Research on gel plugging and fire prevention technology for roadway excavation in residual coal re-mining area

-

摘要:

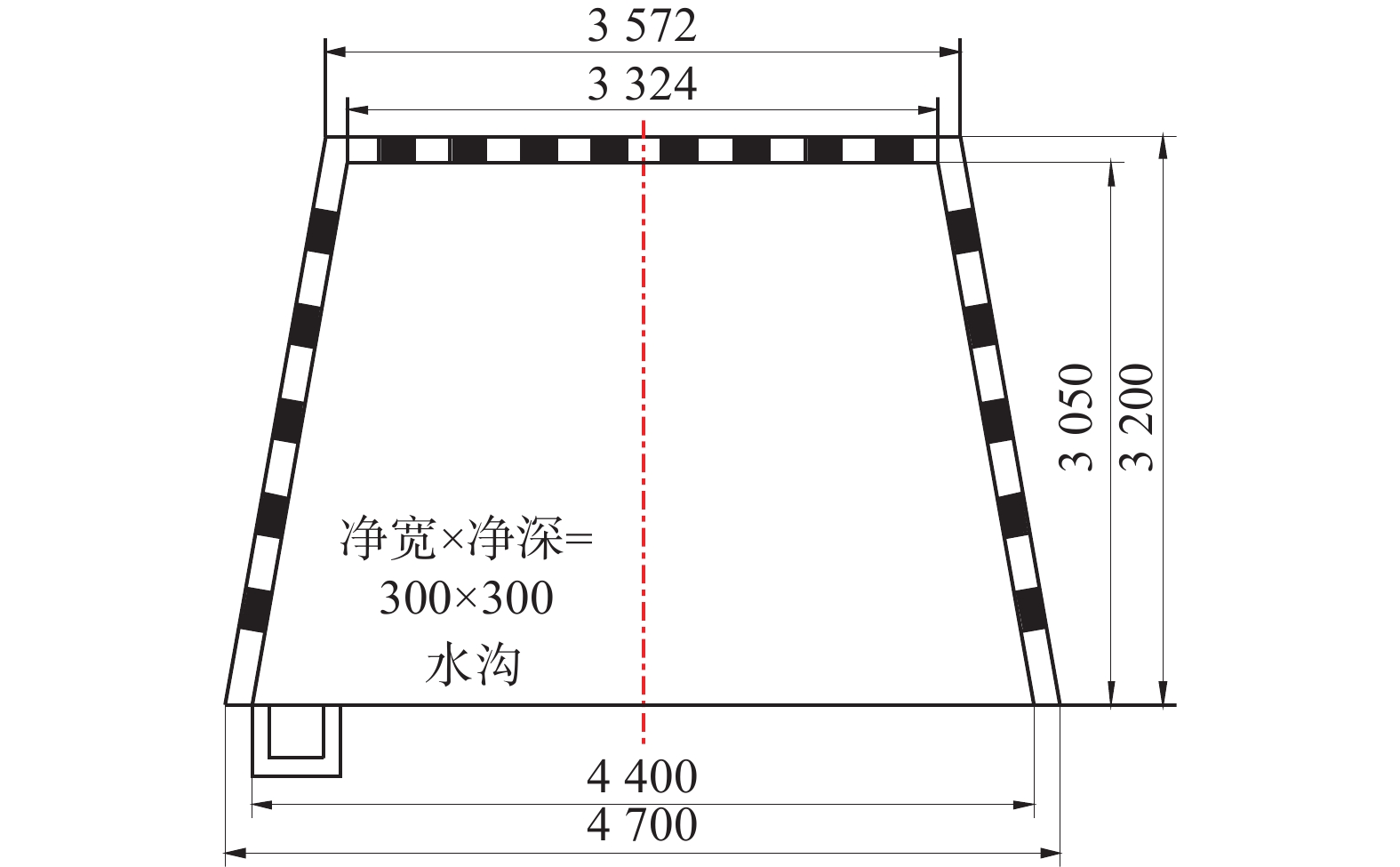

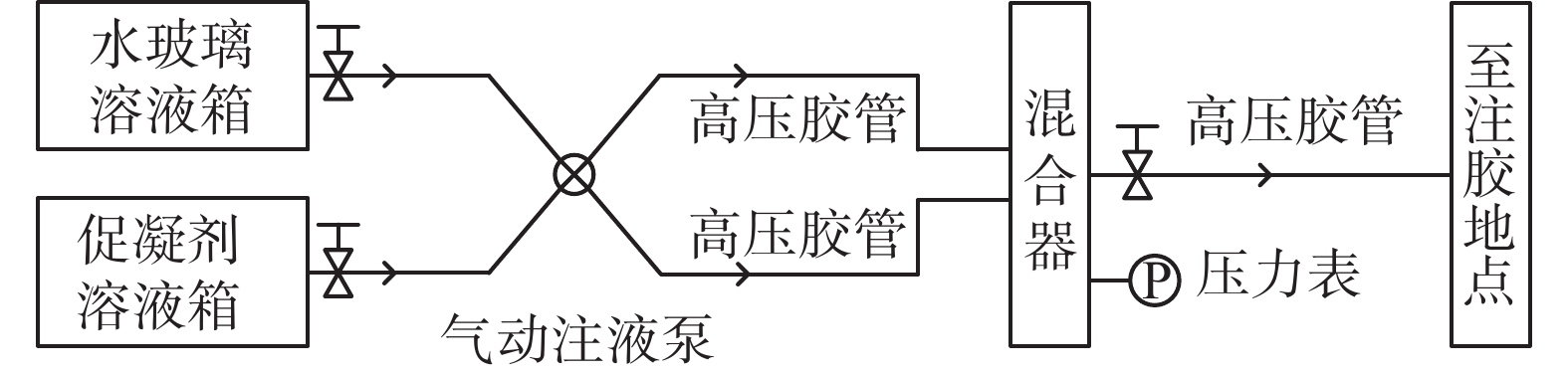

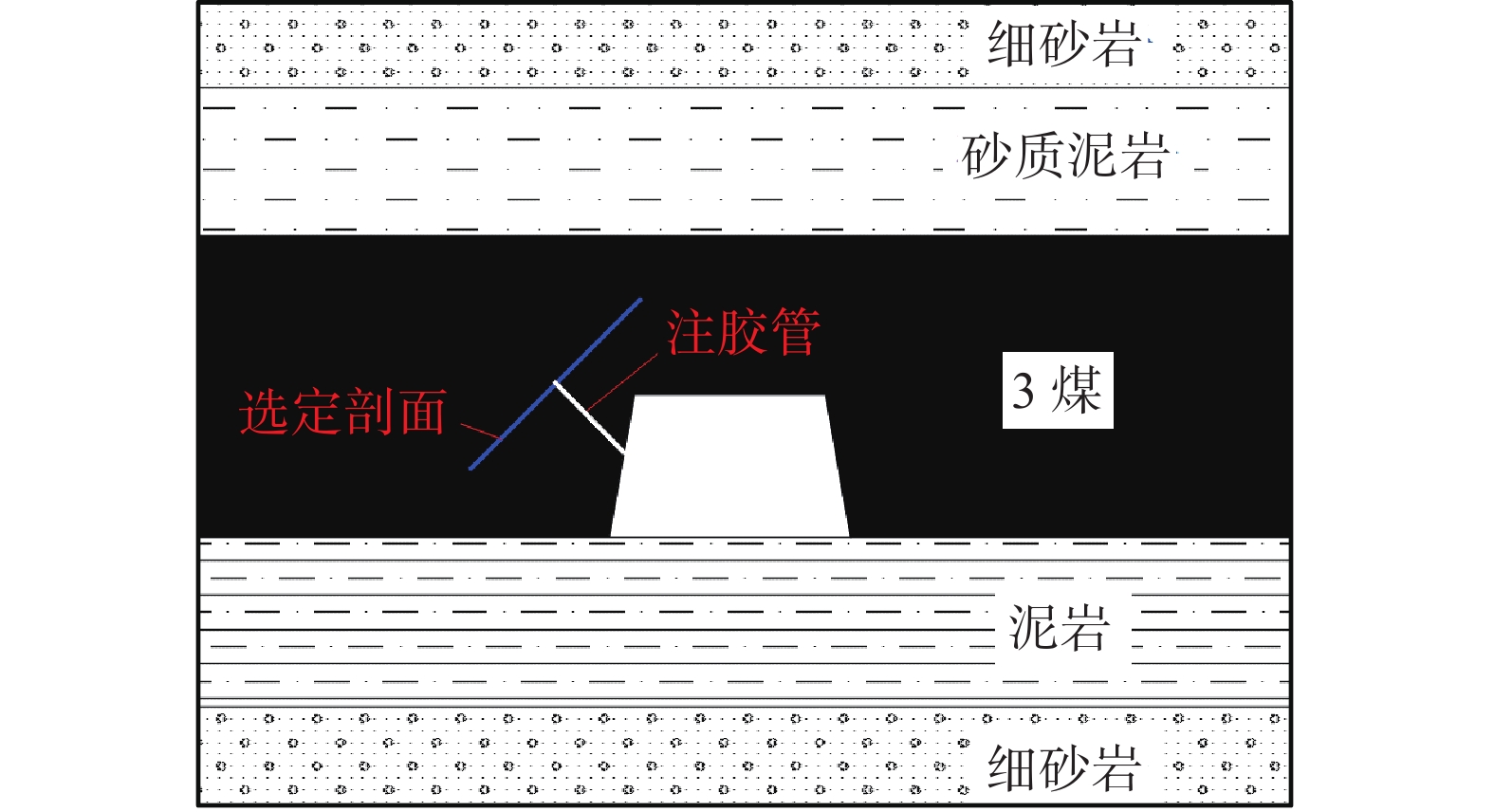

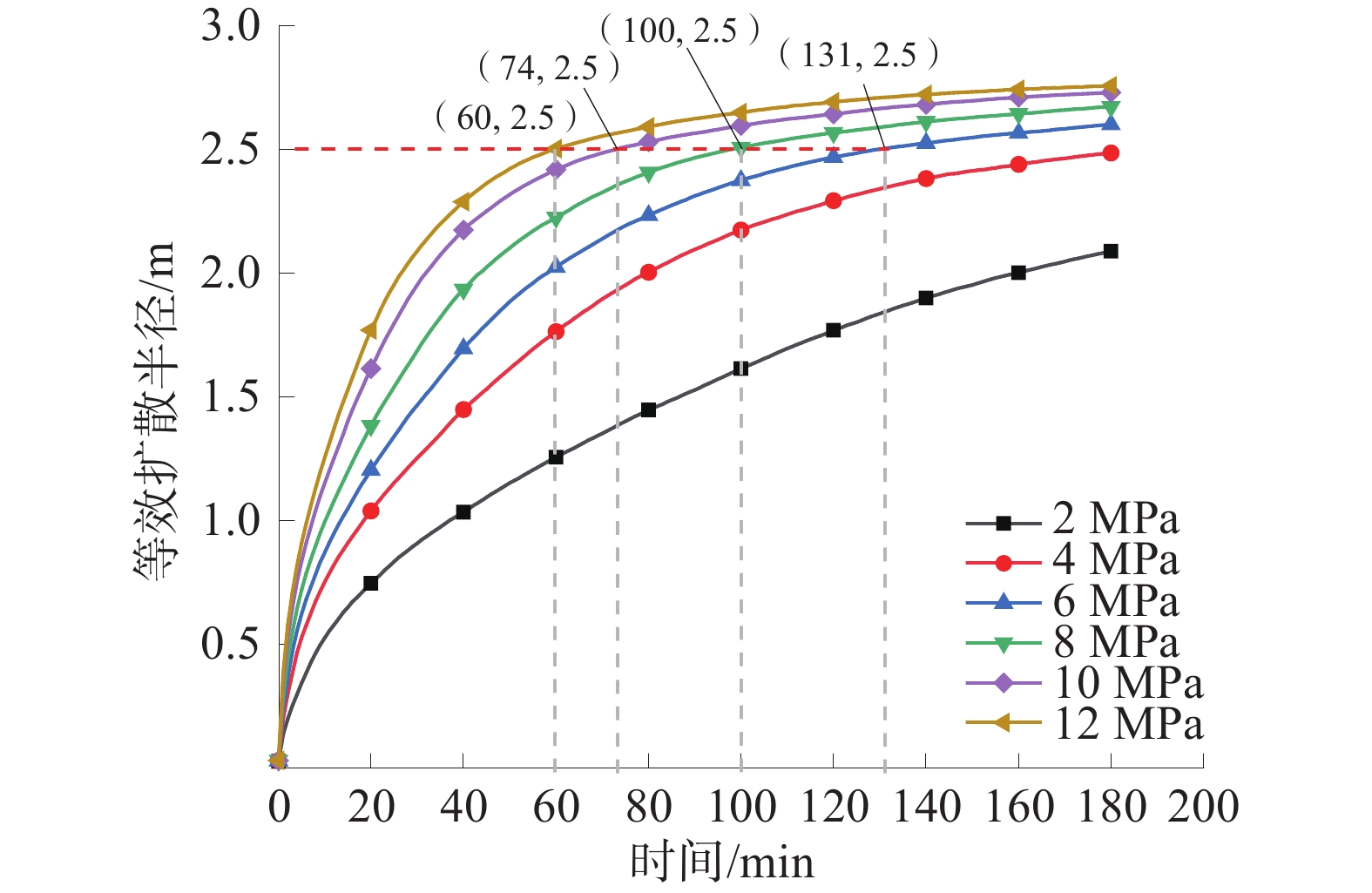

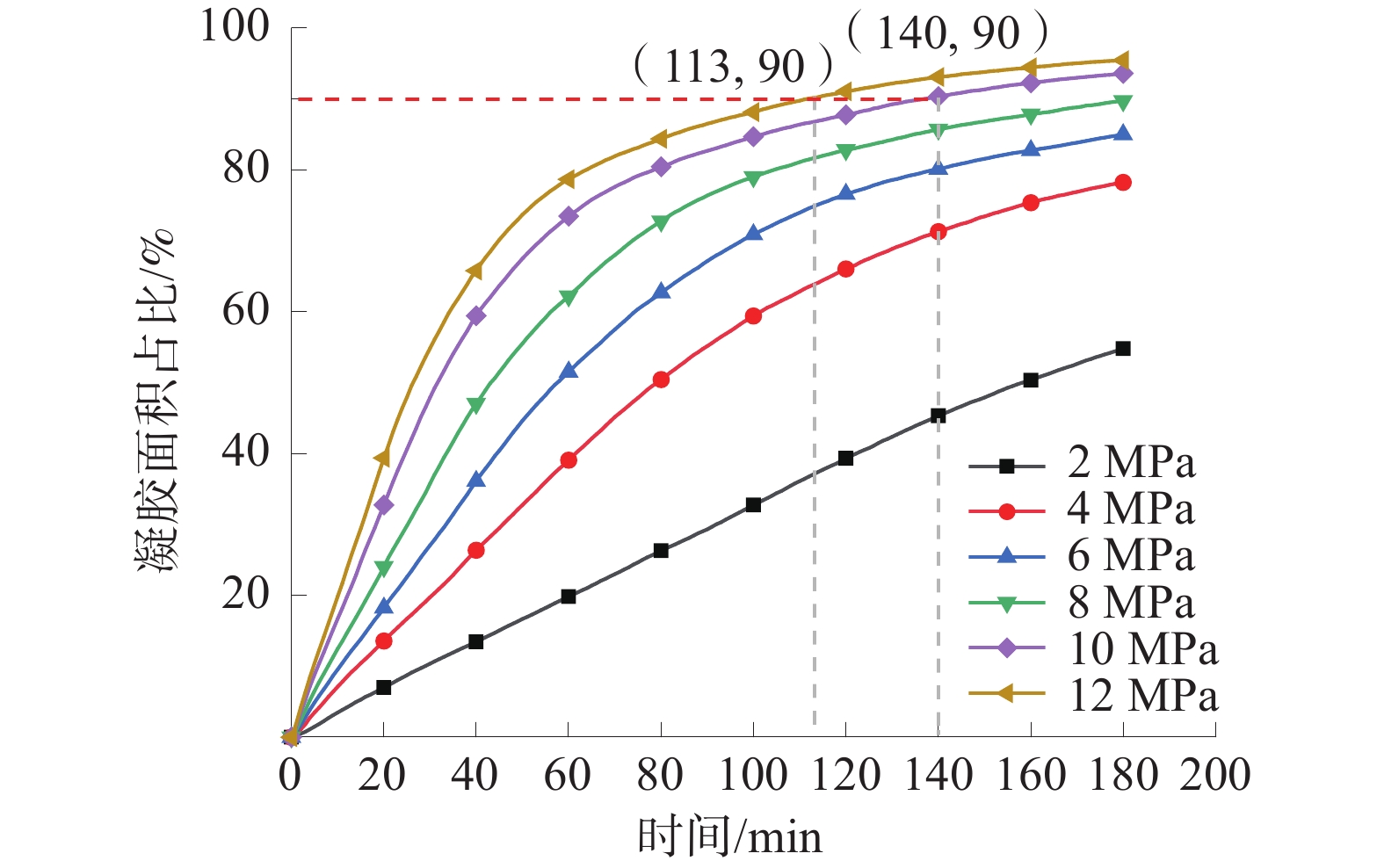

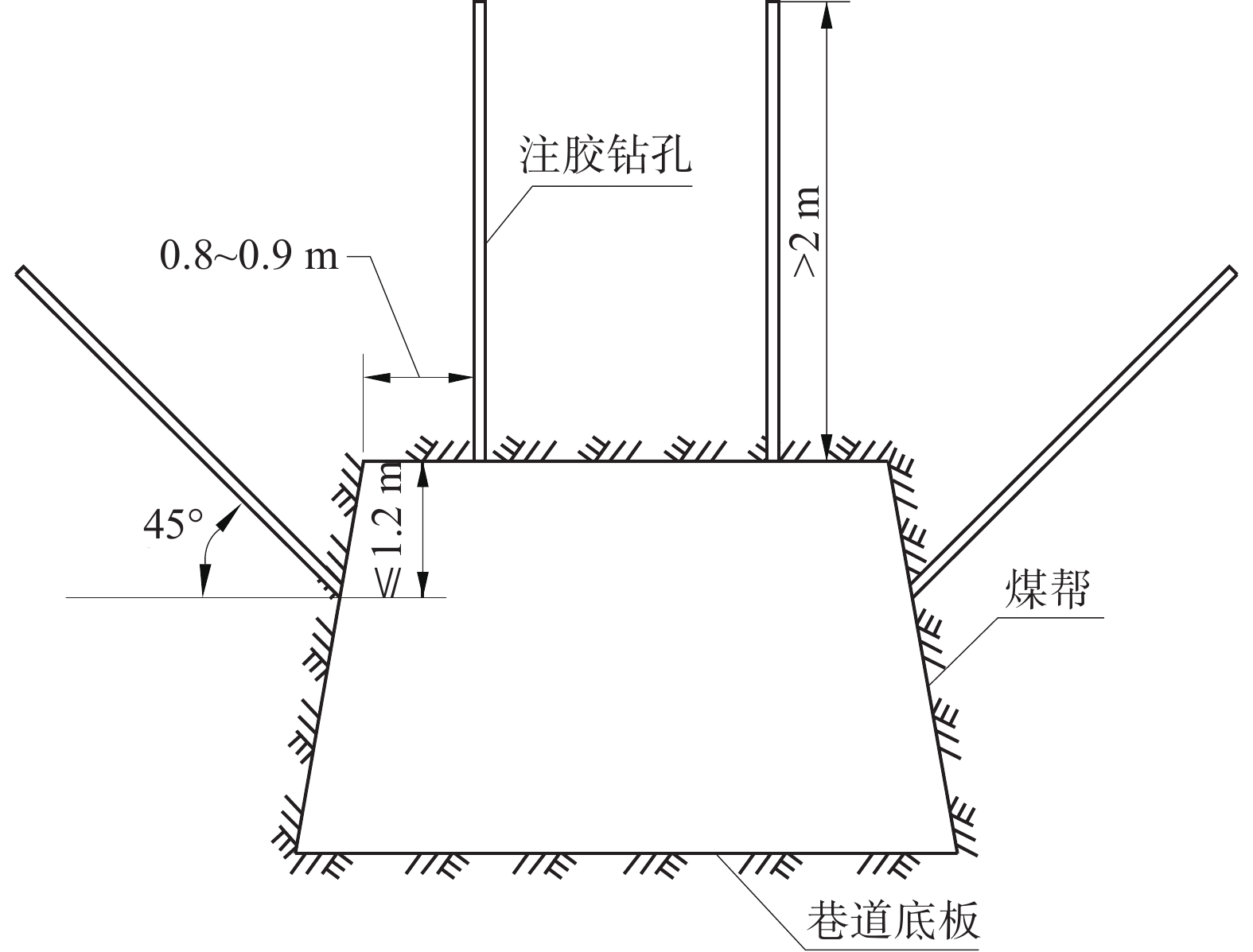

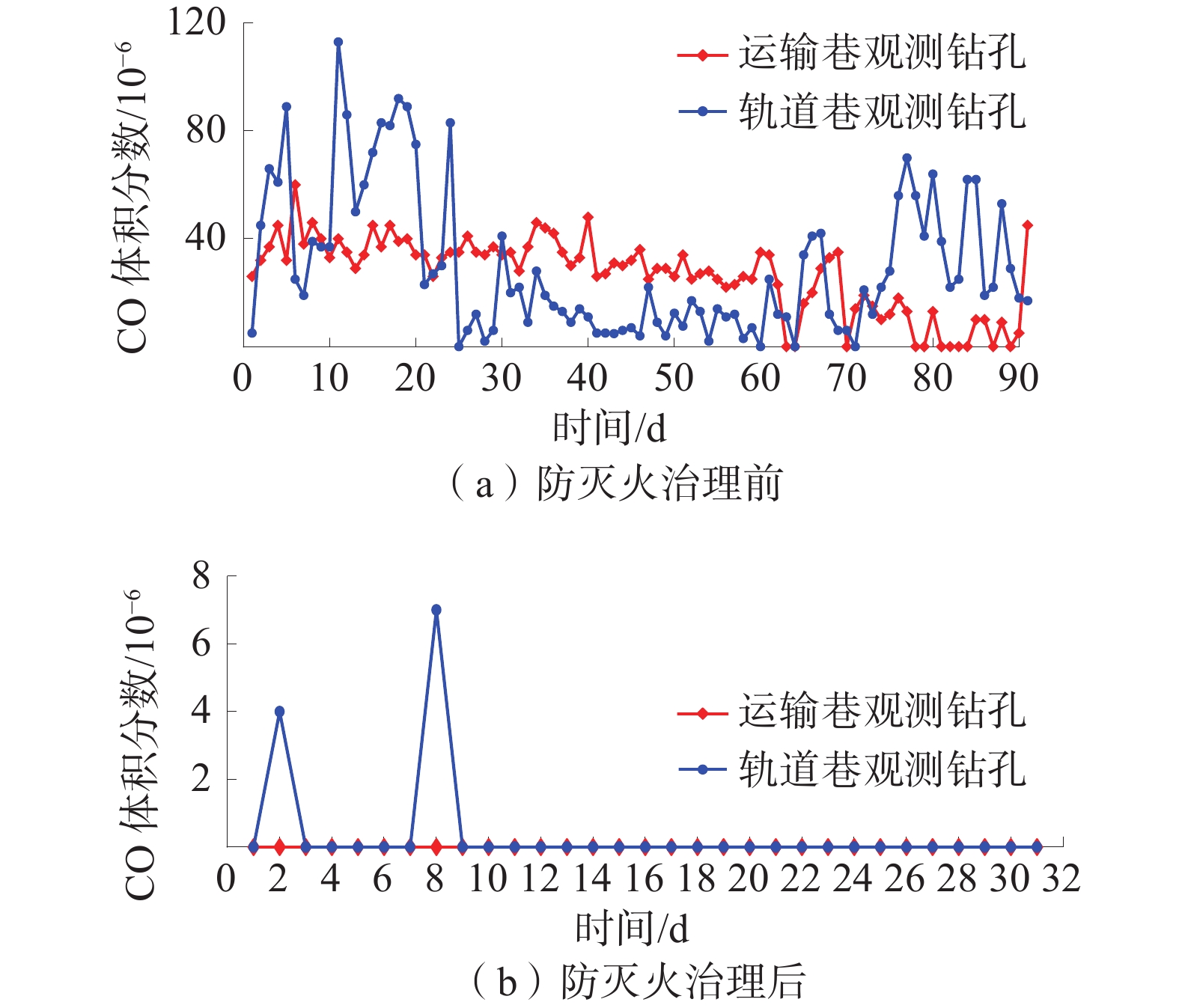

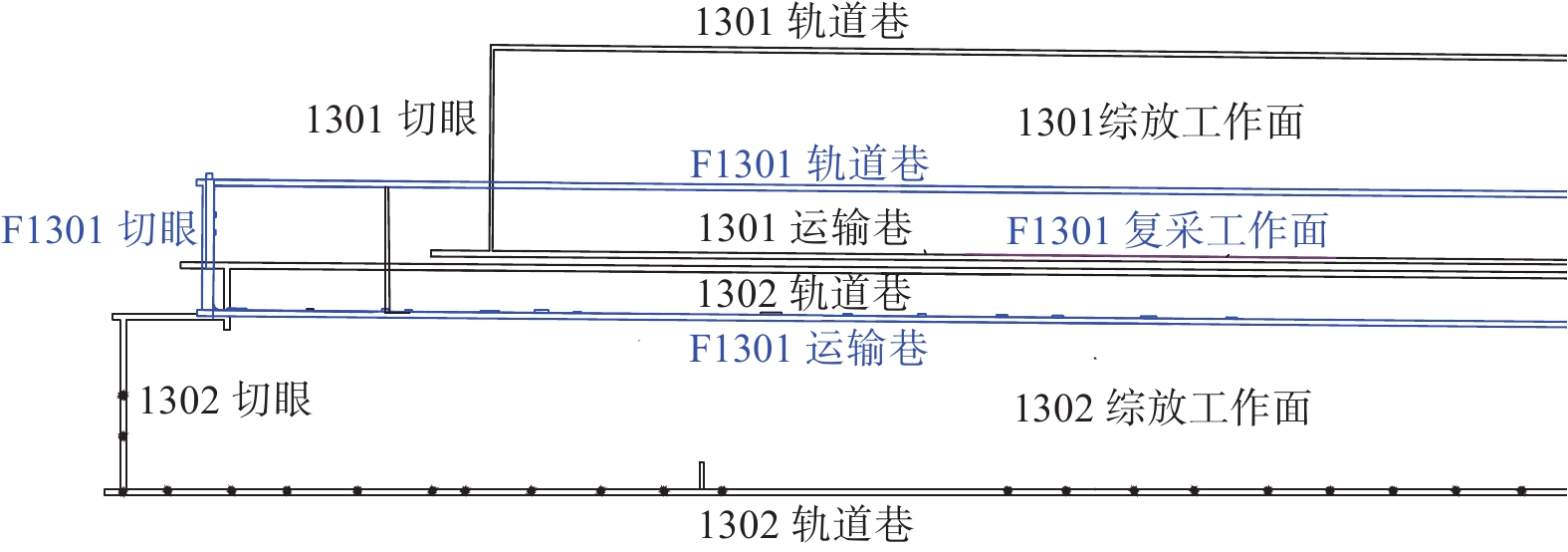

采空区中遗留煤炭自燃现象直接影响着煤矿的安全高效开采,而采用堵漏材料封闭漏风通道是解决采空区煤自燃问题的有效方法。以运河煤矿F1301复采工作面为工程背景,针对在采空区中掘进巷道时遗留松散煤体的自燃隐患问题,制定了松散煤体凝胶堵漏防灭火技术实施方案,采用COMSOL数值模拟方法研究了不同注胶时间与压力下的凝胶扩散规律,并进行了工程应用。结果表明:注胶时间和压力与凝胶扩散范围成正比,综合考虑注胶效果与成本,选取10 MPa、140~160 min为最佳的注胶压力与时间,注胶钻孔间距设置为5 m;实施凝胶堵漏防灭火方案后,巷道两侧观测钻孔监测数据显示,标志气体CO体积分数稳定于24×10−6以下,凝胶堵漏防灭火效果良好,有效消除了采空区遗留煤炭自然发火隐患。

Abstract:The phenomenon of spontaneous combustion of coal left in the goaf directly affects the safe and efficient mining of coal mines, and the use of plugging materials to close the air leakage channel is an effective method to solve the problem of spontaneous combustion of coal in the goaf. Taking the F1301 re-mining face of Yunhe Coal Mine as the engineering background, aiming at the hidden danger of spontaneous combustion of loose coal left in the tunneling roadway in the goaf, the implementation scheme of gel plugging and fire extinguishing technology for loose coal was formulated. The COMSOL numerical simulation method was used to study the gel diffusion law under different injection time and pressures, and the engineering application was carried out. The results show that the injection time and pressure are proportional to the gel diffusion range. Considering the injection effect and cost, 10 MPa and 140-160 min are selected as the best injection pressure and time, and the distance between the injection holes is set to 5 m. After the implementation of the gel plugging fire prevention and extinguishing scheme, the monitoring data of the observation boreholes on both sides of the roadway show that the volume fraction of the iconic gas CO is stable below 24×10−6, and the gel plugging fire prevention and extinguishing effect is good, which effectively eliminates the hidden danger of spontaneous combustion of coal left in the goaf.

-

-

表 1 数值模拟方案

Table 1 Scheme of numerical simulation

序号 注胶压力/MPa 时间/min 渗透率/m2 孔隙率 1 2 180 5×10−15 0.4 2 4 180 5×10−15 0.4 3 6 180 5×10−15 0.4 4 8 180 5×10−15 0.4 5 10 180 5×10−15 0.4 6 12 180 5×10−15 0.4 -

[1] 秦波涛,仲晓星,王德明,等. 煤自燃过程特性及防治技术研究进展[J]. 煤炭科学技术,2021,49(1):66−99. QIN Botao, ZHONG Xiaoxing, WANG Deming, et al. Research progress of coal spontaneous combustion process characteristics and prevention technology[J]. Coal Science and Technology, 2021, 49(1): 66−99.

[2] 张创业,王晓川,吕有厂,等. 下保护层开采扰动卸压效应及瓦斯与煤自燃协同治理技术[J/OL]. 矿业安全与环保,2024: 1-8. [2024-04-26]. http://kns.cnki.net/kcms/detail/50.1062.td.20230829.0847.001.html. ZHANG Chuangye, WANG Xiaochuan, LYU Youchang, et al. Collaborative technology of mining disturbance pressure relief effect and gas-spontaneous combustion collaborative control technology[J/OL]. Mining Safety & Environmental Protection, 2024: 1-8. [2024-04-26]. http://kns.cnki.net/kcms/detail/50.1062.td.20230829.0847.001.html.

[3] 赵亚明,杨伟,陈洋. 冲击地压矿井易自燃厚煤层回撤工作面自燃防治技术[J]. 煤矿安全,2022,53(4):81−86. ZHAO Yaming, YANG Wei, CHEN Yang. Spontaneous combustion prevention technology of withdrawal working face of spontaneous combustion thick coal seam in rock burst mine[J]. Safety in Coal Mines, 2022, 53(4): 81−86.

[4] 仲晓星,杨正杰,窦国兰,等. 地下煤火热交换系统相似准则研究[J]. 中国矿业大学学报,2015,44(6):965−970. ZHONG Xiaoxing, YANG Zhengjie, DOU Guolan, et al. Study on similarity criterion for heat exchange system of underground coal fires[J]. Journal of China University of Mining & Technology, 2015, 44(6): 965−970.

[5] 付伟,宋海洲,陈军,等. 新型矿用防灭火凝胶泡沫制备及阻化性能研究[J]. 煤炭工程,2023,55(9):127−133. FU Wei, SONG Haizhou, CHEN Jun, et al. Study on preparation and chemical inhibition properties of a new gel foam for mine fire extinguishing[J]. Coal Engineering, 2023, 55(9): 127−133.

[6] 陈鹏燕,周春山,程熙宇. CMC/AlCit/GDL防灭火凝胶的流变性能及本构方程研究[J]. 应用化工,2023,52(4):1010−1014. CHEN Pengyan, ZHOU Chunshan, CHENG Xiyu. Study on rheological ability and constitutive equation of mineral CMC/AlCit/GDL gel[J]. Application Chemical Indystry, 2023, 52(4): 1010−1014.

[7] 李洋,戴广龙,杨苗苗. 高保水矿用凝胶阻化材料的制备和性能研究[J]. 煤炭技术,2023,42(3):173−177. LI Yang, DAI Guanglong, YANG Miaomiao. Preparation and performance study of high water retention mineral hydrogel inhibitors[J]. Coal Technology, 2023, 42(3): 173−177.

[8] 段西凯,周睿,何勇军. 矿用超吸水防灭火凝胶制备及性能研究[J]. 煤矿安全,2023,54(2):71−76. DUAN Xikai, ZHOU Rui, HE Yongjun. Study on preparation and performance of mine superabsorbent fire prevention and extinguishing gel[J]. Safety in Coal Mines, 2023, 54(2): 71−76.

[9] 石政锋. 大采高煤层综采工作面采空区自燃“三带”立体分布规律研究[J]. 矿业安全与环保,2019,46(2):47−50. SHI Zhengfeng. Study on stereoscopic distribution law of spontaneous combustion“three-zone”in goaf of fully mechanized working face with large mining height[J]. Mining Safety & Environmental Protection, 2019, 46(2): 47−50.

[10] 王正帅. 复杂通风综采面采空区“三带”分布及防灭火参数研究[J]. 矿业研究与开发,2023,43(8):73−77. WANG Zhengshuai. Study on the distribution of three zones and fire prevention and extinguishing parameters in goaf of complex ventilation fully mechanized mining face[J]. Mining Research and Development, 2023, 43(8): 73−77.

[11] 张嘉麟,董子文. 基于COMSOL动态模型的采空区连续注氮模拟研究[J]. 矿业安全与环保,2019,46(2):15−19. ZHANG Jialin, DONG Ziwen. Simulation study on continuous nitrogen injection in goaf based on COMSOL dynamic model[J]. Mining Safety & Environmental Protection, 2019, 46(2): 15−19.

[12] 李尚国. 采空区氧化中心数值模拟[J]. 煤炭技术,2019,38(4):109−112. LI Shangguo. Numerical simulation of oxidation center in goaf[J]. Coal Technology, 2019, 38(4): 109−112.

[13] 齐庆杰,祁云,周新华. 供风量对采空区自燃动态影响及防灭火技术[J]. 中国安全科学学报,2019,29(4):120−126. QI Qingjie, QI Yun, ZHOU Xinhua. Dynamic effects of air supply volume on spontaneous combustion in goafs and fire prevention and extinguishing technology[J]. China Safety Science Journal, 2019, 29(4): 120−126.

[14] 李宗翔,刘宇,王政,等. 九道岭矿采空区注CO2防灭火技术数值模拟研究[J]. 煤炭科学技术,2018,46(9):153−157. LI Zongxiang, LIU Yu, WANG Zheng, et al. Study on numerical simulation of CO2 injection fire prevention and extinguishing technique in goaf of Jiudaoling mine[J]. Coal Science and Technology, 2018, 46(9): 153−157.

[15] 刘玉良,彭宝山,蒙文军,等. 浅埋深煤层采空区注氮防灭火技术[J]. 煤矿安全,2017,48(5):73−76. LIU Yuliang, PENG Baoshan, MENG Wenjun, et al. Goaf nitrogen injection fire-fighting technology of shallow buried depth coal seam[J]. Safety in Coal Mines, 2017, 48(5): 73−76.

[16] 邓军,李贝,王凯,等. 我国煤火灾害防治技术研究现状及展望[J]. 煤炭科学技术,2016,44(10):1−7. DENG Jun, LI Bei, WANG Kai, et al. Research status and outlook on prevention and control technology of coal fire disaster in China[J]. Coal Science and Technology, 2016, 44(10): 1−7.

[17] 余明高,王亮,李海涛,等. 我国煤矿防灭火材料的研究现状及发展趋势[J]. 矿业安全与环保,2022,49(4):22−36. YU Minggao, WANG Liang, LI Haitao et al. Research status and development trend of fire-extinguishing materials in Chinese coal mines[J]. Mining Safety & Environmental Protection, 2022, 49(4): 22−36.

[18] 谢军,张心静,徐书荣,等. 泡沫防灭火材料研究现状及发展趋势[J]. 煤炭技术,2023,42(1):129−132. XIE Jun, ZHANG Xinjing, XU Shurong, et al. Research status and development trend of foam fire prevention materials[J]. Coal Technology, 2023, 42(1): 129−132.

[19] 韩福志,邵和,司俊鸿,等. 矿用堵漏无机触变防灭火凝胶的流变特性研究[J]. 矿业安全与环保,2022,49(1):1−7. HAN Fuzhi, SHAO He, SI Junhong, et al. Study on rheological characteristics of inorganic thixotropic fire extinguishing gel for blocking air leakage of coal mine[J]. Mining Safety & Environmental Protection, 2022, 49(1): 1−7.

-

期刊类型引用(3)

1. 唐巨鹏,张昕,潘一山. 煤与瓦斯突出物理模拟试验研究现状及展望. 岩石力学与工程学报. 2024(03): 521-541 .  百度学术

百度学术

2. 张超林,王培仲,王恩元,许江,李忠辉,刘晓斐,彭守建. 我国煤与瓦斯突出机理70年发展历程与展望. 煤田地质与勘探. 2023(02): 59-94 .  百度学术

百度学术

3. 张文柯. 基于AHP-MCS的煤与瓦斯突出主控因素分析. 能源技术与管理. 2023(05): 126-127 .  百度学术

百度学术

其他类型引用(1)

下载:

下载: