Study on the optimization formula and performance of high efficiency dust suppressant in mine

-

摘要:

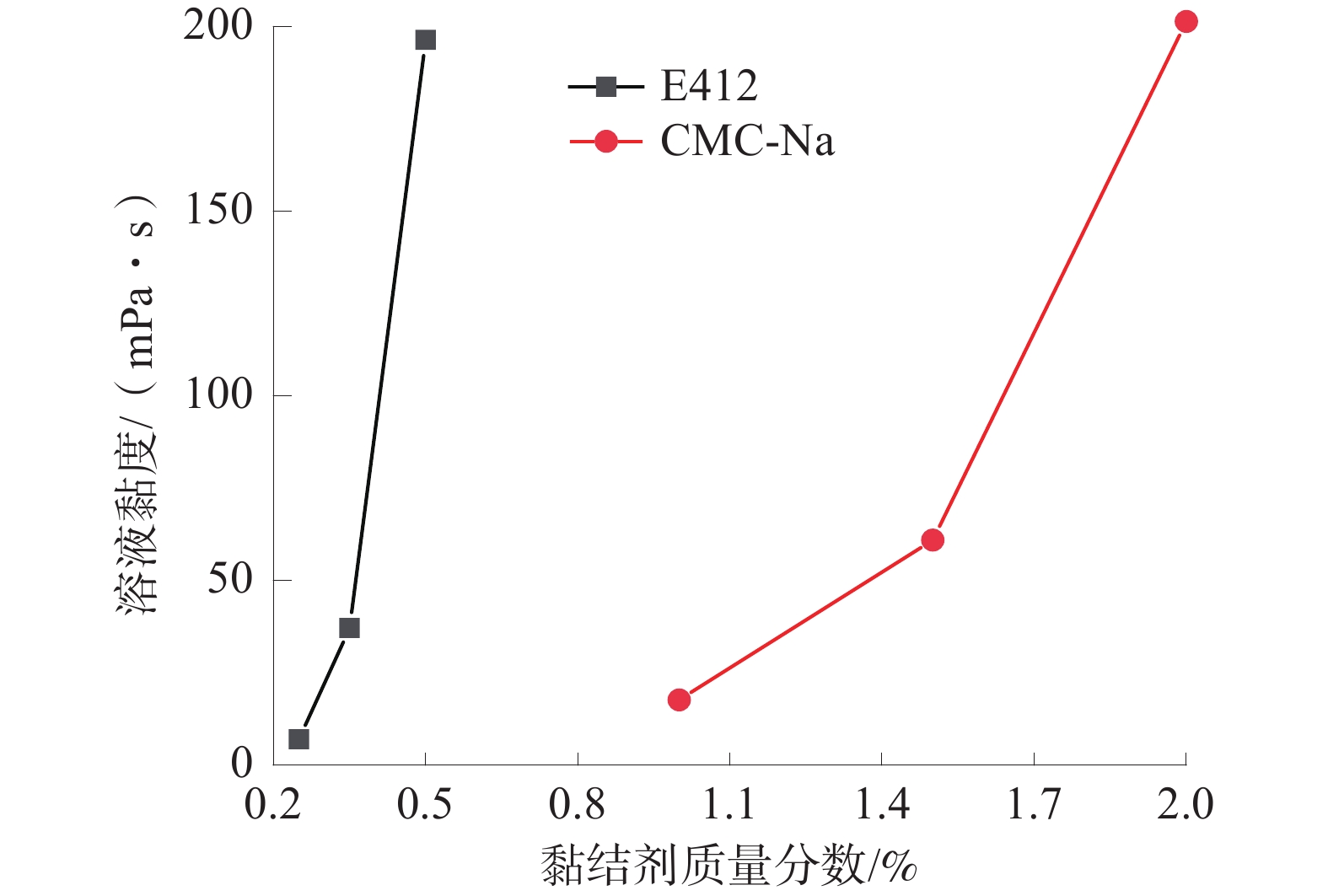

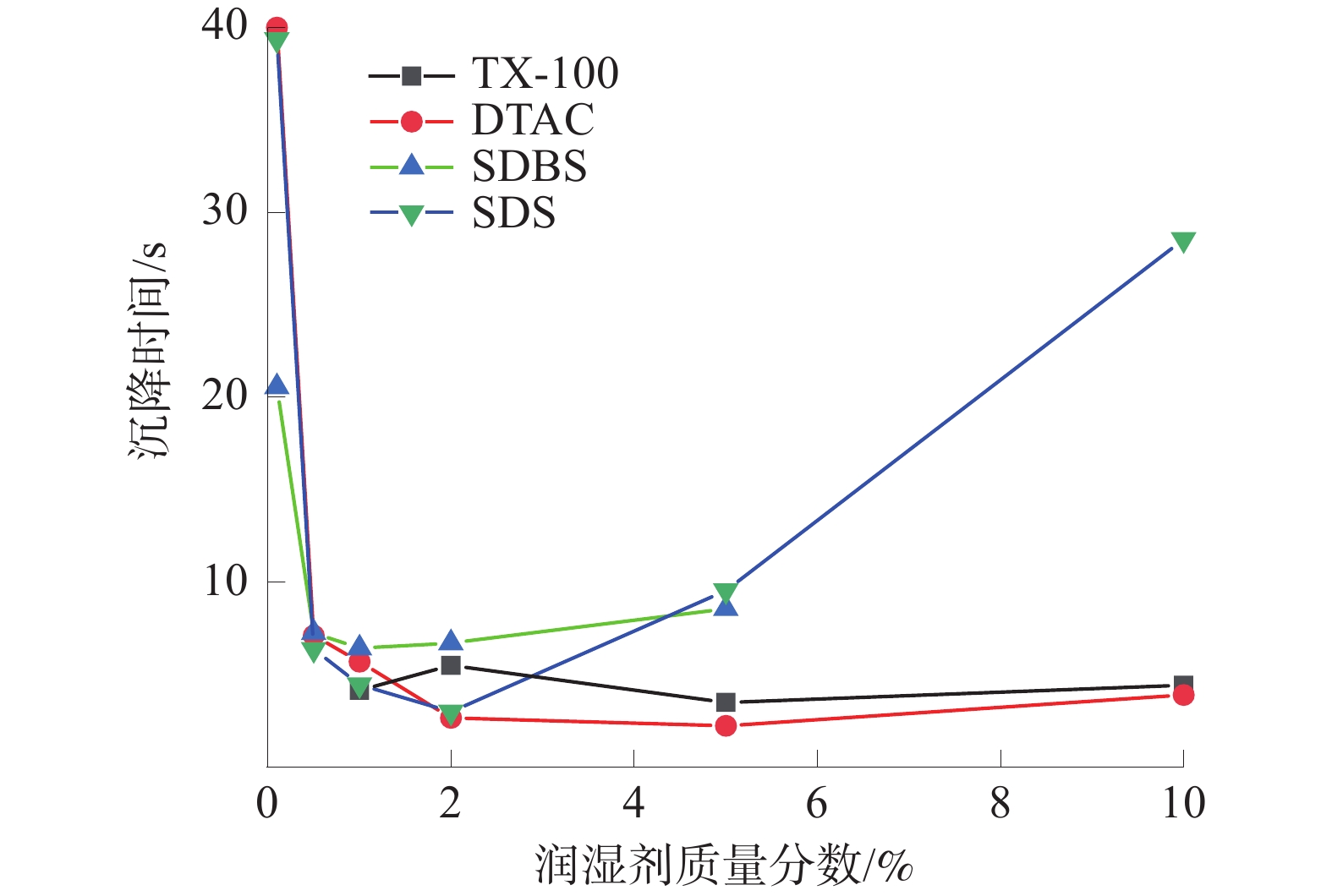

以某煤矿掘进工作面粉尘为研究对象,开展矿井高效抑尘剂优化配方及性能研究。通过沉降实验,确定高效抑尘剂优化配方的润湿剂组分为2%的TX-100和0.5%的SDBS混合溶液;通过黏度测定实验,确定优化配方的黏结剂组分为E412;通过保水性实验,确定优化配方的保水抑尘剂组分为PAAS;通过抑尘剂溶液的酸碱度测定实验,确定选用PHOS调节溶液的pH值为6.8;最终研究得到矿井高效抑尘剂GHY-1配方组分及比例。性能测定实验结果表明:高效抑尘剂优化配方表面张力为68.15 mN/m,左、右接触角分别为11.25°和10.85°,黏度值为0.4 mPa·s,保水率为80.5%,降尘效率可达95.3%。

Abstract:Taking the dust of a coal mine driving face as the research object, the optimization formulation and performance of highly effective dust suppressant were studied. Through sedimentation experiments, the wetting agent components for optimizing the formula of high-efficiency dust suppressants were determined to be a mixture of 2% TX-100 and 0.5% SDBS solution; by conducting viscosity measurement experiments, the adhesive component for optimizing the formula was determined to be E412; by conducting water retention experiments, the water retention agent component for the optimized formula was determined to be PAAS; through the experiment of measuring the acidity and alkalinity of the dust suppressant solution, it was determined that the pH value of the solution adjusted by PHOS was 6.8; the final research obtained the composition and proportion of the high-efficiency dust suppressant GHY-1 formula for mines. The performance measurement experiment results show that the optimized formula of high-efficiency dust suppressant has a surface tension of 68.15 mN/m, the left and right contact angles are 11.25 ° and 10.85 °, respectively, viscosity value is 0.4 mPa·s, water retention rate is 80.5%, and dust reduction efficiency is 95.3%.

-

-

表 1 抑尘剂配方复配组分与比例

Table 1 Compound components of dust suppressant

序号 药剂

组分含量/g 比例/% 样品数量 GHY-1 TX-100 4.00 2.000 3 SDBS 1.00 0.500 E412 0.03 0.015 PAAS 0.01 0.005 GHY-2 TX-100 4.00 2.000 3 SDBS 1.00 0.500 E412 0.05 0.025 PAAS 0.02 0.010 GHY-3 TX-100 4.00 2.000 3 SDBS 1.00 0.500 E412 0.03 0.015 PAAS 0.02 0.010 GHY-4 TX-100 4.00 2.000 3 SDBS 1.00 0.500 E412 0.50 0.250 PAAS 0.05 0.025 小计 12 表 2 多组分混合润湿剂性能测定

Table 2 Performance measurement of multi-component mixed wetting agent

混合配方 黏度/(mPa·s) 沉降

时间/s0.5%SDBS+2%TX-100 0.5 6.42 1.0%SDBS+2%DTAC 12.0 >60 0.5%SDBS+2%DTAC 6.5 2.83 表 3 高效抑尘剂优化配方黏度及pH值测定

Table 3 Viscosity and pH determination of optimized formula of high-efficiency dust suppressant

序号 高效抑尘剂优化配方 黏度/(mPa·s) pH值 1 GHY-1 0.4 8.6 2 GHY-2 1.0 9.0 3 GHY-3 0.5 8.7 4 GHY-4 44.5 10.0 表 4 接触角测试结果

Table 4 Contact angle test results

序号 水接触角/(°) 抑尘剂接触角/(°) 左 右 左 右 1 91.20 91.53 7.92 9.92 2 81.94 77.86 9.05 7.21 3 78.20 75.47 16.79 15.42 平均值 83.78 81.62 11.25 10.85 -

[1] 王双明,师庆民,王生全,等. 富油煤的油气资源属性与绿色低碳开发[J]. 煤炭学报,2021,46(5):1365−1377. WANG Shuangming, SHI Qingmin, WANG Shengquan, et al. Resource property and exploitation concepts with green and low-carbon of tar-rich coal as coal-based oil and gas[J]. Journal of China Coal Society, 2021, 46(5): 1365−1377.

[2] 田敏,李治刚,郭红光,等. 煤尘抑尘剂在不同作业场所的应用与发展前景[J]. 煤矿安全,2022,53(10):168−172. TIAN Min, LI Zhigang, GUO Hongguang, et al. Application and development prospect of coal dust suppressor in different workplaces[J]. Safety in Coal Mines, 2022, 53(10): 168−172.

[3] 耿卫国,宋丽华,宋强,等. 煤矿粉尘化学抑尘剂的试验研究[J]. 煤矿安全,2018,49(11):33−38. GENG Weiguo, SONG Lihua, SONG Qiang, et al. Experimental study on chemical dust suppressant for coal mine dust[J]. Safety in Coal Mines, 2018, 49(11): 33−38.

[4] 边素素,胡相明,贺正龙,等. 基于纳米纤维素的接枝共聚型高分子抑尘剂制备与性能研究[J]. 煤矿安全,2022,53(5):32−39. BIAN Susu, HU Xiangming, HE Zhenglong, et al. Preparation and performance of grafted copolymerized polymer dust suppressant based on nanocellulose[J]. Safety in Coal Mines, 2022, 53(5): 32−39.

[5] 张建国,李红梅,刘依婷. 煤尘微细观润湿特性及抑尘剂研发初探−以平顶山矿区为例[J]. 煤炭学报,2021,46(3):812−825. ZHANG Jianguo, LI Hongmei, LIU Yiting. Micro-wetting characteristics of coal dust and preliminary study on the development of dust suppressant in Pingdingshan mining area[J]. Journal of China Coal Society, 2021, 46(3): 812−825.

[6] 许飞健,陈维旭,王锋,等. 煤炭化学抑尘剂的应用进展[J]. 当代化工研究,2022(19):116−118. XU Feijian, CHEN Weixu, WANG Feng, et al. Application progress of coal chemical dust inhibitors[J]. Modern Chemical Research, 2022(19): 116−118.

[7] 梁文俊,兰童,张志学,等. 新型环保煤尘抑尘剂的制备及其应用[J]. 中国煤炭,2021,47(6):57−65. LIANG Wenjun, LAN Tong, ZHANG Zhixue, et al. Preparation and application of new environment-friendly coal dust suppressant[J]. China Coal, 2021, 47(6): 57−65.

[8] 李振,胡潮,张少波. 环境友好型抑尘剂配方及性能实验研究[J]. 能源技术与管理,2020,45(4):10−12. LI Zhen, HU Chao, ZHANG Shaobo. Experimental study on the formulation and performance of environment-friendly dust suppressant[J]. Energy Technology and Management, 2020, 45(4): 10−12.

[9] BAO Qiu, NIE Wen, LIU Changqi, et al. The preparation of a novel hydrogel based on crosslinked polymers for suppressing coal dusts[J]. Journal of Cleaner Production, 2019, 249: 119343.

[10] ZHOU Qun, QIN Botao, WANG Jun, et al. Effects of preparation parameters on the wetting features of surfactant-magnetized water for dust control in Luwa mine, China[J]. Powder Technology, 2018, 326: 7−15. doi: 10.1016/j.powtec.2017.12.002

[11] ZHANG Haihan, NIE Wen, LIU Yanghao, et al. Synthesis and performance measurement of environment-friendly solidified dust suppressant for open pit coalmine[J]. Journal of Applied Polymer Science, 2018, 135(29): 46505. doi: 10.1002/app.46505

[12] ZHOU Gang, FAN Tao, MA Yunlong. Preparation and chemical characterization of an environmentally-friendly coal dust cementing agent[J]. Journal of Chemical Technology & Biotechnology, 2017, 92(10): 2699−2718.

[13] 李树芳,田进,谢宏,等. 造纸废料制备润湿型抑尘剂及其性能研究[J]. 煤矿安全,2019,50(7):14−16. LI Shufang, TIAN Jin, XIE Hong, et al. Study on preparation of wetting dust suppressant from papermaking waste and its properties[J]. Safety in Coal Mines, 2019, 50(7): 14−16.

[14] 苗欢. 煤炭储运用粘结抑尘剂的性能实验研究[D]. 三河:华北科技学院,2016. [15] 郭王勇,鞠振福,靳昕,等. 煤尘抑尘剂的润湿性能研究[J]. 矿业安全与环保,2021,48(2):66−70. GUO Wangyong, JU Zhenfu, JIN Xin, et al. Study on wettability of coal dust suppressant[J]. Mining Safety & Environmental Protection, 2021, 48(2): 66−70.

-

期刊类型引用(1)

1. 柳昭星. 奥陶系灰岩顶部劈裂注浆裂隙起裂机制试验研究. 采矿与安全工程学报. 2023(01): 204-214 .  百度学术

百度学术

其他类型引用(2)

下载:

下载: