Research on spray characteristics of single nozzle based on grey correlation analysis

-

摘要:

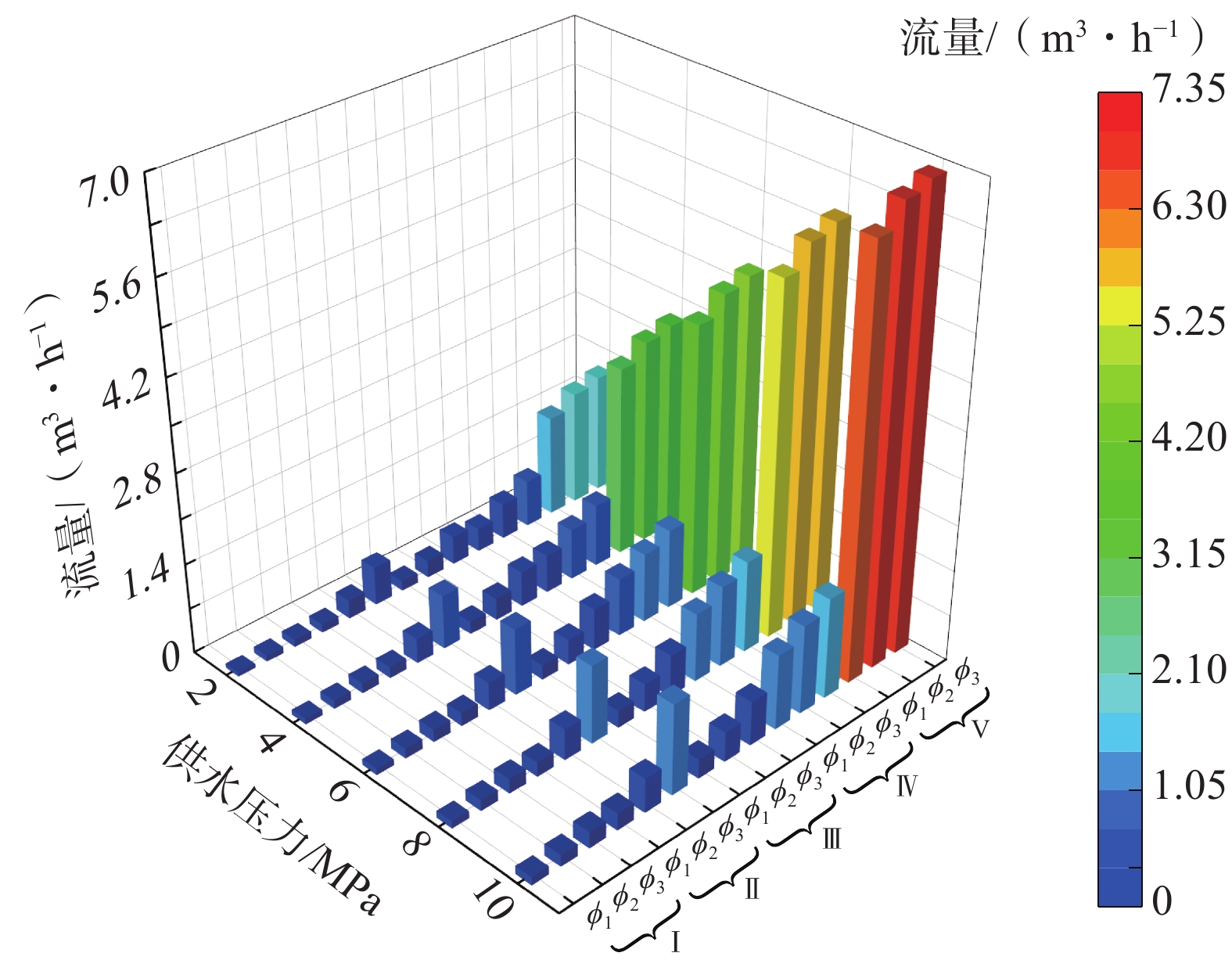

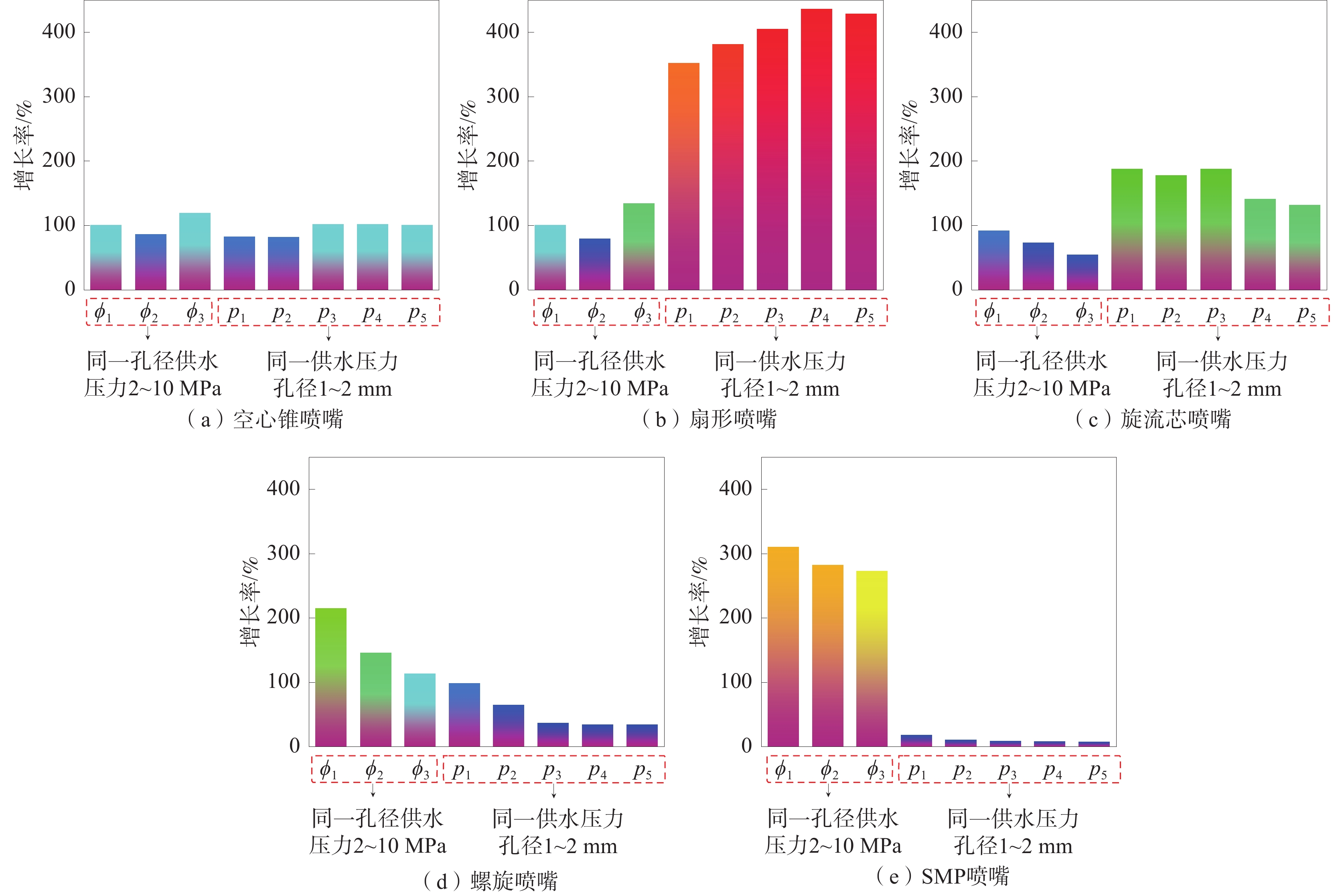

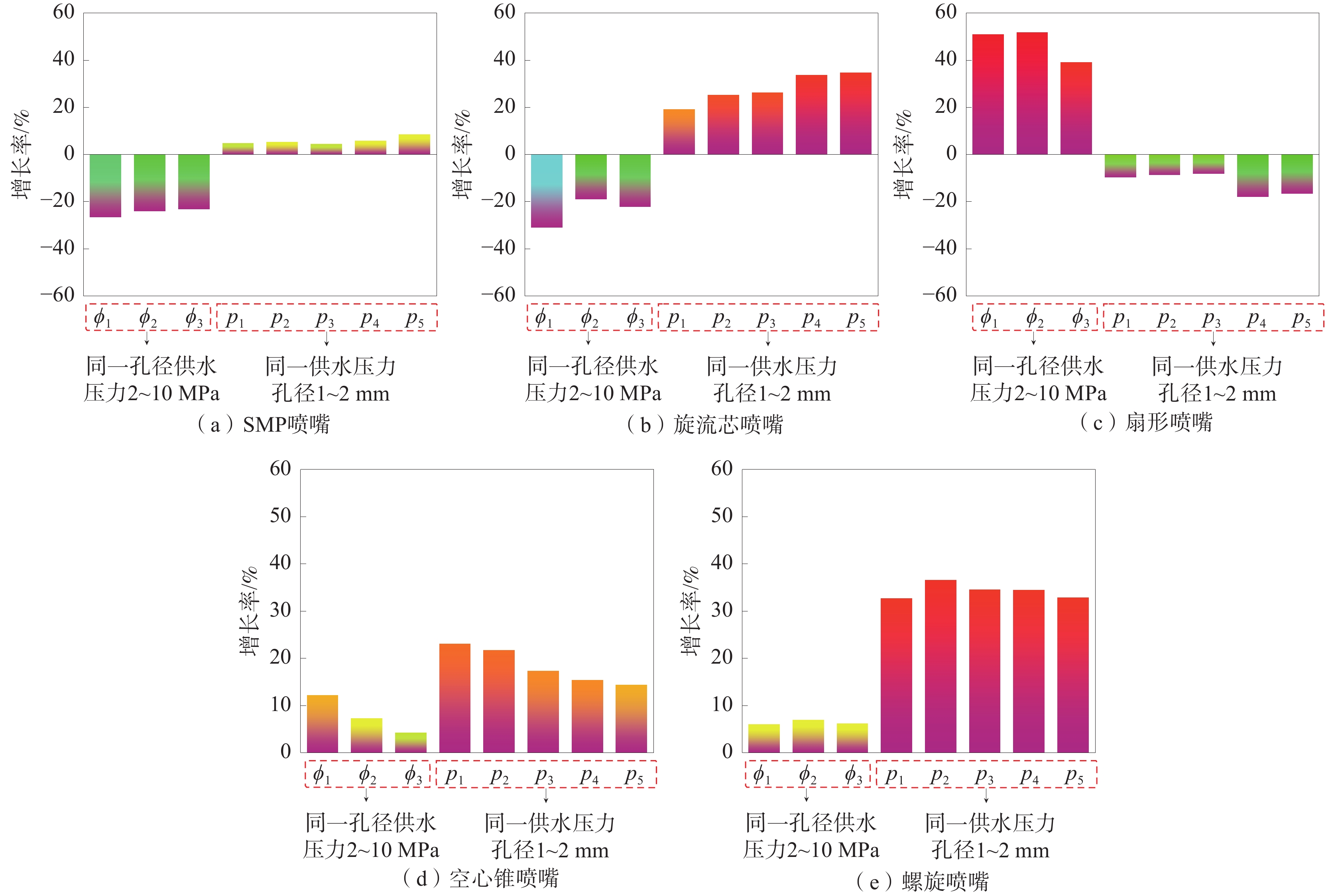

喷雾特性对喷雾降尘效果具有重要影响,提升雾化效果可有效改善工作面环境。压力喷嘴内、外流场与液态介质之间相互作用复杂,当前喷雾研究中存在着现场应用喷嘴选择没有明确依据,喷雾特性控制具有盲目性等问题,为工作面高效降尘带来困难。以矿井中常用的各类单喷嘴为研究对象,研究喷嘴类型、供水压力、孔径3个关键参数对射程、流量、雾化角、轴线射流速度4个喷雾特性的影响,利用灰色关联分析法研究不同参数对喷雾特性影响的重要度,并根据分析结果对井下采煤机和液压支架不同位置处喷嘴进行优选,并对不同类型喷嘴的喷雾过程进行优化控制。研究结果表明:单喷嘴的种类、供水压力和孔径对宏观喷雾特性的影响形式和重要度均有区别;SMP喷嘴、螺旋喷嘴分别适合采煤机内、外喷雾,旋流芯喷嘴适合做前探梁和尾梁喷嘴,扇形喷嘴、空心锥喷嘴分别适合做顶梁和架间喷雾;利用影响因素重要度确定雾化喷嘴敏感指标,对降尘系统进行喷雾控制优化,有效提升喷嘴与工程环境匹配度,研究结果可为加快建设煤矿井下高敏感度、多方位、全覆盖可控湿式除尘体系提供理论依据。

Abstract:The spray characteristics have an important impact on the dust reduction effect of spray, and improving the atomization effect can effectively improve the working face environment. The interaction between the internal and external flow fields of the pressure nozzle and the liquid medium is complex. There are some problems in the current spray research, such as no clear basis for the selection of on-site application nozzles, blindness in the control of spray characteristics, etc., which bring difficulties to the efficient dust suppression of the working face. Taking all kinds of single nozzles commonly used in the mine as the research object, this study studies the influence of three key parameters of nozzle type, water supply pressure and aperture on the four spray characteristics of range, flow, atomization angle and axial jet velocity, studies the importance of different parameters on the influence of spray characteristics by using the grey correlation analysis method, and optimizes the nozzles at different positions of the underground shearer and hydraulic support according to the analysis results, and the spray process of different types of nozzles was optimized. The results show that the type of single nozzle, water supply pressure and aperture have different influence forms and importance on macro spray characteristics; SMP nozzle and spiral nozzle are respectively suitable for internal and external spray of shearer, swirl core nozzle is suitable for front probe beam and tail beam nozzle, fan nozzle and hollow cone nozzle are respectively suitable for roof beam and inter rack spray; the importance of the influencing factors is used to determine the sensitivity index of the atomizing nozzle, optimize the spray control of the dust suppression system, and effectively improve the matching degree between the nozzle and the engineering environment. The research results can provide a theoretical basis for accelerating the construction of a highly sensitive, multi-directional, fully covered and controllable wet dust removal system in coal mines.

-

-

表 1 5种喷嘴不同供水压力、不同孔径对宏观雾化喷雾特性影响的关联度

Table 1 Correlation degree of influence of five nozzles with different water supply pressures and different apertures on macro atomization spray characteristics

影响因素 喷嘴类型 射程 流量 雾化角 轴向射流速度 供水压力 扇形喷嘴 0.596 0.589 0.603 0.619 旋流芯喷嘴 0.553 0.607 0.548 0.682 螺旋喷嘴 0.673 0.717 0.550 0.784 空心锥喷嘴 0.751 0.618 0.541 0.622 SMP喷嘴 0.699 0.901 0.550 0.649 孔径 扇形喷嘴 0.676 0.702 0.576 0.667 旋流芯喷嘴 0.636 0.762 0.776 0.650 螺旋喷嘴 0.632 0.621 0.777 0.622 空心锥喷嘴 0.657 0.712 0.717 0.761 SMP喷嘴 0.632 0.610 0.698 0.621 表 2 相关性分级情况

Table 2 Correlation grading situation

喷嘴类型 相关性等级数量 一般 紧密 非常紧密 扇形喷嘴 3 4 1 旋流芯喷嘴 2 4 2 螺旋喷嘴 1 4 3 空心锥喷嘴 1 3 4 SMP喷嘴 1 6 1 表 3 雾化喷嘴特性

Table 3 Characteristics of atomizing nozzle

喷嘴类型 射程 流量 雾化角 轴向射流速度 扇形喷嘴 √ √ √ 旋流芯喷嘴 √ √ √ 螺旋喷嘴 √ 空心锥喷嘴 √ √ √ √ SMP喷嘴 √ √ -

[1] 侯梅芳. 碳中和目标下中国能源转型和能源安全的现状、挑战与对策[J]. 西南石油大学学报(自然科学版),2023,45(2):1−10. HOU Meifang. Current situation, challenges and countermeasures of China’s energy transformation and energy security under the goal of carbon neutrality[J]. Journal of Southwest Petroleum University (Science & Technology Edition), 2023, 45(2): 1−10.

[2] 聂文,许长炜,彭慧天,等. 矿井新型增润促凝喷雾降尘剂的研制与抑尘性能研究[J]. 材料导报,2023,37(15):264−272. NIE Wen, XU Changwei, PENG Huitian, et al. Development and research on dust suppression performance of a new type of spray dust suppressant for increasing moisturizing and accelerating coagulation in mines[J]. Materials Reports, 2023, 37(15): 264−272.

[3] 胡江,杨英兵,苏志伟. 超大采高综采工作面综合防尘技术及应用[J]. 煤炭科学技术,2021,49(S2):104−109. HU Jiang, YANG Yingbing, SU Zhiwei. Comprehensive dust prevention technology and application of comprehensive mechanized coal mining face with super large mining height[J]. Coal Science and Technology, 2021, 49(S2): 104−109.

[4] 卢义玉,黄杉,葛兆龙,等. 我国煤矿水射流卸压增透技术进展与战略思考[J]. 煤炭学报,2022,47(9):3189−3211. LU Yiyu, HUANG Shan, GE Zhaolong, et al. Research progress and strategic thinking of coal mine water jet technology to enhance coal permeability in China[J]. Journal of China Coal Society, 2022, 47(9): 3189−3211.

[5] 王惠风,陈殿赋. 掘进工作面粉尘综合治理技术与实践[J]. 矿业安全与环保,2020,47(5):90−94. WANG Huifeng, CHEN Dianfu. Technology and practice of comprehensive control of dust in heading face[J]. Mining Safety & Environmental Protection, 2020, 47(5): 90−94.

[6] 蒋仲安,王亚朋,许峰. 金属矿山气−水喷头雾化特性及降尘能力实验研究[J]. 中南大学学报(自然科学版),2020,51(1):184−192. JIANG Zhongan, WANG Yapeng, XU Feng. Experimental study on atomization characteristics and dust reduction capacity of gas-water nozzles in metal mines[J]. Journal of Central South University (Science and Technology), 2020, 51(1): 184−192.

[7] MA R, DONG B, YU Z Q, et al. An experimental study on the spray characteristics of the air-blast atomizer[J]. Applied Thermal Engineering, 2015, 88: 149−156. doi: 10.1016/j.applthermaleng.2014.11.068

[8] ZHALEHRAJABI E, RAHMANIAN N, ZARRINPASHNE S, et al. Investigation of the growth of particles produced in a Laval nozzle[J]. Particulate Science and Technology, 2014, 32(6): 595−601. doi: 10.1080/02726351.2014.933459

[9] WANG P F, SHI Y J, ZHANG L Y, et al. Effect of structural parameters on atomization characteristics and dust reduction performance of internal-mixing air-assisted atomizer nozzle[J]. Process Safety and Environmental Protection, 2019, 128: 316−328. doi: 10.1016/j.psep.2019.06.014

[10] 吴恩启,顾自明,赵兵,等. 空气雾化喷嘴的设计与实验研究[J]. 热能动力工程,2018,33(4):69−75. WU Enqi, GU Ziming, ZHAO Bing, et al. Design of an air atomized nozzle and its experimental study[J]. Journal of Engineering for Thermal Energy and Power, 2018, 33(4): 69−75.

[11] ZHOU R, SHEN C B, JIN X. Numerical study on the morphology of a liquid-liquid pintle injector element primary breakup spray[J]. Journal of Zhejiang University: Science A, 2020, 21(8): 684−694. doi: 10.1631/jzus.A1900624

[12] 蒋仲安,许峰,王亚朋,等. 空气雾化喷嘴雾化机理及影响因素实验分析[J]. 中南大学学报(自然科学版),2019,50(10):2360−2367. doi: 10.11817/j.issn.1672-7207.2019.10.004 JIANG Zhongan, XU Feng, WANG Yapeng, et al. Experimental analysis of atomization mechanism and influencing factors of air atomizing nozzle[J]. Journal of Central South University (Science and Technology), 2019, 50(10): 2360−2367. doi: 10.11817/j.issn.1672-7207.2019.10.004

[13] 李贺,沈先华,田丽,等. 基于FDS的细水雾抑制熄灭带式输送机火灾研究[J]. 煤矿安全,2023,54(9):53−59. LI He, SHEN Xianhua, TIAN Li, et al. Research on suppression and extinguishment of belt conveyor fire by water mist based on FDS[J]. Safety in Coal Mines, 2023, 54(9): 53−59.

[14] 严红,陈福振. 航空发动机燃油雾化特性研究进展[J]. 推进技术,2020,41(9):2038−2058. YAN Hong, CHEN Fuzhen. Review on fuel atomization in aeroengine[J]. Journal of Propulsion Technology, 2020, 41(9): 2038−2058.

[15] QIAN L J, LIN J Z, BAO F B. Numerical models for viscoelastic liquid atomization spray[J]. Energies, 2016, 9(12): 1079. doi: 10.3390/en9121079

[16] 陈景序,荆德吉,葛少成,等. 掘进机外气动涡旋雾幕控尘装置的研制与实验[J]. 煤炭学报,2019,44(10):3233−3240. CHEN Jingxu, JING Deji, GE Shaocheng, et al. Research and experiment on dust control device with external pneumatic vortex mist curtain for road-header[J]. Journal of China Coal Society, 2019, 44(10): 3233−3240.

[17] 李博,韦韬,刘子捷. 西南地区煤层顶板岩溶含水层富水性评价指标体系构建及突水危险性评价[J]. 煤炭学报,2022,47(S1):152−159. LI Bo, WEI Tao, LIU Zijie. Construction of evaluation index system for water abundance of karst aquifers and risk assessment of water inrush on coal seam roof in Southwest China[J]. Journal of China Coal Society, 2022, 47(S1): 152−159.

[18] 张强,韩东,张旭,等. 掘进机负压降尘装置设计及性能分析[J]. 煤炭科学技术,2018,46(12):1−7. ZHANG Qiang, HAN Dong, ZHANG Xu, et al. Design and performance analysis of negative pressure dust control device of roadheader[J]. Coal Science and Technology, 2018, 46(12): 1−7.

-

期刊类型引用(7)

1. 崔忠麒,徐娅煊,苏皓. 基于Stacking-SHAP的煤自燃倾向性影响因素研究. 煤炭技术. 2025(01): 150-155 .  百度学术

百度学术

2. 孙吉平. 基于SF_6质量浓度变化特征的煤矿火灾状态识别分析. 山西煤炭. 2025(01): 42-49 .  百度学术

百度学术

3. 曹富荣,吴学松,李军,付天予,刘佳伟,李志辉,杨小彬. 基于机器学习的多气体指标煤自燃温度预测. 煤矿安全. 2024(04): 106-113 .  本站查看

本站查看

4. 樊永勇,王新瑞,张春雷. 急倾斜特厚煤层分段采空区低温氮气防灭火技术研究与实践. 能源与环保. 2024(11): 254-262 .  百度学术

百度学术

5. 武泽伟,汪伟,祁云,梁然. 采空区遗煤自燃影响因素分析及风险评价. 山西大同大学学报(自然科学版). 2023(04): 116-122 .  百度学术

百度学术

6. 孔彪,朱思想,胡相明,杨涛,赵旭帅,斐达特,万姝含. 基于改进鲸鱼算法优化BP神经网络的煤自燃预测研究. 矿业安全与环保. 2023(05): 30-36 .  百度学术

百度学术

7. 陈鹏燕,周春山,程熙宇,田雅琪. 全物理交联Al~(3+)-CMC/MMT-PAM双网络凝胶的制备及性能. 矿业研究与开发. 2023(11): 143-149 .  百度学术

百度学术

其他类型引用(2)

下载:

下载: