Study on high temperature combustion characteristic parameters of coking coal with different particle sizes

-

摘要:

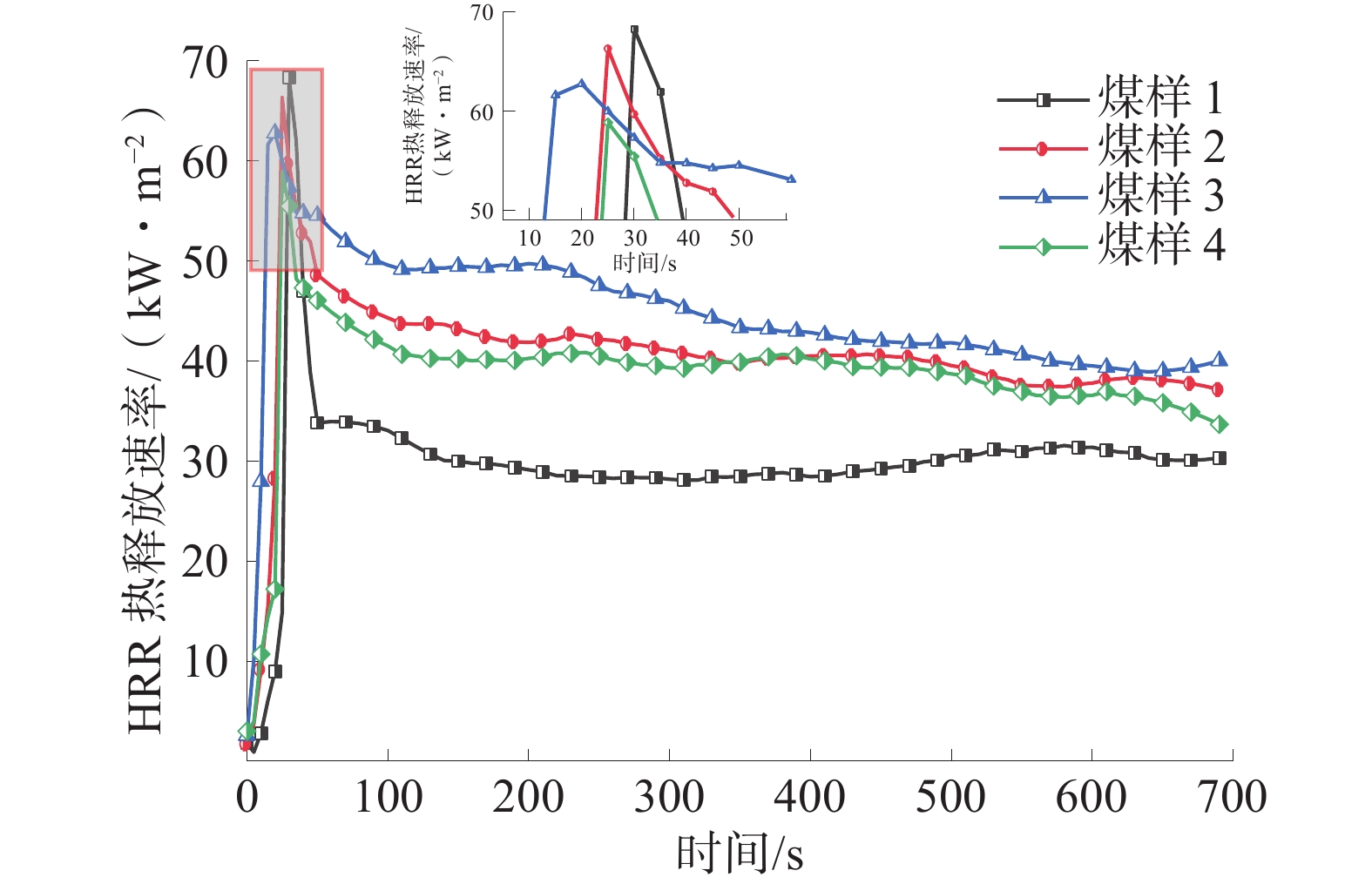

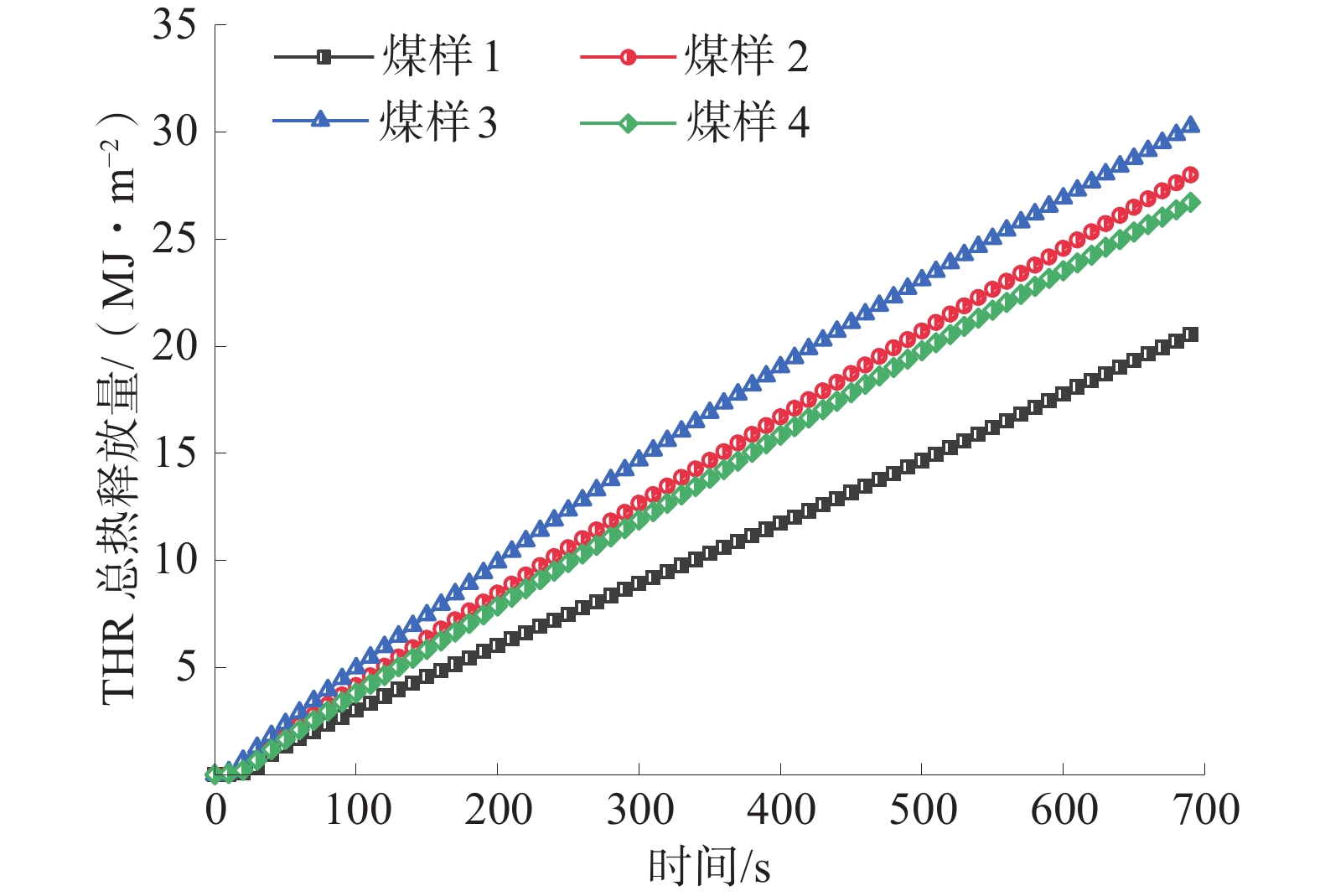

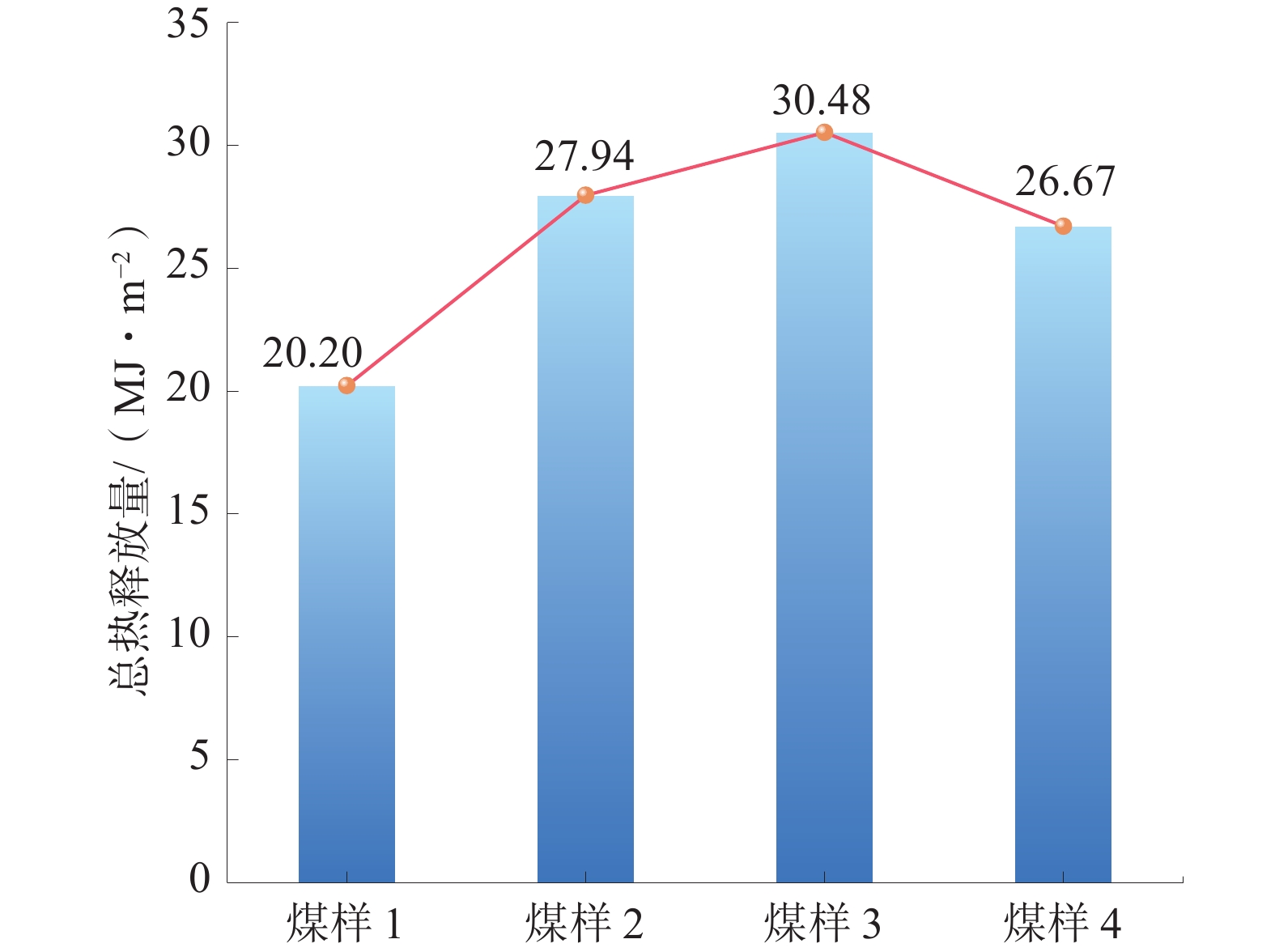

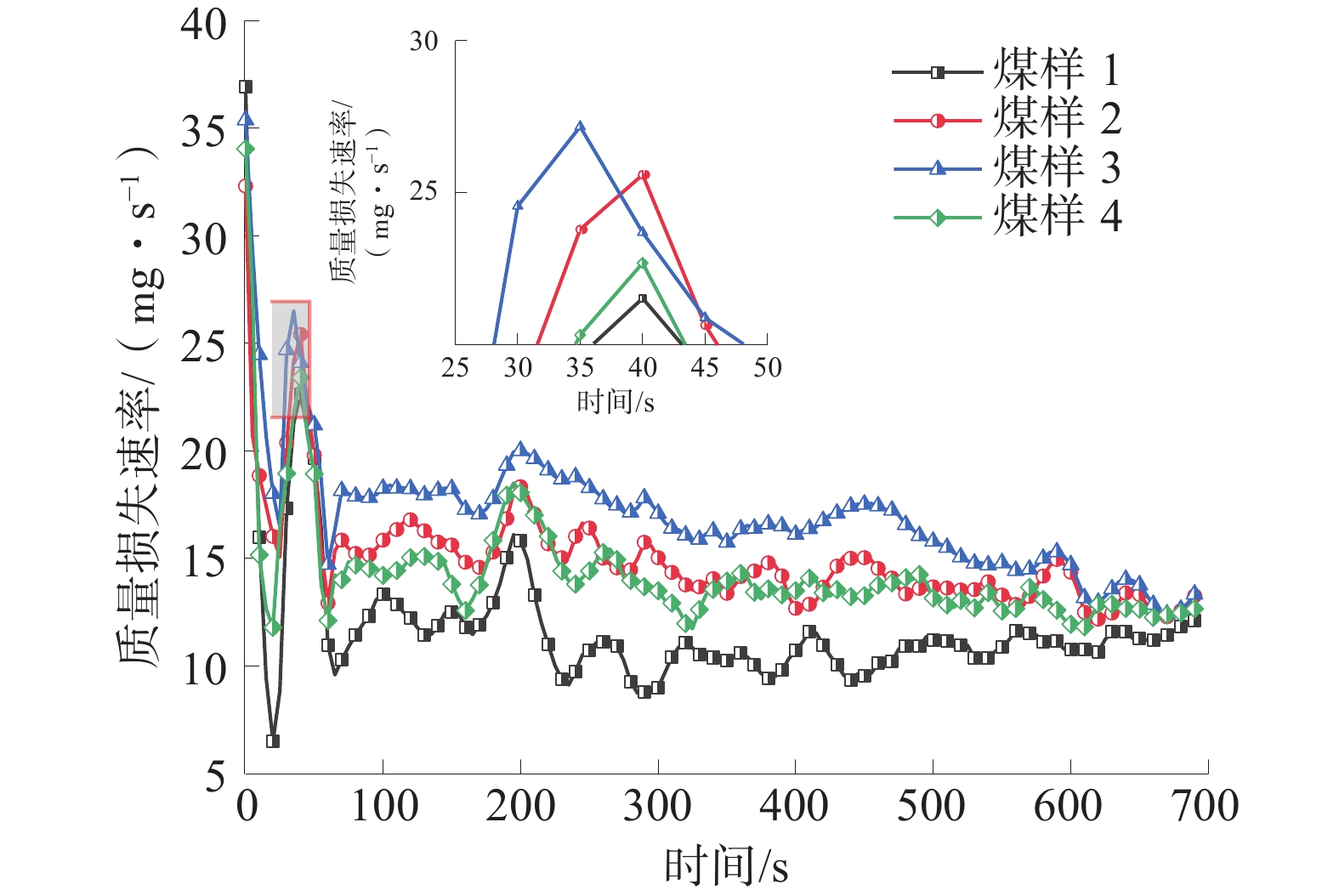

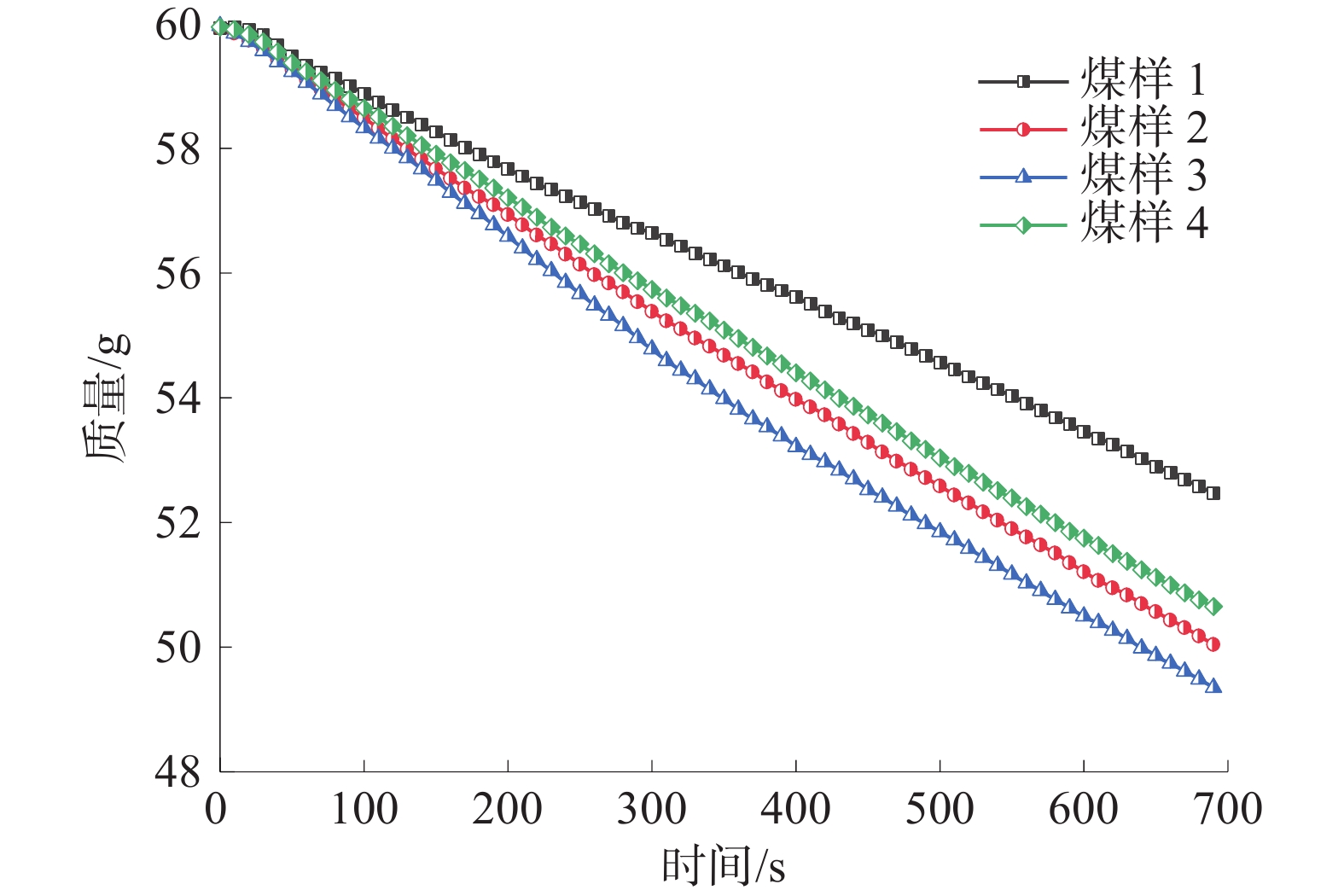

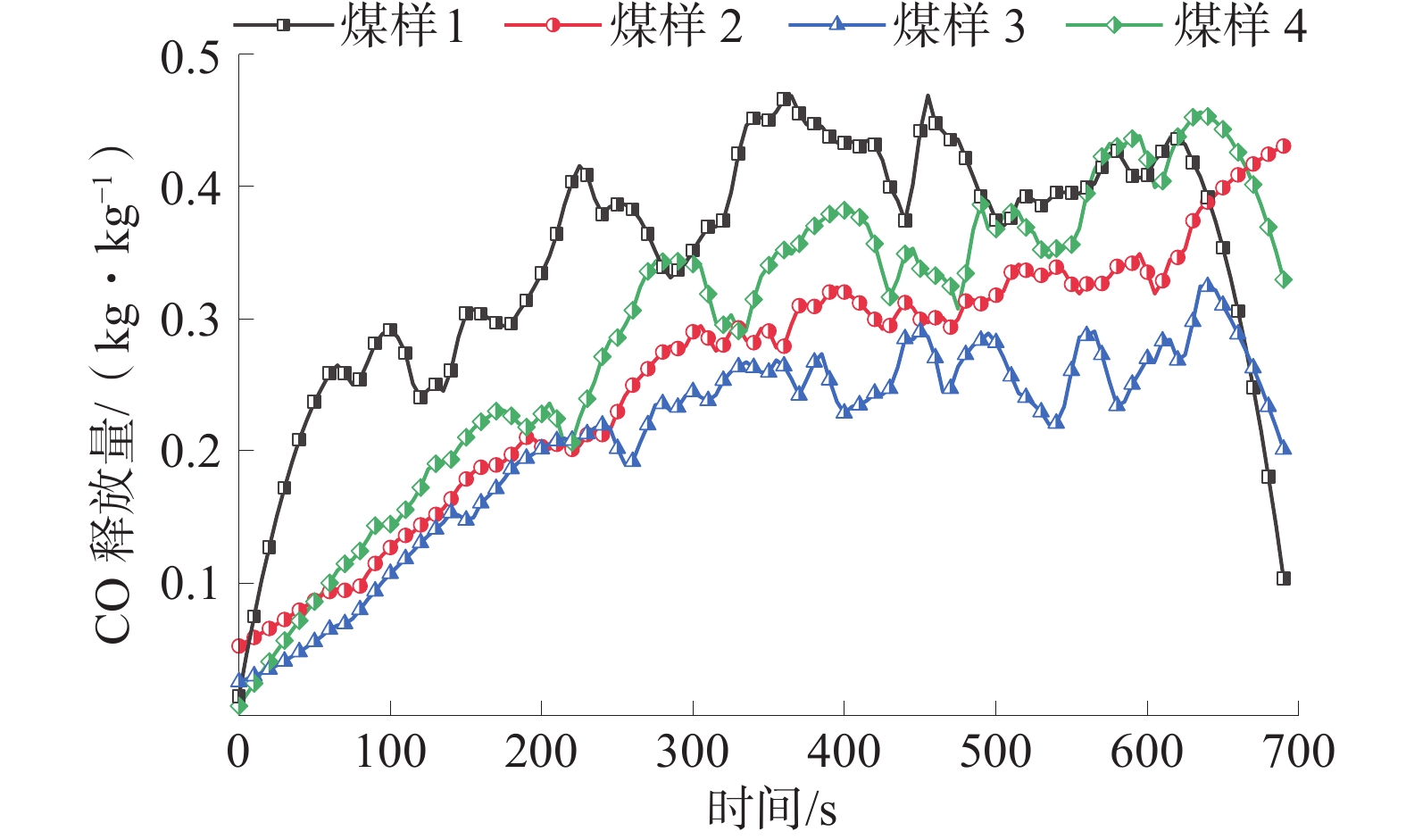

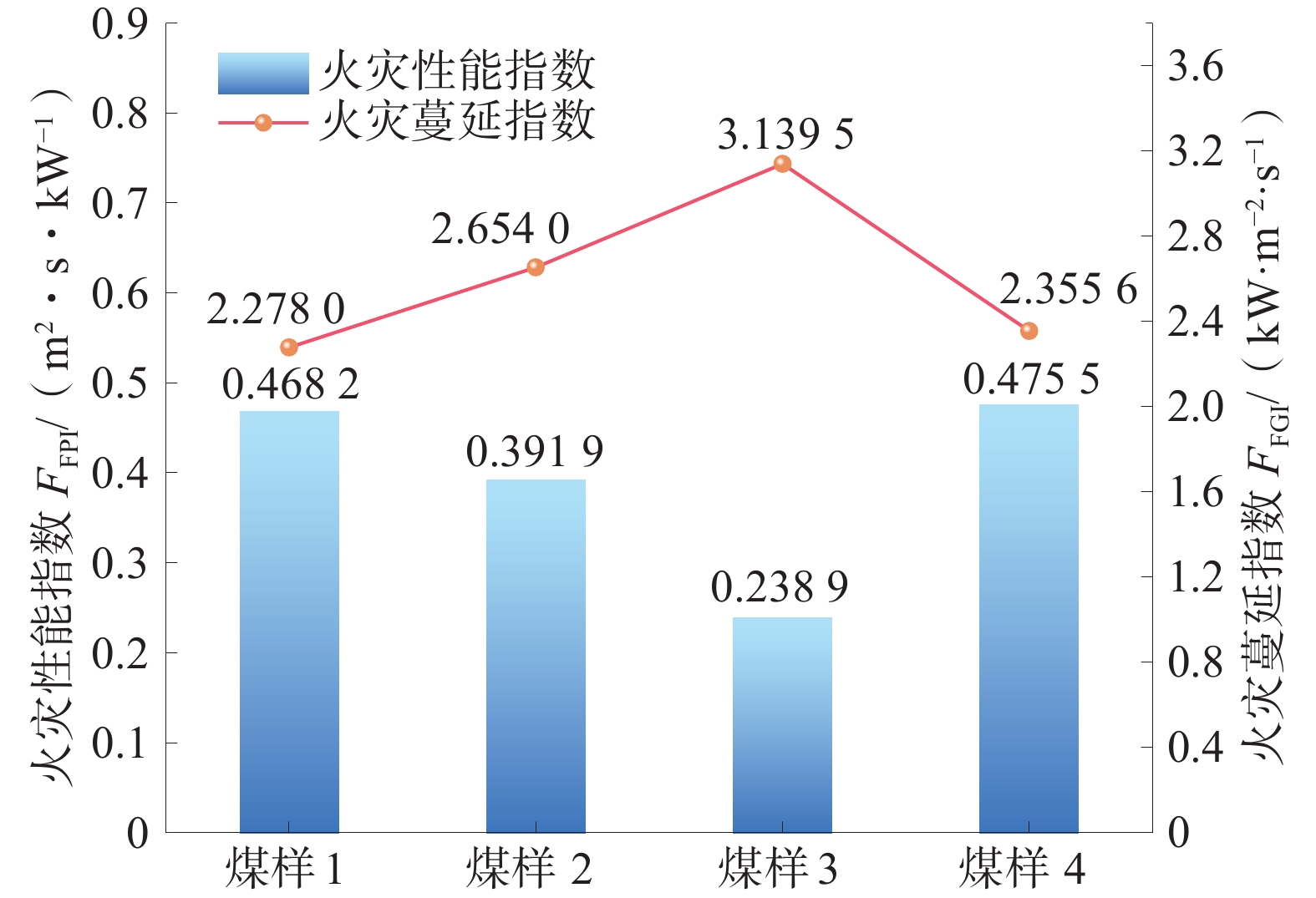

为研究不同粒径煤样在高温条件下的燃烧特性,利用锥形量热仪对粒径为0.200~0.450、0.125~0.200、0.097~0.125 mm的焦煤及其混合煤样的燃烧特性参数进行测试,并计算燃烧效率参数,分析其与煤样粒径之间的关系。结果表明:随着粒径的减小,点燃时间逐渐缩短,表明粒径越小越易燃烧;达到热释放速率峰值所需时间及峰值高低随粒径的减小而减小,其中混合煤样的峰值最低;当热释放速率曲线趋于平稳后,随着粒径的减小,热释放速率及总热释放量均呈增大趋势,且关系均为0.097~0.125 mm>0.125~0.200 mm>混合煤样>0.200~0.450 mm;质量损失速率峰值及稳定后的质量损失速率随粒径的减小而增大,总质量损失也随之增多,且关系均为0.097~0.125 mm>0.125~0.200 mm>混合煤样>0.200~0.450 mm;CO释放量随着粒径的减小呈减小趋势;随着粒径的减小,火灾性能指数逐渐减小,而火灾蔓延指数逐渐增大,其中混合煤样火灾性能指数最大,火灾蔓延指数略高于0.200~0.450 mm煤样;煤样粒径越小火灾危险性越大,混合煤样火灾危险性较低。

Abstract:In order to study the combustion characteristics of coal samples with different particle sizes under high temperature conditions, the combustion characteristic parameters of coking coal and its mixed coal samples with particle sizes of 0.200-0.450 mm, 0.125-0.200 mm and 0.097-0.125 mm were tested by cone calorimeter. The combustion efficiency parameters were calculated and the relationship between combustion efficiency parameters and the particle size of coal samples was analyzed. The results show that with the decrease of particle size, the ignition time becomes shorter, indicating that the smaller the particle size of the coal sample, the easier it is to burn; the time required to reach the peak value of heat release rate and the peak value decrease with the decrease of particle size, and the peak value of mixed coal sample is the lowest. When the heat release rate curve tends to be stable, the heat release rate and total heat release increase with the decrease of particle size, and the relationship is 0.097-0.125 mm > 0.125-0.200 mm > mixed coal sample >

0.2000 -0.450 mm; the peak value of mass loss rate and the stable mass loss rate increase with the decrease of particle size, and the total mass loss also increases, and the relationship is 0.097-0.125 mm > 0.125-0.200 mm > mixed coal sample > 0.200-0.450 mm. The CO release decreases with the decrease of particle size. With the decrease of particle size, the fire performance index decreases, while the fire spread index increases. The fire performance index of mixed coal sample is the largest, and the fire spread index is slightly higher than that of 0.200-0.450 mm coal sample; the fire risk increases with the decrease of coal particle size, and the fire risk of mixed coal sample is low. -

-

表 1 煤样工业分析结果

Table 1 Industrial analysis results of coal samples

煤样 水分/% 挥发分/% 灰分/% 固定碳/% 焦煤 0.96 26.70 12.02 60.16 表 2 不同粒径煤点燃时间

Table 2 Ignition time of coal with different particle sizes

煤样编号 1 2 3 4 点燃时间/s 32 26 15 28 -

[1] 邓军,白祖锦,肖旸,等. 煤自燃灾害防治技术现状与挑战[J]. 煤矿安全,2020,51(10):118−125. DENG Jun, BAI Zujin, XIAO Yang, et al. Present situation and challenge of coal spontaneous combustion disasters prevention and control technology[J]. Safety in Coal Mines, 2020, 51(10): 118−125.

[2] 秦波涛,仲晓星,王德明,等. 煤自燃过程特性及防治技术研究进展[J]. 煤炭科学技术,2021,49(1):66−99. QIN Botao, ZHONG Xiaoxing, WANG Deming, et al. Research progress of coal spontaneous combustion process characteristics and prevention technology[J]. Coal Science and Technology, 2021, 49(1): 66−99.

[3] 王德明,邵振鲁,朱云飞. 煤矿热动力重大灾害中的几个科学问题[J]. 煤炭学报,2021,46(1):57−64. WANG Deming, SHAO Zhenlu, ZHU Yunfei. Several scientific issues on major thermodynamic disasters in coal mines[J]. Journal of China Coal Society, 2021, 46(1): 57−64.

[4] 郭文杰. 煤自燃特性影响因素的试验研究[J]. 安全与环境学报,2018,18(4):1307−1311. GUO Wenjie. Experimental test and examination of the influential factors of the coal spontaneous combustion[J]. Journal of Safety and Environment, 2018, 18(4): 1307−1311.

[5] 贾廷贵,娄和壮,刘剑,等. 不同水分含量煤自燃过程热特性实验研究[J]. 煤炭学报,2020,45(S1):346−352. JIA Tinggui, LOU Hezhuang, LIU Jian, et al. Experimental study on thermal characteristics of spontaneous combustion process of coal with different moisture[J]. Journal of China Coal Society, 2020, 45(S1): 346−352.

[6] CAI Jiawen, YANG Shengqiang, ZHENG Wancheng, et al. Dissect the capacity of low-temperature oxidation of coal with different metamorphic degrees[J]. Fuel, 2021, 292: 120256.

[7] 杨涛,魏博,马金荣,等. 不同粒径准东煤CO2强化水洗脱钠及燃烧特性研究[J]. 动力工程学报,2022,42(7):589−594. YANG Tao, WEI Bo, MA Jinrong, et al. Study on sodium removal and combustion characteristics of Zhundong coal with different particle sizes washed by CO2 enhanced water[J]. Journal of Chinese Society of Power Engineering, 2022, 42(7): 589−594.

[8] 邓军,张宇轩,赵婧昱,等. 基于程序升温的不同粒径煤氧化活化能试验研究[J]. 煤炭科学技术,2019,47(1):214-219. DENG Jun, ZHANG Yuxuan, ZHAO Jingyu, et al. Experiment study on oxidation and activated energy of different partical size coal based on programmed temperature rising[J] Coal Science and Technology, 2019, 47(1): 214-219.

[9] 李德波,张远航,赵菁,等. O2/CO2气氛下煤粉燃烧特性及动力学分析[J]. 燃烧科学与技术,2018,24(3):223−231. LI Debo, ZHANG Yuanhang, ZHAO Jing, et al. Coal combustion characteristics and kinetics analysis in O2/ CO2 atmosphere[J]. Journal of Combustion Science and Technology, 2018, 24(3): 223−231.

[10] 何瑾瑶,单泽,奚志林. 粒度对煤低温氧化特性的影响[J]. 煤炭技术,2021,40(7):189−193. HE Jinyao, SHAN Ze, XI Zhilin. Influence of particle size on low-temperature oxidation characteristics of coal[J]. Coal Technology, 2021, 40(7): 189−193.

[11] 王勇强,陆方,周月桂. 粒径对贫煤空气分级NOX排放特性影响的试验研究[J]. 动力工程学报,2021,41(11):926−932. WANG Yongqiang, LU Fang, ZHOU Yuegui. Experimental study on the effect of coal particle sizes on NOX, emission characteristics of lean coal under air-staged combustion conditions[J]. Journal of Chinese Society of Power Engineering, 2021, 41(11): 926−932.

[12] 贾宏俊,金云灿,孙悦. 阳泉无烟煤不同粒径煤的孔隙结构试验研究[J]. 中国科技论文,2019,14(10):1050−1054. JIA Hongjun, JIN Yuncan, SUN Yue. Experimental study on pore structure of different size coal of Yangquan anthracite[J]. China Sciencepaper, 2019, 14(10): 1050−1054.

[13] ZHOU Buzhuang, YANG Shengqiang, JIANG Xiaoyuan, et al. Experimental study on oxygen adsorption capacity and oxidation characteristics of coal samples with different particle sizes[J]. Fuel, 2023, 331: 1230−1238.

[14] SUNG Y, MOON C, EOM S, et al. Coal-particle size effects on NO reduction and burnout characteristics with air-staged combustion in a pulverized coal-fired furnace[J]. Fuel, 2016, 182: 558−567. doi: 10.1016/j.fuel.2016.05.122

[15] 胡皓玮,祁桢尧,时敬军,等. 不同外部辐射热流下小尺寸原木燃烧特性实验研究[J]. 清华大学学报(自然科学版),2022,62(6):1023−1030. HU Haowei, QI Zhenyao, SHI Jingjun, et al. Experimental investigation of the burning behavior of small logs with various external radiative heat fluxes[J]. Journal of Tsinghua University (Science and Technology), 2022, 62(6): 1023−1030.

[16] 李国栋,张廷尧,曾柱楷,等. 低氧稀释条件下不同煤种着火燃烧特性实验研究[J]. 动力工程学报,2021,41(6):439−445. LI Guodong, ZHANG Tingyao, ZENG Zhukai, et al. Experimental investigation on the ignition and combustion characteristics of different coal ranks under low-oxygen dilution conditions[J]. Journal of Chinese Society of Power Engineering, 2021, 41(6): 439−445.

[17] 王文才,姜宇鸿,张博,等. 巷道中煤燃烧时热释放速率的研究[J]. 煤矿安全,2013,44(12):40−42. WANG Wencai, JIANG Yuhong, ZHANG Bo, et al. Study on heat release rate of coal combustion in tunnel[J]. Safety in Coal Mines, 2013, 44(12): 40−42.

[18] 李文军,陈姗姗,陈艳鹏,等. 基于热重的煤热解反应动力学试验研究[J]. 中国煤炭,2020,46(3):84−89. LI Wenjun, CHEN Shanshan, CHEN Yanpeng, et al. Experimental study on coal pyrolysis kinetics based on thermogravimetry analysis[J]. China Coal, 2020, 46(3): 84−89.

[19] ZHANG Leilin, BIAN Yunpeng, KUAI Duolei. Preparation and flame retardant property of nano-aluminum hydroxide foam for preventing spontaneous coal combustion[J]. Fuel, 2021, 304: 121494. doi: 10.1016/j.fuel.2021.121494

[20] 陈龙,张嬿妮. 氧浓度对煤低温氧化热效应影响规律研究[J]. 中国安全生产科学技术,2020,16(6):49−54. CHEN Long, ZHANG Yanni. Study on influence laws of oxygen concentration on thermal effect of coal low-temperature oxidation[J]. Journal of Safety Science and Technology, 2020, 16(6): 49−54.

[21] 文虎,陆彦博,刘文永. 利用热重法研究不同氧浓度对煤自燃特性的影响[J]. 矿业安全与环保,2021,48(1):1−5. WEN Hu, LU Yanbo, LIU Wenyong. Study on the effects of different oxygen concentrations on spontaneous combustion characteristics of coal with thermogravimetric method[J]. Mining Safety & Environmental Protection, 2021, 48(1): 1−5.

[22] 尤飞,皇甫文豪,王振华,等. 基于热重分析的煤升温氧化及煤氧复合特性分析[J]. 安全与环境学报,2018,18(4):1312−1315. YOU Fei, HUANGFU Wenhao, WANG Zhenhua, et al. Analytic investigation of the coal self-combustion and oxidation characteristic features based on the thermogravimetric analysis[J]. Journal of Safety and Environment, 2018, 18(4): 1312−1315.

[23] 王凤双,杨胜强,李珍宝,等. 不同粒径煤样低温氧化过程升温速率规律研究[J]. 煤炭科学技术,2014,42(5):62−64. WANG Fengshuang, YANG Shengqiang, LI Zhenbao, et al. Study on low-temperature oxidation heating rate regularity of coal samples with different particle size[J]. Coal Science and Technology, 2014, 42(5): 62−64.

[24] 彭扬凡,陈姗姗,孙粉锦,等. 基于热重法的大颗粒煤热解反应动力学[J]. 洁净煤技术,2021,27(6):128−133. PENG Yangfan, CHEN Shanshan, SUN Fenjin, et al. Investigation on the kinetics of pyrolysis reaction of large coal particles based on TGA[J]. Clean Coal Technology, 2021, 27(6): 128−133.

[25] SHEN Li, ZENG Qiang. Investigation of the kinetics of spontaneous combustion of the major coal seam in Dahuangshan mining area of the Southern Junggar coalfield, Xinjiang, China[J]. Scientific Reports, 2021, 11(1): 1−12. doi: 10.1038/s41598-020-79139-8

[26] 刘国磊,牛俊粉,崔嵛,等. 喷涂油漆在薄金属表面燃烧特性研究[J]. 消防科学与技术,2022,41(12):1619−1622. LIU Guolei, NIU Junfen, CUI Yu, et al. Study on combustion characteristics of spray paint on thin metal surface[J]. Fire Science and Technology, 2022, 41(12): 1619−1622.

[27] 邓军,屈高阳,任帅京,等. 松散煤体中低频声波传声频率优选实验研究[J]. 煤矿安全,2022,53(1):15−23. DENG Jun, QU Gaoyang, REN Shuaijing, et al. Experimental study on optimization of low frequency acoustic transmission frequency in loose coal[J]. Safety in Coal Mines, 2022, 53(1): 15−23.

-

期刊类型引用(3)

1. 唐巨鹏,张昕,潘一山. 煤与瓦斯突出物理模拟试验研究现状及展望. 岩石力学与工程学报. 2024(03): 521-541 .  百度学术

百度学术

2. 张超林,王培仲,王恩元,许江,李忠辉,刘晓斐,彭守建. 我国煤与瓦斯突出机理70年发展历程与展望. 煤田地质与勘探. 2023(02): 59-94 .  百度学术

百度学术

3. 张文柯. 基于AHP-MCS的煤与瓦斯突出主控因素分析. 能源技术与管理. 2023(05): 126-127 .  百度学术

百度学术

其他类型引用(1)

下载:

下载: