Research on dust control mechanism of fully-mechanized mining face based on a new air distribution dust control method

-

摘要:

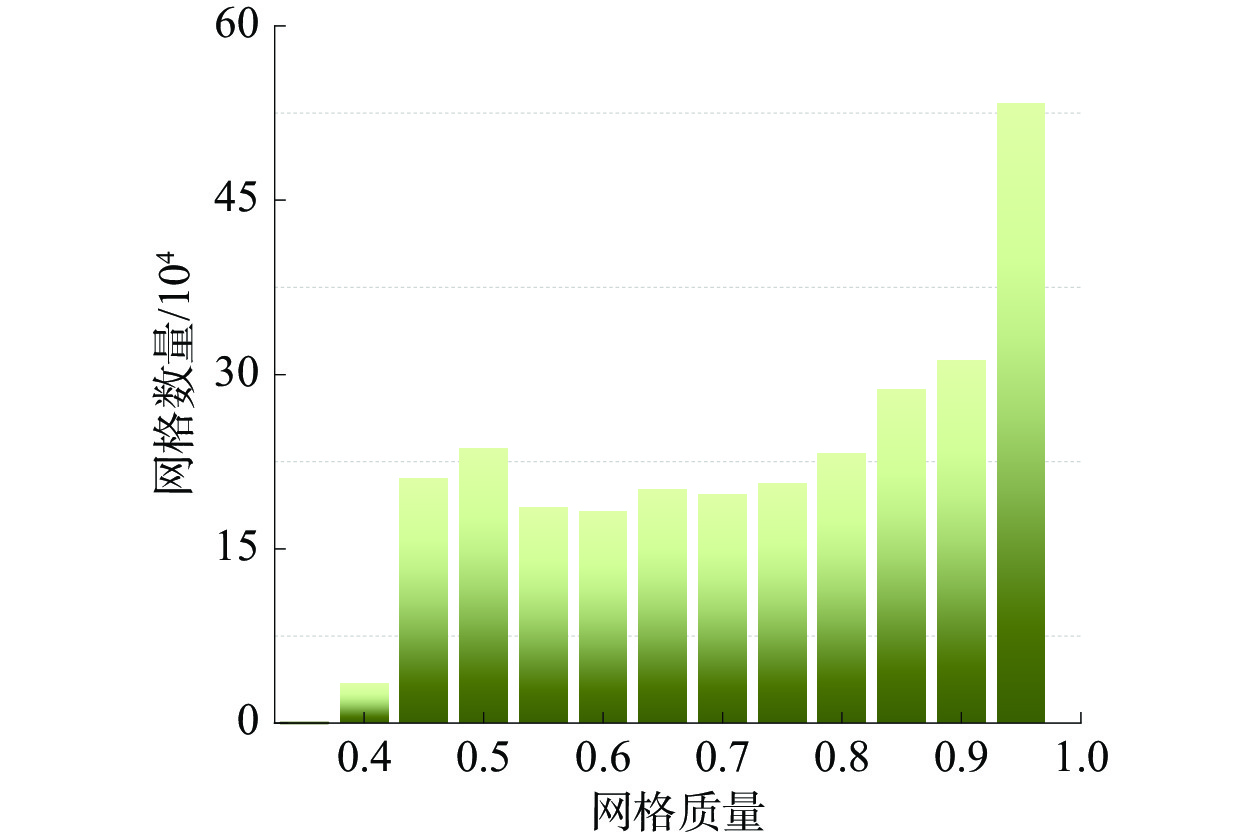

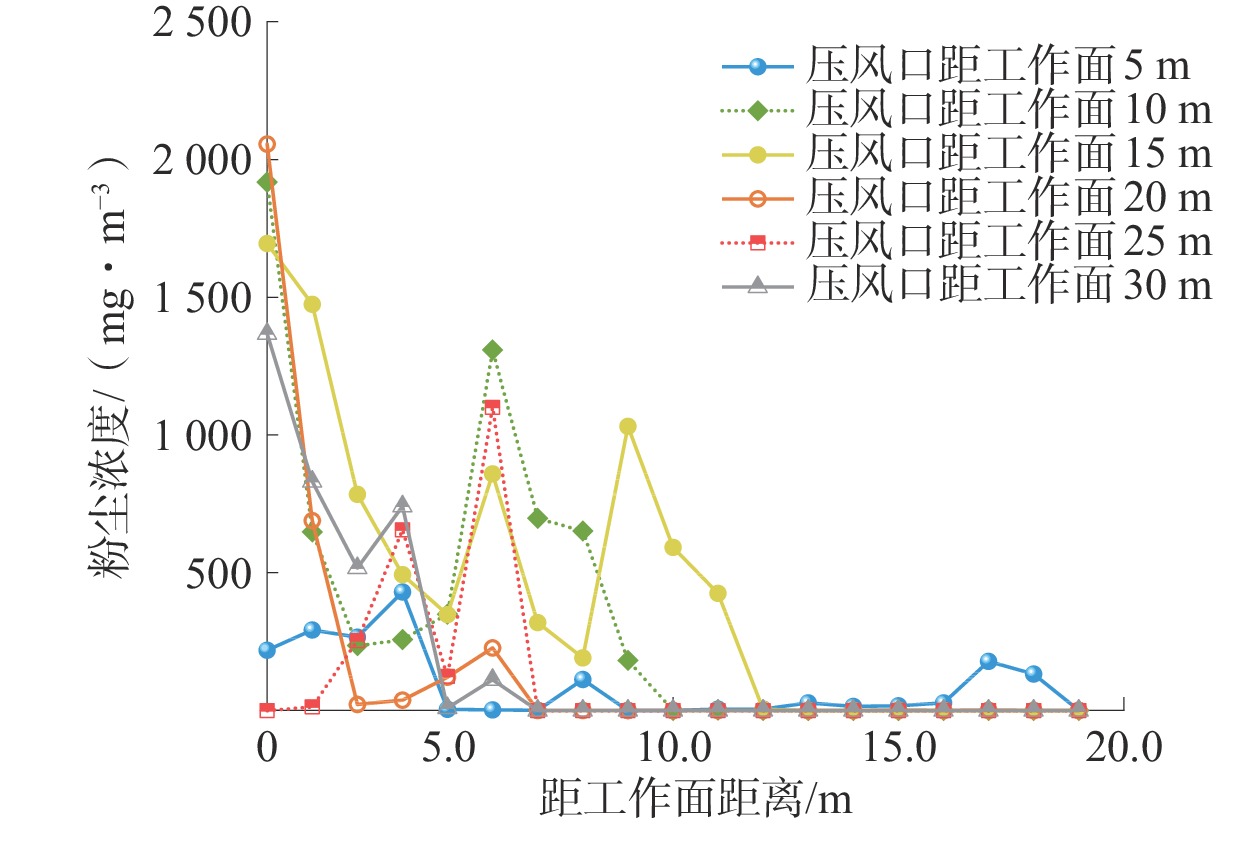

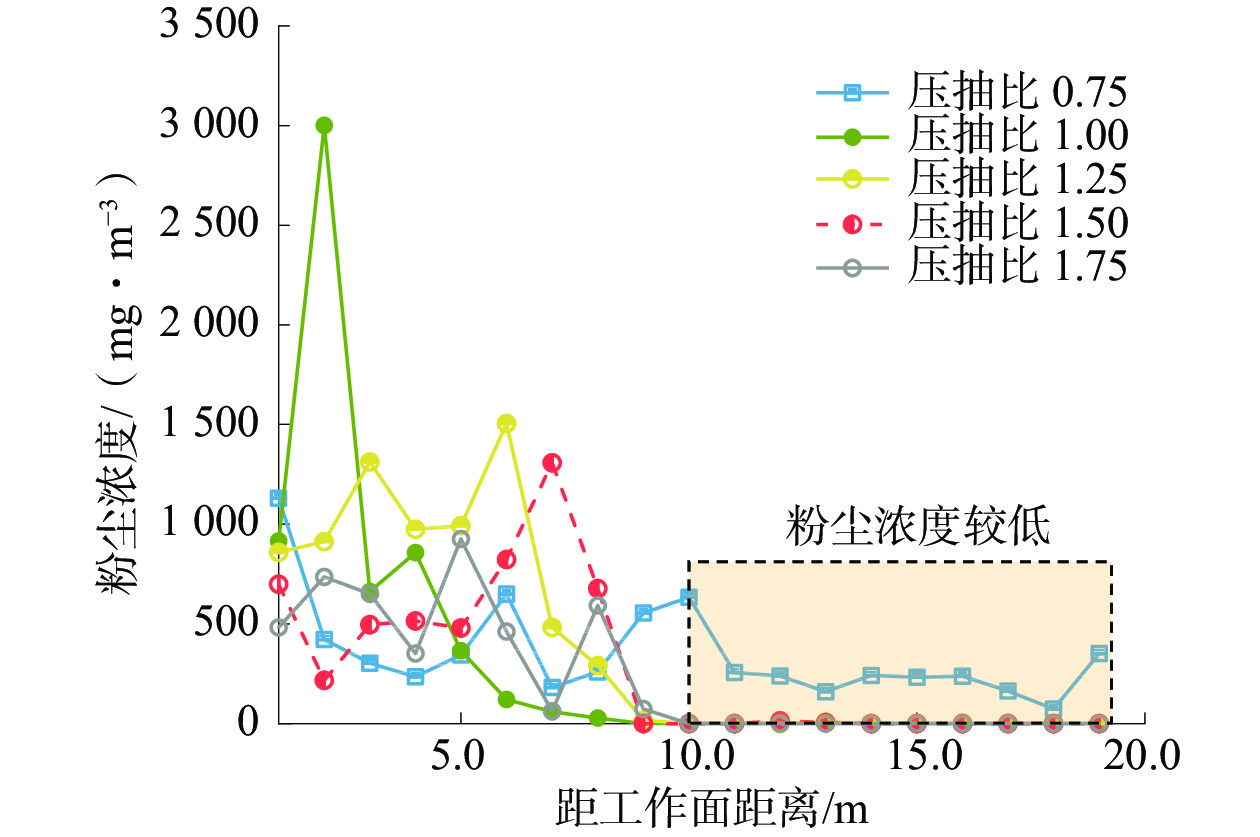

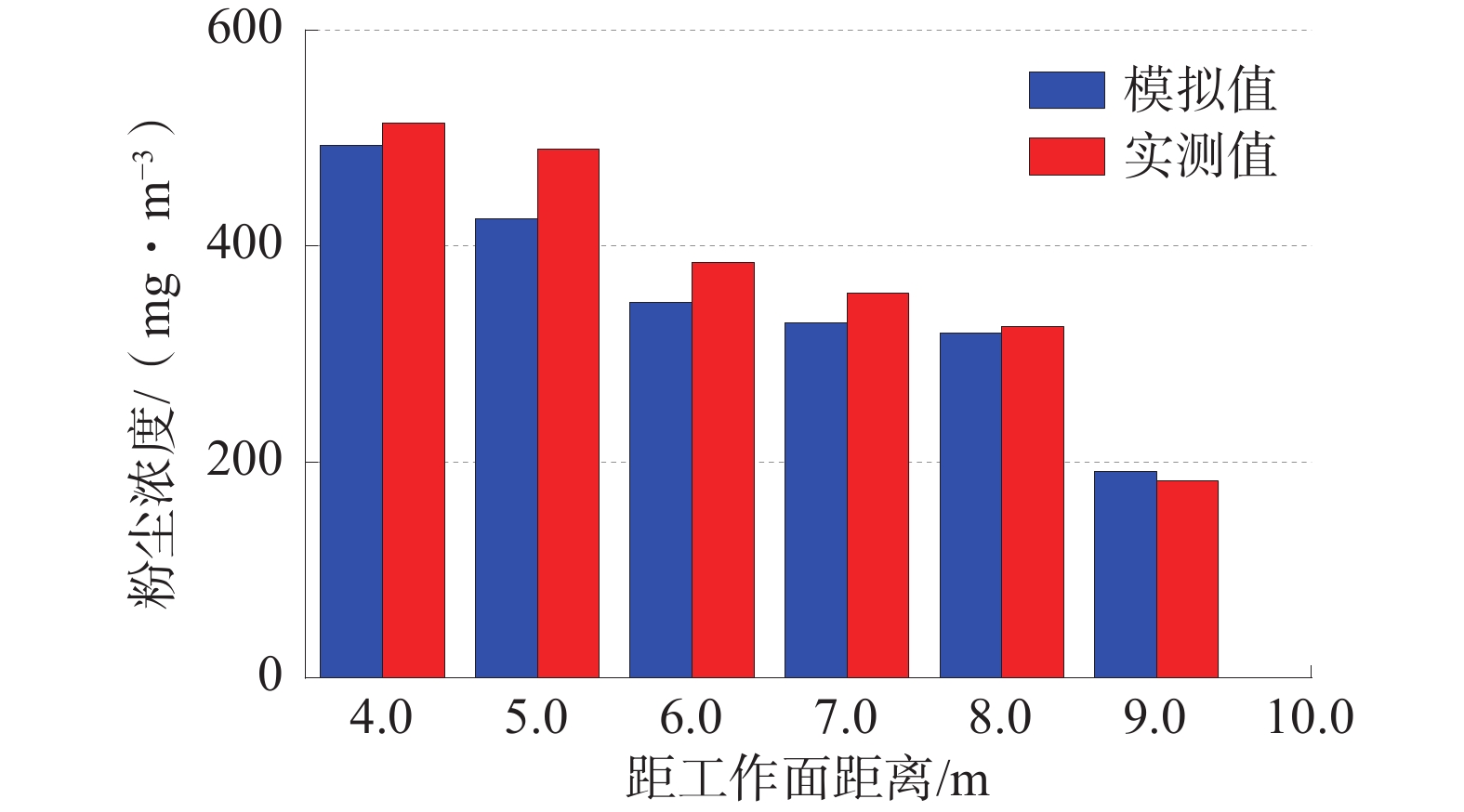

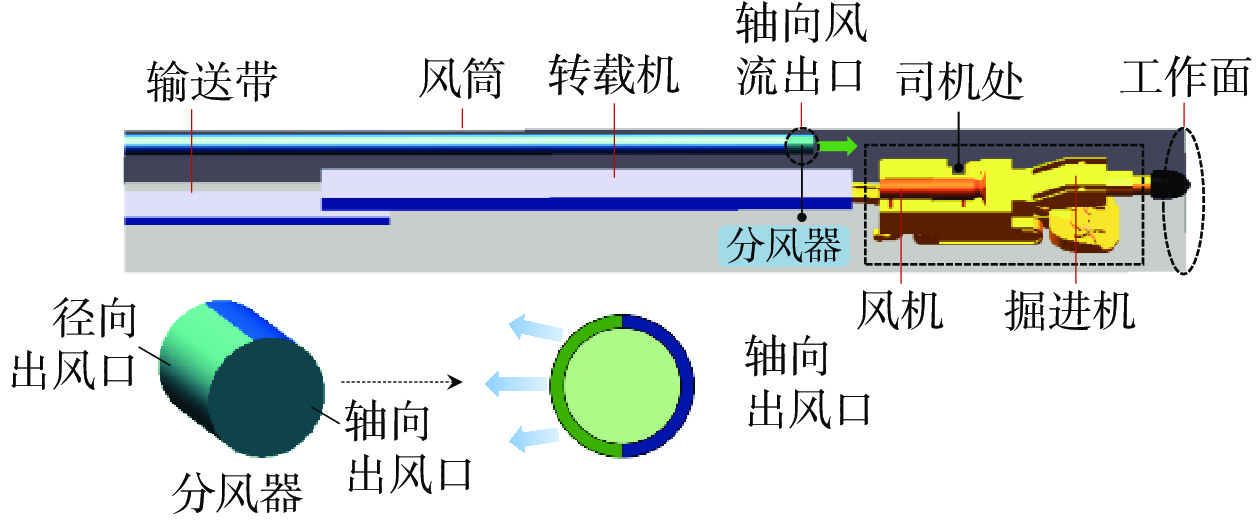

为改善综掘工作面粉尘污染严重的问题,针对陕西榆林大柳塔煤矿综掘工作面,提出一种安装有分风器的新型分风控尘方法,利用Fluent对使用新型分风控尘方法的粉尘扩散规律进行模拟,分析压风口距工作面不同距离及不同压抽比对粉尘扩散规律变化的影响。结果表明:当压风口距工作面10~20 m时,粉尘积聚、沉降在工作面区域巷道底部,司机处粉尘浓度较低,控尘效果较好;固定压风口距工作面的距离为10 m,压抽比为1.0时,高浓度粉尘积聚在工作面区域,司机处粉尘浓度控制在50 mg/m3以下,控尘效果较好;通过现场实测,粉尘浓度与模拟结果的误差小于15.2%。

Abstract:In order to improve the problem of serious dust pollution in the fully-mechanized mining face, a new air distribution dust control method with air separator installed was proposed for the fully-mechanized mining face of Daliuta Coal Mine in Yulin, Shaanxi Province. Fluent was used to simulate the dust diffusion rule of the new-type air distribution dust control method, and the influences of different distances between the air pressure outlet and the working face and different pressure-pumping ratios on the change of dust diffusion rule were analyzed. When the air pressure outlet is 10-20 m away from the working face, dust accumulates and settles in the bottom of the roadway in the working face area, and the dust concentration is low at the driver’s side, and the dust control effect is better. When the distance between the air pressure outlet and the working face is 10 m and the pressure-pumping ratio is 1.0, the high concentration of dust accumulates in the working face area, and the dust concentration at the driver is controlled below 50 mg/m3, and the dust control effect is better. Through field measurement, the error between dust concentration and simulation results is less than 15.2%.

-

-

表 1 边界条件参数设置

Table 1 Boundary condition parameters setting

项目 名称 参数 通用设置 Solver Type Pressure-Based Time Transient 湍流模型 k-epsilon Standard 求解方式 Scheme SIMPLEC Solution Initialization Initialization Methods Standard Initialization 边界条件 出口边界 Pressure-Outlet 入口边界 Velocity-Inlet 粉尘 质量流率/(g·s−1) 3 分布指数 3.5 -

[1] 刘会景. 基于气幕屏蔽的掘进工作面通风除尘参数优化研究[J]. 煤矿安全,2022,53(10):152−159. LIU Huijing. Study on optimization of ventilation and dust removal parameters in heading face based on air curtain shielding[J]. Safety in Coal Mines, 2022, 53(10): 152−159.

[2] 张建国,孙海良,张国川,等. 煤巷中不同截割部位对粉尘运移扩散规律的影响研究[J]. 煤炭技术,2023,42(8):177−181. ZHANG Jianguo, SUN Hailiang, ZHANG Guochuan, et al. Research on influence of different cutting positions in coal roadway on law of dust transport and diffusion[J]. Coal Technology, 2023, 42(8): 177−181.

[3] 徐文君,任晓芬,崔宝库,等. 综掘面双风幕通风系统控尘除尘性能研究[J]. 煤炭工程,2023,55(3):133−138. XU Wenjun, REN Xiaofen, CUI Baoku, et al. Dust control and dust removal performance of double air curtain ventilation system in fully-mechanized excavation face[J]. Coal Engineering, 2023, 55(3): 133−138.

[4] YU Haiming, CHENG Weimin, WANG Hao, et al. Formation mechanisms of a dust-removal air curtain in a fully-mechanized excavation face and an analysis of its dust-removal performances based on CFD and DEM[J]. Advanced Powder Technology, 2017, 28(11): 2830−2847. doi: 10.1016/j.apt.2017.08.010

[5] 王建国,李尧尧. 附壁风筒出风口参数对掘进工作面控尘效果的影响[J]. 煤矿安全,2023,54(10):50−55. WANG Jianguo, LI Yaoyao. Influence of outlet parameters of wall attached air duct on dust control effect in heading face[J]. Safety in Coal Mines, 2023, 54(10): 50−55.

[6] 杨骁禹,王义亮. 综掘工作面外喷雾喷嘴布置方式数值模拟研究[J]. 煤矿安全,2023,54(12):40−47. YANG Xiaoyu, WANG Yiliang. Numerical simulation research on arrangement of spray nozzles outside fully mechanized excavation face[J]. Safety in Coal Mines, 2023, 54(12): 40−47.

[7] 褚新龙,魏伟,龙在海,等. 不同通风方式及压风量下的掘进工作面风流粉尘分布规律研究[J]. 煤矿安全,2023,54(2):35−39. CHU Xinlong, WEl Wei, LONG Zaihai, et al. Research on air flow and dust distribution law of heading face under different ventilation modes and air pressures[J]. Safety in Coal Mines, 2023, 54(2): 35−39.

[8] PARRA M T, VILLAFRUELA J M, CASTRO F, et al. Numerical and experimental analysis of different ventilation systems in deep mines[J]. Building and Environment, 2006, 41(2): 87−93.

[9] TORAÑO J, TORNO S, MENÉNDEZ M, et al. Auxiliary ventilation in mining roadways driven with roadheaders: validated CFD modelling of dust behaviour[J]. Tunnelling and Underground Space Technology, 2011, 26(1): 201−210. doi: 10.1016/j.tust.2010.07.005

[10] KURNIA J C, SASMITO A P, MUJUMDAR A S. Dust dispersion and management in underground mining faces[J]. International Journal of Mining Science and Technology, 2014, 24(1): 39−44. doi: 10.1016/j.ijmst.2013.12.007

[11] 王志宝,黄立宁. 抽出式通风综掘工作面粉尘分布规律的数值模拟研究[J]. 中国煤炭,2019,45(3):78−82. WANG Zhibao, HUANG Lining. Numerical simulation of dust distribution rule in fully mechanized excavation face with exhaust ventilation[J]. China Coal, 2019, 45(3): 78−82.

[12] 周全超,杨胜强,蒋孝元,等. 综掘工作面粉尘分布规律及通风除尘优化研究[J]. 工矿自动化,2019,45(11):70−74. ZHOU Quanchao, YANG Shengqiang, JIANG Xiaoyuan, et al. Research on dust distribution law and optimization of ventilation and dust reduction on fully mechanized heading face[J]. Industry and Mine Automation, 2019, 45(11): 70−74.

[13] 孙连胜. 控尘风筒出风口形式变化对掘进工作面粉尘运移的影响研究[J]. 煤矿安全,2023,54(8):45−51. SUN Liansheng. Study on the influence of air outlet form change of dust control air duct ondust transport in tunneling working face[J]. Safety in Coal Mines, 2023, 54(8): 45−51.

[14] 程卫民,王昊,孙彪,等. 综掘面径向分风与压风配比对风幕阻尘的影响[J]. 中国矿业大学学报,2017,46(5):1014−1023. CHENG Weimin, WANG Hao, SUN Biao, et al. Effects of ratio of radial partial air volume to pressure air volume on air curtain dust control at fully mechanized working face[J]. Journal of China University of Mining & Technology, 2017, 46(5): 1014−1023.

[15] 陈绍杰,祁银鸽,李改革. 压入式通风掘进巷道粉尘悬浮运移规律研究[J]. 煤矿安全,2022,53(4):178−182. CHEN Shaojie, QI Yinge, LI Gaige. Study on dust suspension law in driving roadway with forced ventilation[J]. Safety in Coal Mines, 2022, 53(4): 178−182.

[16] 文伟杰,李宁. 综掘工作面通风除尘合理压抽比实践与试验研究[J]. 山西焦煤科技,2020,44(10):21−24. WEN Weijie, LI Ning. Practical and experimental research on reasonable pressure and extraction ratio of de-dusting and ventilation of comprehensive excavation working face[J]. Shanxi Coking Coal Science & Technology, 2020, 44(10): 21−24.

[17] 王建国,王康,樊亦洋. 附壁风筒条缝参数对综掘工作面控尘效果的影响[J]. 煤矿安全,2021,52(6):206−210. WANG Jianguo, WANG Kang, FAN Yiyang. Influence of slot parameters of wall-attached air duct on dust control effect of fully mechanized mining face[J]. Safety in Coal Mines, 2021, 52(6): 206−210.

[18] 王磊,程煜,徐荣萧. 基于EDEM仿真的煤岩截割产尘规律研究[J]. 煤矿安全,2023,54(1):22−28. WANG Lei, CHENG Yu, XU Rongxiao. Mechanism of dust production during coal and rock cutting based on EDEM[J]. Safety in Coal Mines, 2023, 54(1): 22−28.

[19] 龚晓燕,孙育恒,刘壮壮,等. 基于BP神经网络的煤矿综掘面风流智能调控模型研究[J]. 安全与环境工程,2023,30(6):138−145. GONG Xiaoyan, SUN Yuheng, LIU Zhuangzhuang, et al. Study on airflow intelligent control model of fully mechanized heading face based on BP neural network[J]. Safety and Environmental Engineering, 2023, 30(6): 138−145.

[20] 姬玉成,楼建国,张留祥,等. 综采工作面割煤时粉尘运移变化规律的数值研究[J]. 四川师范大学学报(自然科学版),2014,37(3):419−423. doi: 10.3969/j.issn.1001-8395.2014.03.024 JI Yucheng, LOU Jianguo, ZHANG Liuxiang, et al. Numerical study of the dust distribution laws in airflow of fully-mechanized mining faces[J]. Journal of Sichuan Normal University(Natural Science), 2014, 37(3): 419−423. doi: 10.3969/j.issn.1001-8395.2014.03.024

[21] 王冬辉,白若男,聂文,等. 基于风幕封闭的综掘面综合控除尘技术研究与应用[J]. 煤炭工程,2015,47(12):59−61. WANG Donghui, BAl Ruonan, NIE Wen, et al. Research and application on comprehensive dust control and remove technology with enclosed air curtain in comprehensive mechanized heading face[J]. Coal Engineering, 2015, 47(12): 59−61.

[22] 冯博,卢晓龙,王峰. 综采工作面采煤机在不同区域粉尘逸散规律数值模拟[J]. 煤矿安全,2018,49(11):176−179. FENG Bo, LU Xiaolong, WANG Feng. Numerical simulation of laws of dust dispersion of coal cutter working at different regions of fully mechanized coal mining face[J]. Safety in Coal Mines, 2018, 49(11): 176−179.

[23] 冯恒原,李治刚,朱芷涵,等. 高瓦斯矿井综掘工作面粉尘运移规律及富集特征研究[J]. 中国安全生产科学技术,2023,19(10):59−65. FENG Hengyuan, LI Zhigang, ZHU Zhihan, et al. Study on dust migration law and enrichment characteristics of fully-mechanized heading face in high gas mines[J]. Journal of Safety Science and Technology, 2023, 19(10): 59−65.

[24] 王宝晴,张超,刘建. 不同风速下巷道断面微细粉尘分布模拟试验研究[J]. 中国安全科学学报,2018,28(3):44−49. WANG Baoqing, ZHANG Chao, LIU Jian. Simulation experimental study on fine dust distribution over roadway section under different wind speeds[J]. China Safety Science Journal, 2018, 28(3): 44−49.

[25] 肖旸,孙帅强,杨雪儿,等. 可变角度新鲜风流下煤巷掘进长压短抽除尘效果数值模拟[J]. 煤矿安全,2023,54(1):38−45. XIAO Yang, SUN Shuaiqiang, YANG Xue’er, et al. Numerical simulation of dust removal effect of long pressure and short drainage in coal roadway tunneling with variable angle fresh air flow[J]. Safety in Coal Mines, 2023, 54(1): 38−45.

[26] 刘荣华,朱必勇,王鹏飞,等. 综掘工作面双径向旋流屏蔽通风控尘机理[J]. 煤炭学报,2021,46(12):3902−3911. LIU Ronghua, ZHU Biyong, WANG Pengfei, et al. Dust control mechanism of double radial swirl shielding ventilation in fully mechanized heading face[J]. Journal of China Coal Society, 2021, 46(12): 3902−3911.

[27] 张云峰,王明,陈俊涛,等. 综掘面长压短抽-雾幕除尘系统参数优化研究[J]. 华北科技学院学报,2023,20(2):22−28. ZHANG Yunfeng, WANG Ming, CHEN Juntao, et al. Research on parameter optimization of long-pressure short-pumping and mist screen dust removal system in fully mechanized face[J]. Journal of North China Institute of Science and Technology, 2023, 20(2): 22−28.

-

期刊类型引用(3)

1. 唐巨鹏,张昕,潘一山. 煤与瓦斯突出物理模拟试验研究现状及展望. 岩石力学与工程学报. 2024(03): 521-541 .  百度学术

百度学术

2. 张超林,王培仲,王恩元,许江,李忠辉,刘晓斐,彭守建. 我国煤与瓦斯突出机理70年发展历程与展望. 煤田地质与勘探. 2023(02): 59-94 .  百度学术

百度学术

3. 张文柯. 基于AHP-MCS的煤与瓦斯突出主控因素分析. 能源技术与管理. 2023(05): 126-127 .  百度学术

百度学术

其他类型引用(1)

下载:

下载: