Experimental study on time effect of stress structure in impact coal

-

摘要:

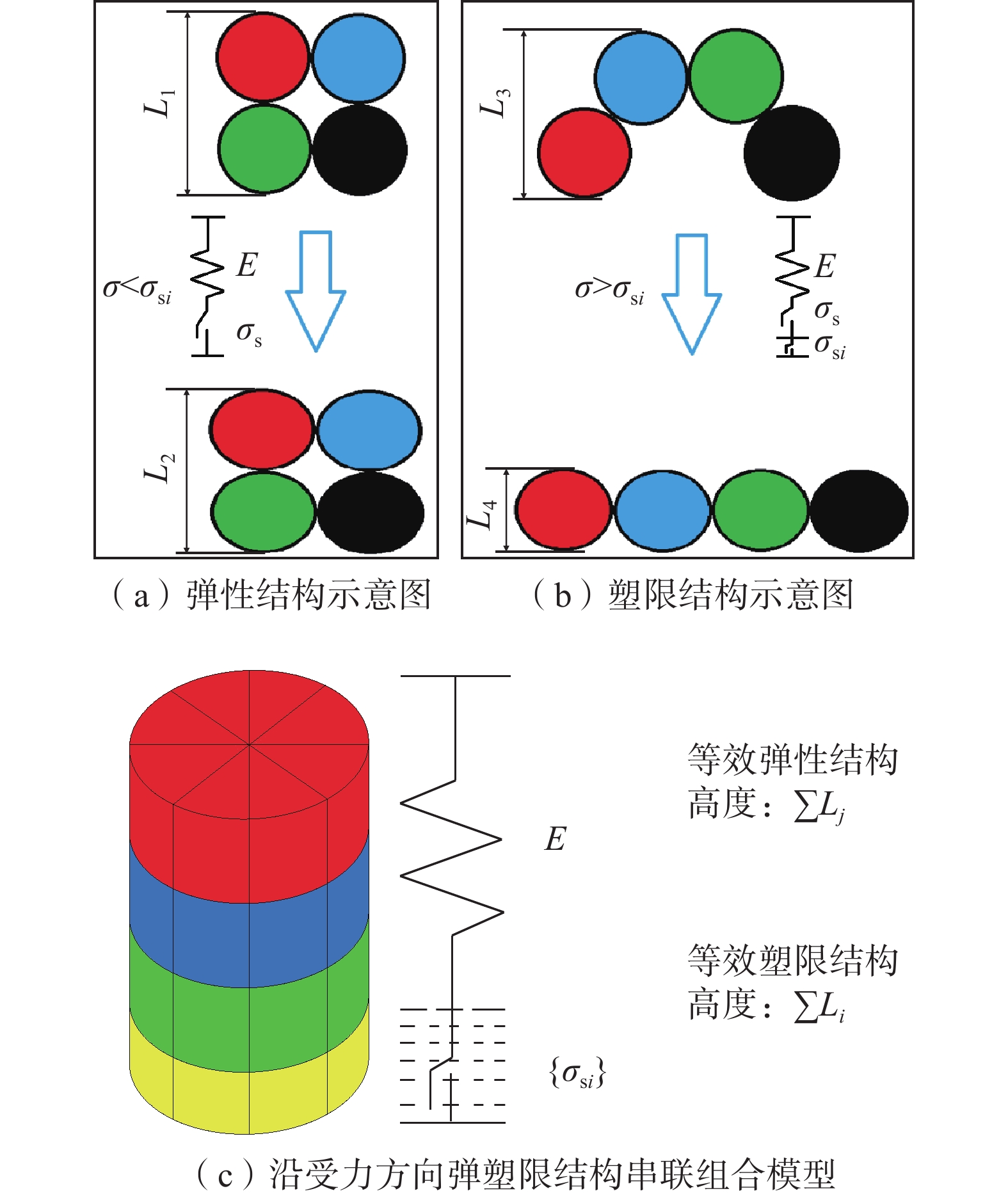

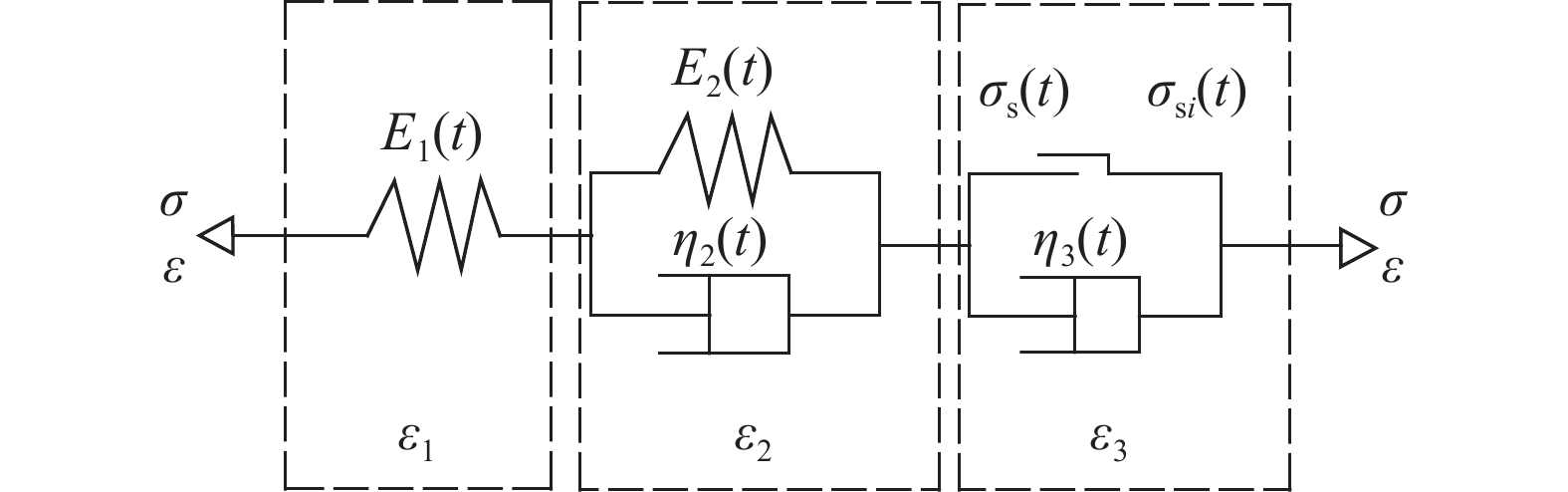

煤矿工程中蕴含复杂的应力结构时间效应问题,与冲击地压灾害的发生与防治密切相关。针对冲击性煤体的应力结构时间效应开展试验研究,在陕西、甘肃以及内蒙古3个冲击地压矿井取得煤岩块体加工试件,通过煤单轴压缩动静载及蠕变试验研究加载速率的应力时间效应,采取长时分段试验方法研究煤原位解除条件下的应力时间效应,开展煤浸水以及煤岩组合试验研究结构时间效应。结果表明:煤体单轴抗压强度与加载速率具有正相关性,与原位解除时长和浸水时间具有负相关性,煤岩结构时间效应下的组合模式对其能量及强度属性有显著影响,冲击性煤体表现出应力与结构2个方面的时间效应。依据试验结果,提出塑限结构来解释应力作用下煤岩体的不可逆变形,再通过构建塑限结构时间效应模型,对比非弹性应变与不可逆应变的数值近似性,对冲击性煤体塑限应变特性进行了验证。

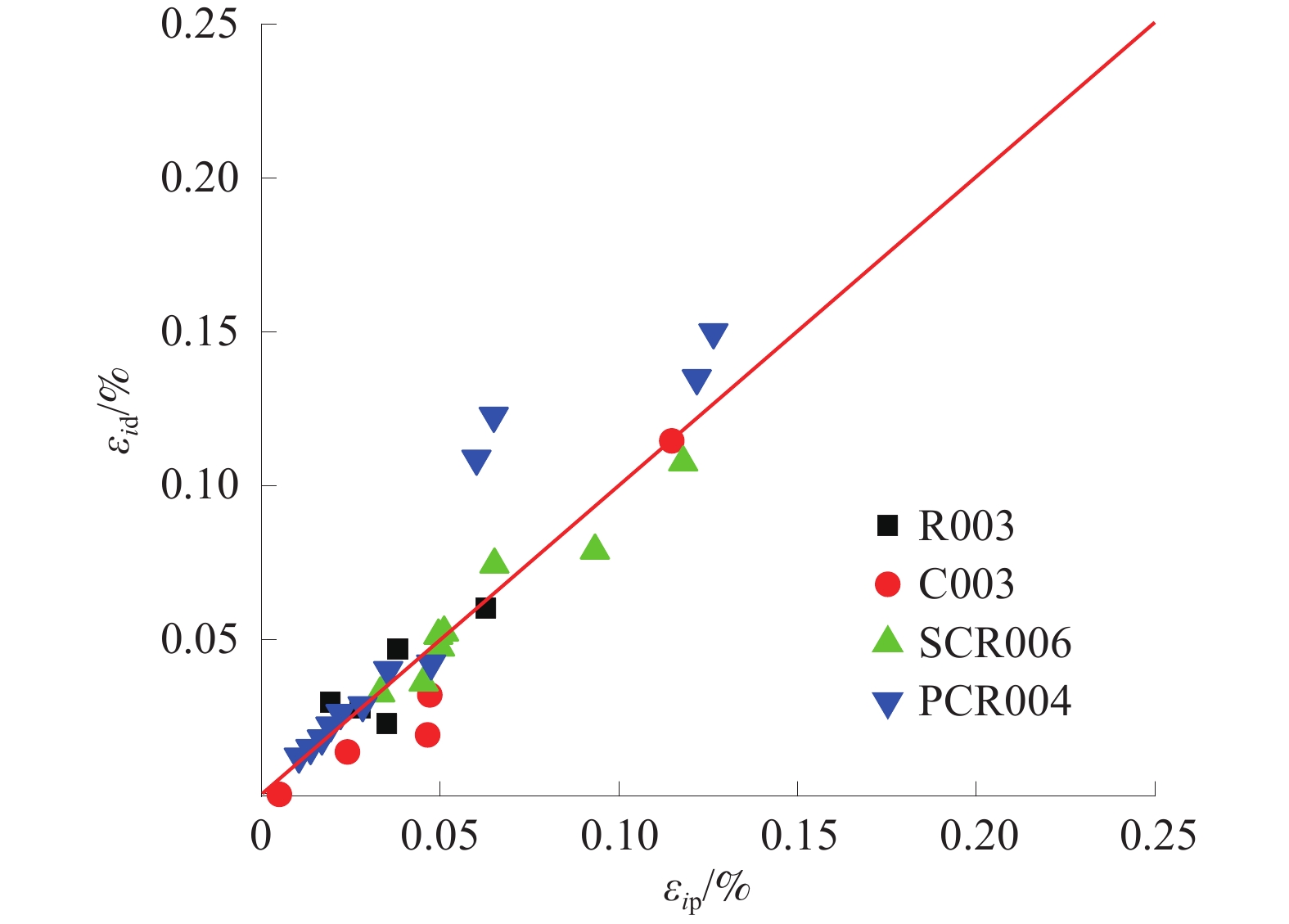

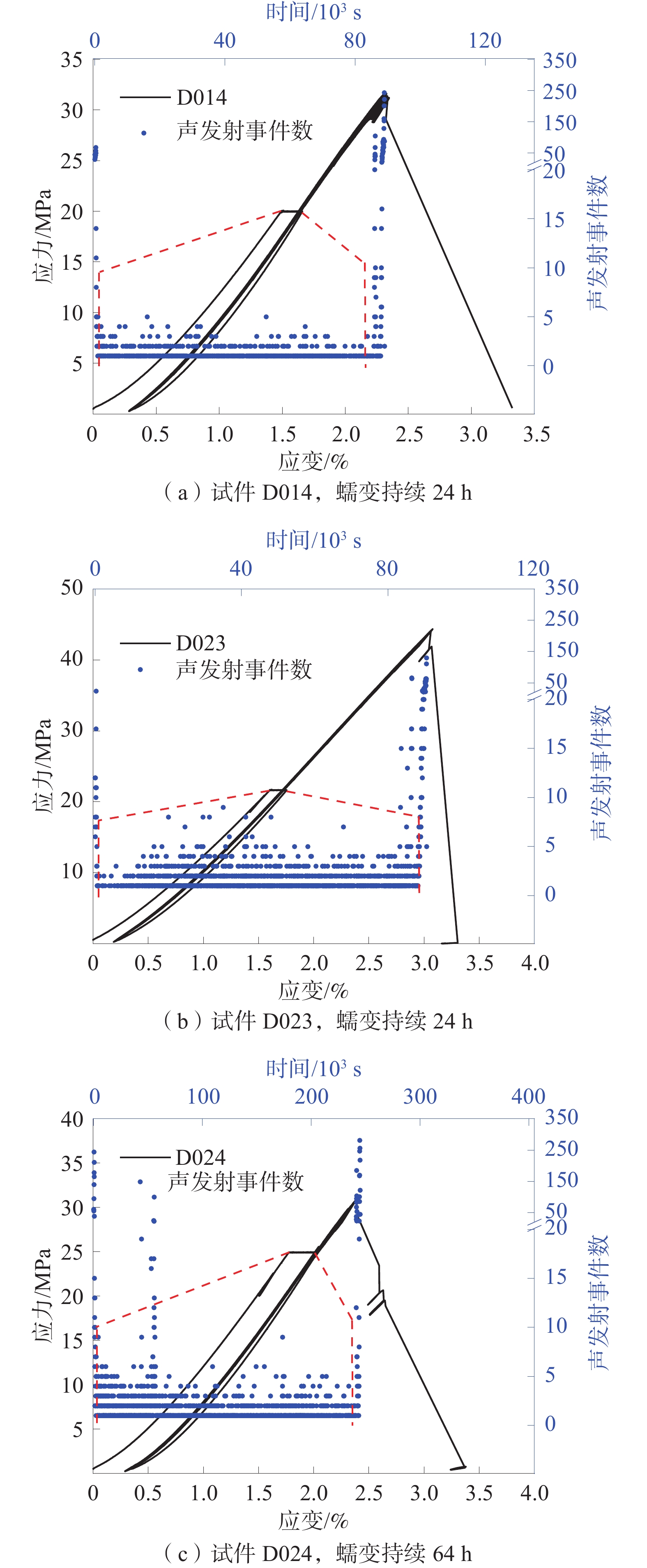

Abstract:Coal mining engineering involves complex stress structure time effect issues, which are closely related to the occurrence and prevention of rock burst disasters. Therefore, this study conducts experimental research on the stress structure time effect of impact coal. Coal rock specimens were obtained from three coal mines in Shaanxi, Gansu, and Inner Mongolia. The stress-time effect of loading rate was studied through coal uniaxial compression static-dynamic load and creep tests. The stress-time effect under the condition of coal in situ release was investigated using a long-term segmented test method. Water immersion tests on coal and structural time-effect studies on coal-rock combinations were conducted. The experimental results indicate that there is a positive correlation between the uniaxial compressive strength of coal and the loading rate, and a negative correlation with the duration of in-situ relief and immersion time. The combined mode of coal-rock structure time effect significantly affects its energy and strength properties, while impact coal exhibits both stress and structural time effects. According to the experimental results, a plastic limit structure is proposed to explain the irreversible deformation of coal-rock mass under stress. Furthermore, by constructing a time-dependent model for plastic strain in coal under impact conditions and comparing the numerical approximations of non-elastic strain and irreversible strain, the plastic limit strain characteristics of shock-induced coal were verified.

-

Keywords:

- time effect /

- rock burst /

- stress-structure /

- plastic limit structure /

- coal-rock combination

-

-

表 1 煤单轴压缩试验结果

Table 1 Test results of uniaxial compression of coal

编号 Rc/MPa E/GPa 编号 Rc/MPa E/GPa s1 11.16 2.09 s5 11.16 2.09 s2 15.95 1.80 s6 19.01 2.22 s3 13.66 1.71 s7 15.96 1.80 s4 26.10 1.87 s8 13.66 1.71 注:Rc为单轴抗压强度;E为弹性模量。 表 2 煤霍普金森试验结果

Table 2 Hopkinson test results of coal

编号 冲击速度/

(m·s−1)最大强度/

MPa切线模量/

GPad1 4.25 28.66 15.26 d2 5.62 30.24 20.74 d3 7.07 34.41 4.05 d4 8.84 37.82 28.87 d5 10.15 34.13 6.75 表 3 蠕变试验关键力学参数

Table 3 Key mechanical parameters of creep test

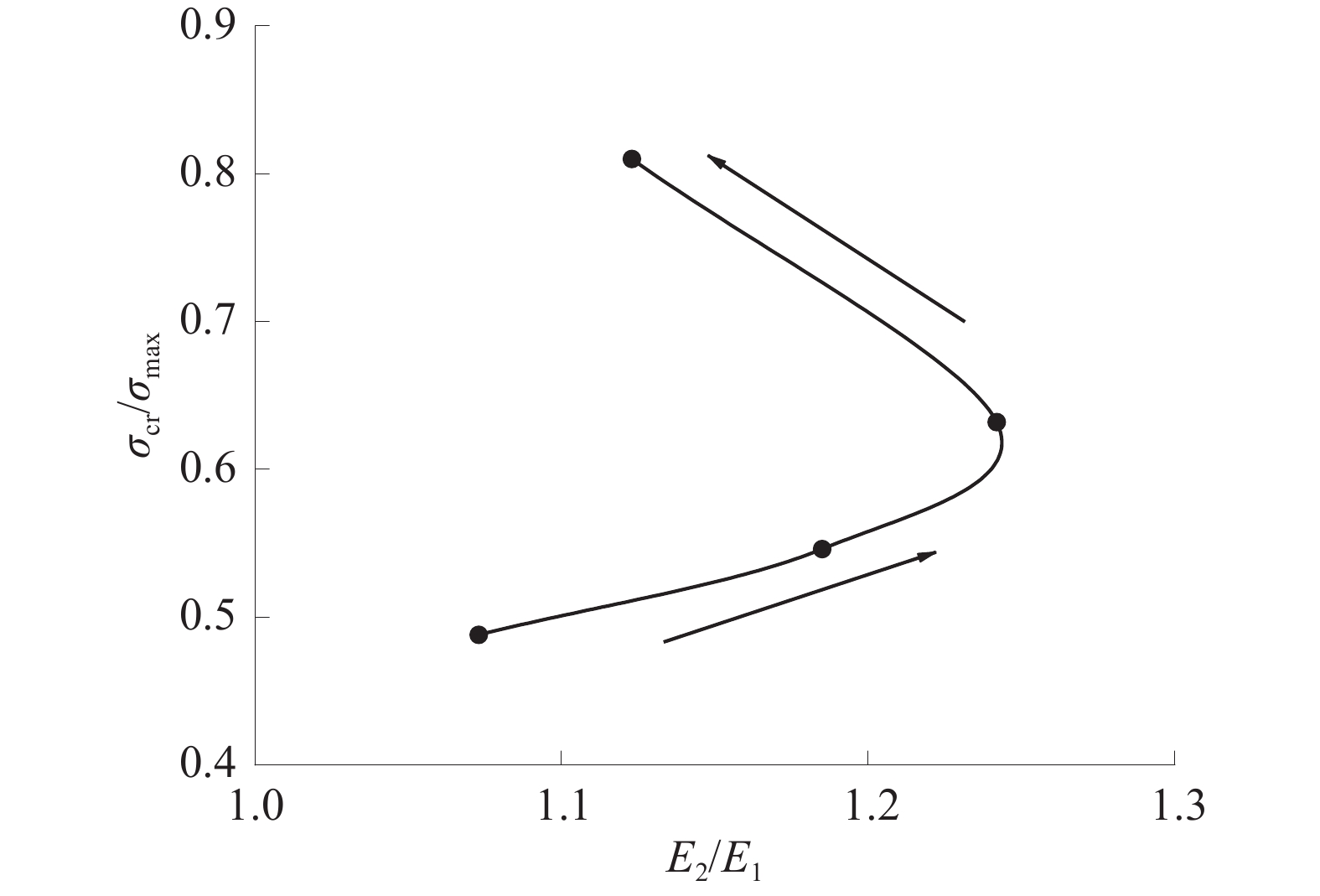

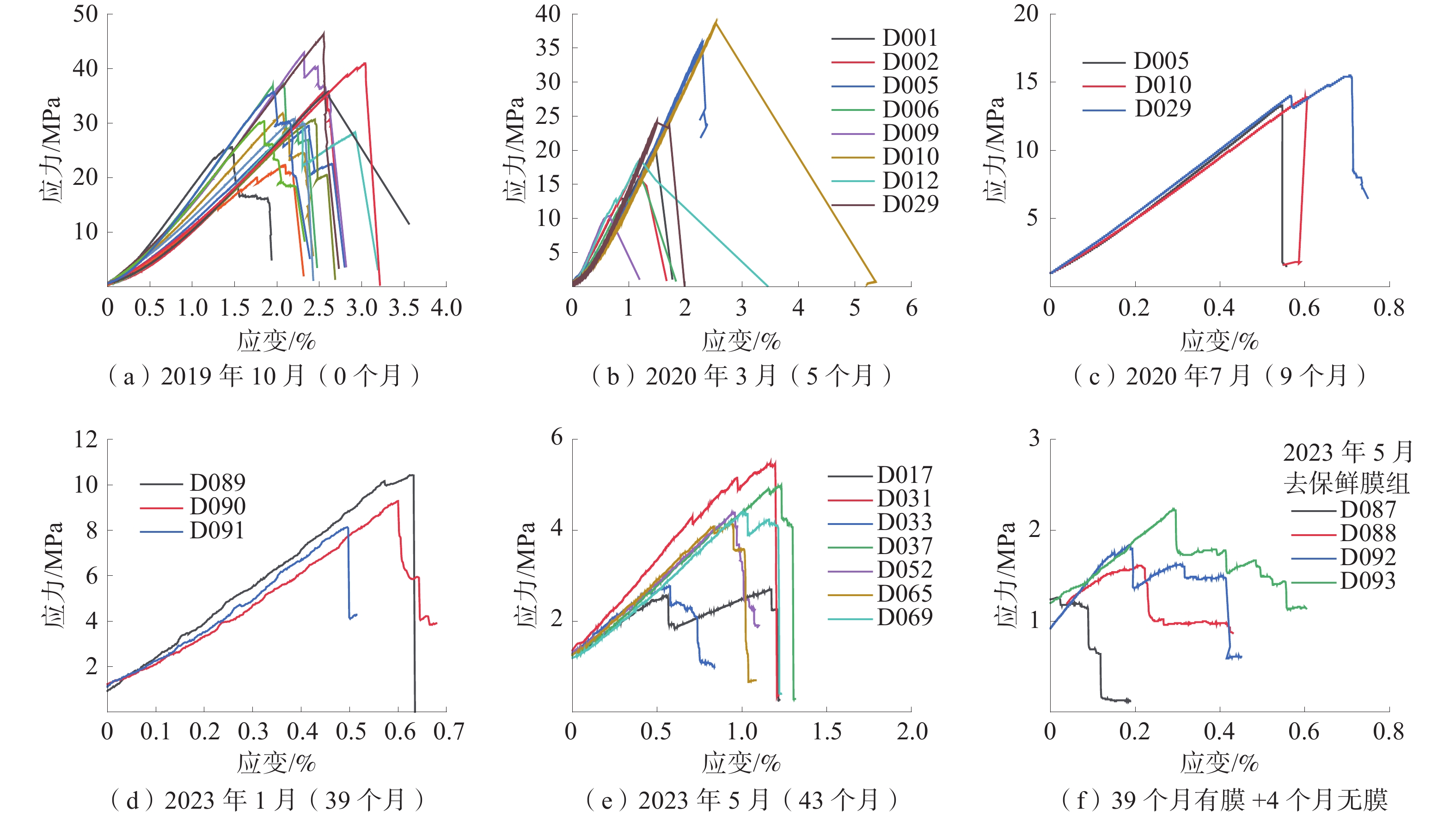

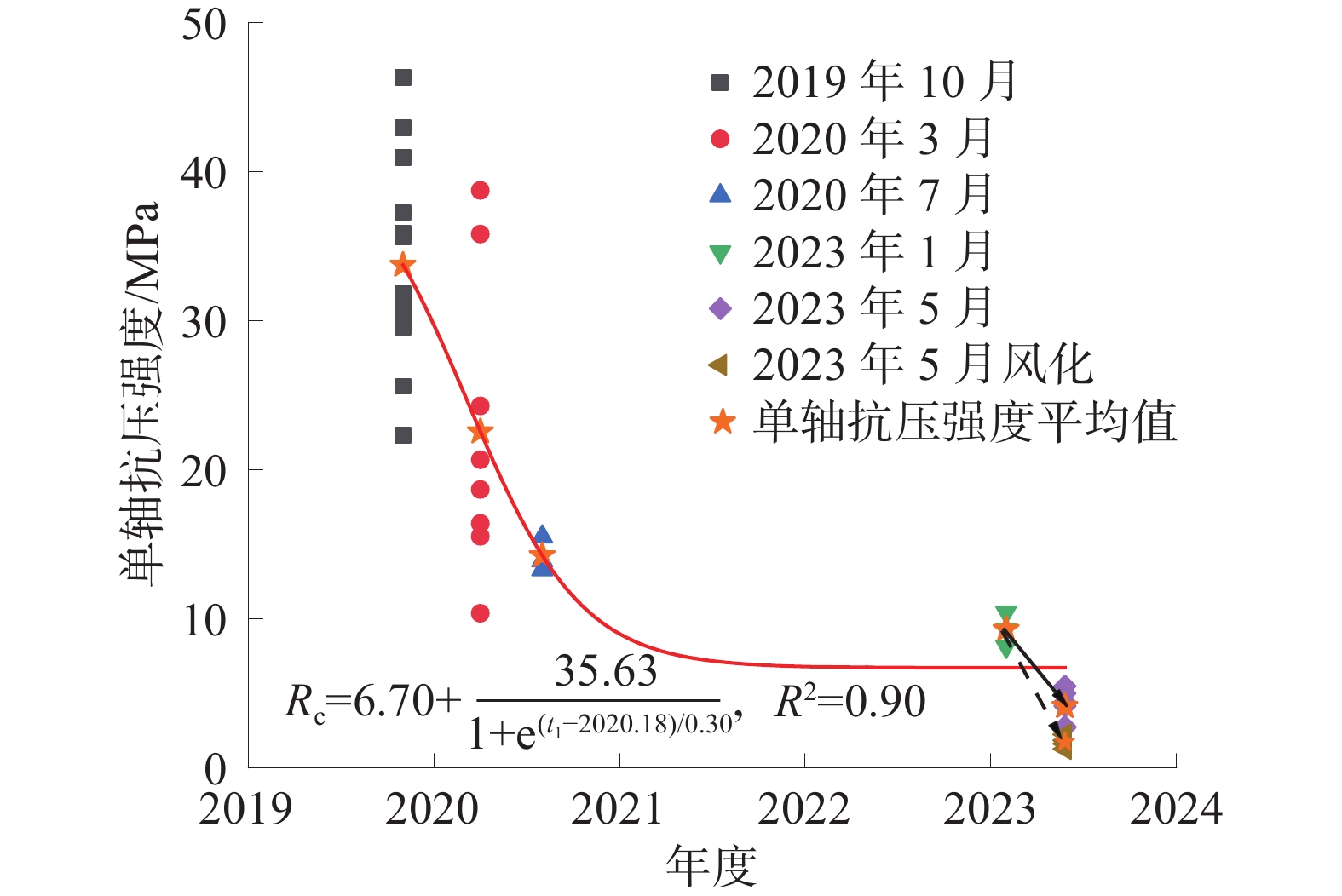

试件 E1 E2 E2/E1 σcr σc σcr/σc εcr/% D014 1.37 1.70 1.24 19.99 31.63 0.63 0.16 D023 1.38 1.48 1.07 21.66 44.36 0.49 0.17 D024 1.32 1.48 1.12 24.96 30.80 0.81 0.26 D034 1.31 1.56 1.18 23.26 42.58 0.55 0.12 注:E1为首次加载煤体的弹性模量;E2为蠕变及卸载后二次加载的煤弹性模量,Pa;σcr为蠕变应力,Pa;σc为最终抗压强度,Pa;εcr为蠕变期间应变。 表 4 煤试件长时养护效果

Table 4 Long-term curing effect of coal specimens

试样 质量/g 直径/mm 高度/mm 密度/(kg·m−3) 体积比 密度比 t2019 t2024 t2019 t2024 t2019 t2024 t2019 t2024 D007 231.27 238.78 48.66 48.41 100.80 100.39 1 233.74 1 292.21 0.986 1.047 D011 228.62 241.44 48.50 48.46 100.37 100.42 1 232.93 1 303.61 0.999 1.057 D018 220.89 233.58 48.43 48.48 100.80 100.49 1 189.59 1 259.21 0.999 1.059 D043 220.24 228.93 48.39 48.47 100.79 100.29 1 188.17 1 237.24 0.998 1.041 D047 222.49 234.18 48.77 48.48 101.60 100.84 1 172.25 1 258.11 0.981 1.073 D050 217.04 227.30 48.24 48.39 100.27 100.30 1 184.31 1 232.37 1.006 1.041 D053 220.66 231.41 48.36 48.51 100.78 100.40 1 192.03 1 247.13 1.002 1.046 D056 223.33 232.19 48.38 48.43 100.76 100.78 1 205.69 1 250.86 1.002 1.037 D077 220.61 235.18 48.50 48.48 100.56 100.05 1 187.48 1 273.19 0.994 1.072 注:t2019为2019年10月;t2024为2024年1月。 表 5 长时原位解除动态破坏时间试验结果

Table 5 Results of dynamic failure time test for long time in situ disarming

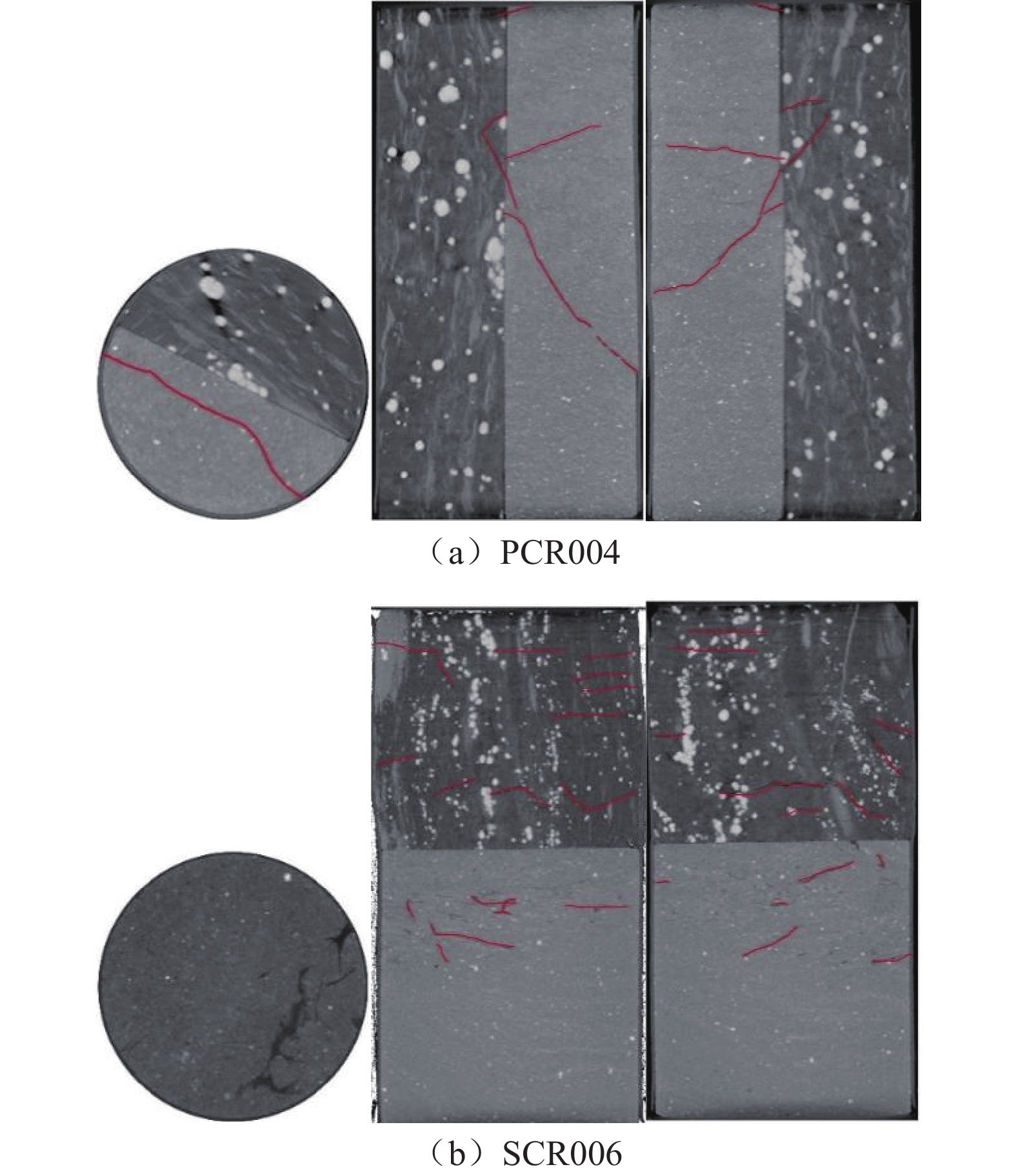

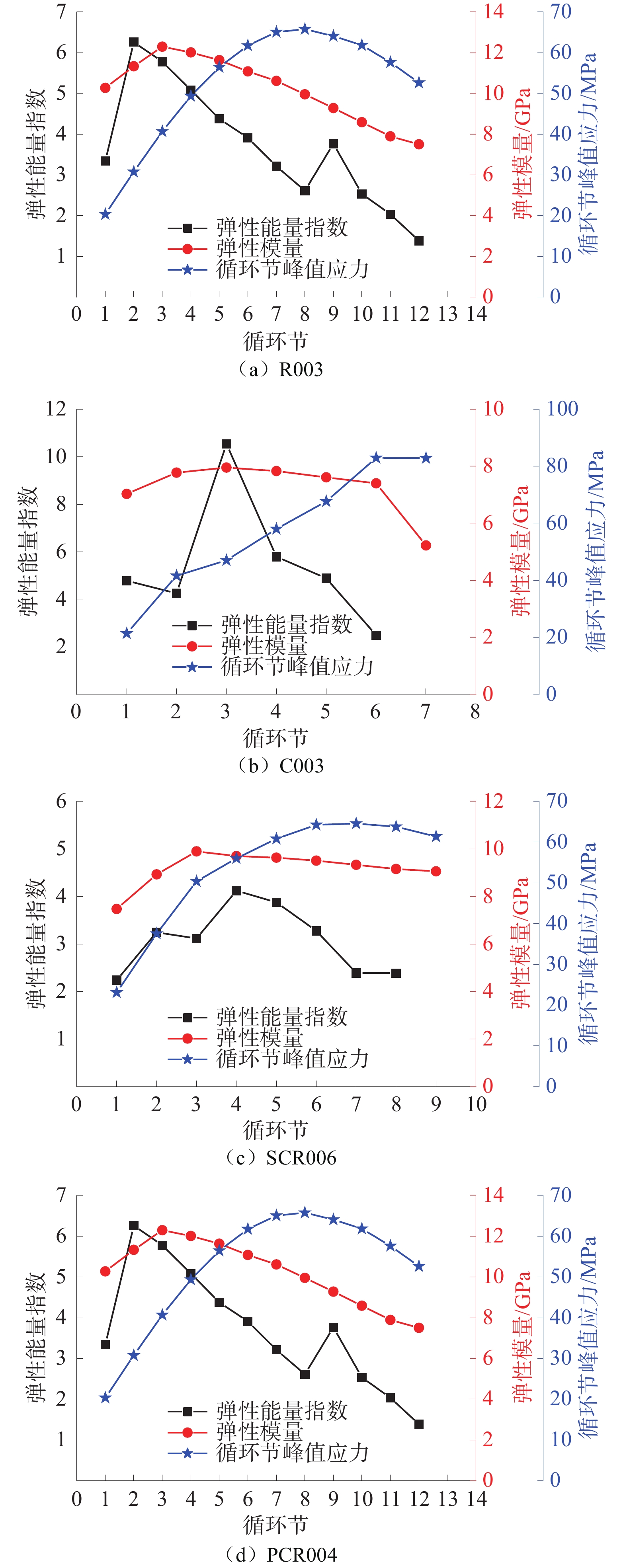

编号 时间 破坏时间/ms 编号 时间 破坏时间/ms 6011 2019−10 72 8015 2019−10 200 6012 2019−10 408 8511 2021−08 472 6013 2019−10 64 8512 2021−08 508 6014 2019−10 504 8513 2021−08 664 6015 2019−10 620 8514 2021−08 404 7011 2019−10 220 8515 2021−08 520 7012 2019−10 232 8611 2021−08 532 7013 2019−10 248 8612 2021−08 468 7014 2019−10 292 8613 2021−08 504 7015 2019−10 432 8614 2021−08 524 8011 2019−10 32 8615 2021−08 500 8012 2019−10 268 D089 2023−01 750 8013 2019−10 204 D090 2023−01 >2 000 8014 2019−10 620 D091 2023−01 >1 000 表 6 组合煤岩体试验情况统计表

Table 6 Statistical table of composite coal rock mass test

试件编号 试件属性 密度/(g·cm−3) 应力路径 抗压强度/MPa R001 砂岩 2.241 常规三轴 99.25 R003 砂岩 2.350 循环加卸载 116.72 C001 煤 1.424 常规三轴 66.00 C003 煤 1.428 循环加卸载 82.92 SCR001 串联1∶1 1.885 常规三轴 82.97 SCR006 串联1∶1 1.899 循环加卸载 64.58 PCR002 并联1∶1 1.846 常规三轴 75.40 PCR004 并联1∶1 1.785 循环加卸载 65.76 -

[1] 程守洙,江之永. 普通物理学(上册)[M]. 北京:高等教育出版社,2006. [2] 大卫·布拉特纳. 宇宙的尺度:从无穷大到无穷小[M]. 北京:北京联合出版公司,2017. [3] 康红普. 煤炭开采与岩层控制的时间尺度分析[J]. 采矿与岩层控制工程学报,2021,3(1):013538. KANG Hongpu. Temporal scale analysis on coal mining and strata control technologies[J]. Journal of Mining and Strata Control Engineering, 2021, 3(1): 013538.

[4] 王高昂,朱斯陶,姜福兴,等. 高应力厚煤层大巷孤立煤体蠕变失稳冲击机理及防治研究[J]. 岩土工程学报,2022,44(9):1689−1698. WANG Gaoang, ZHU Sitao, JIANG Fuxing, et al. Creep instability rock burst mechanism and prevention technology of isolated coal mass in roadways of high-stress thick coal seam[J]. Chinese Journal of Geotechnical Engineering, 2022, 44(9): 1689−1698.

[5] 宋艳芳,潘一山,李忠华,等. 孤立煤柱冲击地压蠕变失稳研究[J]. 煤矿安全,2018,49(5):47−50. SONG Yanfang, PAN Yishan, LI Zhonghua, et al. Creep instability of isolated coal pillar under rock burst[J]. Safety in Coal Mines, 2018, 49(5): 47−50.

[6] 杜学领,姜耀东,王涛. 中国冲击地压的时空分布特征[J]. 煤矿安全,2017,48(8):186−189. DU Xueling, JIANG Yaodong, WANG Tao, et al. Temporal and spatial distribution of rock burst in China[J]. Safety in Coal Mines, 2017, 48(8): 186−189.

[7] 王杰. 变倾角煤层内工作面开采诱冲机理及防治技术[J]. 煤矿安全,2023,54(11):124−132. WANG Jie. Occurrence mechanism and prevention technology of rock burst about mining working faces in variable dip coal seam[J]. Safety in Coal Mines, 2023, 54(11): 124−132.

[8] 赵洪瑞. 煤岩变形破坏电荷感应规律试验研究及现场应用[J]. 煤矿安全,2024,55(3):222−230. ZHAO Hongrui. Experimental study and field application of charge induction law in coal rock deformation and failure[J]. Safety in Coal Mines, 2024, 55(3): 222−230.

[9] 梁文昭,刘国磊,郑寓超,等. 深部构造区大倾角工作面回撤致冲机理及防治技术[J]. 煤矿安全,2024,55(3):127−138. LIANG Wenzhao, LIU Guolei, ZHENG Yuchao, et al. Mechanism and prevention technology of large inclined workface retracement inducing rock burst in deep tectonic zone[J]. Safety in Coal Mines, 2024, 55(3): 127−138.

[10] 齐庆新,李一哲,赵善坤,等. 我国煤矿冲击地压发展70年:理论与技术体系的建立与思考[J]. 煤炭科学技术,2019,47(9):1−40. QI Qingxin, LI Yizhe, ZHAO Shankun, et al. Seventy years development of coal mine rockburst in China: establishment and consideration of theory and technology system[J]. Coal Science and Technology, 2019, 47(9): 1−40.

[11] HU Xiaochuan, SU Guoshao, CHEN Guanyan, et al. Experiment on rockburst process of borehole and its acoustic emission characteristics[J]. Rock Mechanics and Rock Engineering, 2019, 52(3): 783−802. doi: 10.1007/s00603-018-1613-z

[12] LIU Xiaofei, XU Guang, ZHANG Chong, et al. Time effect of water injection on the mechanical properties of coal and its application in rockburst prevention in mining[J]. Energies, 2017, 10(11): 1783. doi: 10.3390/en10111783

[13] 窦林名,田鑫元,曹安业,等. 我国煤矿冲击地压防治现状与难题[J]. 煤炭学报,2022,47(1):152−171. DOU Linming, TIAN Xinyuan, CAO Anye, et al. Present situation and problems of coal mine rock burst prevention and control in China[J]. Journal of China Coal Society, 2022, 47(1): 152−171.

[14] 徐思朋,钟卫平,贾凤苏. 煤柱冲击地压时间效应研究[J]. 矿山压力与顶板管理,2001(1):75−77. XU Sipeng, ZHONG Weiping, JIA Fengsu. Study on the time effect of rock burst for a pillar[J]. Ground Pressure and Strata Control, 2001(1): 75−77.

[15] 李云鹏,张宏伟,韩军,等. 基于分布式光纤传感技术的卸压钻孔时间效应研究[J]. 煤炭学报,2017,42(11):2834−2841. LI Yunpeng, ZHANG Hongwei, HAN Jun, et al. Time effect of borehole pressure relief based on distributed optical fiber sensing technology[J]. Journal of China Coal Society, 2017, 42(11): 2834−2841.

[16] 刘冬桥,何满潮,汪承超,等. 动载诱发冲击地压的实验研究[J]. 煤炭学报,2016,41(5):1099−1105. LIU Dongqiao, HE Manchao, WANG Chengchao, et al. Experimental study on rock burst induced by dynamic load[J]. Journal of China Coal Society, 2016, 41(5): 1099−1105.

[17] 刘少虹,潘俊锋,王书文,等. 岩浆岩侵入区巨厚煤层掘进巷道冲击地压机制研究[J]. 岩石力学与工程学报,2017,36(11):2699−2711. LIU Shaohong, PAN Junfeng, WANG Shuwen, et al. Rock burst mechanism of heading roadway in thick coal seam in magmatic intrusion areas[J]. Chinese Journal of Rock Mechanics and Engineering, 2017, 36(11): 2699−2711.

[18] NIU W, FENG X T, YAO Z, et al. Types and occurrence time of rockbursts in tunnel affected by geological conditions and drilling & blasting procedures[J]. Engineering Geology, 2022, 303: 106671. doi: 10.1016/j.enggeo.2022.106671

[19] ZHANG H, ZENG J, MA J, et al. Time series prediction of microseismic multi-parameter related to rockburst based on deep learning[J]. Rock Mechanics and Rock Engineering, 2021, 54(12): 6299−6321. doi: 10.1007/s00603-021-02614-9

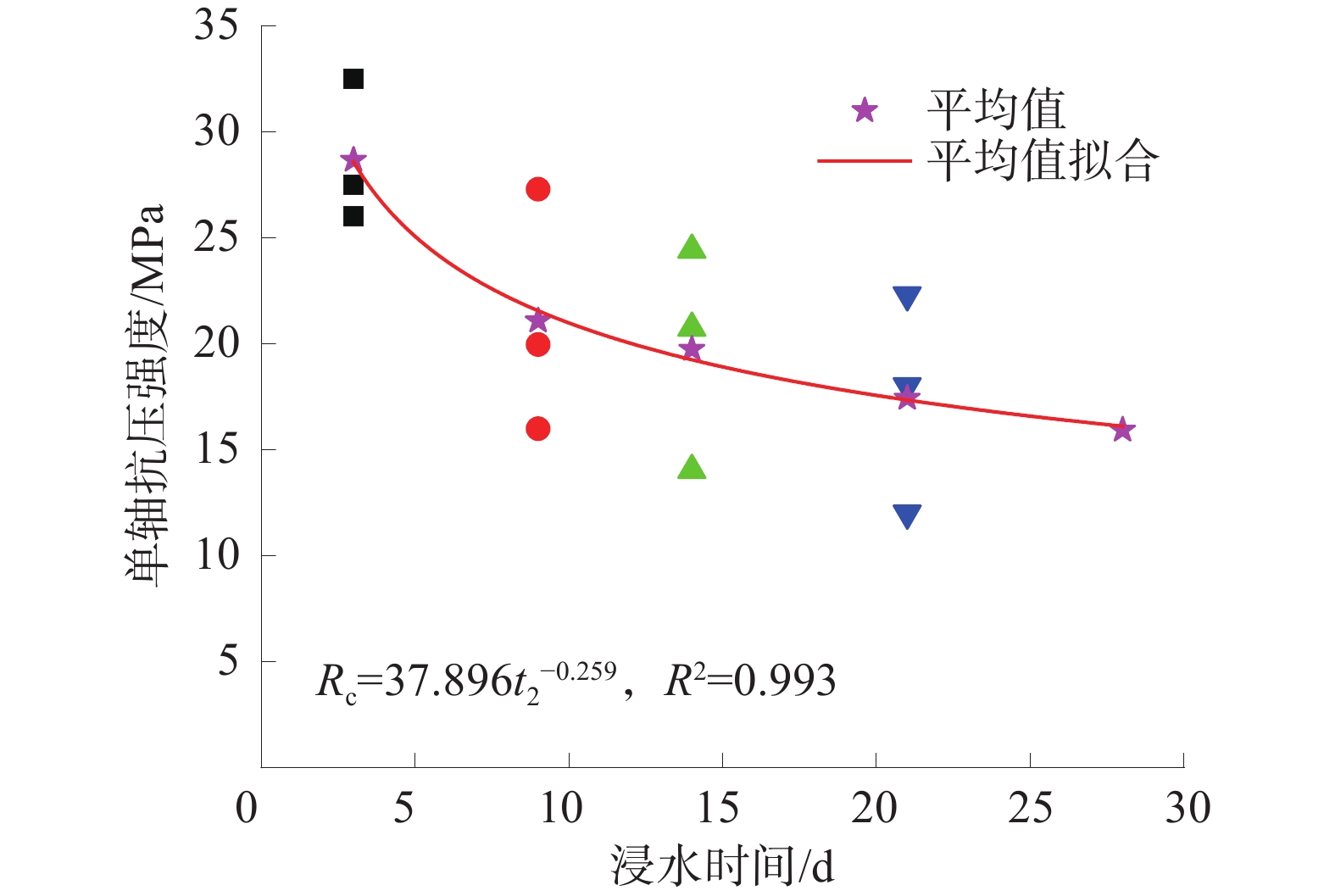

[20] 潘俊锋,宁宇,蓝航,等. 基于千秋矿冲击性煤样浸水时间效应的煤层注水方法[J]. 煤炭学报,2012,37(S1):19−25. PAN Junfeng, NING Yu, LAN Hang, et al. Water injection methods in coal bed based on experiments of water immersion time effect of Qianqiu coal samples with burst trend[J]. Journal of China Coal Society, 2012, 37(S1): 19−25.

[21] 赵善坤,苏振国,侯煜坤,等. 采动巷道矿压显现特征及力构协同防控技术研究[J]. 煤炭科学技术,2021,49(6):61−71. ZHAO Shankun, SU Zhenguo, HOU Yukun, et al. Study on mine pressure characteristics and force-structure cooperative prevention and control on mining roadway with deep thick hard roof[J]. Coal Science and Technology, 2021, 49(6): 61−71.

[22] 赵善坤. 深孔顶板预裂爆破力构协同防冲机理及工程实践[J]. 煤炭学报,2021,46(11):3419−3432. ZHAO Shankun. Mechanism and application of force-structure cooperative prevention and control on rockburst with deep hole roof pre-blasting[J]. Journal of China Coal Society, 2021, 46(11): 3419−3432.

[23] 赵善坤. 采动巷道冲击地压力构协同防控技术研究[D]. 北京:中国矿业大学(北京),2020. [24] 杨朴. 煤矿地下水库煤柱坝体强度损伤机理研究[D]. 徐州:中国矿业大学,2019. [25] 王中伟. 综采面高强度采动影响下浸水煤柱的稳定性研究[D]. 徐州:中国矿业大学,2019. [26] ZHANG Lei, ZHOU Hongwei, WANG Xiangyu, et al. On permeability evolution of coal induced by temperature, creep, and matrix–fracture interaction[J]. Energy & Fuels, 2022, 36(3): 1470−1481.

[27] 孙晓明,缪澄宇,姜铭,等. 基于改进西原模型的不同含水率砂岩蠕变实验及理论研究[J]. 岩石力学与工程学报,2021,40(12):2411−2420. SUN Xiaoming, MIAO Chengyu, JIANG Ming, et al. Experimental and theoretical study on creep behaviors of sandstone with different moisture contents based on modified Nishihara model[J]. Chinese Journal of Rock Mechanics and Engineering, 2021, 40(12): 2411−2420.

下载:

下载: