Experimental study on preparation of mine-used filling cementitious material from multi-source coal-based solid wastes

-

摘要:

为了降低煤矿充填开采成本,实现多源煤基固废协同利用,以粉煤灰、气化炉渣、脱硫石膏等固体废弃物为主要原料,制备充填专用胶凝材料;通过正交试验,确定胶凝材料中各组分最佳配比,并采用Tessier五步法,对胶凝材料的重金属元素赋存及溶出特征开展研究。结果表明:胶凝材料的最佳配比为,粉煤灰质量分数39.1%,炉底灰质量分数23.4%,气化炉渣质量分数15.6%,水泥熟料质量分数10.9%,脱硫石膏质量分数4.7%,生石灰质量分数6.3%;胶凝材料养护7 d,水化产物主要以针状存在,通过团絮状、丝状产物相联结;养护龄期到达28 d,水化产物间主要以团状或块状物质形式存在,水化产物黏结得较紧密,7 d 和 28 d 胶凝材料净浆强度分别达到 1.83、2.44 MPa;采用粉煤灰等固废制备的充填胶凝材料可以有效固化重金属,对采空区地下环境无重金属污染危险。

Abstract:In order to reduce the cost of coal mine filling and mining, and achieve the synergistic utilization of multi-source coal based solid waste, special filling cementitious material is prepared using solid waste such as fly ash, gasification slag, and desulfurization gypsum as the main raw materials. By conducting orthogonal test, the optimal ratio of each component in the cementitious material was determined, and the Tesser five-step method was used to study the occurrence and leaching characteristics of heavy metal elements in the cementitious material. The results show that the optimal ratio of cementitious material, fly ash∶furnace bottom ash∶gasification slag∶cement clinker∶desulfurization gypsum∶quicklime, is 39.1%∶23.4%∶15.6%∶10.9%∶4.7%∶6.3%; after curing for 7 days, the hydration products mainly exist in the form of needles and are connected by flocculent and filamentous products; the curing age reaches 28 days, and the hydration products mainly exist in the form of clumps or blocks. The hydration products bind tightly, and the net slurry strength of the cementitious material reaches 1.83 MPa and 2.44 MPa at 7 and 28 days, respectively. The filling cementitious material prepared from solid waste such as fly ash can effectively solidify heavy metals and has no risk of heavy metal pollution to the underground environment.

-

煤炭开发利用引发的岩移破坏、采煤沉陷,以及煤矸石、粉煤灰等固废排放给生态环境带来巨大压力[1-2]。特别是我国煤炭生产、煤电、煤化工基地常集中建设,固废产量大、类型多、分布集中,实现多种固废的协同、就地处置是将来的发展趋势。在防治采煤沉陷和消纳煤矿固废双重压力的推动下,“以废治害”的固废胶结充填已成为煤炭工业绿色发展重要方向,国家层面发布了大量固废利用、胶结充填指导政策[3-4]。

目前,煤矿胶结充填工程中,硅酸盐水泥因其稳定的性能及较强的胶结能力,而被广泛使用。但是,在胶结充填工程中,水泥基充填材料占整个充填工程成本的40%以上。除了经济成本,水泥的使用还造成了较高的碳排放成本,作为优质的“建材”,其并不适用于煤矿充填工程。另一方面,粉煤灰、气化炉渣等煤基固废经高温冷却,具有火山灰活性潜力[5-6],利用这些固废开发1种专门应用于煤矿充填的充填材料,成为煤矿工作者孜孜不倦的追求[7-8]。加拿大Kidd Creek矿山采用碎石胶结充填开采时,工程人员选择了炼铜炉渣、高炉渣等替代33%~60%的水泥,用于制备胶凝材料。澳大利亚、南非等国的众多金属矿山也致力于研究工业废弃物制备新型胶凝材料,以替代传统水泥[9]。古德生院士团队开展了大量充填胶凝材料研发工作,提出粉煤灰与熟石灰的水化反应使其具有良好的胶结能力,可提高充填体长期强度[10]。利用矿渣和水淬渣制备出新型胶凝材料,胶结性能优良、充填体强度高,满足充填开采要求,可完全替代水泥,大大降低了充填开采的成本[11]。韩克峰[11]将高炉炉渣进一步磨细粉碎,并将其替代部分水泥配制全尾砂胶结充填材料,在张马屯铁矿的充填开采中成功试用;张光存等[12]以金川矿充填开采为研究背景,以废弃的磷石膏为主要原料,添加生石灰、氢氧化钠、芒硝等制备胶凝材料,其强度性能优于硅酸盐水泥;王有团等[13]研制出以脱硫石膏、矿渣粉末、少量水泥和外加剂所构成的金川矿用胶凝材料。大量学者以不同的充填工程为案例背景,利用矿山附近排出的固体废物矿渣[14]、镁渣、油页岩废渣、气化炉渣[15]等,通过不同激发方式的探索[16-17],不同的充填原材料制备低成本的充填胶凝材料。

上述研究对我国充填专用胶凝材料研发有着极大的意义,但新型充填胶凝材料绝大多数是应用于金属矿充填开采中,在国内庞大的煤矿企业中,水泥依然是充填胶凝材料的主力军。原因是煤矿及煤矿周围电厂、煤化工厂的固废产出特征与金属矿及其周围钢铁厂的固废产出特点不同,前者主要以粉煤灰、气化炉渣为主,后者主要以矿渣、钢渣为主,金属矿相关研究成果未能成功应用到煤矿充填,水泥的大量使用成为限制煤矿充填工程发展的重要阻碍[18-19]。为此,以煤炭科学技术研究院承担运行的山西苏村煤矿充填工程为研究背景,利用矿区周边煤化工厂、煤发电厂产出的气化炉渣、粉煤灰、炉底灰、脱硫石膏等废弃物,制备低成本矿用充填胶凝材料,并对材料水化过程中物相和显微结构的变化开展研究。

1. 试验方法

1.1 试验原材料

1)粉煤灰。煤基固废化学成分见表1。试验采用的粉煤灰来源为苏村煤矿附近发电厂。粉煤灰主要化学成分为Al2O3和SiO2,含有少量的Fe2O3和CaO,其中CaO质量分数为2.47%,属于低钙粉煤灰。为了充分激发粉煤灰的活性,在试验前粉煤灰进行研磨处理。

表 1 煤基固废化学成分Table 1. Chemical composition of coal-based solid waste% 材料 SiO2质量分数 Al2O3质量分数 Fe2O3质量分数 CaO质量分数 TiO2质量分数 K2O质量分数 SO3质量分数 MgO质量分数 Na2O质量分数 粉煤灰 58.53 30.00 3.637 2.47 1.85 1.605 0.679 0.489 0.338 炉底灰 54.95 32.82 3.660 4.34 1.43 1.400 0.150 0.280 0.820 气化炉渣 33.58 49.57 4.890 3.54 2.75 0.920 1.410 1.860 1.100 2)炉底灰。炉底灰主要成分为SiO2和Al2O3,含有少量Fe2O3、CaO,其成分与粉煤灰相似,在含量上有差异。由于炉底灰属于粗灰,颗粒较大,利用球磨机进行充分研磨。研磨10 min后,其粒径中位数为5.8 μm;研磨20 min和30 min后,其粒径为1.8 μm和1.2 μm;在研磨时长大于20 min后,研磨效率大幅降低,故选择研磨20 min的炉底灰作为实验材料。

3)气化炉渣。气化炉渣主要成分为SiO2、Al2O3,但SiO2质量分数不及粉煤灰,同时含有少量Fe2O3、CaO。试验所用气化炉渣未经过处理,多为5 cm左右的块状粗渣。在研磨90 min后,样品平均粒度骤然降低,选择研磨90 min后的气化炉渣作为试验原料。

4)激发组分。试验所用水泥熟料为普通硅酸盐水泥熟料,所用脱硫石膏为苏村煤矿附近电厂排放的固体废弃物,在试验前已进行烘干、磨细等预处理,所用粉体均过100目(150 μm)筛。试验所用生石灰为市售普通生石灰,呈现白色粉末状,试验所用粉体过100目筛。

1.2 试验过程

1)单因素激发试验。为了查明水泥熟料、脱硫石膏、生石灰激发组分单独使用时,对粉煤灰等固废基料的激发效果,并为后期复合激发配比试验提供数据支撑,研究设计了单因素激发试验。称取粉煤灰、炉底灰、气化炉渣各200 g。将水泥熟料以质量分数(基数为200 g,下同)6%、8%、10%、12%、14%的剂量掺入,脱硫石膏以质量分数4%、6%、8%、10%、12%的剂量掺入,生石灰以质量分数2%、4%、6%、8%、10%的剂量掺入。制备水灰比为1∶1,40 mm×40 mm×40 mm的标准净浆试块,养护龄期为7、14、28 d。

2)复合激发试验。为了探讨水泥熟料、脱硫石膏、生石灰复配使用时,对粉煤灰等固废基料的激发效果,基于单因素激发试验结果,采取L16(43)正交试验表格,对煤基固废胶凝材料的制备配方进行设计。以不同养护龄期(7、14、28 d)的煤基固废胶凝材料试块的抗压强度作为试验指标,研究3种激发剂(水泥熟料、脱硫石膏、生石灰)复配使用对煤基固废胶凝材料力学性能的影响,正交试验因素水平表见表2。

表 2 正交试验因素水平表Table 2. Orthogonal test factor level table水平 因素A

水泥熟料质量分数/%因素B

脱硫石膏质量分数/%因素C

生石灰质量分数/%1 8 6 2 2 10 8 4 3 12 10 6 4 14 12 8 3)结构表征方法。①XRD测试试验仪器选取SmartLab-9kW,铜靶,加速电压45 kV,电流200 mA扫描范围2θ为5°~70°,扫描速率为2°/min,X射线波长为0.154 18 nm;②SEM测试试验采用日本日立Hitachi公司的S4800冷场发射扫描电子显微镜,分辨率为1.0 nm (15 kV),2.0 nm (1 kV),加速电压为0.5~300 kV,放大倍数30~800 000倍,样品表面喷金以能够在电镜下显示出其形貌特征。

2. 试验结果及分析

2.1 单因素激发试验结果

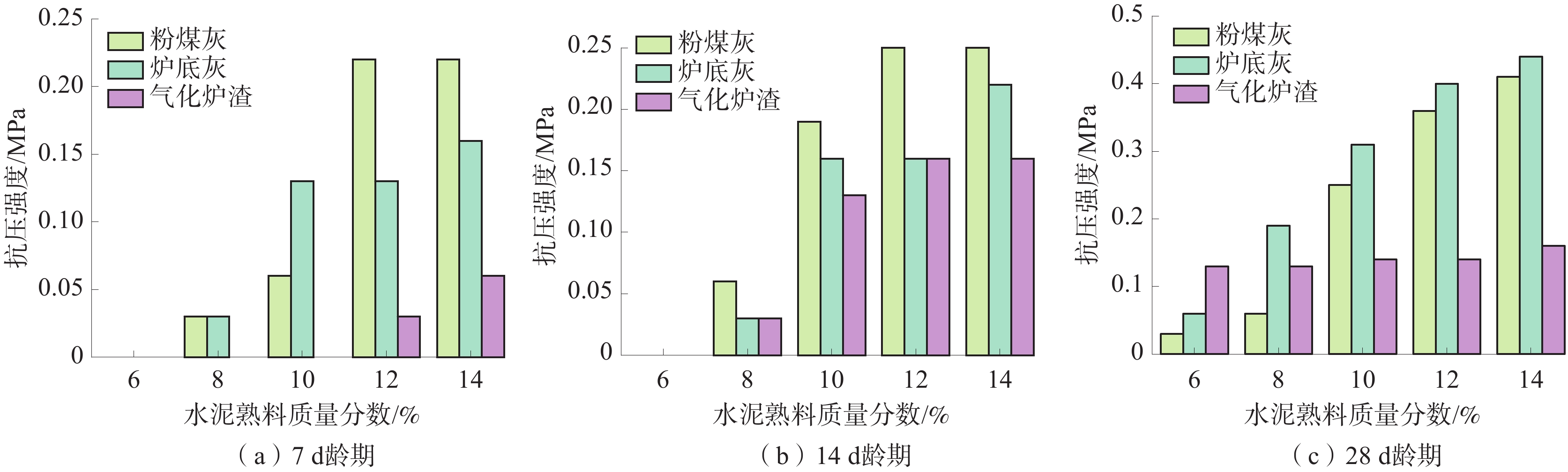

不同掺量水泥熟料对煤基固废激发效果如图1所示,不同掺量脱硫石膏对煤基固废激发效果如图2所示,不同掺量生石灰对煤基固废激发效果如图3所示。

1)水泥熟料单因素激发。由图1可以看出,随着水泥熟料质量分数的增加,试块强度呈不断增加的趋势。水泥熟料除自身胶凝特性外,更为水化反应体系提供了碱性条件。经过研磨后的固废基料,惰性玻璃体外部结构被破坏,表面具有更多活性点位,火山灰活性物质与水接触面积增大,水化反应加快。该掺配条件下,试块多数都能凝结成型,但整体固废激发体系强度发展有限,即使质量分数超过14%,28 d强度不超过0.5 MPa。

2)脱硫石膏单因素激发。脱硫石膏自身具有一定的胶凝性,同时也是常见的硫酸盐激发剂。由图2可以看出,随着脱硫石膏质量分数的增加,试块的强度呈不断增加趋势。脱硫石膏对固废基料后期的激发效果较为明显,试块28 d皆可胶凝成型,强度在0.3 MPa以内;但在水化反应前期,脱硫石膏溶出的SO42−对粉煤灰等固废基料的激发速率和效果有限,不能有效促进基料的水化反应。

3)生石灰单因素激发。生石灰为整个反应体系提供Ca2+,同时构建碱性环境,促进煤基固废材料的水化过程,达到“补钙−激发”的作用。由图3可以看出,随着生石灰质量分数的增加,试块强度呈不断增加的趋势。炉底灰、粉煤灰在掺入生石灰后,在反应早期能产生一定强度,气化炉渣在前期没有被明显激发;但在后期强度上升较快。

激发组分释放了粉煤灰等固废潜在的胶凝活性。对于单一固废材料,激发剂质量分数越大,其产生的强度越高。同时,可以发现各类激发剂对固废基料激发效果各异:水泥熟料因其自身胶凝特性和较强的碱属性,使之具有较好激发效果,当质量分数超过 10%,各类固废试块都产生强度;脱硫石膏未能对固废基料前期水化产生促进作用,表明只加入脱硫石膏,反应体系的 OH−不足,不能充分破坏固废材料的硅氧聚合链;生石灰对炉底灰在 7 d 龄期表现出了较好的激发效果,但对另外2 种固废基料 7 d 龄期激发效果较差,但 3 种固废基料的后期强度增长较为迅速,这是因为生石灰的加入,为体系补充了足量钙离子,也为体系营造了较强碱性环境。

随着各种激发剂质量分数的增加,单一固废基料的强度也在不断提高,但单激发条件下,要满足充填体所需强度,需较大的激发剂掺量,与大规模消纳固废和控制充填成本的原则相斥。因此,基于不同激发剂对基料的激发效果差异,进行复合激发,在尽可能少添加激发剂的条件下,发挥出煤基固废最大胶凝特性。

2.2 复合激发试验结果

复合激发试验结果见表3。

表 3 正交试验结果Table 3. Orthogonal test results实验

编号激发组分配比 试块抗压强度/MPa 因素A

水泥熟料

质量分数/%因素B

脱硫石膏

质量分数/%因素C

生石灰

质量分数/%7 d 14 d 28 d 1 8 6 2 0.67 0.79 0.98 2 8 8 4 0.79 0.87 1.00 3 8 10 6 1.10 1.16 1.32 4 8 12 8 1.12 1.29 1.41 5 10 6 4 1.22 1.38 1.71 6 10 8 2 0.73 0.93 1.32 7 10 10 8 1.22 1.46 1.58 8 10 12 6 1.02 1.31 1.54 9 12 6 6 1.34 1.52 1.71 10 12 8 8 1.53 1.71 2.01 11 12 10 2 0.85 1.16 1.32 12 12 12 4 1.08 1.41 1.83 13 14 6 8 1.83 1.99 2.44 14 14 8 6 1.40 1.65 1.97 15 14 10 4 1.34 1.46 1.78 16 14 12 2 1.02 1.32 1.73 由表3可以看出:

1)随着水泥熟料质量分数的增加,煤基固废胶凝材料各龄期试块的抗压强度均呈增加趋势;当水泥熟料的质量分数由8%提高到14%时,试块7、14、28 d龄期的抗压强度分别由0.92、1.03、1.18 MPa提升至1.4、1.6、1.98 MPa,强度分别增加了53.33%、35.63%、67.8%。表明粉煤灰质量分数对煤基固废胶凝材料抗压强度的影响较大。

2)随着脱硫石膏的质量分数由6%提高到12%,净浆试块7、14、28 d龄期的抗压强度分别由1.27、1.42、1.71 MPa降低至1.06、1.33、1.36 MPa,分别降低了16.5%、6.34%、20.45%。这是由于在复合激发体系中,脱硫石膏与水泥熟料中的铝酸钙(C3A)和铁铝酸钙(C4AF)发生反应生成钙帆石,包裹在大量未反应的铝酸钙(C3A)和铁铝酸钙(C4AF)外面,阻碍其水化进程,表明掺入过多的脱硫石膏对复合激发体系有抑制效果。

3)随着生石灰质量分数的增加,煤基固废胶凝材料各龄期试块的抗压强度呈逐渐增加的趋势。当生石灰的质量分数由2%提高到8%时,净浆试块7、14、28 d龄期的抗压强度分别由0.82、1.05、1.34 MPa提升至1.43、1.61、1.86 MPa,强度分别增加了90.48%、69.56%、36.5%。

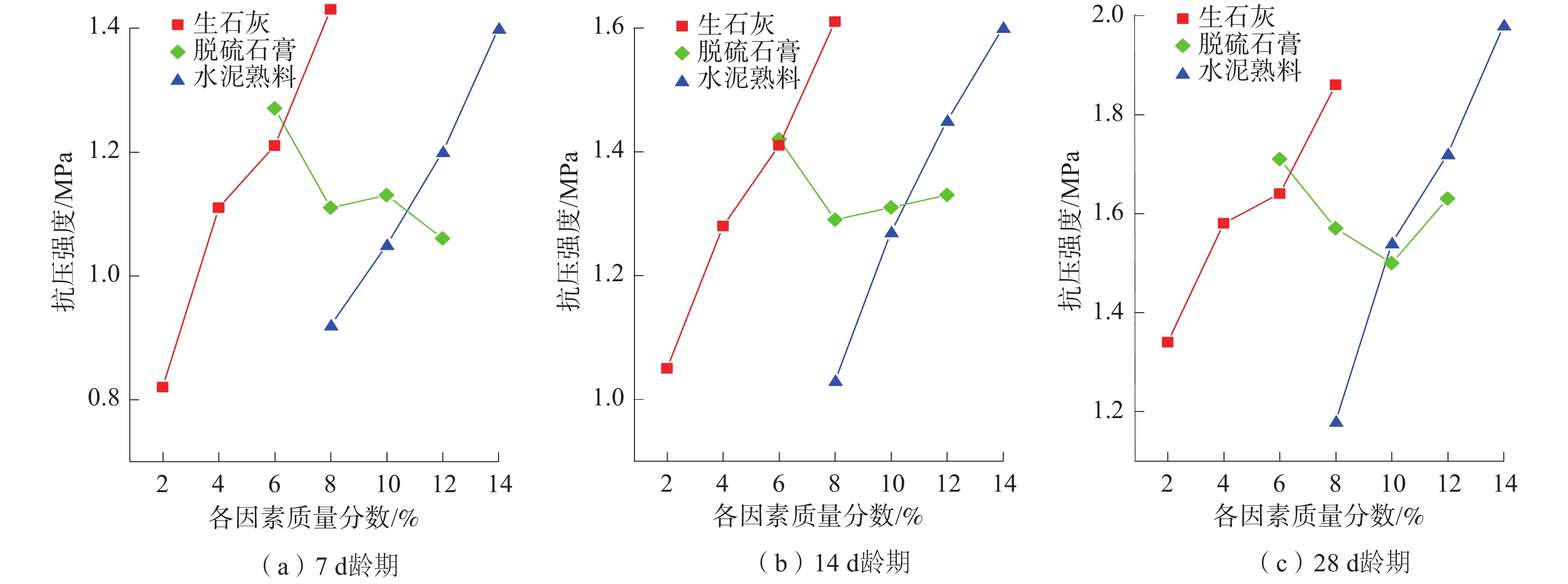

对正交试验结果进行极差分析,得到的抗压强度极差分析效应曲线如图4所示。

由图4可以看出:对试块在7 d龄期时,正交试验中极差较大的因素是生石灰,这是由于固废基料中的钙含量较少,生石灰的加入为胶凝体系提供了大量的Ca2+和$ {\mathrm{O}\mathrm{H}}^{-} $,$ {\mathrm{O}\mathrm{H}}^{-} $破坏了基料中的硅氧、铝氧聚合链,促进后期水化形成硅铝质凝胶。Ca2+则是C−A−S−H、C−S−H凝胶等水化产物的必要组分。在水化反应进入后期时,水泥熟料对体系抗压强度影响更为显著,体现为28 d龄期因素极差值最大。综上,各激发组分对试块的抗压强度影响显著性排序为生石灰>水泥熟料>脱硫石膏,得到最优配比为水泥熟料质量分数14%、脱硫石膏质量分数6%、生石灰质量分数8%;将3种固废材料的含量计算在内,各材料的质量分数分别为,粉煤灰39.1%、炉底灰23.4%、气化炉渣15.6%、水泥熟料10.9%、脱硫石膏4.7%、生石灰6.3%,该配比在不同龄期(7 d、14 d、28 d)的强度分别为1.83、1.99、2.44 MPa。

2.3 水化产物结构分析

2.3.1 XRD分析

不同龄期煤基固废胶凝材料XRD图谱如图5所示。

煤基固废胶凝材料的水化产物主要有:C−S−H凝胶、C−A−S−H凝胶、N−A−S−H凝胶、钙矾石(AFt)以及少量的二水石膏(CaSO4·2H2O)。养护龄期为7 d,材料衍射峰较为尖锐,这表明在反应前期,存在大量的单质矿物;在14 d和28 d的图谱中,尖锐峰逐渐向弥散峰转变,这是由于在反应中后期,水化生成的凝胶逐渐增多,水化产物逐渐由矿物向凝胶状物质转化,这是煤基固废胶凝材料在后期强度增长的主要原因。

2.3.2 SEM分析

煤基固废胶凝材料SEM图谱如图6所示。

由煤基固废胶凝材料不同养护龄期(7、14、28 d)试块的SEM可以看出:①在7 d龄期,主要以针状和网状的C−S−H凝胶为主,其中C−S−H凝胶聚合在一起呈较为紧密的网状连接,钙矾石则呈现更细的针状和短棒状,如图6(a)和图6(b)所示;②随着养护龄期的加深,煤基固废胶凝材料的水化程度也在不断加深,C−S−H胶凝网状颗粒逐渐变大,且孔隙减小,这也是胶凝材料强度增长幅度较大的主要原因,在14 d可看到少量的无定形C−A−S−H凝胶和N−A−S−H凝胶,同时网状C−S−H凝胶不断增多,几何棒状的C−S−H和钙矾石缩短;③28 d龄期,可以看到其网状结构和部分无定形结构的凝胶相互交错、连接,使其结构紧密,彼此之间相互层叠,形成更稳定的网状结构,强度相较14 d时进一步提高,在养护后期粉煤灰等固废材料在碱性条件下生成的主要以无定形的C−A−S−H凝胶和N−A−S−H凝胶为主。

2.4 重金属元素溶出特征分析

充填材料充入采空区后,充填体长期受到地下水化学场和应力场等因素的影响[20-21],经长期侵蚀,其胶结充填体中赋存的重金属可能会释放、迁移,污染地下水资源[22-23]。

采用Tessier五步连续提取法进行试块中重金属元素赋存形态分析。该法将样品中重金属分为5 种结合形态:即金属可交换态、碳酸盐结合态、铁(锰)氧化物结合态、有机质及硫化物结合态和残渣晶格结合态,其中前3种赋存形态容易被淋滤浸出,以有机质硫化物结合态和残渣晶格结合态2种形态难以被溶液浸出。

将危害性较大的Pb、Cd、Cr、Cu、As和Zn元素作为本次研究关注重点,煤基固废胶凝材料SEM图谱如图7所示。图7中:Ⅰ为可变换态;Ⅱ为碳酸盐结合态;Ⅲ为铁锰氧化物结合态。

固废中各元素主要以铁锰氧化物结合态为主。相比于散体态煤基固废,在煤基固废胶结充填体中,水溶态的重金属元素(除Cd和Cr外)被100%固定,碳酸盐结合态的重金属元素质量分数自身较低,其固化率达到70%~100%之间。铁锰氧化物结合态除Pb、Cd和Zn固化率在55%左右外,其他元素的固化率都在90%以上。需要说明的是,本次研究考虑了充填体超长时间效应和井下极端条件,将胶凝体研磨至粉体状态(与散体状态相当)进行Tessier提取。这表明由煤基固废散体材料制备的胶结充填体中,前3种赋存形态中的重金属元素向有机质硫化物结合态和残渣晶格结合态转变,从而使得其本身赋存的重金属元素难以被浸出。

综上所述,采用粉煤灰、煤矸石等固废制备的煤基固废充填材料可以有效固化自身赋存的重金属,其重金属浸出量很少,在进行充填后,采空区地下环境没有重金属方面的环境污染。

3. 结 语

1)单因素激发试验表明,单种激发组分的激发效果水平整体较弱,所有试块28 d强度皆未能超过0.5 MPa。不同激发剂(水泥熟料、脱硫石膏、生石灰)对不同固废(粉煤灰、炉底灰、气化炉渣)作用效果各异:水泥熟料对粉煤灰前期(14 d)的激发效果较好,对炉底灰后期激发效果较好(28 d);生石灰对炉底灰前期(14 d)的激发效果较好,对气化炉渣后期(28 d)激发效果较为明显。

2)以粉煤灰、炉底灰、气化炉渣作为基料,脱硫石膏、水泥熟料和石灰作为激发组分,制备矿用充填胶凝材料,最优配制比例为:粉煤灰质量分数39.1%、炉底灰质量分数23.4%、气化炉渣质量分数15.6%、水泥熟料质量分数10.9%、脱硫石膏质量分数4.7%、生石灰6.3%,该配比在不同龄期(7、14、28 d)的强度分别为1.83、1.99、2.44 MPa。

3)煤基固废胶凝材料的水化产物主要有:C−S−H凝胶、C−A−S−H凝胶、N−A−S−H凝胶、钙矾石。胶凝材料养护龄期 7 d 时,水化产物主要以针状存在,通过团絮状、丝状产物相联结;养护龄期到达28 d 时,水化产物间主要以团状或块状物质形式存在,水化产物黏结得较紧密。

4)通过Tessier五步连续提取证明:煤基固废散体材料制备成胶结充填体过程中,重金属赋存形态会发生变化,固废制备的胶结充填材料可以有效固化自身赋存的重金属,其固化能力普遍在50%,特别是水溶态元素固化水平全部为100%,进行充填后对地下水环境无污染危险。

-

表 1 煤基固废化学成分

Table 1 Chemical composition of coal-based solid waste

% 材料 SiO2质量分数 Al2O3质量分数 Fe2O3质量分数 CaO质量分数 TiO2质量分数 K2O质量分数 SO3质量分数 MgO质量分数 Na2O质量分数 粉煤灰 58.53 30.00 3.637 2.47 1.85 1.605 0.679 0.489 0.338 炉底灰 54.95 32.82 3.660 4.34 1.43 1.400 0.150 0.280 0.820 气化炉渣 33.58 49.57 4.890 3.54 2.75 0.920 1.410 1.860 1.100 表 2 正交试验因素水平表

Table 2 Orthogonal test factor level table

水平 因素A

水泥熟料质量分数/%因素B

脱硫石膏质量分数/%因素C

生石灰质量分数/%1 8 6 2 2 10 8 4 3 12 10 6 4 14 12 8 表 3 正交试验结果

Table 3 Orthogonal test results

实验

编号激发组分配比 试块抗压强度/MPa 因素A

水泥熟料

质量分数/%因素B

脱硫石膏

质量分数/%因素C

生石灰

质量分数/%7 d 14 d 28 d 1 8 6 2 0.67 0.79 0.98 2 8 8 4 0.79 0.87 1.00 3 8 10 6 1.10 1.16 1.32 4 8 12 8 1.12 1.29 1.41 5 10 6 4 1.22 1.38 1.71 6 10 8 2 0.73 0.93 1.32 7 10 10 8 1.22 1.46 1.58 8 10 12 6 1.02 1.31 1.54 9 12 6 6 1.34 1.52 1.71 10 12 8 8 1.53 1.71 2.01 11 12 10 2 0.85 1.16 1.32 12 12 12 4 1.08 1.41 1.83 13 14 6 8 1.83 1.99 2.44 14 14 8 6 1.40 1.65 1.97 15 14 10 4 1.34 1.46 1.78 16 14 12 2 1.02 1.32 1.73 -

[1] 钱鸣高,许家林. 煤炭开采与岩层运动[J]. 煤炭学报,2019,44(4):973−984. QIAN Minggao, XU Jialin. Behaviors of strata movement in coal mining[J]. Journal of China Coal Society, 2019, 44(4): 973−984.

[2] 张吉雄,缪协兴. 煤矿矸石井下处理的研究[J]. 中国矿业大学学报,2006,35(2):197−200. doi: 10.3321/j.issn:1000-1964.2006.02.012 ZHANG Jixiong, MIAO Xiexing. Underground disposal of waste in coal mine[J]. Journal of China University of Mining & Technology, 2006, 35(2): 197−200. doi: 10.3321/j.issn:1000-1964.2006.02.012

[3] 王双明,刘浪,朱梦博,等. “双碳” 目标下煤炭绿色低碳发展新思路[J]. 煤炭学报,2024,49(1):152−171. WANG Shuangming, LIU Lang, ZHU Mengbo, et al. New way for green and low-carbon development of coal industry under the target of “daul-carbon”[J]. Journal of China Coal Society, 2024, 49(1): 152−171.

[4] 李永亮,路彬,杨仁树,等. 煤矿连采连充式胶结充填采煤技术与典型工程案例[J]. 煤炭学报,2022,47(3):1055−1071. LI Yongliang, LU Bin, YANG Renshu, et al. Cemented backfilling mining technology with continuous mining and continuous backfilling method for underground coal mine and typical engineering cases[J]. Journal of China Coal Society, 2022, 47(3): 1055−1071.

[5] LEE C Y, LEE H K, LEE K M. Strength and microstructural characteristics of chemically activated fly ash–cement systems[J]. Cement and Concrete Research, 2003, 33(3): 425−431. doi: 10.1016/S0008-8846(02)00973-0

[6] 许健飞,张罗斌,郭亚奔. 胶结充填材料性能研究及配比优化[J]. 煤矿安全,2022,53(7):52−57,63. XU Jianfei, ZHANG Luobin, GUO Yaben. Research on properties of gangue-based cemented filling materials and ratio optimization[J]. Safety in Coal Mines, 2022, 53(7): 52−57,63.

[7] 常瑞祺,张建波,李会泉,等. 煤基固废制备胶凝材料研究进展及应用[J]. 洁净煤技术,2024,30(2):316−330. CHANG Ruiqi, ZHANG Jianbo, LI Huiquan, et al. Research progress and application of cementing materials prepared from coal based solid waste[J]. Clean Coal Technology, 2024, 30(2): 316−330.

[8] IZQUIERDO M, QUEROL X, DAVIDOVITS J, et al. Coal fly ash-slag-based geopolymers: Microstructure and metal leaching[J]. Journal of Hazardous Materials, 2009, 166(1): 561−566. doi: 10.1016/j.jhazmat.2008.11.063

[9] ERCIKDI B, KESIMAL A, CIHANGIR F, et al. Cemented paste backfill of sulphide-rich tailings: Importance of binder type and dosage[J]. Cement and Concrete Composites, 2009, 31(4): 268−274. doi: 10.1016/j.cemconcomp.2009.01.008

[10] 胡家国,古德生. 粉煤灰作为水泥替代品用于胶结充填的试验研究[J]. 矿业研究与开发,2002,22(5):5−7. doi: 10.3969/j.issn.1005-2763.2002.05.002 HU Jiaguo, GU Desheng. An experimental study on consolidated filling using fly ash as a replacement for cement[J]. Mining Research and Development, 2002, 22(5): 5−7. doi: 10.3969/j.issn.1005-2763.2002.05.002

[11] 韩克峰. 高炉水渣细磨产品在全尾砂胶结充填中的应用[J]. 金属矿山,2001(7):45−47. doi: 10.3321/j.issn:1001-1250.2001.07.017 HAN Kefeng. Application of fine grounded granulated blast-furnace slag in whole tailings cementation filling[J]. Metal Mine, 2001(7): 45−47. doi: 10.3321/j.issn:1001-1250.2001.07.017

[12] 张光存,杨志强,高谦,等. 利用磷石膏开发替代水泥的早强充填胶凝材料[J]. 金属矿山,2015(3):194−198. ZHANG Guangcun, YANG Zhiqiang, GAO Qian, et al. Development of early strength filling cementing material with phosphogypsum as substitute of traditional cement[J]. Metal Mine, 2015(3): 194−198.

[13] 王有团,杨志强,李茂辉,等. 新型充填胶凝材料全尾砂浆工作特性试验研究[J]. 矿业研究与开发,2014,34(7):63−66. WANG Youtuan, YANG Zhiqiang, LI Maohui, et al. Experimental studies of the performance characteristic on new filling cementing material with unclassified tailings[J]. Mining Research and Development, 2014, 34(7): 63−66.

[14] 李高鲁,吴明跃,张宝阳,等. 基于固废物的矿用充填材料研制[J]. 煤矿安全,2018,49(10):62−65. LI Gaolu, WU Mingyue, ZHANG Baoyang, et al. Development of mine-used filling material based on solid waste[J]. Safety in Coal Mines, 2018, 49(10): 62−65.

[15] 屈慧升,索永录,刘浪,等. 改性煤气化渣基矿用充填材料制备与性能[J]. 煤炭学报,2022,47(5):1958−1973. QU Huisheng, SUO Yonglu, LIU Lang, et al. Preparation and properties of modified coal gasification slag-based filling materials for mines[J]. Journal of China Coal Society, 2022, 47(5): 1958−1973.

[16] 周茜,刘娟红. 矿用富水充填材料的蠕变特性及损伤演化[J]. 煤炭学报,2018,43(7):1878−1883. ZHOU Qian, LIU Juanhong. Study on creep property and damage evolution of rich-water packing material for mining[J]. Journal of China Coal Society, 2018, 43(7): 1878−1883.

[17] 孙希奎,强辉,施现院,等. 矸石膏体充填材料配比优化[J]. 煤矿安全,2017,48(10):69−72,75. SUN Xikui, QIANG Hui, SHI Xianyuan, et al. Mixture ratio optimization of mine gangue paste filling materials[J]. Safety in Coal Mines, 2017, 48(10): 69−72,75.

[18] 杨宝贵,王俊涛,李永亮,等. 煤矿井下高浓度胶结充填开采技术[J]. 煤炭科学技术,2013,41(8):22−26. YANG Baogui, WANG Juntao, LI Yongliang, et al. Backfill coal mining technology with high concentrated cementing material in underground mine[J]. Coal Science and Technology, 2013, 41(8): 22−26.

[19] 杨捷. 煤矿高浓度胶结充填料浆矸石颗粒悬浮性研究[D]. 北京:中国矿业大学(北京),2019. [20] 杨科,魏祯,赵新元,等. 黄河流域煤电基地固废井下绿色充填开采理论与技术[J]. 煤炭学报,2021,46(S2):925−935. YANG Ke, WEI Zhen, ZHAO Xinyuan, et al. Theory and technology of green filling of solid waste in underground mine at coal power base of Yellow River Basin[J]. Journal of China Coal Society, 2021, 46(S2): 925−935.

[21] 王莹,董霁红. 徐州矿区充填复垦地重金属污染的潜在生态风险评价[J]. 煤炭学报,2009,34(5):650−655. WANG Ying, DONG Jihong. Potential ecological risk assessment of filling reclaimed soils polluted by heavy metals in mining area[J]. Journal of China Coal Society, 2009, 34(5): 650−655.

[22] 徐阳,徐再刚,谢红飞,等. 煤气化渣高水充填材料的制备及其性能研究[J]. 煤矿安全,2020,51(9):41−46,51 XU Yang, XU Zaigang, XIE Hongfei, et al. Preparation and properties of high water filling material for coal gasification slag[J]. Safety in Coal Mines, 2020, 51(9): 41−46,51.

[23] 柯贤敏,丁湘,王玮,等. 化工固废井下充填对地下水环境的影响研究[J]. 煤矿安全,2020,51(6):223−226,231. KE Xianmin, DING Xiang, WANG Wei, et al. Study on environmental impact of underground backfilling with chemical solid waste[J]. Safety in Coal Mines, 2020, 51(6): 223−226,231.

下载:

下载: