Experimental study on porosity and permeability characteristics of damaged coal in different shear end faces and confining pressures

-

摘要:

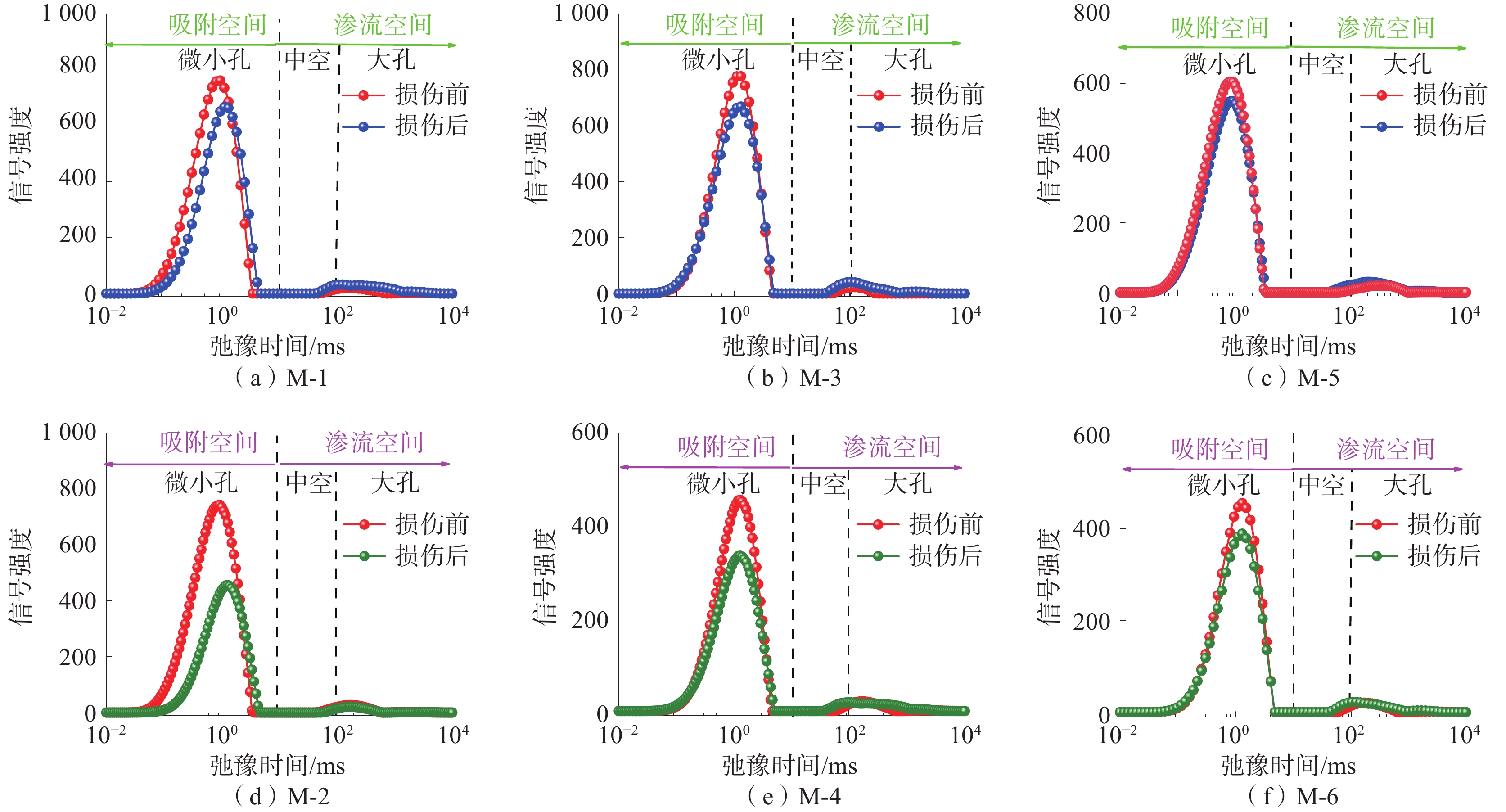

煤体损伤是影响渗透率变化和瓦斯流动的重要因素;采用多剪切端面损伤渗流测试系统和核磁共振仪,分析了不同剪切端面和围压下损伤煤体孔渗特性变化规律。结果表明:损伤煤体内中大孔增多,吸附空间向渗流空间转化,孔隙间连通性变好;50%剪切端面情况下,渗流空间(驰豫时间T2>10 ms)平均面积百分比由9.89%增大为14.94%;剪切应力作用下,煤体轴向变形量不断增大,50%剪切端面比30%剪切端面导致的轴向变形量大,而围压值越大,轴向变形量越小;随着剪切应力的增大,煤体渗透率先降低后缓慢增加,当应力达到煤体强度阈值时,损伤煤体渗透率以指数形式增大,50%剪切端面对应的渗透率值普遍比30%剪切端面的大,前者是后者的7倍左右。

Abstract:Coal damage is a significant factor which affects coal permeability changes and gas flow. Damage-based seepage testing system with multi-shear end faces and nuclear magnetic resonance instrument were adopted to analyze porosity and permeability characteristics of damaged coal in different shear end faces and confining pressures. It is found that the number of macro-pores in damaged coal increases. Meanwhile, adsorption space transforms into seepage space, with better connectivity between pores. In the case of 50% shear end face, average area percentage of seepage space (relaxation time T2>10 ms) rises from 9.89% to 14.94%. Affected by shear stress, the axial deformation of coal continuously increases, 50% shear end face causing bigger axial deformation than the 30% shear end face. The larger the confining pressure value, the smaller the axial deformation. With increasing shear stress, permeability of coal decreases first before slowly growing. When stress reaches the threshold of coal strength, permeability of damaged coal rises exponentially. The permeability value corresponding to 50% shear face is generally larger than that of 30% shear face, and the former is about 7 times that of the latter.

-

-

表 1 剪切-渗流实验方案

Table 1 Experimental design for shear-seepage test

实验编号 气体压力/MPa 围压/MPa 剪切端面 M-1 0.5 3 30% M-2 0.5 3 50% M-3 0.5 5 30% M-4 0.5 5 50% M-5 0.5 8 30% M-6 0.5 8 50% -

[1] 王双明,耿济世,李鹏飞,等. 煤炭绿色开发地质保障体系的构建[J]. 煤田地质与勘探,2023,51(1):33−43. WANG Shuangming, GENG Jishi, LI Pengfei, et al. Construction of geological guarantee system for green coal mining[J]. Coal Geology & Exploration, 2023, 51(1): 33−43.

[2] 周宏伟,荣腾龙,牟瑞勇,等. 采动应力下煤体渗透率模型构建及研究进展[J]. 煤炭学报,2019,44(1):221−235. ZHOU Hongwei, RONG Tenglong, MOU Ruiyong, et al. Development in modeling approaches to mining-induced permeability of coals[J]. Journal of China Coal Society, 2019, 44(1): 221−235.

[3] 许江,谭皓月,王雷,等. 不同法向应力下含瓦斯煤剪切破坏细观演化过程研究[J]. 岩石力学与工程学报,2012,31(6):1192−1197. doi: 10.3969/j.issn.1000-6915.2012.06.014 XU Jiang, TAN Haoyue, WANG Lei, et al. Meso-evolution process of gas-containing coal shear failure under different normal stresses[J]. Chinese Journal of Rock Mechanics and Engineering, 2012, 31(6): 1192−1197. doi: 10.3969/j.issn.1000-6915.2012.06.014

[4] 陆朝晖,贾云中,汤积仁,等. 深层页岩剪切滑移裂缝渗透率变化规律[J]. 天然气工业,2021,41(1):146−153. LU Zhaohui, JIA Yunzhong, TANG Jiren, et al. Evolution laws of fracture permeability of deep shale in the process of shear slip[J]. Natural Gas Industry, 2021, 41(1): 146−153.

[5] 李庆文,高森林,黄筱. 加载速率效应对煤样损伤演化研究[J]. 煤矿安全,2022,54(11):1−11. LI Qingwen, GAO Senlin, HUANG Xiao. Study on damage evolution of coal samples by loading rate effect[J]. Safety in Coal Mines, 2022, 54(11): 1−11.

[6] 彭守建,许江,张超林,等. 含瓦斯煤岩剪切破断过程中裂纹演化及其分形特征[J]. 煤炭学报,2015,40(4):801−808. PENG Shoujian, XU Jiang, ZHANG Chaolin, et al. Fractal characteristics of crack evolution in gas-bearing coal under shear loading[J]. Journal of China Coal Society, 2015, 40(4): 801−808.

[7] XIA C C, QIAN X, LIN P, et al. Experimental investigation of nonlinear flow characteristics of real rock joints under different contact conditions[J]. Journal of Hydraulic Engineering, 2017, 43(3): 04016090.

[8] 刘静波,赵阳升,胡耀青,等. 剪应力对煤体渗透性影响的研究[J]. 岩土工程学报,2009,31(10):1631−1635. doi: 10.3321/j.issn:1000-4548.2009.10.025 LIU Jingbo, ZHAO Yangsheng, HU Yaoqing, et al. Influence of shear stress on permeability coefficient of coal[J]. Chinese Journal of Geotechnical Engineering, 2009, 31(10): 1631−1635. doi: 10.3321/j.issn:1000-4548.2009.10.025

[9] 赵鹏,冯子军,南翰墨,等. 花岗岩干热岩体裂隙的大位移动态剪切-渗流特征[J]. 煤炭学报,2023,48(3):1139−1154. ZHAO Peng, FENG Zijun, NAN Hanmo, et al. Characteristics of large-displacement based dynamic shearing-flow through the fractures in the granitic hot dry rock mass[J]. Journal of China coal society, 2023, 48(3): 1139−1154.

[10] 肖畅,王开,詹傲,等. 超临界CO2作用下无烟煤抗拉与抗剪试验研究[J]. 煤矿安全,2022,53(12):48−53. XIAO Chang, WANG Kai, ZHAN Ao, et al. Experimental study on tensile and shear strength of anthracite under supercritical CO2[J]. Safety in Coal Mines, 2022, 53(12): 48−53.

[11] 许江,李波波,周婷,等. 加卸载条件下煤岩变形特性与渗透特征的试验研究[J]. 煤炭学报,2012,37(9):1493−1498. XU Jiang, LI Bobo, ZHOU Ting, et al. Experimental study of coal deformation and permeability characteristics under loading-unloading conditions[J]. Journal of China Coal Society, 2012, 37(9): 1493−1498.

[12] 许江,彭守建,尹光志,等. 含瓦斯煤岩细观剪切试验装置的研制及应用[J]. 岩石力学与工程学报,2011,30(4):677−685. XU Jiang, PENG Shoujian, YIN Guangzhi, et al. Development of meso-shear test equipment for coal rock containing gas and its application[J]. Chinese Journal of Rock Mechanics and Engineering, 2011, 30(4): 677−685.

[13] 许江,王威,刘义鑫,等. 剪切-渗流作用下煤岩剪断面形态特征试验研究[J]. 岩土力学,2018,39(12):4313−4324. XU Jiang, WANG Wei, LIU Yixin, et al. Experimental study on shear-seepage for coal-rock shear fracture surface morphological characteristics[J]. Rock and Soil Mechanics, 2018, 39(12): 4313−4324.

[14] 李祥春,张良,赵艺良. 常规三轴压力下含瓦斯煤蠕变-渗流演化规律[J]. 工程科学与技术,2018,50(4):55−62. LI Xiangchun, ZHANG Liang, ZHAO Yiliang. Evolution of gas-filled coal creep-seepage under conventional triaxial compression[J]. Advanced Engineering Sciences, 2018, 50(4): 55−62.

[15] 谢松彬,姚艳斌,陈基瑜,等. 煤储层微小孔孔隙结构的低场核磁共振研究[J]. 煤炭学报,2015,40(S1):170−176. XIE Songbin, YAO Yanbin, CHEN Jiyu, et al. Research of micro-pore structure in coal reservoir using low-field NMR[J]. Journal of China Coal Society, 2015, 40(S1): 170−176.

[16] WU S, TANG D, LI S, et al. Effects of geological pressure and temperature on permeability behaviors of middle-low volatile bituminous coals in eastern Ordos Basin, China[J]. Journal of Petroleum Science and Engineering, 2017, 153: 372−384. doi: 10.1016/j.petrol.2017.03.034

-

期刊类型引用(7)

1. 崔忠麒,徐娅煊,苏皓. 基于Stacking-SHAP的煤自燃倾向性影响因素研究. 煤炭技术. 2025(01): 150-155 .  百度学术

百度学术

2. 孙吉平. 基于SF_6质量浓度变化特征的煤矿火灾状态识别分析. 山西煤炭. 2025(01): 42-49 .  百度学术

百度学术

3. 曹富荣,吴学松,李军,付天予,刘佳伟,李志辉,杨小彬. 基于机器学习的多气体指标煤自燃温度预测. 煤矿安全. 2024(04): 106-113 .  本站查看

本站查看

4. 樊永勇,王新瑞,张春雷. 急倾斜特厚煤层分段采空区低温氮气防灭火技术研究与实践. 能源与环保. 2024(11): 254-262 .  百度学术

百度学术

5. 武泽伟,汪伟,祁云,梁然. 采空区遗煤自燃影响因素分析及风险评价. 山西大同大学学报(自然科学版). 2023(04): 116-122 .  百度学术

百度学术

6. 孔彪,朱思想,胡相明,杨涛,赵旭帅,斐达特,万姝含. 基于改进鲸鱼算法优化BP神经网络的煤自燃预测研究. 矿业安全与环保. 2023(05): 30-36 .  百度学术

百度学术

7. 陈鹏燕,周春山,程熙宇,田雅琪. 全物理交联Al~(3+)-CMC/MMT-PAM双网络凝胶的制备及性能. 矿业研究与开发. 2023(11): 143-149 .  百度学术

百度学术

其他类型引用(2)

下载:

下载: