Study on dynamic evolution law of development height of overburden water-flowing fractured zone

-

摘要:

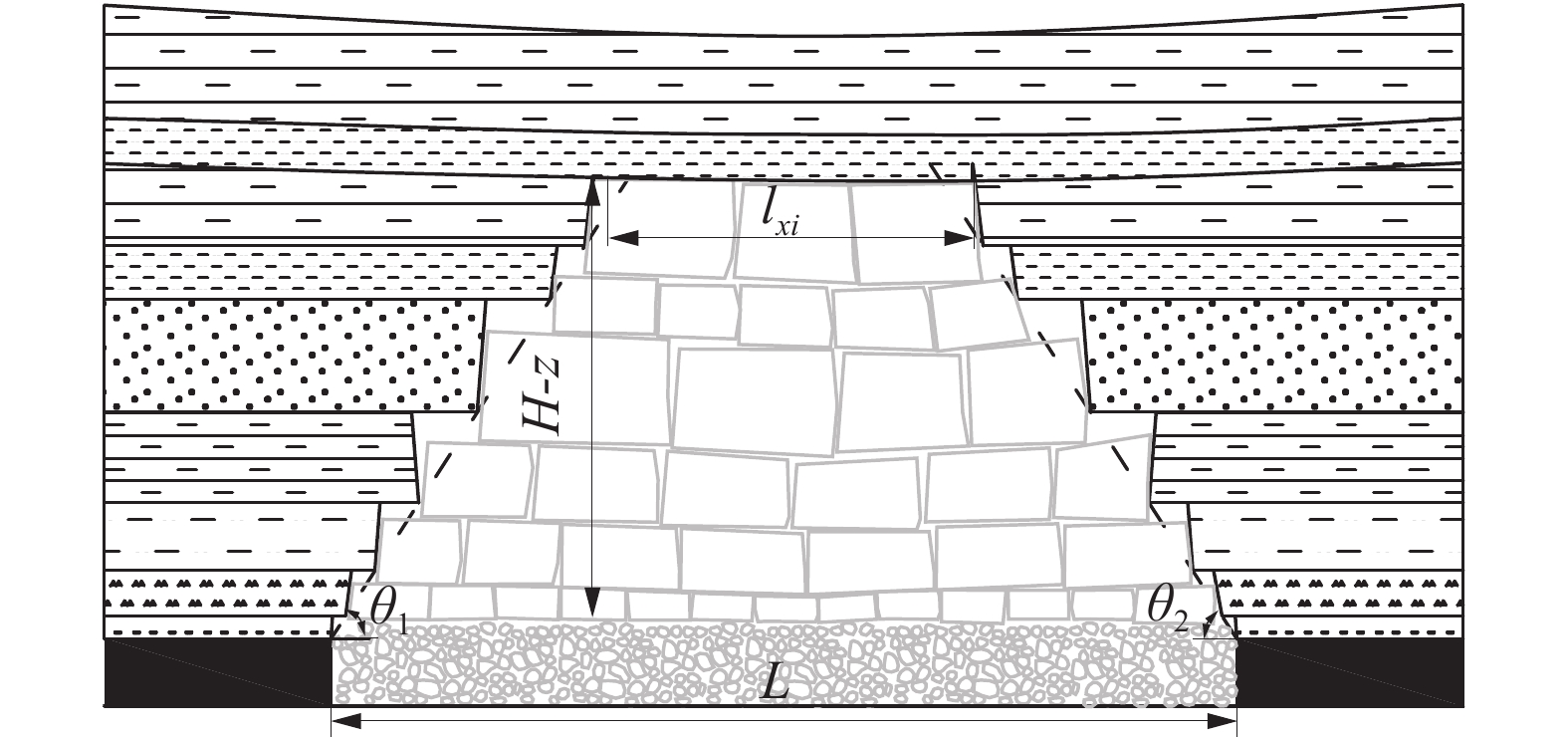

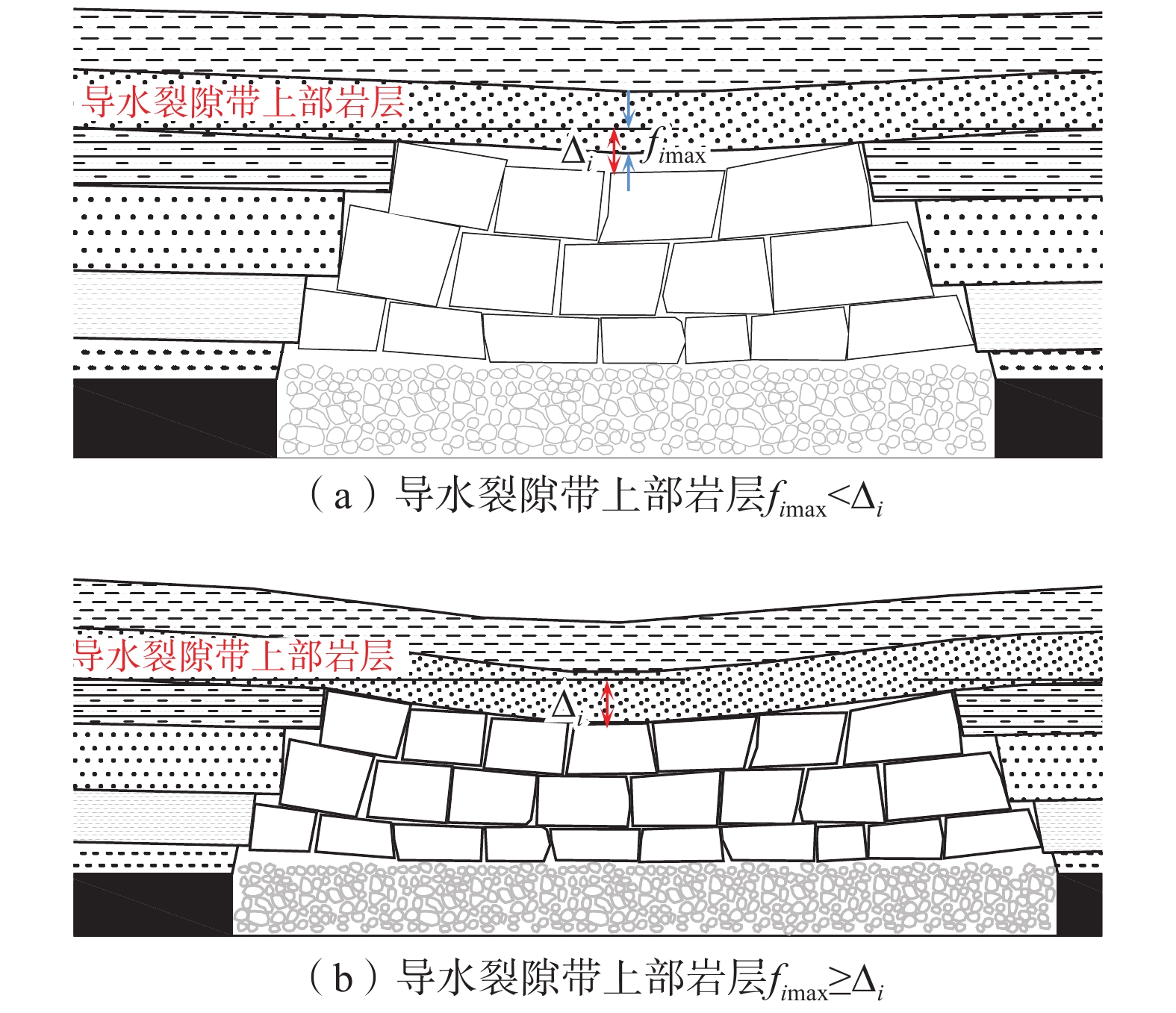

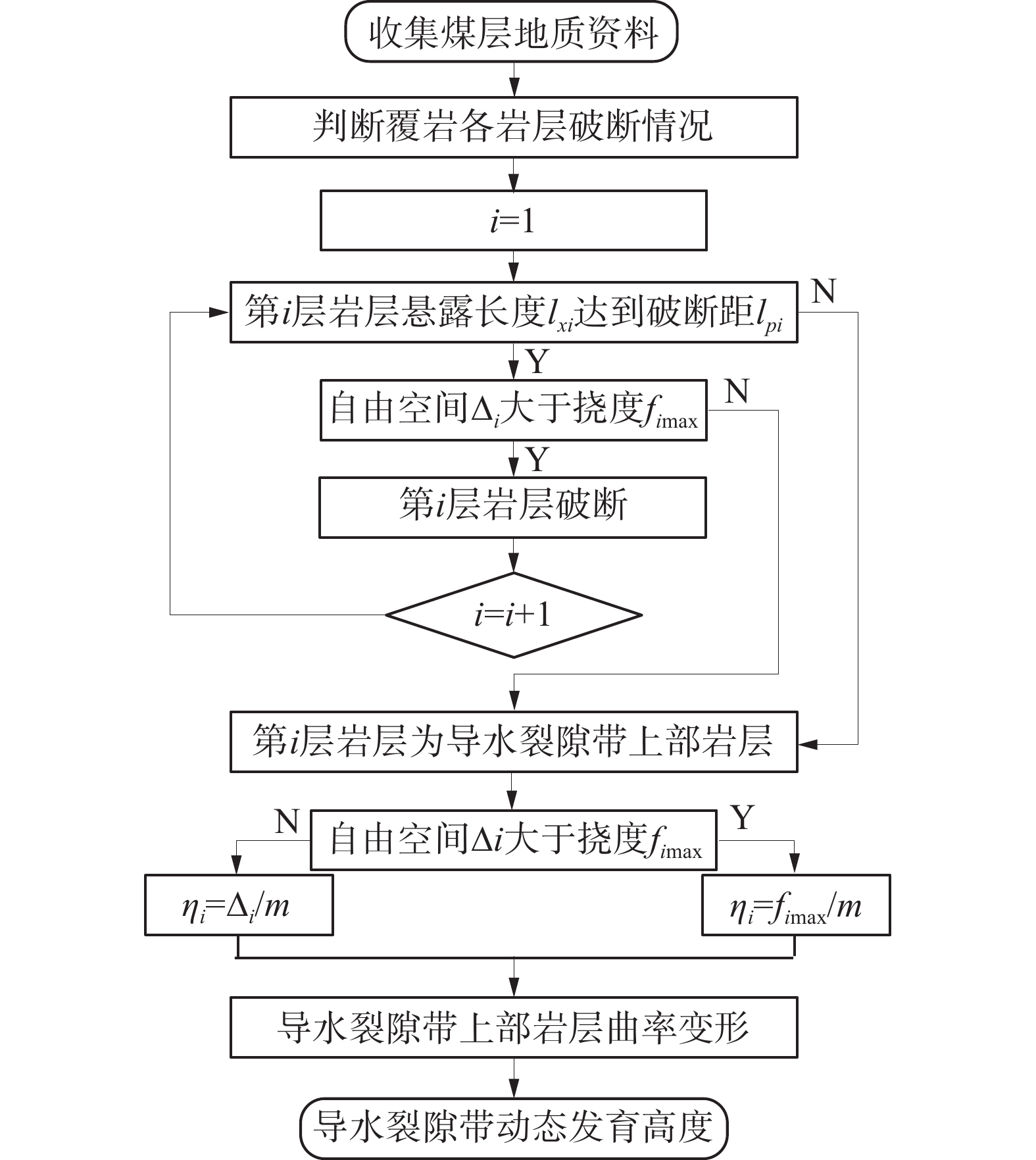

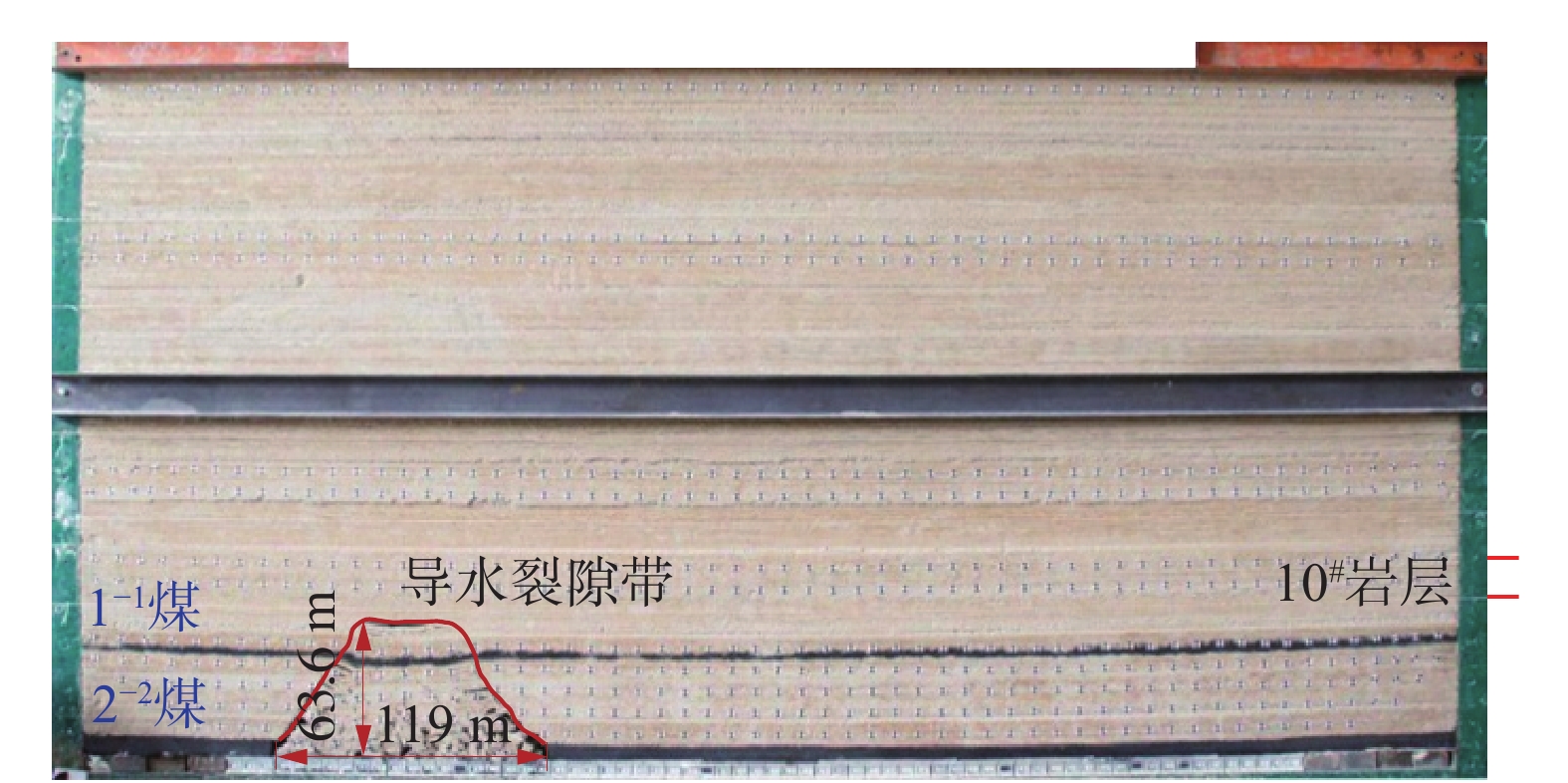

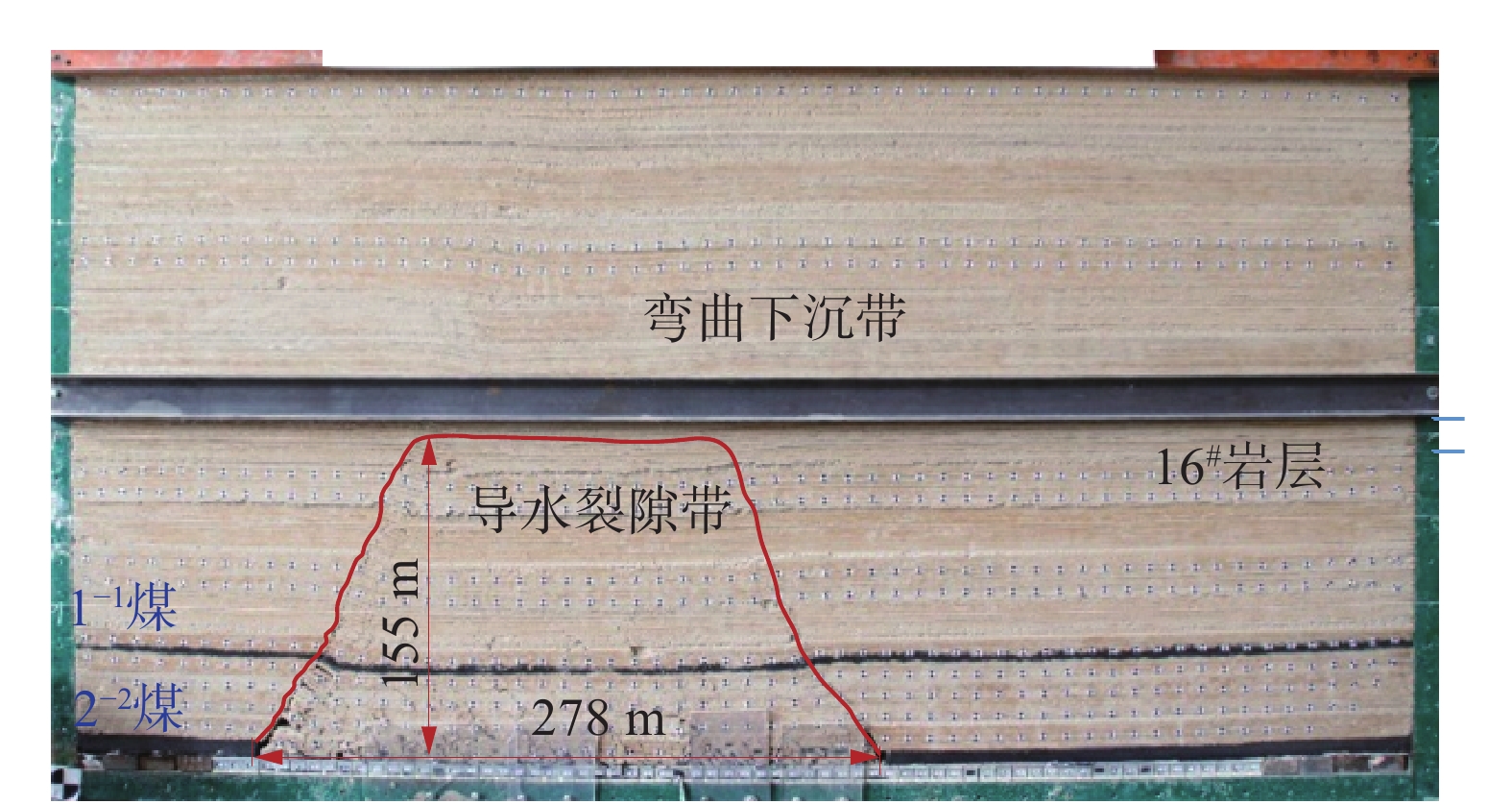

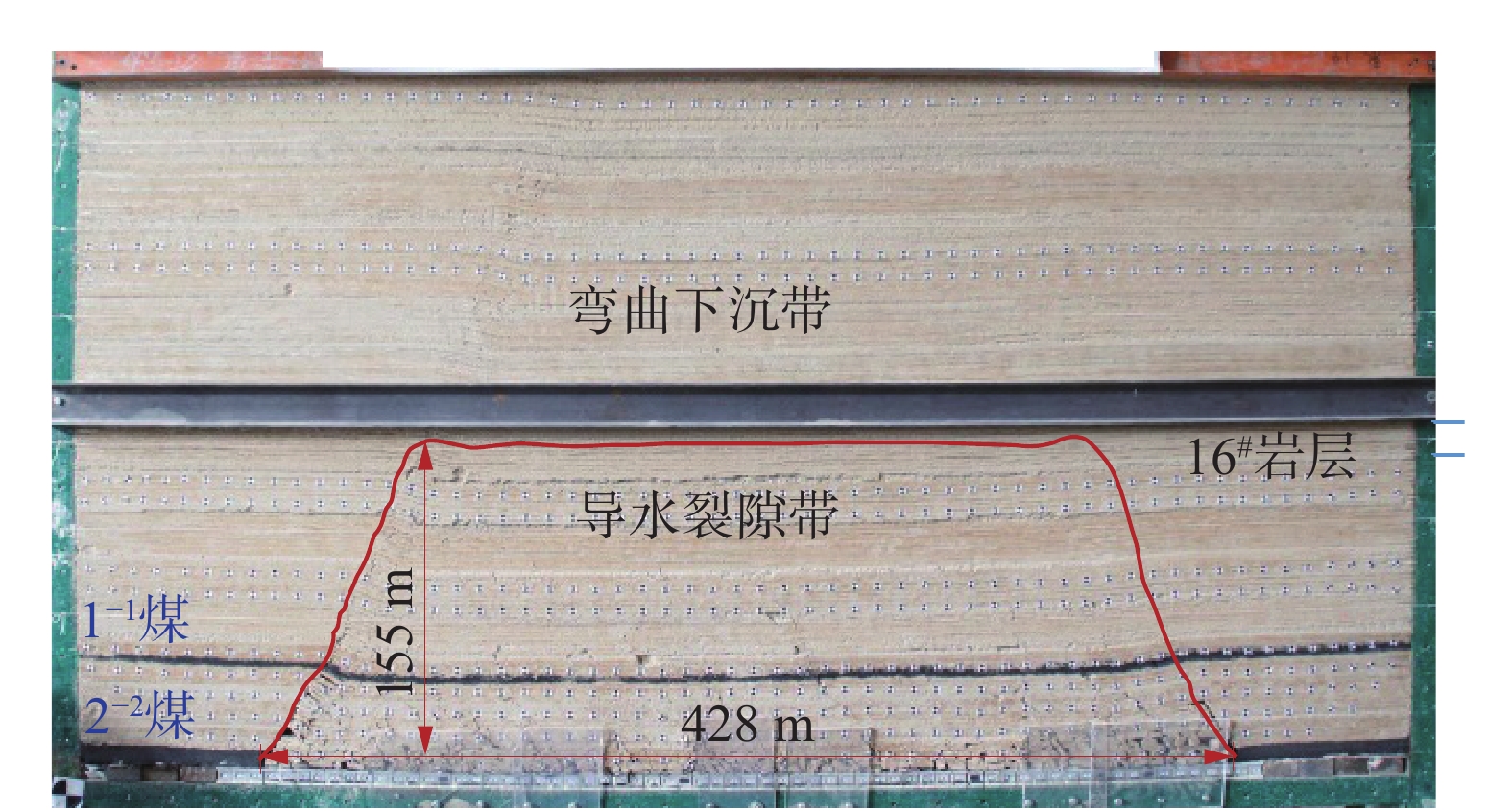

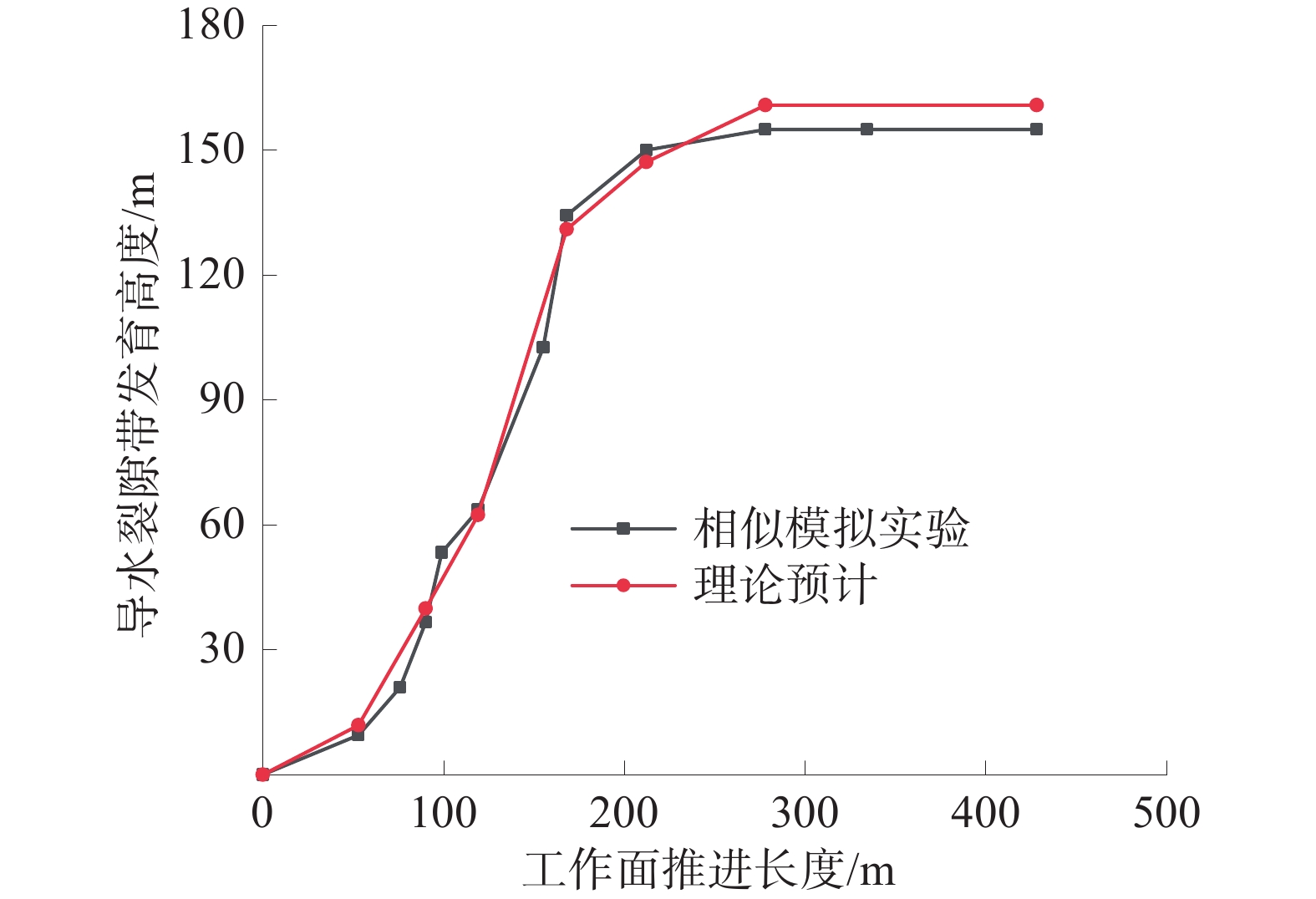

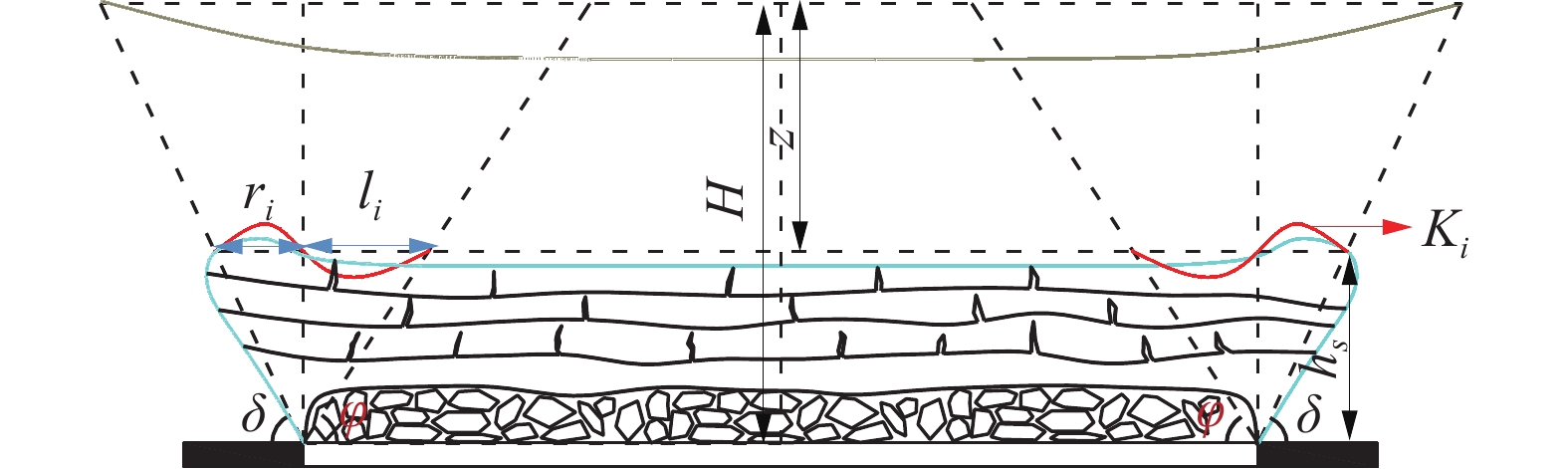

为了研究覆岩导水裂隙带发育高度动态演化规律,以小保当矿区2−2煤层为研究对象,通过理论分析、相似模拟实验及实例验证的方法,对导水裂隙带动态发育高度进行研究;借助概率积分法预计其上部岩层移动变形的理论公式,给出了1种基于覆岩曲率变形的导水裂隙带动态发育高度预计方法。研究表明:导水裂隙带上部岩层下沉系数是1个与挠度及下部自由空间高度相关的分段函数,上部岩层曲率变形大小是决定导水裂隙带发育高度的关键因素;导水裂隙带发育高度与工作面推进长度相关;理论预计小保当矿区2−2煤层导水裂隙带发育高度为160.8 m,相似模拟实验发育高度为155 m,现场实测发育高度为152.01~175.57 m。

Abstract:In order to study the dynamic evolution law of the development height of overburden water conducting fractured zone, taking 2−2 coal seam in Xiaobaodang Mining Area as the research object, the dynamic development height of water conducting fractured zone was studied by theoretical analysis, similar simulation experiment and case verification; a prediction method of dynamic development height of water-flowing fractured zone based on curvature deformation of overburden strata is proposed by using the theoretical formula of predicting the movement and deformation of upper strata with probability integral method. The research shows that the subsidence coefficient of the upper strata of the water-conducting fractured zone is a piecewise function related to the deflection and the height of the lower free space. The curvature deformation of the upper strata is the key factor to determine the development height of the water-conducting fractured zone. The development height of water-flowing fractured zone is related to the advance length of working face; the theoretical prediction of the development height of the water conducting fractured zone in 2−2 coal seam of Xiaobaodang Mining Area is 160.8 m, the development height of the similar simulation experiment is 155 m, and the development height of the field measurement is 152.01-175.57 m.

-

-

表 1 覆岩动态破断判据

Table 1 Dynamic fracture criterion of overburden rock

推进长度/m 第i层岩层挠度/m 是否破断 L<Lpi fimax≥∆i 否 fimax<∆i 否 L≥Lpi fimax≥∆i 否 fimax<∆i 是 表 2 相似模拟实验配比表

Table 2 Similar simulation experiment ratio table

序号 岩性 厚度/m 相似材料配比 河砂 石膏 大白粉 32 粉沙 2.70 9 1 9 31 细沙 53.80 9 1 9 30 红土 12.37 — — — 29 细粒砂岩 17.64 8 2 8 28 细粒砂岩 17.00 8 2 8 27 泥岩 7.00 9 2 8 26 细粒砂岩 2.20 8 2 8 25 砂质泥岩 7.77 9 4 6 24 细粒砂岩 18.96 8 3 7 23 砂质泥岩 8.68 9 4 6 22 细粒砂岩 3.09 8 2 8 21 砂质泥岩 12.10 9 4 6 20 砂质泥岩 12.00 9 4 6 19 细粒砂岩 5.00 8 2 8 18 砂质泥岩 6.48 9 4 6 17 细粒砂岩 13.64 8 2 8 16 粉砂岩 16.70 7 2 8 15 细粒砂岩 10.10 8 3 7 14 粉砂岩 6.01 7 2 8 13 细粒砂岩 13.01 8 3 7 12 粉砂岩 15.13 7 2 8 11 细粒砂岩 8.66 8 3 7 10 粉砂岩 19.40 7 2 8 9 细粒砂岩 9.88 8 3 7 8 粉砂岩 8.20 7 2 8 7 细粒砂岩 14.90 8 3 7 6 煤(1−1) 2.00 粉煤灰∶河砂∶石膏∶大白粉= 21∶1∶2∶21 5 细粒砂岩 18.75 8 3 7 4 粉砂岩 4.20 7 2 8 3 细粒砂岩 5.10 8 3 7 2 中粒砂岩 8.34 8 2 8 1 细粒砂岩 3.50 8 3 7 煤(2−2) 6.00 粉煤灰∶河砂∶石膏∶大白粉= 21∶1∶2∶21 表 3 覆岩破断情况判别表

Table 3 Overburden rock fracture discrimination table

岩层序号 岩层厚度/m Lpi/m ∆i/m 是否破断 16 16.70 212.0 4.52 否 15 10.10 212.0 4.63 是 14 6.01 168.0 4.69 是 13 13.01 168.0 4.82 是 12 15.13 155.0 4.97 是 11 8.66 126.0 5.06 是 10 19.40 126.0 5.25 是 9 9.88 119.0 5.35 是 8 8.20 99.0 5.43 是 7 14.90 99.0 5.58 是 6 2.00 99.0 5.60 是 5 18.75 90.0 5.79 是 4 4.20 76.0 5.83 是 3 5.10 76.0 5.88 是 2 8.34 53.0 5.97 是 1 3.50 41.6 6.00 是 -

[1] 钱鸣高. 煤炭的科学开采[J]. 煤炭学报,2010,35(4):529−534. QIAN Minggao. On sustainable coal mining in China[J]. Journal of China Coal Society, 2010, 35(4): 529−534.

[2] 王双明,黄庆享,范立民,等. 生态脆弱矿区含(隔)水层特征及保水开采分区研究[J]. 煤炭学报,2010,35(1):7−14. WANG Shuangming, HUANG Qingxiang, FAN Limin, et al. Study on overburden aquclude and water protection mining regionazation in the ecological fragile mining area[J]. Journal of China Coal Society, 2010, 35(1): 7−14.

[3] 黄庆享. 浅埋煤层保水开采隔水层稳定性的模拟研究[J]. 岩石力学与工程学报,2009,28(5):987−992. HUANG Qingxiang. Simulation of clay aquifuge stability of water conservation mining in shallow-buried coal seam[J]. Chinese Journal of Rock Mechanics and Engineering, 2009, 28(5): 987−992.

[4] 黄庆享. 浅埋煤层覆岩隔水性与保水开采分类[J]. 岩石力学与工程学报,2010,29(S2):3622-3627. HUANG Qingxiang. Impermeability of overburden rock in shallow buried coal seam and classification of water conservation mining[J]. Chinese Journal of Rock Mechanics and Engineering, 2010, 29(S2): 3622-3672.

[5] 孙学阳,卢明皎,李成,等. 双煤层错距开采优选及对隔水关键层影响研究[J]. 采矿与安全工程学报,2021,38(1):51−57. SUN Xueyang, LU Mingjiao, LI Cheng, et al. Optimal selection of staggered distance mining in double seams and its influence on water-resisting key strata[J]. Journal of Mining & Safety Engineering, 2021, 38(1): 51−57.

[6] 张京民,孟凡林,武海文,等. 烧变岩含水层下煤层开采导水断裂带发育规律研究[J]. 煤矿安全,2022,53(8):180−186. ZHANG Jingmin, MENG Fanlin, WU Haiwen, et al. Study on development law of water conducting fracture zone in coal seam mining under burnt rock aquifer[J]. Safety in Coal Mines, 2022, 53(8): 180−186.

[7] 刘瑞瑞,刘洋,方刚,等. 袁大滩煤矿覆岩破坏规律及顶板水害防治对策[J]. 煤矿安全,2022,53(7):82−91. LIU Ruirui, LIU Yang, FANG Gang, et al. Law of overburden failure and roof water damage in Yuandatan Coal Mine[J]. Safety in Coal Mines, 2022, 53(7): 82−91.

[8] 侯恩科,刘博,龙天文,等. 深埋缓倾斜双煤层开采导水断裂带发育规律研究[J]. 煤矿安全,2022,53(3):50−57. HOU Enke, LIU Bo, LONG Tianwen, et al. Study on development law of water-conducting fault zone in deep gently inclined double coal seam mining[J]. Safety in Coal Mines, 2022, 53(3): 50−57.

[9] 杨达明,郭文兵,赵高博,等. 厚松散层软弱覆岩下综放开采导水裂隙带发育高度[J]. 煤炭学报,2019,44(11):3308−3316. YANG Daming, GUO Wenbing, ZHAO Gaobo, et al. Height of water-conducting zone in longwall top-coal caving mining under thick alluvium and soft overburden[J]. Journal of China Coal Society, 2019, 44(11): 3308−3316.

[10] 李树刚,李志梁,林海飞,等. 采高对采动裂隙演化规律的影响研究[J]. 矿业安全与环保,2015,42(5):25−28. LI Shugang, LI Zhiliang, LIN Haifei, et al. Research on influence of mining height on mining fissure evolution[J]. Mining safety & Environmental Protection, 2015, 42(5): 25−28.

[11] 秦洪岩,王海东,张帆,等. 基于板壳理论的充填开采覆岩导水断裂带发育规律[J]. 煤矿安全,2021,52(1):64−70. QIN Hongyan, WANG Haidong, ZHANG Fan, et al. Development law of fractured zone of overburden strata in backfill mining based on plate and shell theory[J]. Safety in Coal Mines, 2021, 52(1): 64−70.

[12] 樊振丽,刘治国. 厚黏土层软弱覆岩采动破坏的泥盖效应[J]. 采矿与安全工程学报,2020,37(6):1196−1204. FAN Zhenli, LIU Zhiguo. Mud cover effect of mining-induced failure of soft overburden in thick clay strata[J]. Journal of Mining & Safety Engineering, 2020, 37(6): 1196−1204.

[13] 余学义,穆驰,李剑锋. 孟巴矿强含水体下分层开采覆岩导水裂隙带发育规律[J]. 煤炭学报,2022,47(S1):29−38. YU Xueyi, MU Chi, LI Jianfeng. Development law of water-conducting fracture zone in overlying rock with layered mining under strong water-bearing body in Barapukuria coal mine[J]. Journal of China Coal Society, 2022, 47(S1): 29−38.

[14] 赵宝峰. 上行开采条件下多煤层开采覆岩破坏规律研究[J]. 矿业安全与环保,2016,43(6):13−15. ZHAO Baofeng. Study on overlying strata failure rule in process of multi-seam ascending mining[J]. Mining safety & environmental protection, 2016, 43(6): 13−15.

[15] 尹尚先,徐斌,徐慧,等. 综采条件下煤层顶板导水裂隙带高度计算研究[J]. 煤炭科学技术,2013,41(9):138−142. YIN Shangxian, XU Bin, XU Hui, et al. Study on height calculation of water conducted fractured zone caused by fully mechanized mining[J]. Coal Science and Technology, 2013, 41(9): 138−142.

[16] 黄万朋,高延法,王波,等. 覆岩组合结构下导水裂隙带演化规律与发育高度分析[J]. 采矿与安全工程学报,2017,34(2):330−335. HUANG Wanpeng, GAO Yanfa, WANG Bo, et al. Evolution rule and development height of permeable fractured zone under combined-strata structure[J]. Journal of Mining & Safety Engineering, 2017, 34(2): 330−335.

[17] 许家林,王晓振,刘文涛,等. 覆岩主关键层位置对导水裂隙带高度的影响[J]. 岩石力学与工程学报,2009,28(2):380−385. XU Jialin, WANG Xiaozhen, LIU Wentao, et al. Effects of primary key stratum location on height of water flowing fracture zone[J]. Chinese Journal of Rock Mechanics and Engineering, 2009, 28(2): 380−385.

[18] 许家林,朱卫兵,王晓振. 基于关键层位置的导水裂隙带高度预计方法[J]. 煤炭学报,2012,37(5):762−769. XU Jialin, ZHU Weibin, WANG Xiaozhen. New method to predict the height of fractured water-conducting zone by location of key strata[J]. Journal of China Coal Society, 2012, 37(5): 762−769.

[19] 乔伟,韩昌民,李连刚,等. 煤矿导水裂隙带高度预测的PSO-SVR法及应用[J]. 煤炭科技,2022,43(4):77−84. QIAO Wei, HAN Changmin, LI Liangang, et al. PSO-SVR method for the height of water flowing fractured zone in coal mine and its application[J]. Coal Science & Technology Magazine, 2022, 43(4): 77−84.

[20] 赵兵朝,余学义. 导水裂隙带的广义损伤因子研究[J]. 中国矿业大学学报,2010,39(5):705−708. ZHAO Bingchao, YU Xueyi. Research on broad sense damage gene of fracture zone[J]. Journal of China University of Mining & Technology, 2010, 39(5): 705−708.

[21] 赵兵朝,刘樟荣,同超,等. 覆岩导水裂隙带高度与开采参数的关系研究[J]. 采矿与安全工程学报,2015,32(4):634−638. ZHAO Bingchao, LIU Zhangrong, TONG Chao, et al. Relation between height of water flowing fractured zone and mining parameters[J]. Journal of Mining & Safety Engineering, 2015, 32(4): 634−638.

[22] 格维尔茨曼. 水体下安全采煤[M]. 北京:煤炭工业出版社,1980:62-68. [23] 余学义,张恩强. 开采损害学[M]. 北京:煤炭工业出版社,2010:53-62. [24] 郭文兵,娄高中. 覆岩破坏充分采动程度定义及判别方法[J]. 煤炭学报,2019,44(3):755−766. GUO Wenbing, LOU Gaozhong. Definition and distinguishing method of critical mining degree of overburden failure[J]. Journal of China Coal Society, 2019, 44(3): 755−766.

-

期刊类型引用(6)

1. 李润芝. 动压影响孤岛工作面巷道围岩“卸-支平衡”协同控制技术. 煤矿安全. 2024(03): 199-208 .  本站查看

本站查看

2. 胡威,高志强. 基于薄板理论的覆岩导水裂隙带高度研究. 煤炭科技. 2024(03): 126-130 .  百度学术

百度学术

3. 李辉,宋宇航,毕健成,李强. 孤岛工作面侧向顶板结构及切顶卸压技术. 科学技术与工程. 2024(36): 15396-15403 .  百度学术

百度学术

4. 王鹏,王虎伟,王帅,王鹏程. 孤岛工作面回采巷道围岩破坏机理及差异化控制技术. 金属矿山. 2024(12): 96-105 .  百度学术

百度学术

5. 秦忠诚,张国兴,詹召伟,王彦敏,高超. 1310孤岛工作面初采矿压特征与支架适应性评价. 矿业研究与开发. 2023(03): 147-153 .  百度学术

百度学术

6. 杨旭,王涛. 孤岛工作面顶板条带弱化技术研究及应用. 矿业安全与环保. 2023(03): 111-116+123 .  百度学术

百度学术

其他类型引用(3)

下载:

下载: