The Influence of low-temperature cold shock saturated water on the permeability characteristics of coal body and experimental study on permeability enhancement

-

摘要:

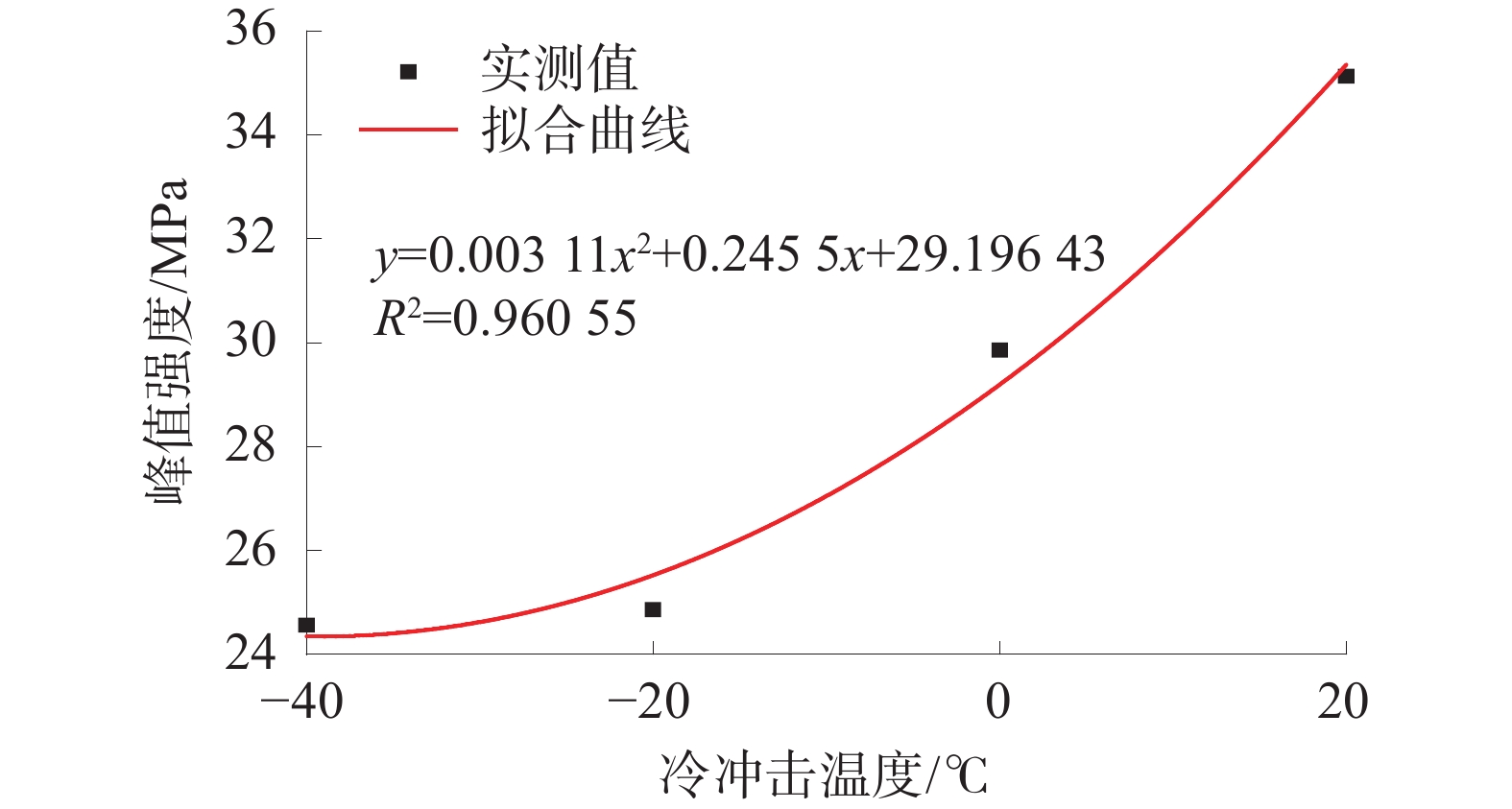

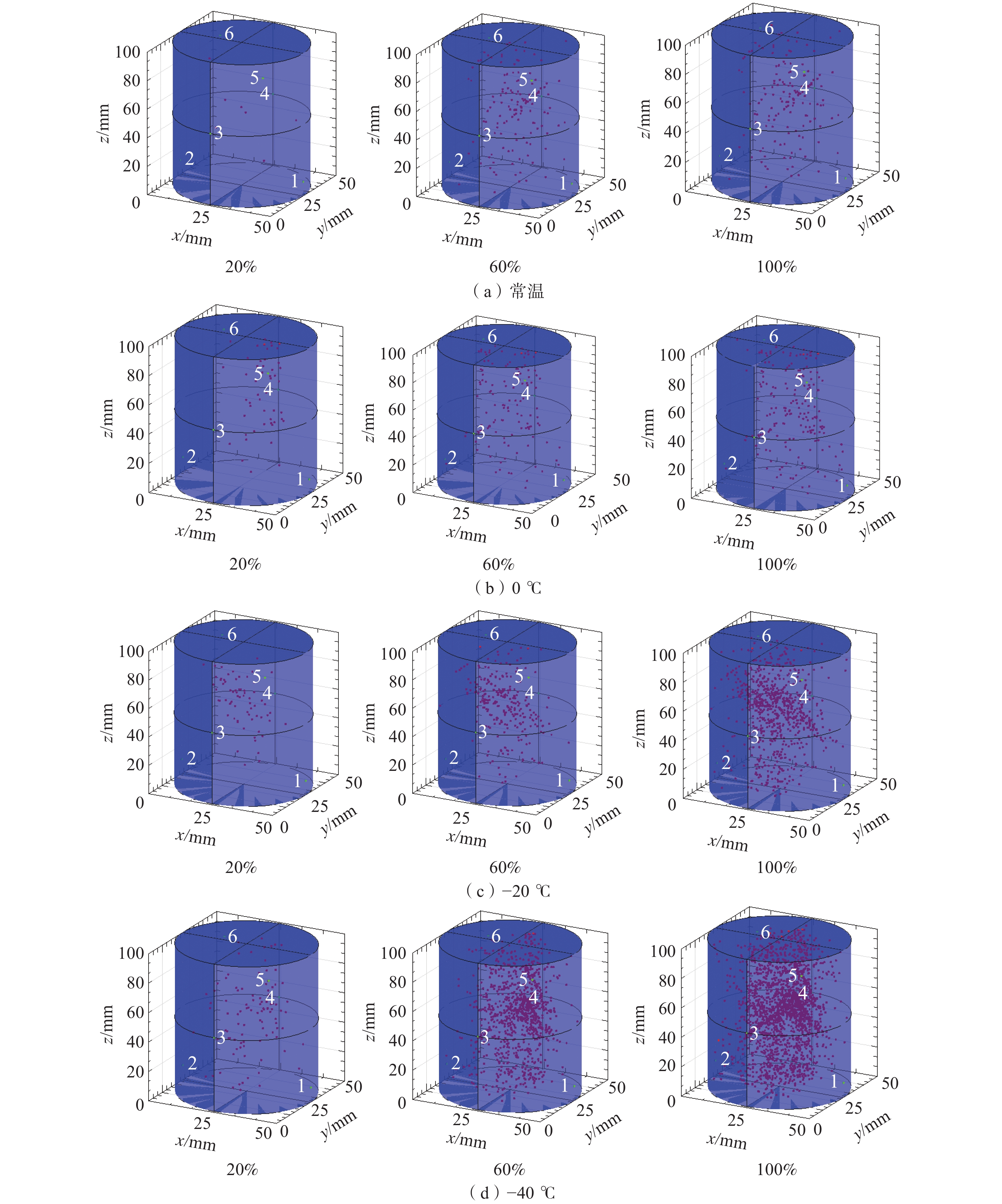

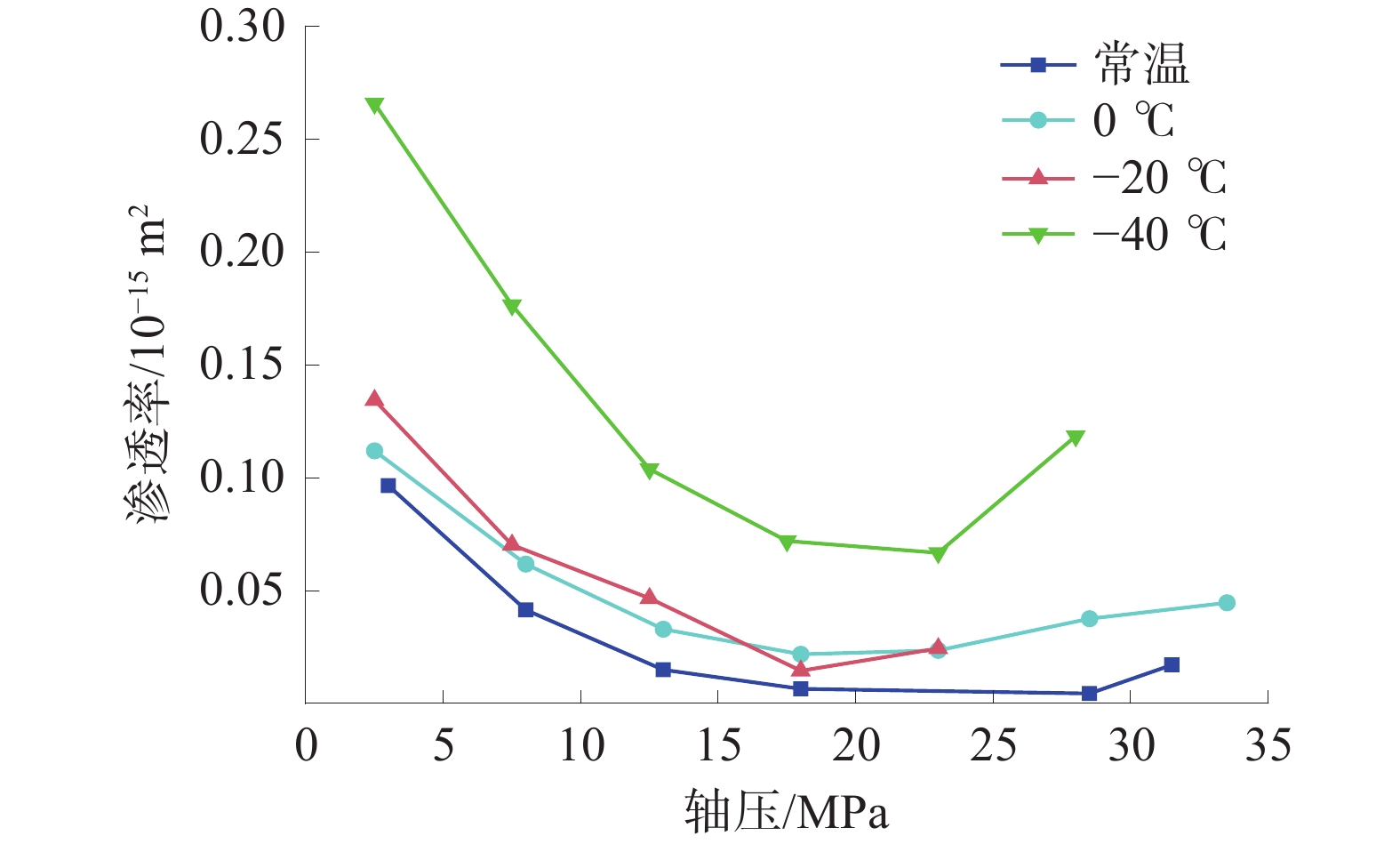

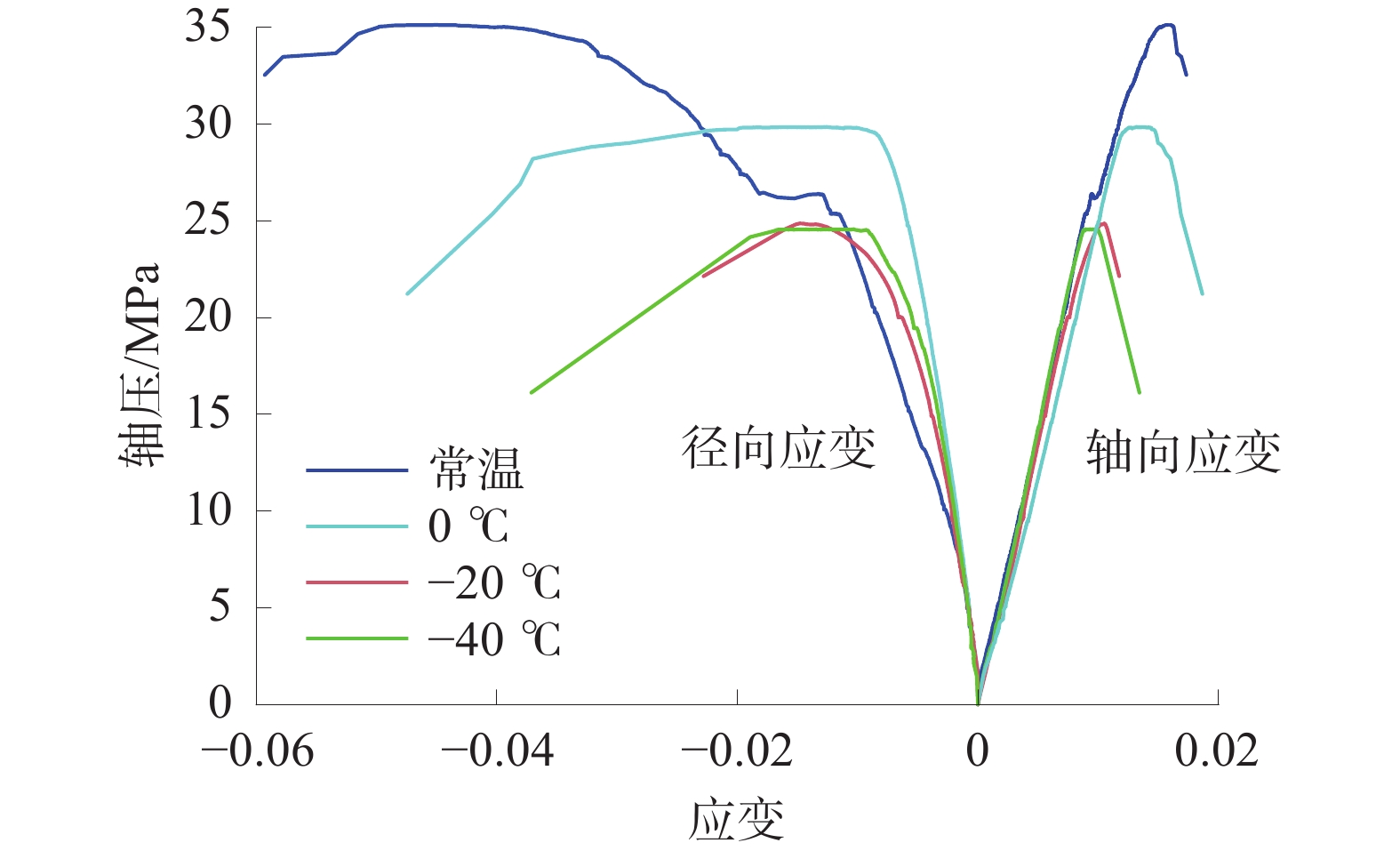

煤层气开发工作中,由于煤层的普遍渗透率较低,需采取有效的增透技术来提高煤层气抽采效率,低温致裂增透技术被广泛研究和应用。通过对煤体进行低温冷冲击饱水处理,模拟实际开采中的低温环境,以探究不同温度冷冲击饱水煤体的力学特性及渗流规律;采用负压饱水装置对试样进行饱水处理,试样完全饱水后,放入高低温试验箱,分别对不同试样进行常温、0、−20、−40 ℃的冲击;饱水试样冷冲击处理完成后,使用三轴渗流仪进行渗流试验和三轴压缩试验。试验结果表明:冷冲击处理饱水试样,会对试样造成损伤,煤体内部裂隙发育扩张,试样抗压强度减小,渗透率增大;随着冷冲击温度的降低,试样的渗透率逐渐增大;−40 ℃冲击的试样初始渗透率最大,较常温试样增长了202.9%。

Abstract:In the development of coalbed methane (CBM), due to the generally low permeability of coal beds, effective permeability enhancement technology is needed to improve the extraction efficiency of CBM. Among them, low-temperature fracturing and permeability enhancement technology has been widely studied and applied. In this paper, we simulate the low-temperature environment in actual mining by applying low-temperature cold impact water saturation treatment to the coal body, in order to investigate the mechanical properties and seepage law of the coal body saturated with cold impact water at different temperature conditions. Negative pressure water-saturated device is used to saturate the specimen, after the specimen is completely saturated with water, it is put into the high and low temperature test chamber, and different specimens are impacted at room temperature, 0 ℃, −20 ℃ and −40 ℃, respectively. After the cold shock treatment of water-saturated specimens was completed, a triaxial percolation meter was used to carry out percolation test and triaxial compression test. The test results show that: cold shock treatment of water-saturated specimens will cause damage to the specimen, the development and expansion of internal cracks in the coal body, the specimen compressive strength decreases, and the permeability increases. And with the decrease of cold impact temperature, the permeability of the specimen gradually increases. The initial permeability of the specimen impacted at −40 ℃ was the largest, which increased by 202.9% compared with the normal temperature specimen.

-

-

表 1 试样参数及冲击温度

Table 1 Specimen parameters and impact temperatures

试样编号 尺寸/(mm×mm) 冲击温度/ ℃ 1# ϕ50.22×102.01 — 2# ϕ50.12×101.53 0 3# ϕ50.34×101.23 −20 4# ϕ50.24×101.06 −40 表 2 试样的峰值强度及应变

Table 2 Peak strength and strain of specimens

试样 峰值强度/MPa 峰值轴向应变 峰值径向应变 1# 35.128 66 0.017 34 −0.059 28 2# 29.859 87 0.018 67 −0.047 44 3# 24.866 24 0.011 76 −0.022 80 4# 24.570 70 0.013 43 −0.037 12 表 3 常温及不同温度冷冲击处理试样渗透率表

Table 3 Permeability table of samples treated with cold shock at normal temperature and different temperatures

试样 冷冲击

温度/ ℃初始渗透率/

10−15 m2较常温试样

渗透率增幅/%较上一档冷冲击

处理试样的

渗透率增幅/%1 常温 0.096 6 — — 2 0 0.111 9 15.89 15.89 3 −20 0.134 4 39.19 20.10 4 −40 0.292 5 202.90 117.62 -

[1] 张超林,王恩元,王奕博,等. 近20年我国煤与瓦斯突出事故时空分布及防控建议[J]. 煤田地质与勘探,2021,49(4):134−141. doi: 10.3969/j.issn.1001-1986.2021.04.016 ZHANG Chaolin, WANG Enyuan, WANG Yibo, et al. Spatial-temporal distribution of outburst accidents from 2001 to 2020 in China and suggestions for prevention and control[J]. Coal Geology & Exploration, 2021, 49(4): 134−141. doi: 10.3969/j.issn.1001-1986.2021.04.016

[2] 秦勇,袁亮,胡千庭,等. 我国煤层气勘探与开发技术现状及发展方向[J]. 煤炭科学技术,2012,40(10):1−6. QIN Yong, YUAN Liang, HU Qianting, et al. Status and development orientation of coal bed methane exploration and development technology in China[J]. Coal Science and Technology, 2012, 40(10): 1−6.

[3] 荆俊杰,于丽雅,延婧. 高瓦斯低渗煤层水力造穴增透技术优化研究[J]. 煤矿安全,2022,53(1):8−14. JING Junjie, YU Liya, YAN Jing. Research on optimization of hydraulic flushing and permeability enhancement technology in high gas and low permeability coal seam[J]. Safety in Coal Mines, 2022, 53(1): 8−14.

[4] 冯仁俊. 煤层群分层水力压裂与多层综合压裂增透效果对比研究[J]. 煤矿安全,2021,52(12):21−28. FENG Renjun. Comparative study on permeability enhancement effect of separate-layer fracturing and multi-layers comprehensive fracturing in coal seam group[J]. Safety in Coal Mines, 2021, 52(12): 21−28.

[5] 田苗苗,张磊,薛俊华,等. 液氮致裂煤体技术研究现状及展望[J]. 煤炭科学技术,2022,50(7):191−198. TIAN Miaomiao, ZHANG Lei, XUE Junhua, et al. Study and prospection of liquid nitrogen fracturing coal technology[J]. Coal Science and Technology, 2022, 50(7): 191−198.

[6] 王登科,孙刘涛,魏建平. 温度冲击下煤的微观结构变化与断裂机制[J]. 岩土力学,2019,40(2):529−538. WANG Dengke, SUN Liutao, WEI Jianping. Microstructure evolution and fracturing mechanism of coal under thermal shock[J]. Rock and Soil Mechanics, 2019, 40(2): 529−538.

[7] 张震,刘高峰,李宝林,等. CO2相变致裂煤的纳米孔隙尺度改造效应[J]. 岩石力学与工程学报,2023,42(3):672−684. ZHANG Zhen, LIU Gaofeng, LI Baolin, et al. Transformed effect of nano-pores in coal by CO2 phase transition fracturing[J]. Chinese Journal of Rock Mechanics and Engineering, 2023, 42(3): 672−684.

[8] ALLEN J C, BAUER C L. Method of increasing the permeability of a subterranean hydrocarbon bearing formation: US338727 A [P]. 1968-09-27.

[9] MCDANIEL B W, GRUNDMANN S R, ENDRCK W D, et al. Field applications of cryogenic nitrogen as a hydraulic-fracturing fluid[J]. Journal of Petroleum Technology, 1998, 50(3): 38−39. doi: 10.2118/0398-0038-JPT

[10] 李波,吕小权,黄来胜,等. 低温作用下煤体细观结构变化及相变致裂实验研究[J]. 中国安全生产科学技术,2020,16(7):25−29. LI Bo, LYU Xiaoquan, HUANG Laisheng, et al. Experimental study on meso-structure change and phase-transforming fracturing of coal under low temperature[J]. Journal of Safety Science and Technology, 2020, 16(7): 25−29.

[11] 翟成,孙勇. 低温循环致裂煤体孔隙结构演化规律试验研究[J]. 煤炭科学技术,2017,45(6):24−29. ZHAI Cheng, SUN Yong. Experimental study on evolution of pore structure in coal after cyclic cryogenic fracturing[J]. Coal Science and Technology, 2017, 45(6): 24−29.

[12] 张春会,张海霞,于永江,等. 饱水度和再溶浸对液氮冷冻煤致裂的影响[J]. 煤炭学报,2016,41(S2):400−406. ZHANG Chunhui, ZHANG Haixia, YU Yongjiang, et al. Effects of saturation and re-submersion on coal fracturing subjected to liquid nitrogen shock[J]. Journal of China Coal Society, 2016, 41(S2): 400−406.

[13] 张磊,卢硕,唐俊,等. 液氮溶浸时间对烟煤渗流特性的影响及传热过程模拟[J]. 采矿与安全工程学报,2021,38(6):1231−1239. ZHANG Lei, LU Shuo, TANG Jun, et al. Effect of liquid nitrogen immersion time on seepage characteristics of bituminous coal and simulation of heat transfer process[J]. Journal of Mining & Safety Engineering, 2021, 38(6): 1231−1239.

[14] 戎彦龙,王毅,赵东,等. 冷冲击条件下饱水试样结构损伤规律研究[J]. 中国安全生产科学技术,2022,18(10):86−93. RONG Yanlong, WANG Yi, ZHAO Dong, et al. Research on structural damage law of water-saturated coal sample under cold shock conditions[J]. Journal of Safety Science and Technology in China, 2022, 18(10): 86−93.

[15] GB/T 23561.9—2009煤和岩石物理力学性质测定方法[S]. [16] WINKLER E M. Frost damage to stone and concrete: Geological considerations[J]. Engineering Geology, 1968, 2(5): 315−323. doi: 10.1016/0013-7952(68)90010-0

[17] YAMABE T, NEAUPANE K M. Determination of some thermo-mechanical properties of Sirahama sandstone under subzero temperature condition[J]. International Journal of Rock Mechanics and Mining Sciences, 2001, 38(7): 1029−1034. doi: 10.1016/S1365-1609(01)00067-3

-

期刊类型引用(6)

1. 李润芝. 动压影响孤岛工作面巷道围岩“卸-支平衡”协同控制技术. 煤矿安全. 2024(03): 199-208 .  本站查看

本站查看

2. 胡威,高志强. 基于薄板理论的覆岩导水裂隙带高度研究. 煤炭科技. 2024(03): 126-130 .  百度学术

百度学术

3. 李辉,宋宇航,毕健成,李强. 孤岛工作面侧向顶板结构及切顶卸压技术. 科学技术与工程. 2024(36): 15396-15403 .  百度学术

百度学术

4. 王鹏,王虎伟,王帅,王鹏程. 孤岛工作面回采巷道围岩破坏机理及差异化控制技术. 金属矿山. 2024(12): 96-105 .  百度学术

百度学术

5. 秦忠诚,张国兴,詹召伟,王彦敏,高超. 1310孤岛工作面初采矿压特征与支架适应性评价. 矿业研究与开发. 2023(03): 147-153 .  百度学术

百度学术

6. 杨旭,王涛. 孤岛工作面顶板条带弱化技术研究及应用. 矿业安全与环保. 2023(03): 111-116+123 .  百度学术

百度学术

其他类型引用(3)

下载:

下载: