The influence of gas injection pressure and osmotic pressure on the permeability of loose coal body at different temperature conditions

-

摘要:

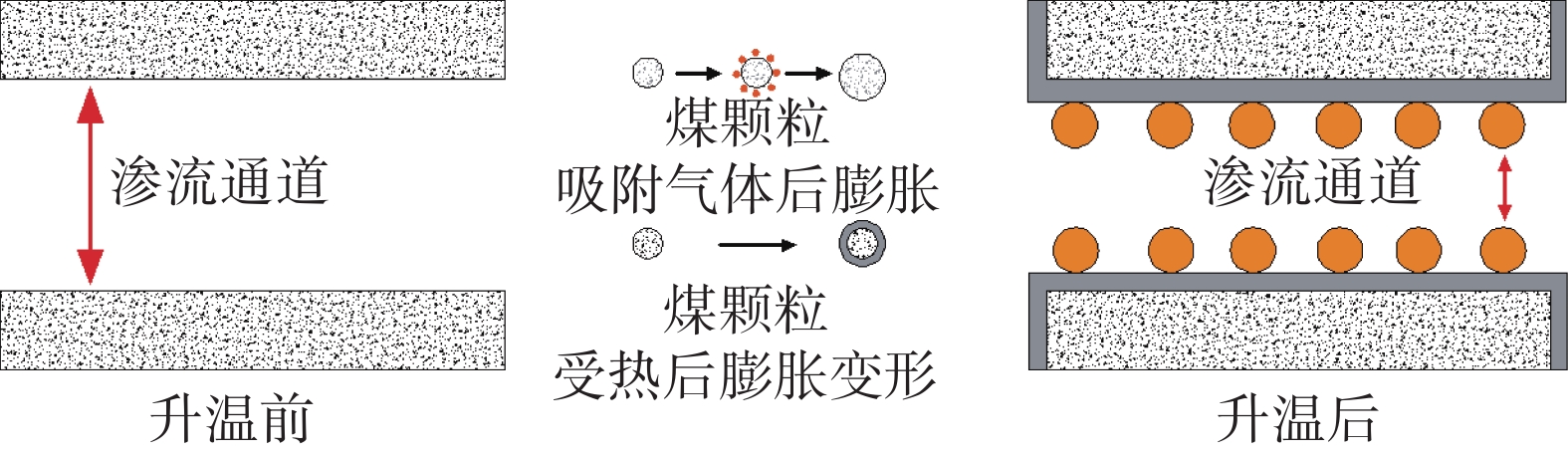

为了探究采空区遗煤自燃过程中温度对松散煤体渗透率的影响机理,综合考虑温度引起的煤体吸附变形、热膨胀变形、热裂变形以及滑脱效应等因素对煤体渗透率的影响,建立了不同温度下煤体渗透率数学模型,通过控制变量法控制渗透率数学模型单一影响因素参数来研究温度变化对松散煤体渗透率的影响机理。基于物理相似原理,设计搭建了松散煤体渗流实验平台,选取山西成庄矿无烟煤为实验对象,以空气为渗流气体模拟井下环境,开展了不同温度(40~100 ℃)、不同注气压力(0.3~0.5 MPa)、不同渗透压力(0.04~0.08 kPa)条件下松散煤体中气体运移实验,通过实验与模型结果相互验证来探究温度变化对松散煤体渗透率的影响机理。结果表明:松散煤体渗透率随气体压力梯度增加呈指数型递增;同一压力梯度条件下,渗透率随温度升高逐渐减小,40~60 ℃时温度对渗透率影响较小,渗透率变化不明显,60 ℃之后渗透率开始明显降低,90、100 ℃时渗透率降低更为显著;受滑脱效应影响,注气压力的升高抑制煤体渗透率;不同渗透压下(0.04~0.08 kPa),松散煤体渗透率模型值与渗流实验值吻合度高,随着温度的升高吸附形变对松散煤体渗透率有抑制作用,热裂形变和滑脱效应对松散煤体渗透率有促进作用,热膨胀变形对松散煤体渗透率影响微弱,温度通过吸附形变、热裂形变及滑脱效应综合作用影响松散煤体渗透率。

Abstract:In order to investigate the influence mechanism of temperature on the permeability of loose coal body in the process of spontaneous combustion of residual coal in the gob, the mathematical model of the permeability of coal body under different temperature conditions was established by considering the effects of temperature-induced adsorption deformation, thermal expansion deformation, thermal fission deformation and sliding effect, etc., and the parameters of the single influencing factors of the mathematical model of the permeability were controlled by the method of controlling variables to investigate the influence mechanism of the temperature change on the permeability of the loose coal body. Based on the principle of physical similarity, an experimental platform for loose coal seepage was designed and constructed, and anthracite coal from Chengzhuang Mine in Shanxi Province was selected as the experimental object, and air was used as the seepage gas to simulate the underground environment, so that gas transport experiments were carried out in the loose coal body under different temperature conditions (40-100 ℃), different injection pressures (0.3-0.5 MPa), and different permeability pressures (0.04-0.08 kPa). The mechanism of the influence of temperature change on the permeability of the loose coal body was investigated by mutual verification of the experimental and modeling results. The results show that: the permeability of loose coal body increases exponentially with the increase of gas pressure gradient; under the condition of the same pressure gradient, the permeability decreases gradually with the increase of temperature; the influence of the temperature on the permeability is small when it is from 40 ℃ to 60 ℃, and the change of the permeability is not obvious, and the permeability starts to decrease after 60 ℃, and the decrease of the permeability is more significant when it is from 90 ℃ to 100 ℃; under the influence of the slippage effect, the increase of the injection pressure inhibits the permeability of the coal body. Under different osmotic pressure conditions (0.04-0.08 kPa), the model values of the permeability of the loose coal body and the experimental values of the seepage flow are in high agreement. With the increase of temperature, adsorption deformation has an inhibitory effect on the permeability of the loose coal body, thermal cracking deformation and the slipping effect have a promotional effect on the permeability of the loose coal body, and the effect of the deformation of the thermal expansion on the permeability of the loose coal body is weak. Temperature affects the permeability of loose coal body through the combined effect of adsorption deformation, thermal cracking deformation and sliding effect.

-

-

表 1 不同压力梯度渗透率最终损失率

Table 1 Final permeability loss rates of different pressure gradients

压力梯度/(Pa·m−1) 渗透率损失率/% 60 17.96 80 16.28 100 18.06 120 20.00 140 20.72 160 23.92 180 26.76 表 2 渗透模型引用参数

Table 2 Reference parameters of permeability model

参数 参数值 参数来源 EA/MPa 1 900 文献[19] ρc/(g·cm−3) 1.483 9 自测 ϕ0 0.504 8 自测 $ \vartheta $ 23.7 自测 表 3 无烟煤等温吸附常数

Table 3 Anthracite isotherm adsorption constants

温度/℃ a b 40 6.520 12.0 50 6.127 10.0 60 5.802 12.0 70 5.460 9.8 80 5.326 12.0 90 5.220 11.0 100 5.100 12.0 -

[1] 曾强,王德明,蔡忠勇. 煤田火区裂隙场及其透气率分布特征[J]. 煤炭学报,2010,35(10):1670−1673. ZENG Qiang, WANG Deming, CAI Zhongyong. The distribution of fissures/cracks and its permeability with coal fire zones[J]. Journal of China Coal Society, 2010, 35(10): 1670−1673.

[2] 秦波涛,仲晓星,王德明,等. 煤自燃过程特性及防治技术研究进展[J]. 煤炭科学技术,2021,49(1):66−99. QIN Botao, ZHONG Xiaoxing, WANG Deming, et al. Research progress of coal spontaneous combustion process characteristics and prevention technology[J]. Coal Science and Technology, 2021, 49(1): 66−99.

[3] 余明高,晁江坤,褚廷湘,等. 承压破碎煤体渗透特性参数演化实验研究[J]. 煤炭学报,2017,42(4):916−922. YU Minggao, CHAO Jiangkun, CHU Tingxiang, et al. Experimental study on the evolution of permeability characteristics parameters of pressurized and fractured coal bodies[J]. Journal of China Coal Society, 2017, 42(4): 916−922.

[4] 蔡婷婷,冯增朝,姜玉龙,等. 不同温度应力下煤体蠕变中的渗流规律研究[J]. 岩石力学与工程学报,2018,37(S2):3898−3904. CAI Tingting, FENG Zengchao, JIANG Yulong, et al. Seepage evolution in coal creep under different temperatures and different stresses[J]. Chinese Journal of Rock Mechanics and Engineering, 2018, 37(S2): 3898−3904.

[5] 聂琦苗,牛会永,鲁义,等. 不同孔隙率对采空区自燃的影响规律研究[J]. 安全,2020,41(5):46−51. NIE Qimiao, NIU Huiyong, LU Yi, et al. Study on the influence of different porosity on spontaneous combustion in goaf[J]. Safety & Security, 2020, 41(5): 46−51.

[6] 褚廷湘,李品,余明高. 工作面推进下采空区煤自燃进程的动态模拟研究[J]. 中国矿业大学学报,2019,48(3):529−537. CHU Tingxiang, LI Pin, YU Minggao. Dynamic simulation of coal spontaneous combustion in gob under working face advancing[J]. Journal of China University of Mining & Technology, 2019, 48(3): 529−537.

[7] GAO Z, LI B, LI J, et al. Coal permeability related to matrix-fracture interaction at different temperatures and stresses[J]. Journal of Petroleum Science and Engineering, 2021, 200(5): 108428.

[8] 杨新乐,张永利,李成全,等. 考虑温度影响下煤层气解吸渗流规律试验研究[J]. 岩土工程学报,2008,30(12):1811−1814. doi: 10.3321/j.issn:1000-4548.2008.12.007 YANG Xinle, ZHANG Yongli, LI Chengquan, et al. Experimental study on desorption and seepage rules of coal-bed gas considering temperature conditions[J]. Chinese Journal of Geotechnical Engineering, 2008, 30(12): 1811−1814. doi: 10.3321/j.issn:1000-4548.2008.12.007

[9] 冯子军,万志军,赵阳升,等. 高温三轴应力下无烟煤、气煤煤体渗透特性的试验研究[J]. 岩石力学与工程学报,2010,29(4):689−696. FENG Zijun, WAN Zhijun, ZHAO Yangsheng, et al. Experimental study of permeability of anthracite and gas coal masses under high temperature and triaxial stress[J]. Chinese Journal of Rock Mechanics and Engineering, 2010, 29(4): 689−696.

[10] 冯子军,赵阳升,万志军,等. 热力耦合作用下无烟煤变形过程中渗透特性[J]. 煤炭学报,2010,35(S1):86−90. FENG Zijun, ZHAO Yangsheng, WAN Zhijun, et al. Permeability characteristics of anthracite during deformation under thermal coupling action[J]. Journal of Coal Society, 2010, 35(S1): 86−90.

[11] 孙光中,王公忠,张瑞林. 构造煤渗透率对温度变化响应规律的实验研究[J]. 岩土力学,2016,37(4):1042−1048. SUN Guangzhong, WANG Gongzhong, ZHANG Ruilin. An experimental study on response law of permeability of tectonic coal samples to temperature variation[J]. Rock and Soil Mechanics, 2016, 37(4): 1042−1048.

[12] 李志强,鲜学福,徐龙君,等. 地应力、地温场中煤层气相对高渗区定量预测方法[J]. 煤炭学报,2009,34(6):766−770. doi: 10.3321/j.issn:0253-9993.2009.06.010 LI Zhiqiang, XIAN Xuefu, XU Longjun, et al. Quantitative predicting method of coalbed methane relative high permeability region in geo-stress and geothermal field[J]. Journal of China Coal Society, 2009, 34(6): 766−770. doi: 10.3321/j.issn:0253-9993.2009.06.010

[13] 杨凯,林柏泉,朱传杰,等. 温度和围压耦合作用下煤样渗透率变化的试验研究[J]. 煤炭科学技术,2017,45(12):121−126. YANG Kai, LIN Baiquan, ZHU Chuanjie, et al. Experiment study on permeability variation of coal samples under coupling effect of temperature and confined pressure[J]. Coal Science and Technology, 2017, 45(12): 121−126.

[14] 滕腾,王伟,刘斌,等. 煤体基质热开裂增透模型[J]. 煤炭学报,2020,45(2):676−683. TENG Teng, WANG Wei, LIU Bin, et al. Model of thermal fracturing induced permeability enhancement in coal matrix block[J]. Journal of China Coal Society, 2020, 45(2): 676−683.

[15] 王公忠,徐星. 基于连续变温变件的含瓦斯煤渗流特性数值模拟[J]. 煤矿安全,2016,47(8):1−4. WANG Gongzhong, XU Xing. Numerical simulation on permeability properties of coal containing gas based on continuously variable temperature conditions[J]. Safety in Coal Mines, 2016, 47(8): 1−4.

[16] 陈术源,秦勇,申建,等. 高阶煤渗透率温度应力敏感性试验研究[J]. 煤炭学报,2014,39(9):1845−1851. CHEN Shuyuan, QIN Yong, SHEN Jian, et al. Temperature-stress sensitivity of high-rank coal permeability[J]. Journal of China Coal Society, 2014, 39(9): 1845−1851.

[17] JIANG Changbao, WANG Yifan, DUAN Minke, et al. Experimental study on the evolution of pore-fracture structures and mechanism of permeability enhancement in coal under cyclic thermal shock[J]. Fuel, 2021, 304: 121455. doi: 10.1016/j.fuel.2021.121455

[18] 于永江,张华,张春会,等. 温度及应力对成型煤样渗透性的影响[J]. 煤炭学报,2013,38(6):936−941. YU Yongjiang, ZHANG Hua, ZHANG Chunhui, et al. Effects of temperature and stress on permeability of standard coal briquette specimen[J]. Journal of China Coal Society, 2013, 38(6): 936−941.

[19] 李心田. 浅埋厚煤层工作面CO产生运移积聚规律与超限防治技术研究[D]. 包头:内蒙古科技大学,2023. [20] LIU S, HARPALANI S. A new theoretical approach to model sorption-induced coal shrinkage or swelling[J]. AAPG Bulletin, 2013, 97(7): 1033−1049. doi: 10.1306/12181212061

[21] LIU J, CHEN Z, ELSWORTH D, et al. Interactions of multiple processes during CBM extraction: A critical review[J]. International Journal of Coal Geology, 2011, 87(3/4): 175−189.

[22] 李波波,杨康,李建华,等. 力热耦合作用下煤岩吸附及渗透特性的试验研究[J]. 煤炭学报,2018,43(10):2857−2865. LI Bobo, YANG Kang, LI Jianhua, et al. Experimental study on the adsorption and permeability characteristics of coal under the coupling of stress and temperature[J]. Journal of China Coal Society, 2018, 43(10): 2857−2865.

[23] 张志成. 阳煤一矿81301采空区遗煤孔隙特征及对多元气体吸附规律研究[D]. 徐州:中国矿业大学,2020. [24] 赵伞. 环境温度对废弃矿井遗煤吸附瓦斯特性影响[D]. 焦作:河南理工大学,2020. [25] 闫静,孙臣. 低温对不同水分条件下煤的坚固性系数影响研究[J]. 能源与环保,2021,43(4):156−160. YAN Jing, SUN Chen. Research on influence of low temperature on coal firmness coefficient under different moisture conditions[J]. China Energy and Environmental Protection, 2021, 43(4): 156−160.

[26] 沈书豪. 淮南潘集矿区深部煤系岩石力学性质及其控制因素研究[D]. 淮南:安徽理工大学,2020. [27] 孙南翔. 低阶煤热敏特性及其热力破碎机理研究[D]. 北京:中国矿业大学(北京),2016. [28] 陈旭. 热损伤后砂岩气体渗透特性及孔隙结构特征演化规律研究[D]. 徐州:中国矿业大学,2021. [29] 武朝然. 有效应力下甲烷水合物沉积物渗流特性研究[D]. 大连:大连理工大学,2020. [30] 刘萱,许浩,汤达祯,等. 低渗煤层气藏中的滑脱效应及影响因素[J]. 科技创新导报,2014,11(20):32−33. doi: 10.3969/j.issn.1674-098X.2014.20.025 [31] 李波波,高政,杨康,等. 考虑温度、孔隙压力影响煤岩渗透性演化机制分析[J]. 煤炭学报,2020,45(2):626−632. LI Bobo, GAO Zheng, YANG Kang, et al. Analysis of coal permeability evolution mechanism considering the effect of temperature and pore pressure[J]. Journal of China Coal Society, 2020, 45(2): 626−632.

[32] 周银波,李晓丽,李晗晟,等. 煤体吸附变形对3种气体渗透率演化的影响[J]. 煤矿安全,2021,52(11):16−21. ZHOU Yinbo, LI Xiaoli, LI Hansheng, et al. Influence of coal adsorption deformation on permeability evolution of three kinds of gas[J]. Safety in Coal Mines, 2021, 52(11): 16−21.

[33] 侯浩然. 微波辐射下煤体的热效应及热力学响应特征[D]. 徐州:中国矿业大学,2020. [34] 贾荔丹,李波波,李建华,等. 采气-采煤阶段煤岩渗透率演化机制研究[J]. 岩石力学与工程学报,2022,41(1):132−146. JIA Lidan, LI Bobo, LI Jianhua, et al. Study on the evolution mechanism of coal permeability during gas production and coal mining[J]. Chinese Journal of Rock Mechanics and Engineering, 2022, 41(1): 132−146.

[35] 贾立锋,董擎,梁冰,等. 吸附作用下煤体变形叠加关系研究[J]. 煤矿安全,2022,53(1):181−185. JIA Lifeng, DONG Qing, LIANG Bing et al. Study on superposition relation of coal deformation under adsorption[J]. Safety in Coal Mines, 2022, 53(1): 181−185.

[36] 周凤,姜永东,覃超,等. 应力环境对煤岩吸附变形和渗透率的影响试验研究[J]. 煤矿安全,2021,52(10):19−23. ZHOU Feng, JIANG Yongdong, QIN Chao, et al. Experimental study on influence of stress environment on coal-rock adsorption deformation and permeability[J]. Safety in Coal Mines, 2021, 52(10): 19−23.

-

期刊类型引用(1)

1. 柳昭星. 奥陶系灰岩顶部劈裂注浆裂隙起裂机制试验研究. 采矿与安全工程学报. 2023(01): 204-214 .  百度学术

百度学术

其他类型引用(2)

下载:

下载: