Research on multi-layer spiral spray dust removal technology in heading face

-

摘要:

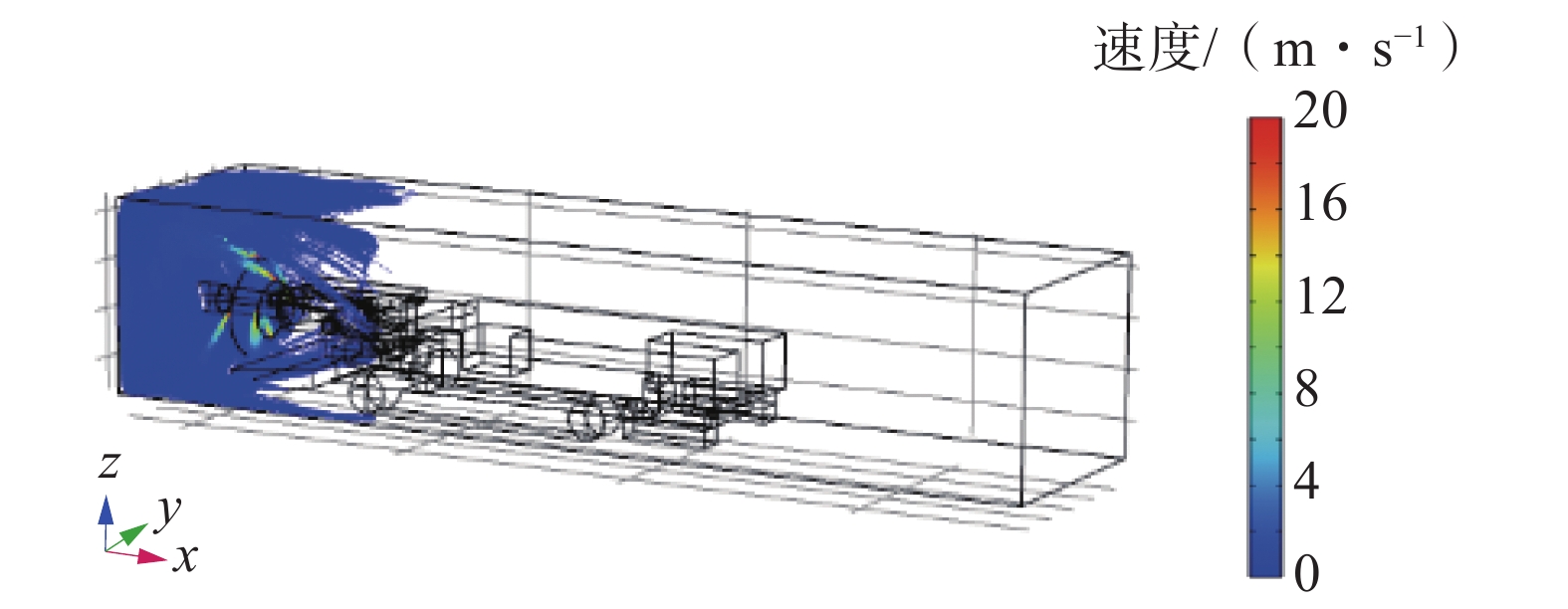

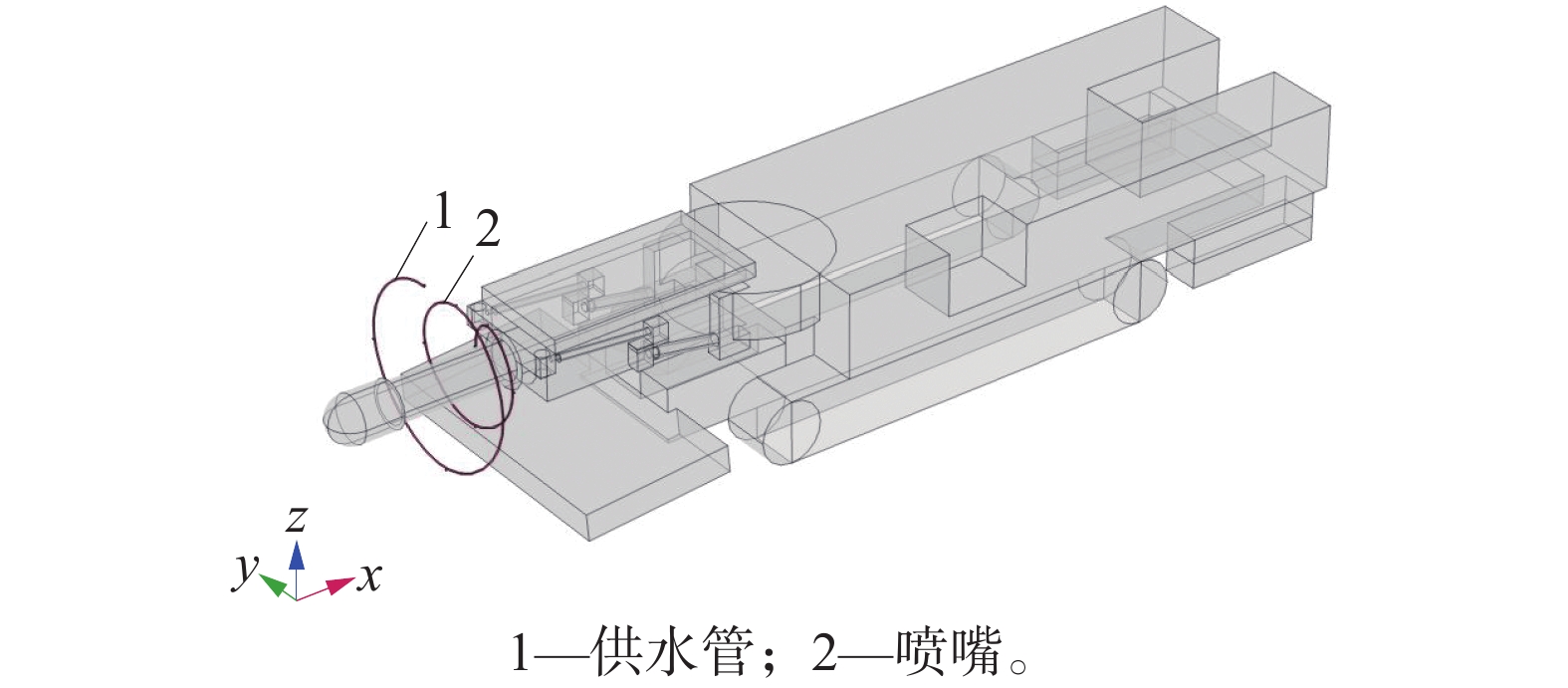

为解决掘进工作面呼吸性粉尘的污染问题,提出一种将超声速气动喷嘴布置成螺旋状的多层喷雾降尘方法。以棋盘井煤矿掘进工作面为研究对象,采用离散元和有限元方法,通过COMSOL软件中的k-ω湍流模型和流体流动颗粒跟踪模型,建立多层螺旋喷雾降尘技术装置三维数值模型,得出了多层螺旋喷雾风流速度场,速度切面和水雾粒子轨迹的变化规律。模拟结果表明:掘进机截割头处风流速度较快,距离截割部越远,风流的速度越小,且截割头附近的风流非常紊乱;水雾粒子在喷嘴开启后会形成多层螺旋雾幕,20 s后螺旋雾幕覆盖到整个模拟的掘进工作面,且水雾粒子的粒径相较传统喷雾方法更小。

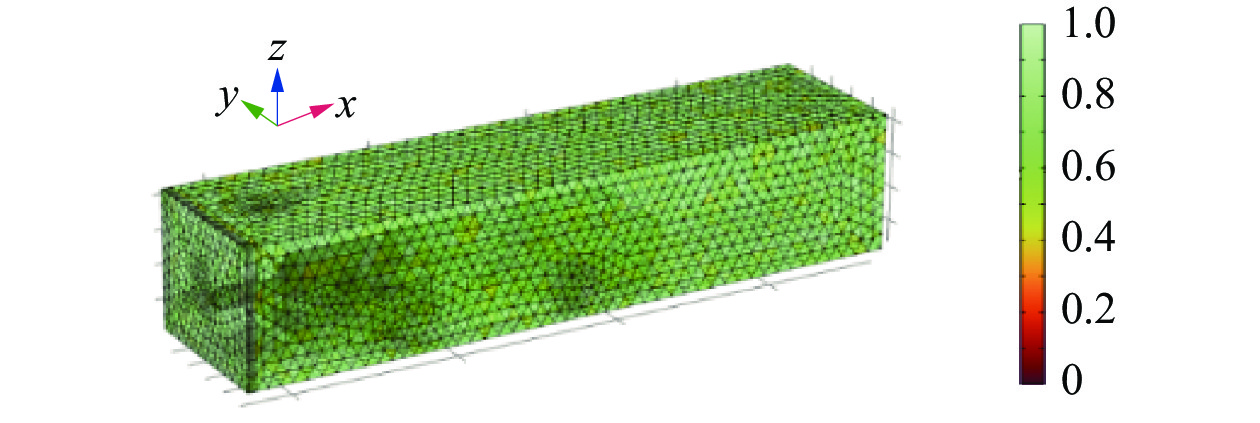

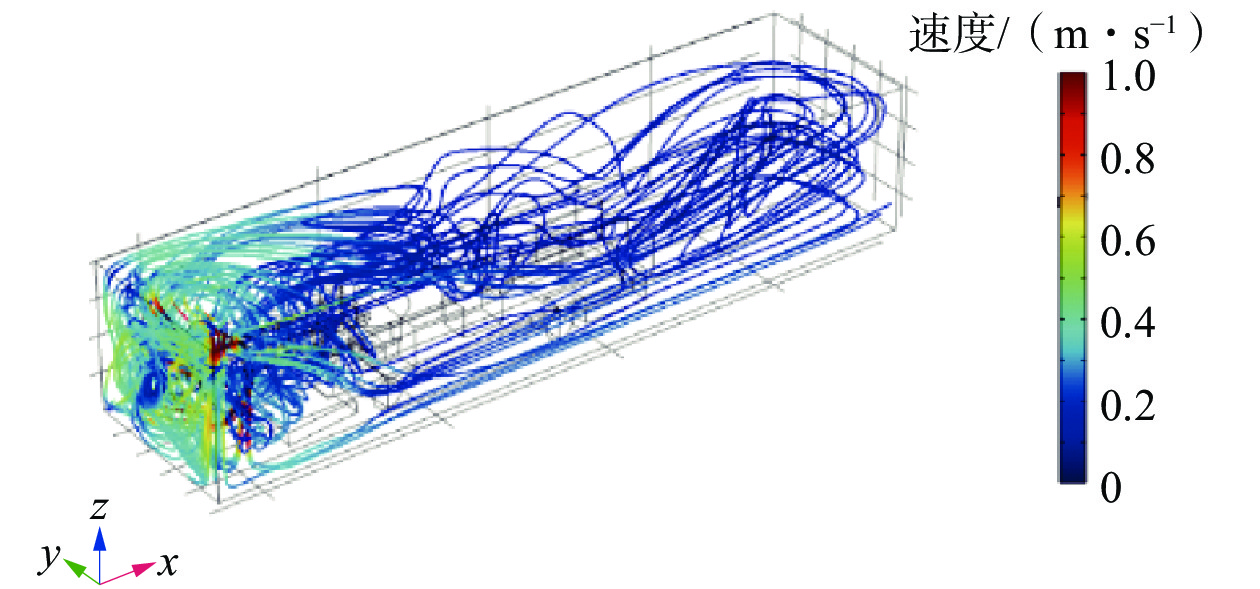

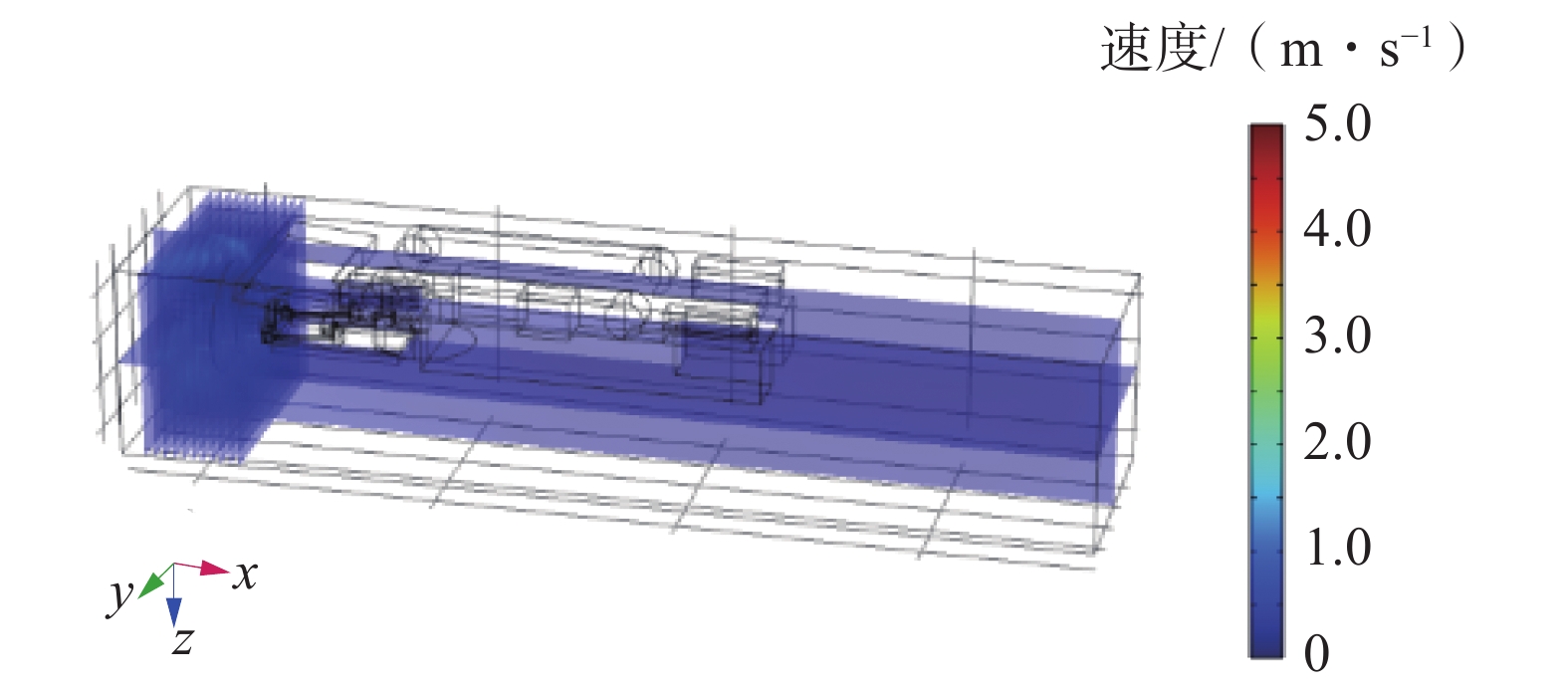

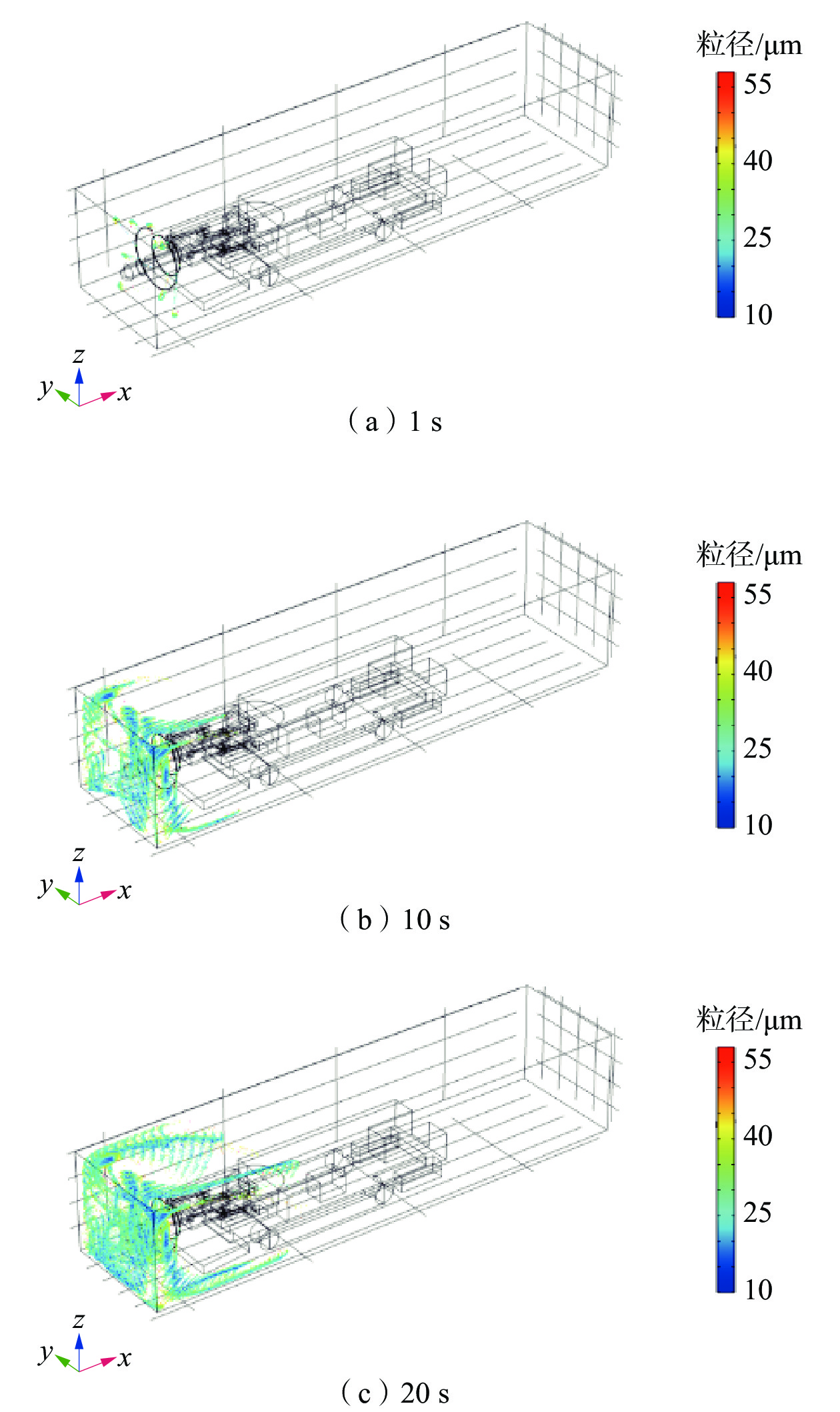

Abstract:In order to solve the problem of respirable dust pollution in the heading face, a multi-layer spiral spray dust removal method was proposed, in which supersonic pneumatic nozzles were arranged in a spiral shape. Taking the heading face of Qipan Coal Mine as the research object, the three-dimensional numerical model of multi-layer spiral spray dust removal technology device was established by using discrete element and finite element method and k-ω turbulence model and fluid flow particle tracking model in COMSOL software. The velocity field of multi-layer spiral spray air flow, velocity section and trajectory of water mist particles were obtained. The simulation results show that the airflow velocity at the cutting head of the TBM is faster, the farther away from the cutting head, the smaller the airflow velocity, and the airflow near the cutting head is very disorganized; after the nozzle is opened, the water mist particles will form a multi-layer spiral fog curtain, and the spiral fog curtain will cover the entire simulated driving surface after 20 s, and the particle size of the water mist particles is smaller than that of the traditional spray method.

-

-

表 1 边界条件和参数值

Table 1 Boundary conditions and parameter values

参数名称 参数取值 入口风速/(m·s−1) 0.6 出口压力/Pa 0 空气密度/(kg·m−3) 1.25 颗粒自身密度/(g·cm−3) 1.33 连续相动力黏度/Pa 1.8×10−5 气体分子扩散系数/(m2·s−1) 2×10−5 入口粒子数 1000 喷嘴流量/(L·min−1) 11.5 初始速度/(m·s−1) 10 雾化半角/(°) 40 -

[1] GAO R Z, WANG P F, LI Y J, et al. Determination of optimal blowing-to-suction flow ratio in mechanized excavation face with wall-mounted swirling ventilation using numerical simulations[J]. International Journal of Coal Science & Technology, 2021, 8(2): 248−264.

[2] 康树棕,种化省,屈华. 掘进工作面风流-粉尘耦合运移规律模拟研究[J]. 山东煤炭科技,2022,40(7):100−102. doi: 10.3969/j.issn.1005-2801.2022.07.033 KANG Shuzong, CHONG Huasheng, QU Hua. Simulation study on coupling movement law of air flow and dust in driving working face[J]. Shandong Coal Science and Technology, 2022, 40(7): 100−102. doi: 10.3969/j.issn.1005-2801.2022.07.033

[3] 石花军. 气水喷雾降尘系统参数优化及应用研究[J]. 华北科技学院学报,2022,19(3):38−42. SHI Huajun. Study on parameter optimization and application of air-water spray dust removal system[J]. Journal of North China Institute of Science and Technology, 2022, 19(3): 38−42.

[4] 陈凯,宋亚新,王卓龑,等. 李家壕煤矿粉尘特性及音爆雾化降尘系统应用[J]. 能源与环保,2021,43(12):14−19. CHEN Kai, SONG Yaxin, WANG Zhuoyan, et al. Dust characteristics and application of sonic atomization system in Lijiahao Coal Mine[J]. China Energy and Environmental Protection, 2021, 43(12): 14−19.

[5] 刘宝明,寇子明,寇保福. 旋转喷雾降尘装置在掘进机上的应用研究[J]. 煤矿机械,2011,32(4):187−189. doi: 10.3969/j.issn.1003-0794.2011.04.079 LIU Baoming, KOU Ziming, KOU Baofu. Application research of circumgyrated water spraying dust control device used on roadheader[J]. Coal Mine Machinery, 2011, 32(4): 187−189. doi: 10.3969/j.issn.1003-0794.2011.04.079

[6] 荆德吉,徐放,葛少成,等. 多层螺旋雾幕技术的喷雾模拟及降尘试验研究[J]. 中国安全生产科学技术,2019,15(8):70−76. JING Deji, XU Fang, GE Shaocheng, et al. Study on spray simulation and dust removal experiments of multi-layer spiral fog curtain technology[J]. Journal of Safety Science and Technology, 2019, 15(8): 70−76.

[7] 卫志敏. 掘进巷道降尘技术的应用研究[J]. 山西化工,2022,42(1):185−187. WEI Zhimin. Study on application of dust reduction technology in driving roadway[J]. Shanxi Chemical Industry, 2022, 42(1): 185−187.

[8] 张俊. 煤矿用掘进机喷雾降尘控制系统研究[J]. 机械管理开发,2021,36(9):261−263. ZHANG Jun. Research on spray dust control system for the boring machine in a coal mine[J]. Mechanical Management and Development, 2021, 36(9): 261−263.

[9] 杨征,庄学安,陈真,等. 快掘工作面粉尘污染规律模拟及防尘技术探讨[J]. 煤矿机械,2022,43(2):79−82. YANG Zheng, ZHUANG Xue’an, CHEN Zhen, et al. Simulation of dust pollution law and discussion on dust prevention technology in fast-tunneling working face[J]. Coal Mine Machinery, 2022, 43(2): 79−82.

[10] 李雨成,刘宗桃,刘蓉蒸,等. 综掘工作面风幕控尘装置设计及试验研究[J]. 煤炭科学技术,2017,45(10):66−71. LI Yucheng, LIU Zongtao, LIU Rongzheng, et al. Design and experiment study on air curtain dust control device of mine fully-mechanized heading face[J]. Coal Science and Technology, 2017, 45(10): 66−71.

[11] 钱杰,胡鸣. 综采工作面气水联合旋转风幕隔尘效果研究[J]. 煤矿安全,2017,48(7):29−31. QIAN Jie, HU Ming. Research on dust-isolating of air-water combined rotating curtain at fully mechanized working face[J]. Safety in Coal Mines, 2017, 48(7): 29−31.

[12] 肖峻峰,许峰,樊世星,等. 大断面综掘巷道长压短抽条件下粉尘运移模拟[J]. 中国安全科学学报,2017,27(2):127−132. XIAO Junfeng, XU Feng, FAN Shixing, et al. Simulation of dust diffusion in fully mechanized excavation face having large cross-section under FPNA ventilation condition[J]. China Safety Science Journal, 2017, 27(2): 127−132.

[13] CHENG W M, MA Y Y, YANG J L, et al. Effects of atomization parameters of dust removal nozzles on the de-dusting results for different dust sources[J]. International Journal of Mining Science and Technology, 2016, 26(6): 1025−1032. doi: 10.1016/j.ijmst.2016.09.010

[14] XU C W, NIE W, LIU Z Q, et al. Multi-factor numerical simulation study on spray dust suppression device in coal mining process[J]. Energy, 2019, 182: 544−558. doi: 10.1016/j.energy.2019.05.201

[15] 马威. 煤矿井下气水喷雾雾化效果实验研究及应用[J]. 煤矿安全,2021,52(11):32−37. MA Wei. Experimental research and application of atomization effect of gas-water spray in underground coal mine[J]. Safety in Coal Mines, 2021, 52(11): 32−37.

[16] 张江石,王文晖,刘绍灿. 大柳塔煤矿连续采煤机除尘系统优化改进[J]. 煤矿安全,2020,51(5):114−117. ZHANG Jiangshi, WANG Wenhui, LIU Shaocan. Optimization and improvement of dust removal system of continuous shearer in daliuta coal mine[J]. Safety in Coal Mines, 2020, 51(5): 114−117.

-

期刊类型引用(8)

1. 周玮鸿,杜胜蛟,周袁,叶辰,楚亚培. 高温作用下砂岩孔隙结构损伤演化规律研究. 金属矿山. 2025(02): 75-80 .  百度学术

百度学术

2. 张波,陈博源,马立涛,吴鹏,刘成,陈建奇,李洋冰,姜洋. 煤岩氦气孔隙度测量关键参数优化. 非常规油气. 2025(02): 25-32 .  百度学术

百度学术

3. 谭彩,潘展钊,袁明道,黄锦林,史永胜,张旭辉. 基于计算机断层扫描的浆砌石真实三维孔隙网络模型及其渗流数值模拟. 水电能源科学. 2024(02): 89-93 .  百度学术

百度学术

4. 金霏阳,陈学习,高泽帅. 不同变质程度煤体微孔多重分形特征研究. 煤矿安全. 2024(03): 9-17 .  本站查看

本站查看

5. 孙璐,周国晓,荆雪媛,张君莹,吴陈君. 鄂尔多斯盆地中东部本溪组深部煤岩分形特征与成储机理. 西安石油大学学报(自然科学版). 2024(03): 1-11 .  百度学术

百度学术

6. 关欣,刘育伟,任重阳,汤迅. 基于CT三维重构的无烟煤孔隙结构及连通性特征对比表征. 非常规油气. 2023(01): 69-76 .  百度学术

百度学术

7. 孙丕臣,王海超. 东营凹陷博兴洼陷沙河街组页岩孔隙特征研究. 当代化工研究. 2023(09): 32-34 .  百度学术

百度学术

8. 卢宏伟,徐宏杰,杨祎超,丁海,祝月,苟博明,戴王杰. 煤储层孔隙结构与甲烷吸附能量变化的非均质性特征. 科学技术与工程. 2023(30): 12817-12826 .  百度学术

百度学术

其他类型引用(5)

下载:

下载: