Research and development of anti-high pressure sealing material and sealing characteristics in hydraulic fracturing borehole

-

摘要:

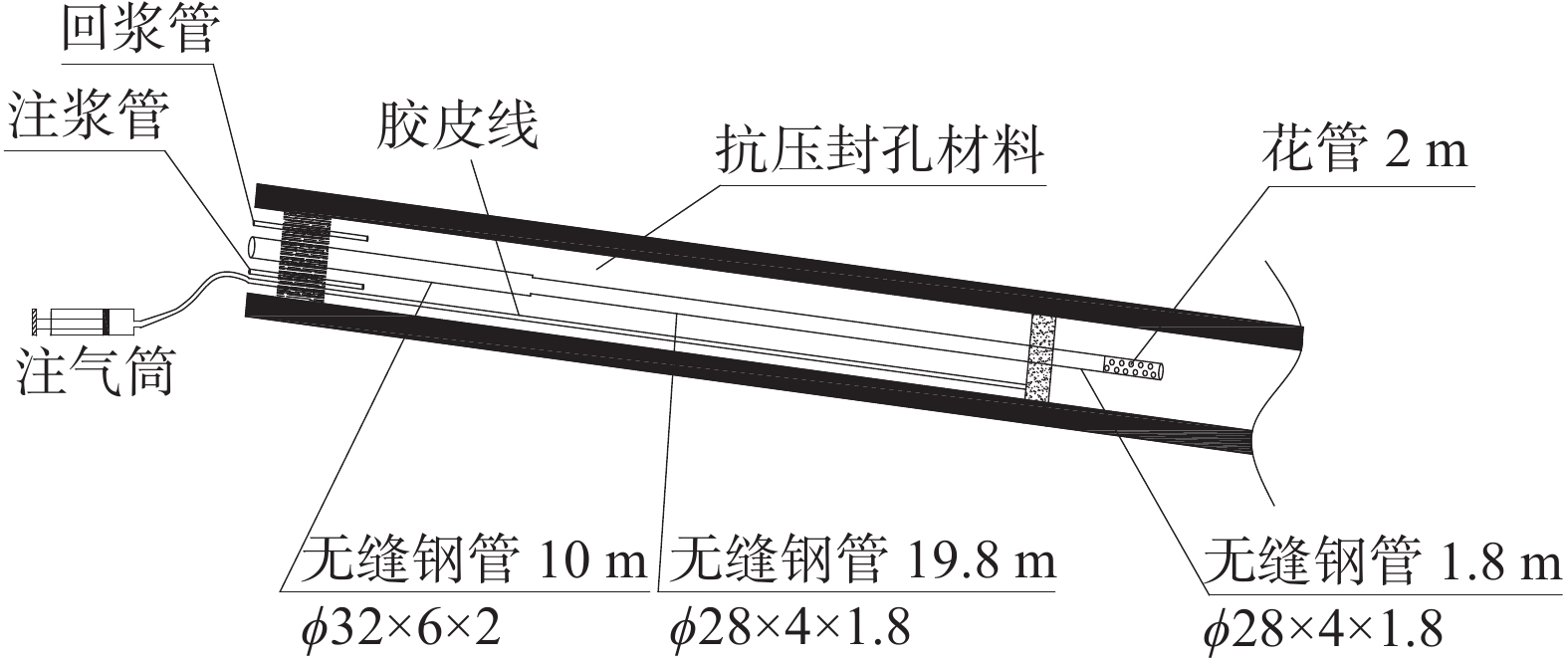

为解决因封孔质量不达标导致的水力压裂卸压增透技术在井下现场应用的难题,在总结国内外抗高压封孔材料及封孔方法的基础上,通过系统性基础实验,探究了普通水泥添加特种复合水泥、膨胀剂和减水剂等辅助材料对抗高压封孔材料的凝结时间、流动性、抗压强度以及膨胀倍率等基础性能的影响规律。研究表明:抗高压封控材料最佳水灰比为0.5,特种复合水泥添加量为20%~25%,复合膨胀剂添加量为4%,萘系减水剂添加量为1.6%时,抗高压封孔材料在保障流动度及膨胀倍率前提下呈现早强高强特性。为验证新材料性能,在龙煤集团平岗煤矿进行现场工业性试验,其凝固时间及抗压强度等参数均达到性能要求。

Abstract:In order to solve the problem of hydraulic fracturing presure relief and permeability improvement technology applied in underground field due to the substandard sealing and control quality, in this paper, on the basis of summarizing the existing hole sealing materials and sealing methods at home and abroad, through a large number of basic experiments, the influence of auxiliary materials such as ordinary cement added with special composite cement, swelling agent and water reducing agent on the basic properties of anti-high pressure sealing materials such as setting time, fluidity, compressive strength and swelling multiplication rate was studied. The best water-cement ratio of 0.5, 20%-25% of special composite cement, 4% of compound expander and 1.6% of naphthalene water reducer were determined to ensure the early strength and high strength of the anti-high-pressure sealing material with the premise of flowability and expansion rate. It also conducted on-site industrial experiments in Pinggang Coal Mine of Longmei Coal Group, and its parameters such as solidification time and compressive strength met the performance requirements.

-

-

表 1 封孔材料的基本参数

Table 1 Basic parameters of sealing material

普通硅酸盐水泥

含量/%特种水泥

含量/%流动度/

mm凝固时间/

min抗压强度/

MPa初凝 终凝 1 d 3 d 95 5 279 410 664 6.8 8.8 90 10 281 230 342 13.0 16.7 85 15 288 118 159 17.9 22.5 80 20 293 82 98 22.8 31.3 75 25 292 72 88 24.1 32.7 70 30 292 60 76 23.4 32.1 65 35 291 50 63 22.6 29.8 60 40 287 38 46 21.8 28.8 55 45 282 28 34 20.2 26.5 表 2 膨胀剂的掺量对封孔材料的影响

Table 2 Influence of swelling agent content on sealing material

膨胀剂添加量/% 流动度/

mm凝固时间/min 膨胀倍率/% 初凝 终凝 1 282 71 83 5 2 261 67 77 10 3 245 62 70 15 4 223 55 61 16 5 194 54 57 18 6 171 51 55 22 表 3 平岗煤矿压裂钻孔参数

Table 3 Parameters of fracturing hole in Pinggang Coal Mine

孔号 水平角/(°) 仰角/(°) 孔径/mm 封孔长度/m 孔深/m 1 0 −8 89 18 127.5 2 0 −9 89 21 101.0 3 0 −8 89 24 123.0 -

[1] 袁亮. 我国煤炭工业高质量发展面临的挑战与对策[J]. 中国煤炭,2020,46(1):6−12. YUAN Liang. Challenges and countermeasures for high quality development of China’s coal industry[J]. China Coal, 2020, 46(1): 6−12.

[2] 袁亮. 我国煤炭主体能源安全高质量发展的理论技术思考[J]. 中国科学院院刊,2023,38(1):11−22. YUAN Liang. Theory and technology considerations on high-quality development of coal main energy security in China[J]. Bulletin of Chinese Academy of Sciences, 2023, 38(1): 11−22.

[3] 曹垚林. 水力化技术防治煤与瓦斯突出研究现状及展望[J]. 煤矿安全,2020,51(10):60−66. CAO Yaolin. Research status and prospect of coal and gas outburst prevention and control by hydraulic technology[J]. Safety in Coal Mines, 2020, 51(10): 60−66.

[4] 郑凯歌. 碎软低透煤层底板梳状长钻孔分段水力压裂增透技术研究[J]. 采矿与安全工程学报,2020,37(2):272−281. ZHENG Kaige. Permeability improving technology by sectional hydraulic fracturing for comb-like long drilling in floor of crushed and soft coal seam with low permeability[J]. Journal of Mining & Safety Engineering, 2020, 37(2): 272−281.

[5] 张超,延婧,李树刚,等. 瓦斯抽采钻孔动态密封黏液型材料实验研究[J]. 采矿与安全工程学报,2022,39(5):1033−1040. ZHANG Chao, YAN Jing, LI Shugang, et al. Experimental study on dynamic sealing of mucilage material in gas extraction borehole[J]. Journal of Mining & Safety Engineering, 2022, 39(5): 1033−1040.

[6] 王帅. 新型瓦斯抽采钻孔保压封孔技术[J]. 煤矿安全,2021,52(7):61−66. WANG Shuai. A new pressure maintaining and sealing technology for gas drainage borehole[J]. Safety in Coal Mines, 2021, 52(7): 61−66.

[7] 杨伟东,霍中刚,舒龙勇,等. 瓦斯抽采钻孔封孔段注浆密封全过程分析[J]. 煤矿安全,2021,52(10):1−6. YANG Weidong, HUO Zhonggang, SHU Longyong, et al. Analysis of the whole process of grouting sealing for gas extraction drilling hole sealing section[J]. Safety in Coal Mines, 2021, 52(10): 1−6.

[8] 孙志东,马耕,孙玉宁. 瓦斯抽采注浆封孔器定值爆破阀设计[J]. 煤矿安全,2021,52(4):137−141. SUN Zhidong, MA Geng, SUN Yuning. Design of fixed blast valve for gas extraction grouting sealing device[J]. Safety in Coal Mines, 2021, 52(4): 137−141.

[9] 姚壮壮,林府进,武文宾,等. 采煤工作面顺层钻孔分段水力压裂增渗试验[J]. 煤矿安全,2021,52(3):9−13. YAO Zhuangzhuang, LIN Fujin, WU Wenbin, et al. Permeability enhancement test of staged hydraulic fracturing of bedding drilling borehole in working face[J]. Safety in Coal Mines, 2021, 52(3): 9−13.

[10] 刘浩,周晓华,刘旗旗. 煤层注水封孔材料优化[J]. 煤炭技术,2018,37(3):166−167. LIU Hao, ZHOU Xiaohua, LIU Qiqi. Optimization of sealing material for coal seam water injection[J]. Coal Technology, 2018, 37(3): 166−167.

[11] 黄旭超,王正帅,陈建杰,等. 煤层群联合压裂增透石门快速揭煤技术研究与应用[J]. 煤炭科学技术,2018,46(6):52−56. HUANG Xuchao, WANG Zhengshuai, CHENG Ji-anjie, et al. Research and application of rapid seam opening technology to crosscut in seam group with combined fracturing and permeability improvement[J]. Coal Science and Technology, 2018, 46(6): 52−56.

[12] 王志明,孙玉宁,宋维宾,等. 瓦斯抽采二次膨胀封孔材料膨胀机理及应用研究[J]. 中国安全生产科学技术,2018,14(12):28−33. WANG Zhiming, SUN Yuning, SONG Weibin, et al. Study on expansion mechanism and application of double-expansive material for borehole sealing in gas drainage[J]. Journal of Safety Science and Technology, 2018, 14(12): 28−33.

[13] 王杰,张雷林,伍清. 新型爆破封孔材料的制备与应用[J]. 煤矿安全,2018,49(3):56−59. WANG Jie, ZHANG Leilin, WU Qing. Preparation and application of new sealing material for blasting[J]. Safety in Coal Mines, 2018, 49(3): 56−59.

[14] 吴海龙,刘健,吉小利,等. 新型硫酸锂复合早强剂对煤矿封孔水泥早强效果的影响研究[J]. 中国安全生产科学技术,2014,10(8):34−38. WU Hailong, LIU Jian, JI Xiaoli, et al. Study on influence to early strength performance of hole sealing cement used in coal mine by new lithium sulfate compound early strength agent[J]. Journal of Safety Science and Technology, 2014, 10(8): 34−38.

[15] 肖乔,余晓康,冯康武,等. “两堵一注”带压封孔工艺在龙门峡南煤矿的研究与应用[J]. 中国煤炭,2020,46(6):52−56. XIAO Qiao, YU Xiaokang, FENG Kangwu, et al. Research and application of “double-sealing and single-grouting” hole sealing technique with pressure in Longmen Gorge South Coal Mine[J]. China Coal, 2020, 46(6): 52−56.

[16] 张钧祥,宋维宾,孙玉宁,等. 新型高分子泡沫堵漏材料试验研究及工程应用[J]. 煤炭学报,2018,43(S1):158−166. ZHANG Junxiang, SONG Weibin, SUN Yuning, et al. Experimental study and application of new polymer foam plugging material[J]. Journal of China Coal Society, 2018, 43(S1): 158−166.

[17] ZHOU Fubao, SHI Bobo, LIU Yingke, et al. Coating material of air sealing in coal mine: Clay composite slurry (CCS)[J]. Applied Clay Science, 2013, 80/81: 299−304. doi: 10.1016/j.clay.2013.05.001

[18] 张昊,胡相明,王伟,等. 黄原胶和氧化镁改性黏土-水泥基新型喷涂堵漏风材料的制备及特征[J]. 煤炭学报,2021,46(6):1768−1780. ZHANG Hao, HU Xiangming, WANG Wei, et al. Preparation and characteristics of xanthan gum and MgO modified clay-cement based new spraying material of gas sealing[J]. Journal of China Coal Society, 2021, 46(6): 1768−1780.

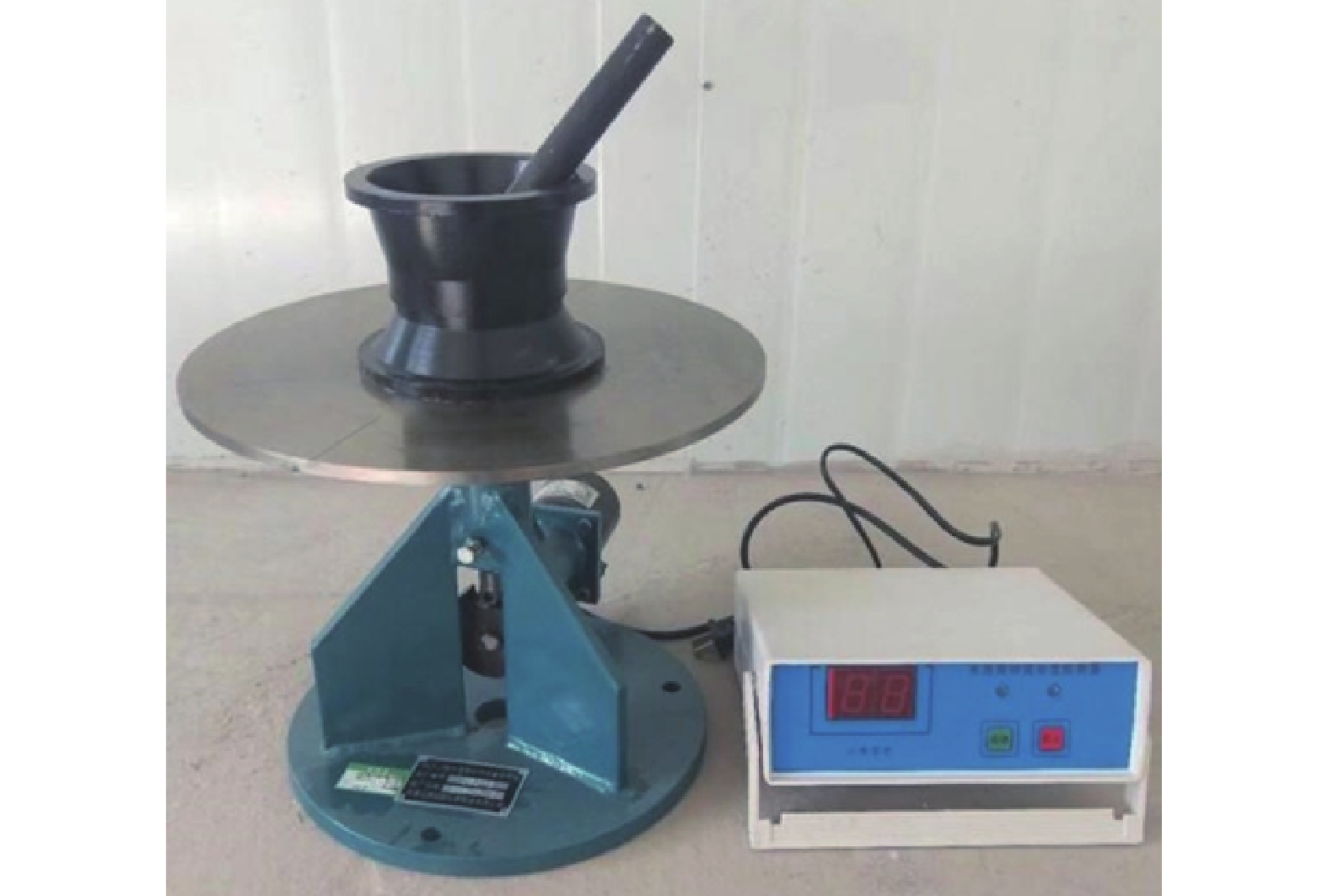

[19] GB/T 2419—2016水泥胶砂流动度测定方法[S]. [20] 刘慧妮,李训刚,李彦志,等. 煤矿巷道围岩注浆堵水新型水泥浆液性能研究[J]. 煤矿安全,2021,52(10):57−63. LIU Huini, LI Xungang, LI Yanzhi, et al. Research on performance of new type cement slurry for water shutoff in coal mine roadway[J]. Safety in Coal Mines, 2021, 52(10): 57−63.

-

期刊类型引用(7)

1. 崔忠麒,徐娅煊,苏皓. 基于Stacking-SHAP的煤自燃倾向性影响因素研究. 煤炭技术. 2025(01): 150-155 .  百度学术

百度学术

2. 孙吉平. 基于SF_6质量浓度变化特征的煤矿火灾状态识别分析. 山西煤炭. 2025(01): 42-49 .  百度学术

百度学术

3. 曹富荣,吴学松,李军,付天予,刘佳伟,李志辉,杨小彬. 基于机器学习的多气体指标煤自燃温度预测. 煤矿安全. 2024(04): 106-113 .  本站查看

本站查看

4. 樊永勇,王新瑞,张春雷. 急倾斜特厚煤层分段采空区低温氮气防灭火技术研究与实践. 能源与环保. 2024(11): 254-262 .  百度学术

百度学术

5. 武泽伟,汪伟,祁云,梁然. 采空区遗煤自燃影响因素分析及风险评价. 山西大同大学学报(自然科学版). 2023(04): 116-122 .  百度学术

百度学术

6. 孔彪,朱思想,胡相明,杨涛,赵旭帅,斐达特,万姝含. 基于改进鲸鱼算法优化BP神经网络的煤自燃预测研究. 矿业安全与环保. 2023(05): 30-36 .  百度学术

百度学术

7. 陈鹏燕,周春山,程熙宇,田雅琪. 全物理交联Al~(3+)-CMC/MMT-PAM双网络凝胶的制备及性能. 矿业研究与开发. 2023(11): 143-149 .  百度学术

百度学术

其他类型引用(2)

下载:

下载: