of different reservoir rocks[J]. Journal of Engineering Geology, 2022, 30(4): 1169−1178.

-

期刊类型引用(1)

1. 张志军,商秀琳,魏中奇,汤迪,李贞庆. 准格尔褐煤分子结构模型构建及其分子模拟. 选煤技术. 2024(06): 7-14 .  百度学术

百度学术

其他类型引用(0)

下载:

下载: