Study on compound optimization and performance of pulverized coal wetting suspension agent

-

摘要:

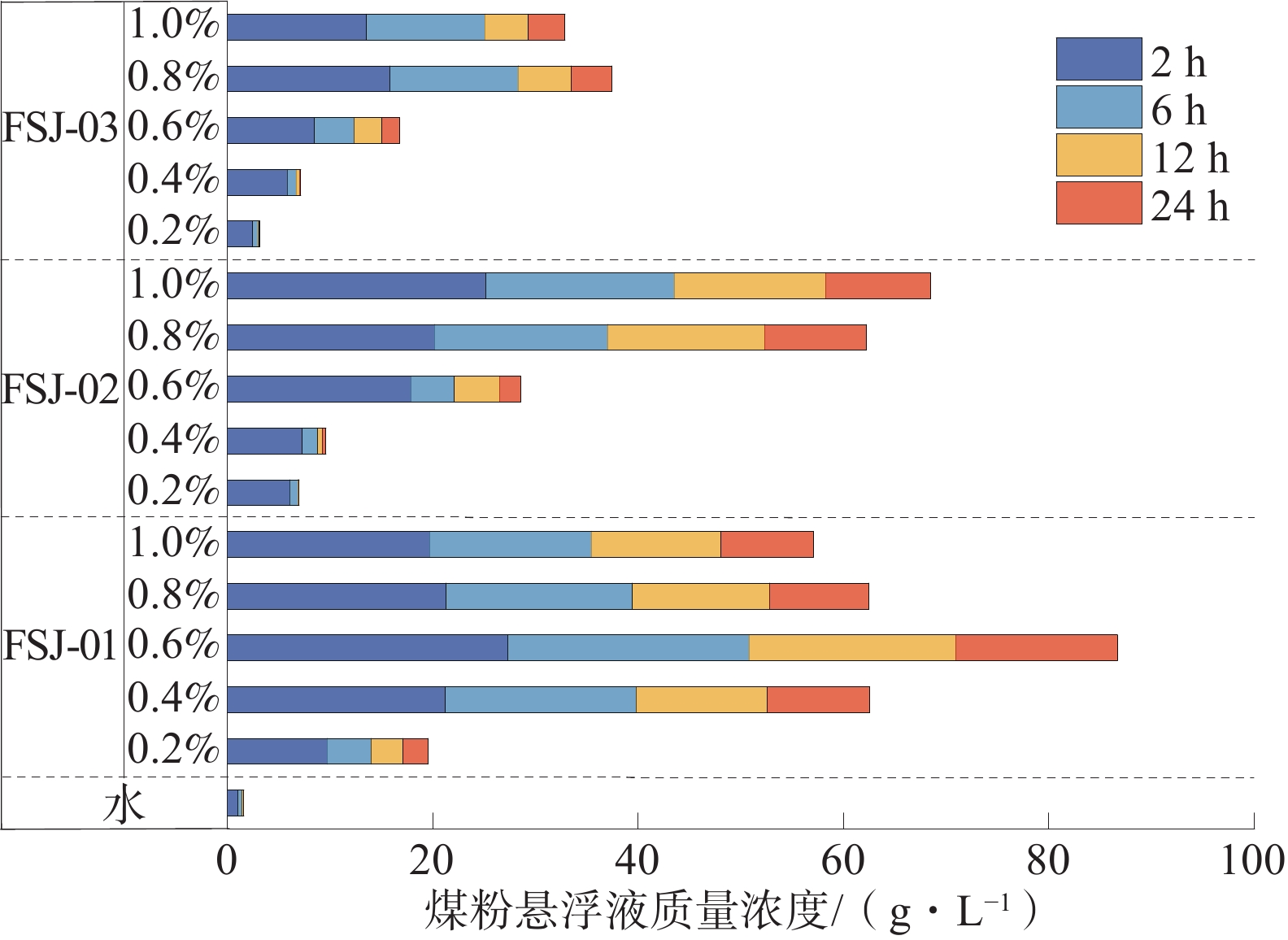

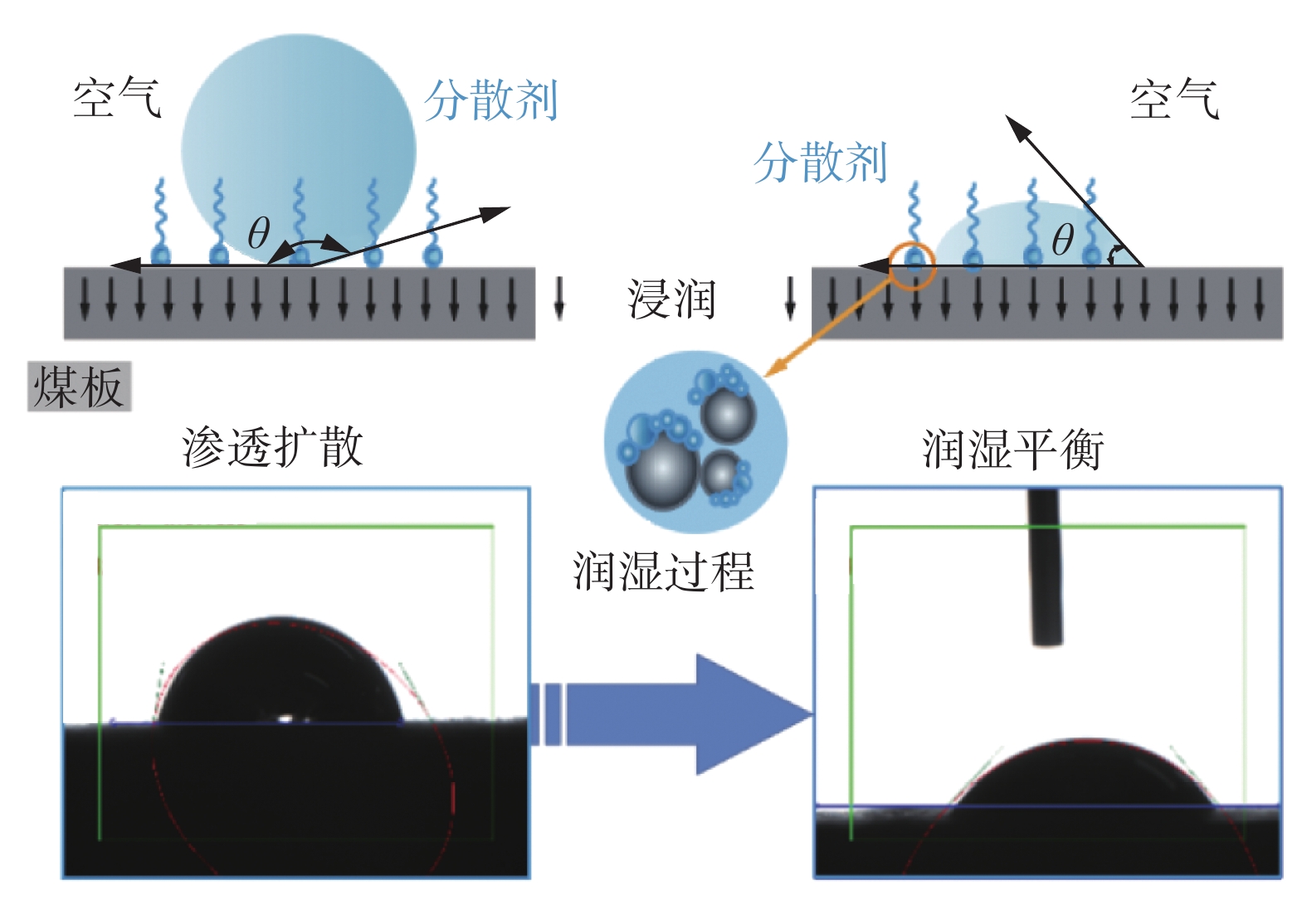

为有效解决湿式钻孔作业由于煤粉与水结合形成煤泥导致塌孔、夹钻、卡钻、水路阻塞、排气通道堵塞等问题,利用煤粉静置沉降实验、接触角实验以及表面张力测试实验等方法,对3种分散剂进行优选并与无机盐助剂进行复配,最终确定各试剂的最佳质量分数。结果表明:煤粉润湿悬浮剂复合溶液的最佳配比为0.6%FSJ-01+0.8%NaCl;3种分散剂的润湿悬浮分散效果排序为FSJ-01>FSJ-02>FSJ-03;FSJ-01在质量分数为0.6%时接触角达到最小,为31.2°,较清水在煤粉表面的接触角减小了61.72%,加入质量分数为0.8%的NaCl后,复合溶液表面张力达到最小,为26.3 mN/m,此时较清水的表面张力降低了64.75%,较单一分散剂溶液降低了36.17%。

Abstract:In order to effectively solve the problems of hole collapse, clamping, sticking, waterway blockage and exhaust channel blockage caused by the combination of coal powder and water to form slime in wet drilling operation, three dispersants were optimized and compounded with inorganic salt additives by using the methods of static sedimentation experiment, contact angle experiment and surface tension test experiment of coal powder, and the optimum mass fraction of each reagent was finally determined. The results showed that the optimum ratio of the composite solution was 0.6 % FSJ-01 + 0.8 % NaCl; the wetting suspension dispersion effect of the three dispersants was ranked as FSJ-01 > FSJ-02 > FSJ-03. When the mass fraction of FSJ-01 was 0.6 %, the contact angle reached a minimum of 31.2 °, which was 61.72 % lower than that of water on the surface of pulverized coal. After adding NaCl with a mass fraction of 0.8 %, the surface tension of the composite solution reached a minimum of 26.3 mN/m, which was 64.75 % lower than that of water and 36.17 % lower than that of a single dispersant solution.

-

Keywords:

- wet-type drilling operation /

- pulverized coal wetting /

- dispersant /

- wettability /

- suspensibility

-

-

表 1 实验煤样的工业分析指标

Table 1 Industrial analysis indexes of experimental coal samples

煤样 硫分/% 水分/% 灰分/% 挥发分/% 原煤 0.31 1.64 17.38 7.71 浮煤 0.35 1.39 7.24 5.96 表 2 分散剂成分

Table 2 Dispersants composition

编号 名称 简称 化学分子式 FSJ-01 十二烷基硫酸钠 SDS C12H25SO4Na FSJ-02 木质素磺酸钠 CMN C20H24Na2O10S2 FSJ-03 十二烷基苯磺酸钠 SDBS C18H29NaO3S -

[1] 仵胜利. 复杂岩层底板钻孔施工工艺探索与应用[J]. 陕西煤炭,2019,38(4):176−178. doi: 10.3969/j.issn.1671-749X.2019.04.041 WU Shengli. Research and application of floor drilling construction technology in complex strata[J]. Shaanxi Coal, 2019, 38(4): 176−178. doi: 10.3969/j.issn.1671-749X.2019.04.041

[2] 李守振. “三软”煤层顺层钻孔煤尘收集处理装备研究及应用[J]. 企业技术开发,2016,35(9):69−71. [3] 李刚,杨洪亮. 浅谈气动手持式锚杆钻机实现湿式钻孔的改进[J]. 神华科技,2013,11(4):30−32. doi: 10.3969/j.issn.1674-8492.2013.04.011 [4] 王贵根,朱志兴. 潜孔钻机湿式除尘系统的改造[J]. 铜业工程,2020(3):70−72. WANG Guigen, ZHU Zhixing. Transformation of wet dust removal system for drilling machine[J]. Copper Engineering, 2020(3): 70−72.

[5] 褚志伟. 煤矿井下负压抽吸分级净化除尘装置应用研究[J]. 煤矿安全,2022,53(1):116−120. CHU Zhiwei. Application research of dust removal device with negative pressure suction and classification purification in underground coal mine[J]. Safety in Coal Mines, 2022, 53(1): 116−120.

[6] 张鹏. 掘进工作面的注水防尘技术应用[J]. 河南科技,2020(8):86−87. doi: 10.3969/j.issn.1003-5168.2020.08.031 ZHANG Peng. Application of water injection and dust prevention technology in driving face[J]. Henan Science and Technology, 2020(8): 86−87. doi: 10.3969/j.issn.1003-5168.2020.08.031

[7] 张帆. 新型矿用湿式除尘器在钻孔施工中的应用[J]. 中州煤炭,2012(2):55−56. [8] 李再有,王希鹏. 湿式钻箱漏水原因分析与改进措施[J]. 煤矿机械,2022,43(7):156−157. LI Zaiyou, WANG Xipeng. Cause analysis and improvement measures of water leakage in wet drilling box[J]. Coal Mine Machinery, 2022, 43(7): 156−157.

[9] 李宗翔,吴邦大,李刚,等. 段王矿煤层注水可注性指标实验与预判[J]. 辽宁工程技术大学学报(自然科学版),2017,36(11):1121−1125. LI Zongxiang, WU Bangda, LI Gang, et al. Pre-judgement and index experiment on the water injection feasibility of coal seam in Duanwang mine[J]. Journal of Liaoning Technical University(Natural Science), 2017, 36(11): 1121−1125.

[10] 张巨峰,余岚,杨日丽,等. 高瓦斯煤层顺层钻孔瓦斯抽采与注水防尘一体化技术实践[J]. 煤炭技术,2018,37(4):159−160. ZHANG Jufeng, YU Lan, YANG Rili, et al. Integration technology of gas drainage and water injection and dust prevention in high gas coal seam[J]. Coal Technology, 2018, 37(4): 159−160.

[11] 卢义玉,王洁,蒋林艳,等. 煤层钻孔孔口除尘装置的设计与实验研究[J]. 煤炭学报,2011,36(10):1725−1730. LU Yiyu, WANG Jie, JIANG Linyan, et al. Design and experimental study of drilling hole dust collector apparatus used in coal drilling[J]. Journal of China Coal Society, 2011, 36(10): 1725−1730.

[12] 高冬. 无可视尘粒钻机干式除尘技术的应用[J]. 内蒙古煤炭经济,2021(6):148−149. doi: 10.3969/j.issn.1008-0155.2021.06.072 [13] 李坤,张杰. 空气定向钻进智能多功能除尘车研制与应用[J]. 煤矿安全,2023,54(2):223−228. LI Kun, ZHANG Jie. Development and application of intelligent multi-functional dust removal system for air directional drilling[J]. Safety in Coal Mines, 2023, 54(2): 223−228.

[14] 刘建林,刘飞,李泉新,等. 碎软煤层瓦斯抽采钻孔孔壁稳定性分析[J]. 煤矿安全,2018,49(8):189−193. LIU Jianlin, LIU Fei, LI Quanxin, et al. Stability analysis of borehole wall for gas drainage boreholes in broken soft coal seam[J]. Safety in Coal Mines, 2018, 49(8): 189−193.

[15] 沈君东,张雪城,丁鹏. 钻机除尘注浆护孔装置设计改造[J]. 西部探矿工程,2023,35(11):184−186. doi: 10.3969/j.issn.1004-5716.2023.11.055 SHEN Jundong, ZHANG Xuecheng, DING Peng. Design and transformation of dust removal grouting hole protection device for drilling rig[J]. West-China Exploration Engineering, 2023, 35(11): 184−186. doi: 10.3969/j.issn.1004-5716.2023.11.055

-

期刊类型引用(3)

1. 唐巨鹏,张昕,潘一山. 煤与瓦斯突出物理模拟试验研究现状及展望. 岩石力学与工程学报. 2024(03): 521-541 .  百度学术

百度学术

2. 张超林,王培仲,王恩元,许江,李忠辉,刘晓斐,彭守建. 我国煤与瓦斯突出机理70年发展历程与展望. 煤田地质与勘探. 2023(02): 59-94 .  百度学术

百度学术

3. 张文柯. 基于AHP-MCS的煤与瓦斯突出主控因素分析. 能源技术与管理. 2023(05): 126-127 .  百度学术

百度学术

其他类型引用(1)

下载:

下载: