Experimental study on automatic docking technology of grouping screen pipe for hydraulic transportation in drill pipes

-

摘要:

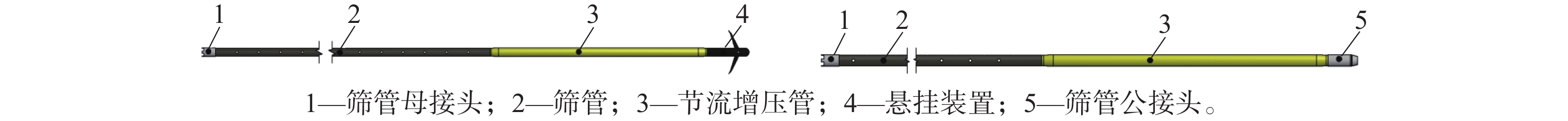

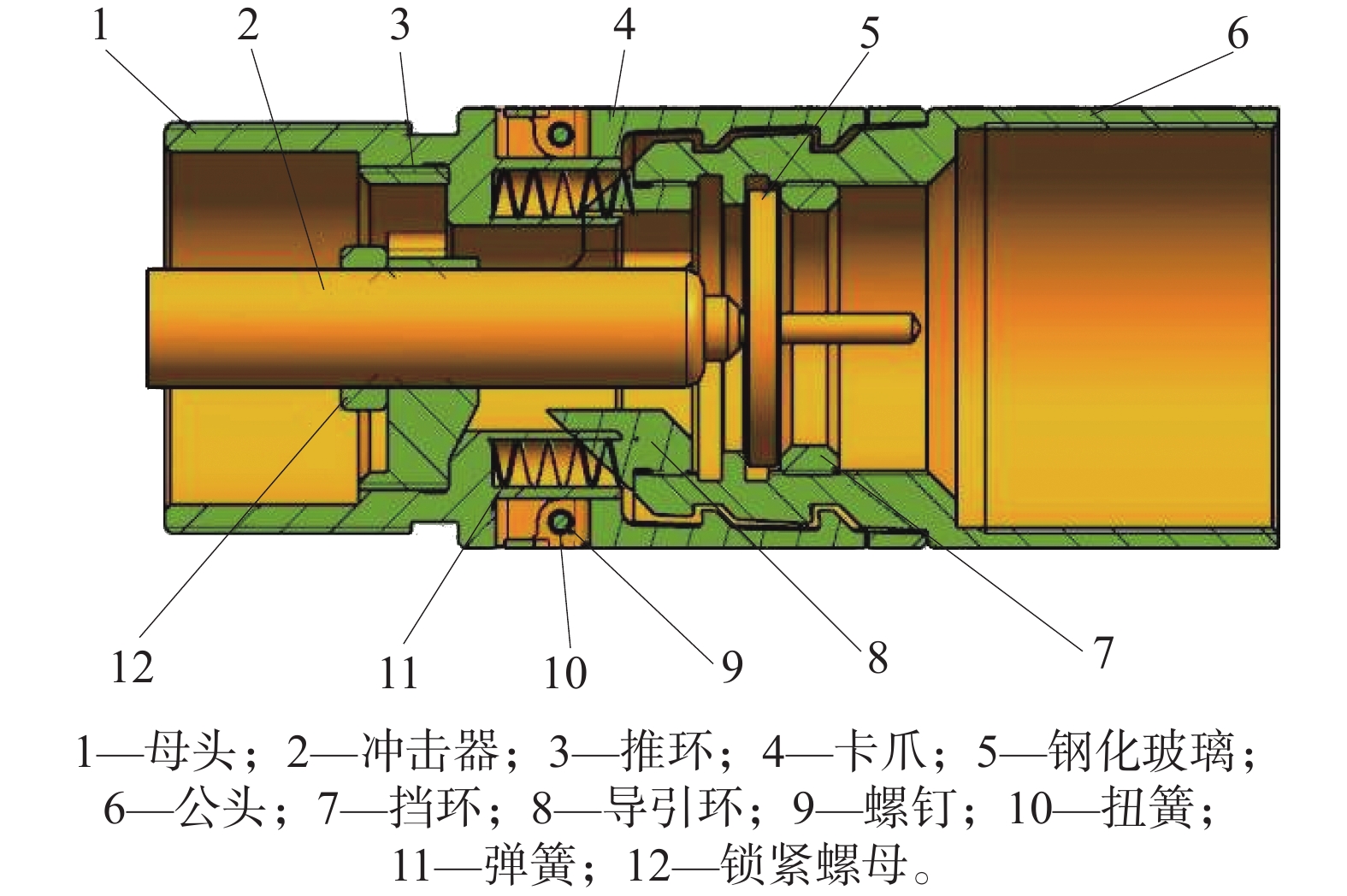

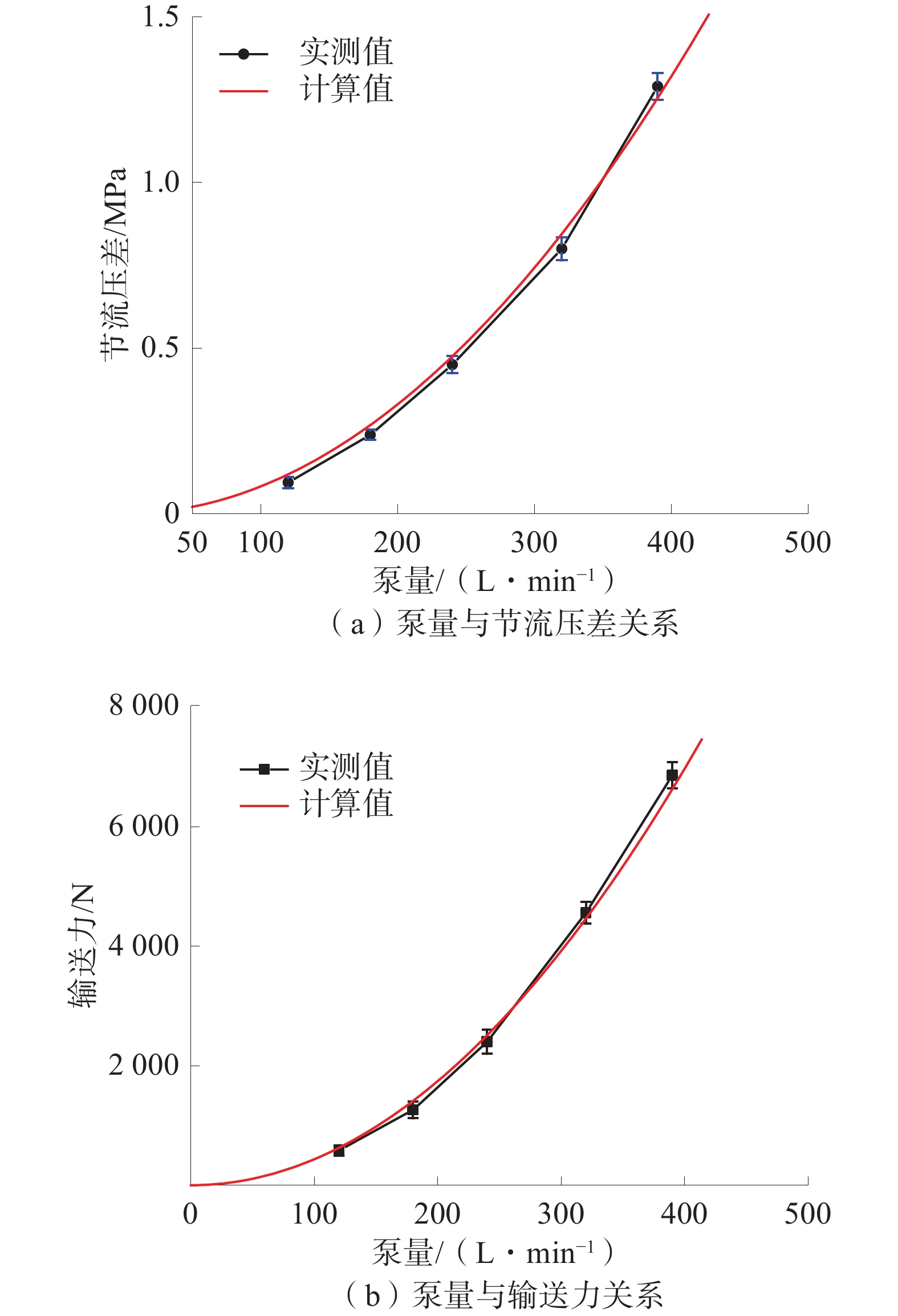

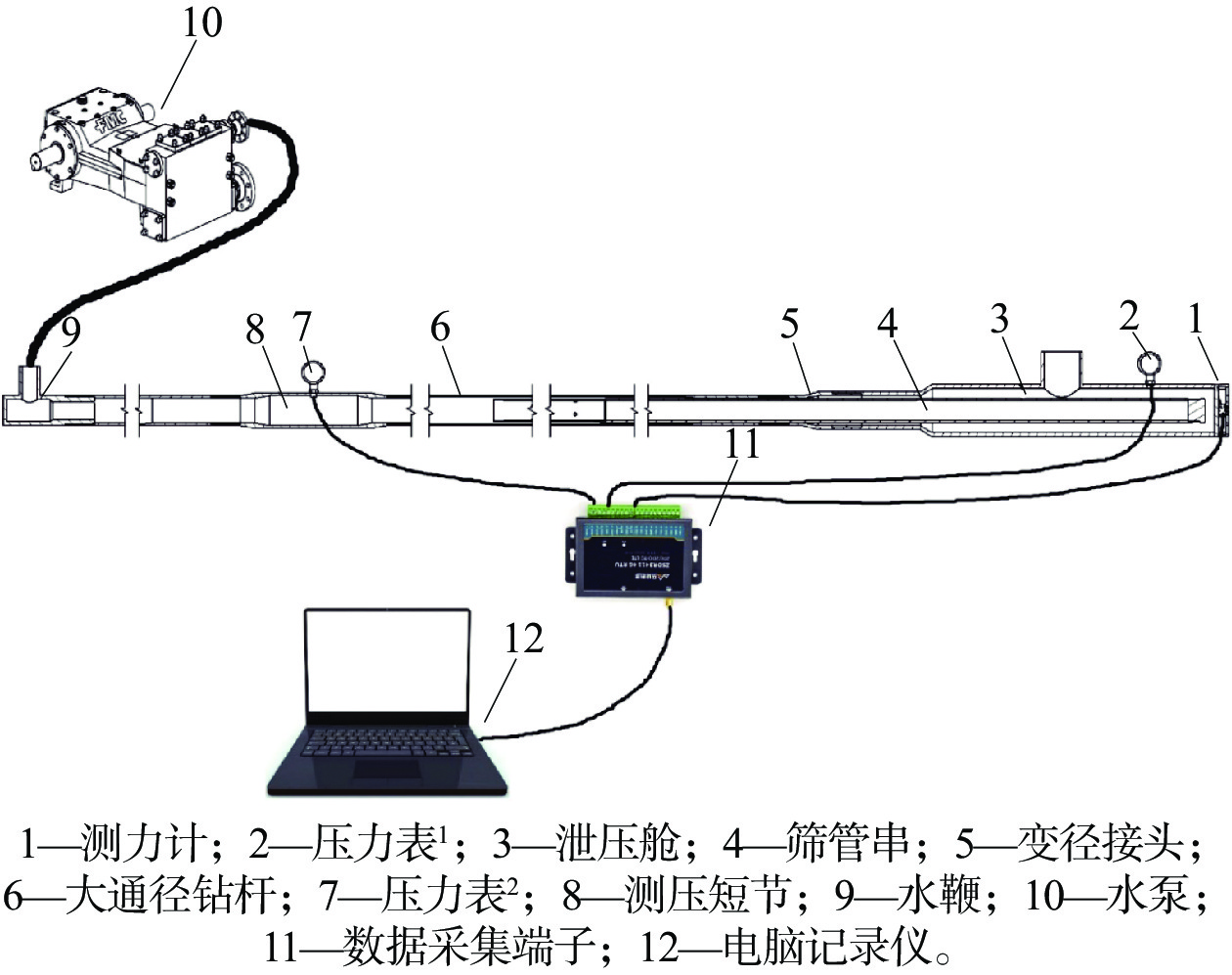

煤层顶板定向长钻孔成孔后采用筛管完孔是保障工作面回采过程中瓦斯抽采效果的有效护孔措施。为了研究利用钻孔内重入大通径钻杆并在其内水力输送分组筛管自动对接完成全孔段筛管护孔的可行性,利用设计的水力输送筛管测试装置和分组筛管对接装置,进行了钻杆内分组筛管水力输送力及自动对接模拟试验,得到了不同泵量下分组筛管的水力输送节流压差与输送力,并与理论计算结果进行对比分析,同时对分组筛管对接装置的对接可靠性和分组筛管自动对接成功率进行了分析试验。试验结果表明:不同泵量下,节流压差和水力输送力实测值与理论计算值相近且呈指数式增长趋势,在泵量390 L/min时,配套ϕ82 mm节流增压管的分组筛管在ϕ102/ϕ83 mm大通径钻杆内的实测节流压差、水力输送力分别达到1.29 MPa、6 860 N,且分组筛管对接装置的单次对接成功率和分组筛管自动对接成功率分别不小于94.18%、82.23%。

Abstract:It is an effective hole protection measure to ensure the effect of gas drainage in the mining process of the working face by using the screen pipe to complete the borehole after the directional long hole drilling in the coal seam roof. In order to study the feasibility of using the large-diameter drill pipe re-entered into the drill hole and the hydraulic transportation of the grouping screen pipe automatic docking in the drill pipe to complete the full-hole section screen pipe protection, the hydraulic transportation and automatic docking simulation tests of the grouping screen pipe in the drill pipe were carried out using the designed hydraulic transportation screen pipe testing device and the grouping screen pipe docking device, and the hydraulic transportation differential throttling pressure and transportation force of the grouping screen pipe under different pump volumes were obtained, and compared with the theoretical calculation results. At the same time, the docking reliability of the grouping screen pipe docking device and the automatic docking success rate of the grouping screen pipe are analyzed and tested. The test results show that the measured values of differential throttling pressure and hydraulic transportation force are close to the theoretical values and show an exponential growth trend under different pump volumes. When the pump volume is 390 L/min, the measured differential throttling pressure and hydraulic transportation force of the grouping screen pipe with ϕ82 mm throttling booster pipe in the ϕ102/ϕ83 mm large-diameter drill pipe reach 1.29 MPa and 6 860 N respectively, and the single docking success rate of the grouping screen pipe docking device and the automatic docking success rate of the grouping screen pipe are not less than 94.18% and 82.23% respectively.

-

-

[1] 李泉新,许超,刘建林,等. 煤矿井下全域化瓦斯抽采定向钻进关键技术与工程实践[J]. 煤炭学报,2022,47(8):3108−3116. LI Quanxin, XU Chao, LIU Jianlin, et al. Key technology and practice of directional drilling for gas drainage in all the mining time and space in underground coal mine[J]. Journal of China Coal Society, 2022, 47(8): 3108−3116.

[2] 闫保永,曹柳,张家贵. 煤层顶板裂隙带瓦斯抽采技术与装备探索[J]. 煤炭科学技术,2020,48(10):60−66. YAN Baoyong, CAO Liu, ZHANG Jiagui. Exploration on gas drainage technology and equipment of fracture zone in coal seam roof[J]. Coal Science and Technology, 2020, 48(10): 60−66.

[3] 郭明功,王彬彬,刘思博,等. 深部缓倾斜煤层“以孔代巷”抽采技术[J]. 西安科技大学学报,2022,42(6):1071−1079. GUO Minggong, WANG Binbin, LIU Sibo, et al. Drainage technology of “replacing roadway with borehole” in deep gently-inclined coal seam[J]. Journal of Xi’an University of Science and Technology, 2022, 42(6): 1071−1079.

[4] 孙荣军,李泉新,方俊,等. 采空区瓦斯抽采高位钻孔施工技术及发展趋势[J]. 煤炭科学技术,2017,45(1):94−99. SUN Rongjun, LI Quanxin, FANG Jun, et al. Construction technology and development tendency of high level borehole for gas drainage in goaf[J]. Coal Science and Technology, 2017, 45(1): 94−99.

[5] 郝世俊,段会军,莫海涛,等. 大直径高位定向长钻孔瓦斯抽采技术及实践[J]. 煤田地质与勘探,2020,48(6):243−248. doi: 10.3969/j.issn.1001-1986.2020.06.032 HAO Shijun, DUAN Huijun, MO Haitao, et al. Gas drainage technology and practice analysis of large diameter high position directional long borehole[J]. Coal Geology & Exploration, 2020, 48(6): 243−248. doi: 10.3969/j.issn.1001-1986.2020.06.032

[6] 童碧. 复杂顶板高位定向长钻孔全程下筛管技术实践[J]. 煤矿安全,2021,52(9):85−89. TONG Bi. Technical practice of running screen in the whole process for high level directional drilling of complex roof[J]. Safety in Coal Mines, 2021, 52(9): 85−89.

[7] 赵亮宏. 全程筛管护孔技术在高位瓦斯抽采钻孔中的应用[J]. 现代矿业,2020,36(2):110−112. doi: 10.3969/j.issn.1674-6082.2020.02.034 ZHAO Lianghong. Application of whole-process screen pipe hole protection in highly-located gas drainage borehole[J]. Modern Mining, 2020, 36(2): 110−112. doi: 10.3969/j.issn.1674-6082.2020.02.034

[8] 徐瑞,王新琨,曹建军,等. 大孔径定向长钻孔成孔及筛管护孔技术研究[J]. 科学技术创新,2021(1):139−140. doi: 10.3969/j.issn.1673-1328.2021.01.064 [9] 杨刚,鲜保安,毕延森,等. 煤层气超短半径水平井筛管完井技术研究[J]. 煤炭科学技术,2019,47(3):175−181. YANG Gang, XIAN Baoan, BI Yansen, et al. Study on technology of screen completion of CBM ultra-short radius horizontal well[J]. Coal Science and Technology, 2019, 47(3): 175−181.

[10] 毕延森,鲜保安,石小磊,等. 超短半径水平井液压驱动非金属完井筛管下入长度计算[J]. 石油勘探与开发,2022,49(4):818−827. doi: 10.11698/PED.20210828 BI Yansen, XIAN Baoan, SHI Xiaolei, et al. The extending length calculation of hydraulic drive non-metallic completion screen pipe running into ultra-short radius horizontal well[J]. Petroleum Exploration and Development, 2022, 49(4): 818−827. doi: 10.11698/PED.20210828

[11] 鲜保安,毕延森,赵立朋,等. 大曲率水平裸眼井筒柔性筛管下入装置及下入方法:CN201911044745.7[P]. 2019-10-30. [12] ZHAO Y Z, SHI Z J, HAO S J, et al. Well completion technology using screen pipe for horizontally-intersected well in soft coal seam[J]. Procedia Engineering, 2014, 73: 311−317. doi: 10.1016/j.proeng.2014.06.204

[13] 申瑞臣,时文,徐义,等. 煤层气U型井PE筛管完井泵送方案[J]. 中国石油大学学报(自然科学版),2012,36(5):96−99. doi: 10.3969/j.issn.1673-5005.2012.05.017 SHEN Ruichen, SHI Wen, XU Yi, et al. PE screen completion for U-shaped coal-bed methane wells with pumping method[J]. Journal of China University of Petroleum (Edition of Natural Science), 2012, 36(5): 96−99. doi: 10.3969/j.issn.1673-5005.2012.05.017

[14] 谭天宇,李浩,李宗源,等. 煤层气多分支水平井分支井眼重入筛管完井技术[J]. 石油钻探技术,2020,48(4):78−82. doi: 10.11911/syztjs.2019121 TAN Tianyu, LI Hao, LI Zongyuan, et al. Re-entry screen completion technology for multi-lateral boreholes in CBM multi-lateral horizontal wells[J]. Petroleum Drilling Techniques, 2020, 48(4): 78−82. doi: 10.11911/syztjs.2019121

[15] 付利,申远思,王开龙,等. 煤层气水平井PE筛管完井用泵送工具推进力研究[J]. 石油钻探技术,2017,45(1):68−72. FU Li, SHEN Yuansi, WANG Kailong, et al. Research on the driving force of the pumping down tool for a PE screen completion in CBM horizontal wells[J]. Petroleum Drilling Techniques, 2017, 45(1): 68−72.

[16] 毕延森,鲜保安,高德利. 煤层气T型水平井柔性筛管泵送下入技术研究[J]. 煤炭科学技术,2019,47(11):170−175. BI Yansen, XIAN Baoan, GAO Deli. Study on technology of flexible screen running for T-shaped CBM wells with pumping method[J]. Coal Science and Technology, 2019, 47(11): 170−175.

[17] 高德利,毕延森,鲜保安. 中国煤层气高效开发井型与钻完井技术进展[J]. 天然气工业,2022,42(6):1−18. doi: 10.3787/j.issn.1000-0976.2022.06.001 GAO Deli, BI Yansen, XIAN Bao’an. Technical advances in well types and drilling & completion for high-efficient development of coalbed methane in China[J]. Natural Gas Industry, 2022, 42(6): 1−18. doi: 10.3787/j.issn.1000-0976.2022.06.001

下载:

下载: