Study on the influence laws of hole distribution parameters on guided groove-static expansion synergistic fracturing effect

-

摘要:

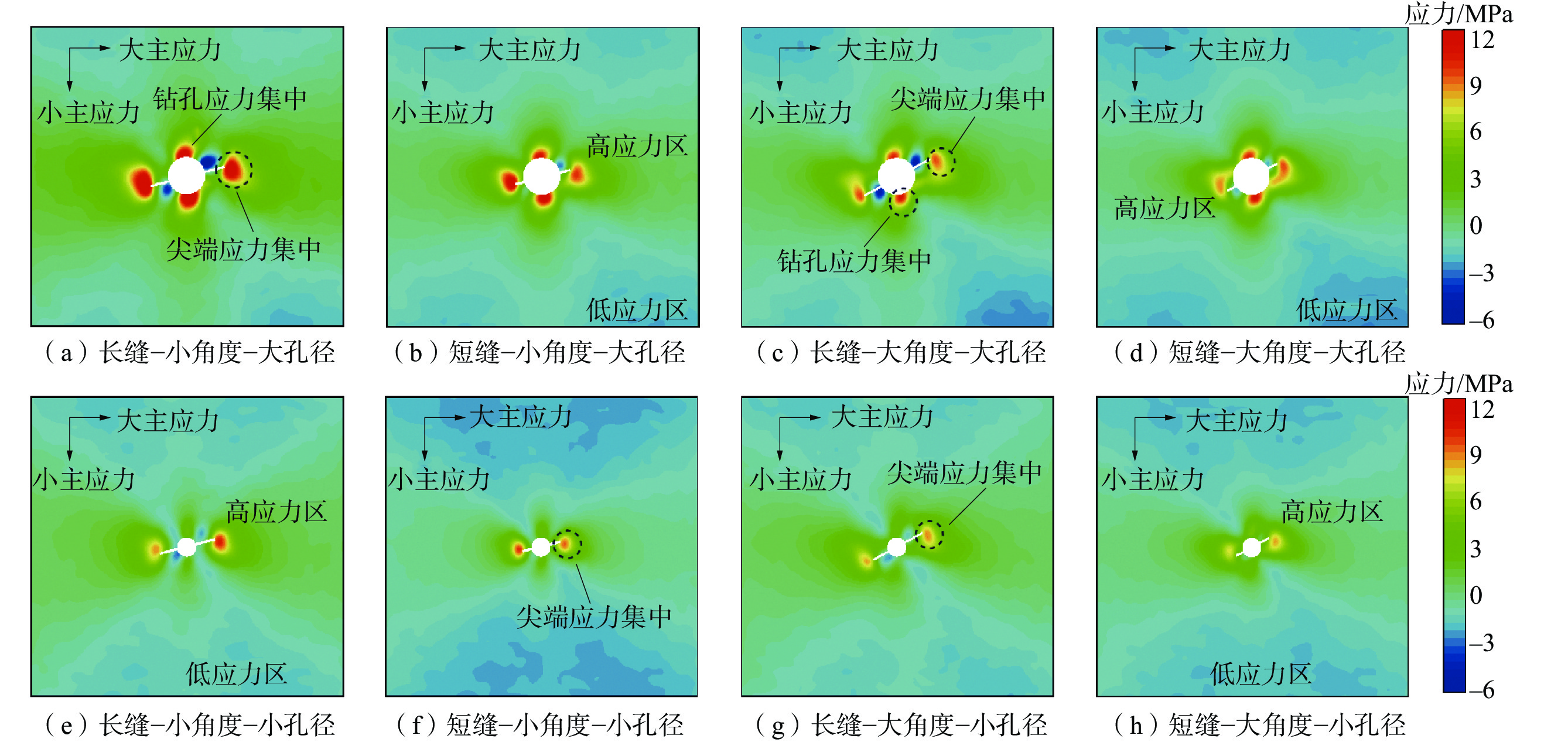

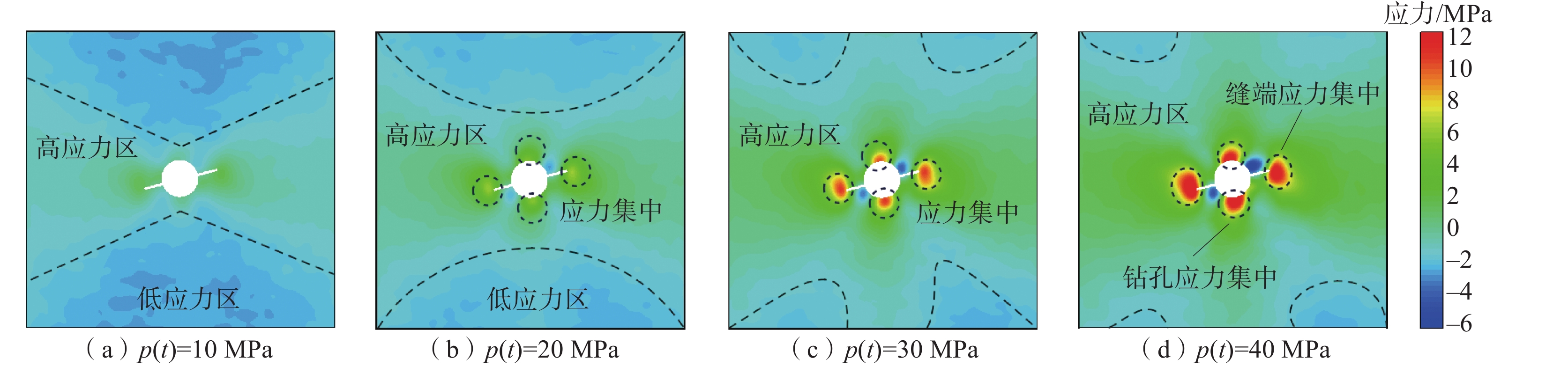

为进一步提升静态膨胀致裂技术顶板弱化能力,探究施工参量对钻孔周围应力分布的影响规律,基于弹性力学、断裂力学揭示了导向缝槽−静态膨胀协同致裂力学机制;采用PFC2D离散元法建立了相应静态膨胀致裂数值模型,通过设置不同施工参量来进行双向围压与静态膨胀耦合作用下的数值模拟研究。结果表明:相较于常规单孔无围压静态膨胀致裂,导向缝槽可有效提升静态膨胀致裂效果,距离孔心越远的位置提升作用越明显;离散元法可有效模拟静态膨胀致裂过程中应力分布情况,静态膨胀力、孔径以及导向缝槽长度与环向应力呈现正相关关系,导向缝槽角度、应力系数以及埋深与环向应力呈现负相关关系;布孔参量敏感参数排序为:孔径>缝槽角度>缝槽长度,实际应用时应尽量增大孔径与缝槽长度,减小缝槽角度;导向缝槽改变了环向应力分布特征,但缝槽的引导作用存在局限性,缝槽尖端与钻孔周边存在竞争起裂、扩展行为。

Abstract:To further enhance the weakening capability of the roof by static expansion fracturing technology, the study explores the influence of construction parameters on the stress distribution around boreholes. Based on the principles of elasticity and fracture mechanics, the synergistic fracturing mechanism between guided groove and static expansion was revealed. Adopting the PFC2D discrete element method, a corresponding numerical model for static expansion fracturing was established and biaxial confinement and static expansion interaction simulations were conducted by setting different construction parameters. The results indicate that: compared to the conventional single-hole unconfined static expansion fracturing, the guided groove can effectively enhance the effect of static expansion fracturing, and the further the distance from the hole center, the more obvious the lifting effect; the discrete element method can effectively simulate the stress distribution during the static expansion-induced cracking process. There is a positive correlation between the static expansion force, borehole diameter, and the length of the guided groove, and the circumferential stress. Conversely, the angle of the guided groove, the stress coefficient, and the burial depth are negatively correlated with the circumferential stress; the sensitivity ranking of hole parameters is as follows: borehole diameter > groove angle > groove length. In practical applications, the aperture and slot length should be increased as much as possible and the groove angle should be reduced; the groove alters the characteristics of circumferential stress distribution; however, the guiding effect of the groove has its limitations. There exists competitive crack initiation and propagation behavior between the tip of the groove and the surrounding area of the borehole.

-

煤储层含气量是煤层气资源勘探测试的关键参数[1-4],也是表征煤储层开发潜力和确保矿井瓦斯安全的关键参数之一[4-11];煤储层含气量测试可为煤层气资源量、储量估算和煤层气开发设计提供重要依据[4]。煤储层含气量测值的不准确性是导致煤层气资源计算出现差异的重要原因[12]。现阶段,我国煤炭资源勘探和煤层气资源勘探开发煤层含气量测试方法主要采用GB/T19559—2021《煤层气含量测定方法》提供的解吸法及其矫正计算方法[13-17],其中损失气量计算采用最初10个地面实测解吸气量数据,由损失气时间与解吸时间和的平方根与累计解吸气量之间线性关系倒推零时间解吸气量得出。

应用上述方法,多年来我国在多个煤层气勘探开发区块获取了大量含气量数据。然而,目前煤层含气量计算仍有以下不足:吸附气欠饱和储层现场含气量测试的可靠性缺乏数值模拟验证,特别是损失气量估算的准确程度尚未有数值模型验证;另外,上述方法对含气饱和储层(吸附气、游离气均饱和,下同)含气量测试的准确性尚不清楚,饱和储层煤心含气量测试过程模拟尚未开展。基于此,选取新疆低煤化煤(本次为长焰煤)煤心为研究对象,构建了储层煤心含气量解吸-扩散数值模型,并通过模型计算分析了吸附气欠饱和与含气饱和储层煤心解吸动态,对比分析了数值模型与现场测试损失气量、解吸气量、残余气量构成的差异性,以期为我国低煤化储层煤层气勘探提供含气性分析新思路。

1. 测试方法

1.1 现场含气量相关测试

按照GB/T 19559—2021《煤层气含量测定方法》国家标准提供的方法,开展自然煤心采样,记录采样及装样时间,开展自然解吸气量连续测试和残余气测试;根据GB/T 19560—2008《煤的高压等温吸附试验方法》、GB/T 212—2008《煤的工业分析方法》等开展煤等温吸附实验和工业分析。现场煤心采样及上述相关工作开展于新疆某长焰煤储层煤层气开发先导试验区,煤心样品为长焰煤(属于低煤化度煤),且煤心对应的实测含气饱和度分别为54.77%、77.51%、99.79%。工业分析及煤岩组分分析成果见表1。

表 1 煤心工业分析及煤岩组分分析成果Table 1. Coal core industrial analysis and coal rock composition analysis results样品编号 直径/mm 长度/cm 宏观煤岩类型 平均镜质组最大反射率/% 水分/% 灰分/% 挥发分/% 镜质组组分/% 惰质组组分/% 壳质组组分/% BF-1 63.0 26.8 半亮煤 0.60 0.90 11.77 43.79 84.2 14.8 1.0 BF-2 60.1 30.0 半亮煤 0.61 0.86 22.08 40.45 79.6 19.4 1.0 BF-3 61.0 34.0 半亮煤 0.67 1.12 13.40 37.17 78.6 25.5 1.0 1.2 储层煤心含气量测试数值模拟流程

1.2.1 假设条件

煤是一种复杂的多孔介质,为了方便求解,通常对煤心样品做出以下假设:①煤屑由球形颗粒组成;②煤颗粒为均质、各向同性体;③CH4解吸-扩散遵从连续性原理;④扩散系数与浓度、时间和坐标无关;⑤煤屑瓦斯解吸为等温条件下的解吸过程;⑥煤心含气量测试过程中孔隙度不变。

1.2.2 控制方程

单位体积吸附气欠饱和储层煤心基质CH4质量可表述为(CH4全部吸附在煤基质表面,在储层压力条件下吸附解吸平衡,孔隙表面外不含游离CH4):

$$ {m}_{\mathrm{m}\mathrm{u}}={\varphi }_{\mathrm{u}\mathrm{n}}(1-{\phi }_{\mathrm{m}})\left(\dfrac{100-{M}_{\mathrm{a}\mathrm{d}}-{A}_{\mathrm{a}\mathrm{d}}}{100}\right)\dfrac{{V}_{\mathrm{L}}{p}_{\mathrm{m}}}{{p}_{\mathrm{m}}+{p}_{\mathrm{L}}}{\rho }_{\mathrm{c}\mathrm{o}\mathrm{a}\mathrm{l}}{\rho }_{\mathrm{s}\mathrm{c}} $$ 式中:mmu为单位体积煤基质中赋存的瓦斯质量,g;φun为欠饱和储层含气饱和度,%;ϕm为基质孔隙度;Mad为空气干燥基水分含量,%;Aad为空气干燥基灰分产率,%;VL为朗缪尔体积,单分子层最大的吸附量,cm3/g;pm为基质孔隙中的CH4压力,MPa;pL为朗缪尔压力,吸附量为最大吸附量1/2时间的吸附平衡压力,MPa;ρcoal为煤视密度,kg/m3;ρsc为标准状态下的CH4密度,g/cm3。

煤心解吸至大气环境控制方程:

$$\begin{array}{c} \dfrac{\partial p}{\partial t}\left({\varphi }_{{\mathrm{un}}}\left(1-{\phi }_{{\mathrm{m}}}\right)\left(\dfrac{100-{{M}}_{\mathrm{a}\mathrm{d}}-{{A}}_{\mathrm{a}\mathrm{d}}}{100}\right)\dfrac{{V}_{{\mathrm{L}}}{p}_{{\mathrm{L}}}}{{\left(p+{p}_{{\mathrm{L}}}\right)}^{2}}{\rho }_{{\mathrm{coal}}}\dfrac{{M}_{{\mathrm{c}}}}{{V}_{{\mathrm{M}}}}\right)=\\ \nabla \left(\dfrac{{M}_{{\mathrm{c}}}}{RT}D\nabla p\right) \end{array} $$ 式中:t为时间,s;p为煤心孔隙气体压力,MPa;Mc为甲烷分子摩尔质量,kg/mol;VM为CH4分子摩尔体积,m3/mol;R为理想气体常数,J/(mol·K);T为煤层温度,K;D为扩散系数,10−9 m2/s。

单位体积饱和储层煤心基质CH4质量可表述为(CH4在煤基质表面吸附饱和,且在储层压力条件下游离CH4充满孔隙):

$$ \begin{array}{c} {m}_{{\mathrm{mo}}}=(1-{\phi }_{{\mathrm{m}}})\left(\dfrac{100-{{M}}_{\mathrm{a}\mathrm{d}}-{{A}}_{\mathrm{a}\mathrm{d}}}{100}\right)\dfrac{{V}_{{\mathrm{L}}}{p}_{{\mathrm{m}}}}{{p}_{{\mathrm{m}}}+{p}_{{\mathrm{L}}}}{\rho }_{{\mathrm{coal}}}{\rho }_{{\mathrm{sc}}}+\\ {\phi }_{{\mathrm{m}}}\dfrac{{M}_{{\mathrm{c}}}}{RT}{p}_{{\mathrm{m}}} \end{array} $$ 式中:mmo为初始条件下单位体积饱和储层煤心基质CH4质量,g。

饱和储层煤心含气饱和度:

$$ {\varphi }_{{\mathrm{m}}}=\dfrac{{m}_{{\mathrm{mo}}}}{(1-{\phi }_{{\mathrm{m}}})\left(\dfrac{100-{{M}}_{\mathrm{a}\mathrm{d}}-{{A}}_{\mathrm{a}\mathrm{d}}}{100}\right)\dfrac{{V}_{{\mathrm{L}}}{p}_{0}}{{p}_{0}+{p}_{{\mathrm{L}}}}{\rho }_{{\mathrm{coal}}}{\rho }_{{\mathrm{sc}}}} $$ 煤心扩散、解吸控制方程:

$$ \begin{array}{c} \dfrac{\partial p}{\partial t}\left(\left(1 - {\phi }_{{\mathrm{m}}}\right)\left(\dfrac{100 - {{M}}_{\mathrm{a}\mathrm{d}} - {{A}}_{\mathrm{d}}}{100}\right)\dfrac{{V}_{{\mathrm{L}}}{p}_{{\mathrm{L}}}}{{\left(p + {p}_{{\mathrm{L}}}\right)}^{2}}{\rho }_{{\mathrm{coal}}}\dfrac{{M}_{{\mathrm{c}}}}{{V}_{{\mathrm{M}}}} + {\phi }_{{\mathrm{m}}}\dfrac{{M}_{{\mathrm{c}}}}{RT}\right) =\\ \nabla \left(\dfrac{{M}_{{\mathrm{c}}}}{RT}D\nabla p\right) \end{array} $$ 1.2.3 几何模型和边界条件

几何模型为实际圆柱体煤心物理模型,几何尺寸与现场测量一致;初始煤心各点孔隙压力为根据煤层气井试井储层压力推算得出,由于解吸时煤心已与大气接触,认为边界条件煤心柱面和断面表面压力为大气压力0.1 MPa。煤心几何模型如图1。

2. 结果与讨论

2.1 欠饱和储层煤心自然解吸测试与数值模拟

采用与煤心参数近似数据开展模拟并拟合解吸体积曲线,还原现场解吸参数和煤样特性参数。储层煤心参数实测值与拟合值对比见表2,煤心xy中心截面单位体积煤心含气性变化如图2。BF-1煤心累计解吸体积与解吸时间关系如图3。

表 2 储层煤心参数实测值与拟合值对比Table 2. Comparison between measured values and fitting values of coal core parameters of reservoir参数 实测值(BF1/BF2/BF3) 拟合值(BF1/BF2/BF3) 误差率/%

(BF1/BF2/BF3)储层压力/ MPa 9.88/9.25/8.96 9.88/9.25/8.96 0/0/0 兰氏压力/ MPa 1.92/2.05/1.65 1.92/2.05/1.65 0/0/0 兰氏体积/

(cm3·g−1)19.23/22.05/15.40 18.60/20.10/13.80 3.28/8.84/10.39 水分含量

(空干基)/%0.90/0.86/1.12 0.93/0.93/1.08 3.33/8.14/3.57 灰分产率

(干燥基)/%11.77/22.08/13.40 11.72/23.18/14.20 0.42/4.98/5.97 煤心密度/

(g· cm−3)1.36/1.44/1.44 1.36/1.44/1.44 0/0/0 孔隙度 0.10/0.09/0.08 0.10/0.08/0.072 0/11.1/10.0 扩散系数/

10−9(m2·s−1)4×10−9/—/— 3.70/1.00/0.80 7.50/—/— 含气

饱和度/%54.77/77.51/99.79 54.77/77.51/99.79 0/0/0 由图2可知:解吸开始24 h,含气量快速下降,各时刻煤心中心位置含气量最高而边缘最低。

由图3可知:BF-1扣除损失气时间拟合累计解吸气量(6 427.66 cm3)与现场煤心累计解吸气量(6 346.73 cm3)接近,相差2.00%;未扣损失气时间模拟累计解吸量(7 361.4 cm3)大于上述二者,显示损失气的存在;同理,BF-2和BF-3也有类似结果。

吸附气饱和储层煤心现场解吸与数值模拟含气量构成对比见表3,BF-1、BF-2、BF-3煤心损失气时间(T)与解吸时间(t)和的平方根和解吸初期累计解吸气量回归关系如图4。

表 3 吸附气饱和储层煤心现场解吸与数值模拟含气量构成对比Table 3. Comparison of adsorbed gas saturated reservoirs between on-site desorption and numerical simulation of cores样品 含气饱和度/% 含气量构成 实测体积/cm3 占比/实测/% 拟合体积/cm3 占比(拟合)/% 实测-拟合误差/% BF-1 54.77 损失气 979.43 13.28 880.26 11.95 10.12 解吸气 6 346.73 86.06 6427.66 87.32 2.00 残余气 48.43 0.66 46.24 0.63 4.52 总含气量 7 374.59 100.00 7361.40 100.00 0.18 BF-2 77.51 损失气 823.04 7.80 755.37 7.03 8.22 解吸气 9680.43 91.78 9937.60 92.52 2.66 残余气 43.88 0.42 47.89 0.45 9.14 总含气量 10290.96 100.00 10740.86 100.00 1.83 BF-3 99.79 损失气 793.71 6.36 841.77 6.75 6.06 解吸气 11638.39 93.26 11575.20 92.84 0.54 残余气 47.56 0.38 50.32 0.40 5.80 总含气量 12479.66 100.00 12467.29 100.00 0.10 对于BF-1煤心,现场测试BF-1煤心损失气量结果为979.43 cm3,与数值模拟结果前15 min解吸气量(880.26 cm3)(图4(a))接近。现场BF-1煤心解吸气量和残余气量与数值模型计算的解吸气量和残余气量也较接近。

BF-2和BF-3煤心现场测试煤心损失气量结果分别为823.04、793.71 cm3,略低于与数值模拟结果前15 min解吸气量(952.40、1015.80 cm3) (图4(b)、图4(c)),说明吸附气饱和度较高煤心解吸初期损失气量时间平方根法计算结果可能略偏小。这可能是吸附气饱和度较高,煤心内CH4浓度高,扩散作用更显著导致。用损失气时间与解吸时间和的平方根与解吸初期累计解吸气量的线性回归关系计算BF-2和BF-3煤心损失气量,发现基于数值模拟计算的损失气量结果(755.37、841.77 cm3)与基于现场实测的损失气量计算结果(832.04、793.71 cm3)较为接近。说明基于数值模拟数据利用时间平方根法计算的损失气量与实测时间平方根法估算的损失气量较为接近。

现场实测BF-1、BF-2和BF-3煤心解吸气量和残余气量与数值模型计算出的解吸气量和残余气量也较为接近,误差不超过10.12%(表3)。说明数值模型可以近似反映吸附气欠饱和储层煤心真实解吸过程和损失气量、解吸气量、残余气量特征。

2.2 饱和储层煤心含气量测试与数值模拟

以BF-1煤心为例,采用现场实测参数数据(表2),假设煤心处于饱和状态(即吸附气饱和、游离气在储层压力条件下充满孔隙也达到饱和状态),对现阶段现场含气量测试难度较大的含气饱和煤心解吸-扩散过程进行模拟。含气饱和煤心xy中心截面各位置单位体积煤心含气性变化如图5。

由图5可知:解吸前24 h煤心含气量快速下降,各时刻煤心中心位置含气量最高而煤心边缘含气量最低。

损失气时间与解吸时间和的平方根和累计解吸气量的线性回归关系如图6。饱和储层煤心解吸-扩散数值模拟含气量构成预测见表4。

表 4 饱和储层煤心解吸-扩散数值模拟含气量构成预测Table 4. Prediction of gas content composition of coal core desorption-diffusion numerical simulation in saturated core含气量构成 预测体积/cm3 占比/% 损失气 3 792.50 18.64 解吸气 16 460.70 80.90 残余气 93.51 0.46 总含气量 20 346.71 100.00 数值模拟显示,损失气时间内(15 min)假设的饱和煤心解吸-扩散气量达到4 441.3 cm3,相同损失气时间的情况下,约为相应吸附气欠饱和储层煤心此时间段解吸气量(即本例损失气量)的4倍。

损失气时间与解吸时间和的平方根与解吸初期累计解吸气量的线性回归关系截距为正数(R2=0.9988),暗示采用解吸时间平方根与解吸初期累计解吸气量线性回归方法并不适用于饱和煤心损失气量的估算;采用解吸时间平方根与解吸初期累计解吸气量多项式回归方法,计算得煤心损失气量仅为433.11 cm3(R2=0.9988),甚至小于吸附气欠饱和储层煤心损失气量估算值,说明基于时间平方根与累计解吸气量的相关性分析方法可能无法准确估算损失气量。同时测试初期时间平方根与累计解吸气量的回归关系(图6蓝色标记)和损失气时间与累计气量的回归关系(图6红色标记,实测测不出部分)也存在较大差异,说明饱和煤心损失气时间解吸-扩散规律较为复杂,常规回归分析法可能难以实现对损失气量的准确估算。

由表4可知:饱和煤心损失气、解吸气、残余气占比分别为18.64%、80.90%、0.46%,其损失气占比高于吸附气欠饱和煤心损失气占比、解吸气占比低于吸附气欠饱和煤心解吸气占比。

数值模型可以近似反映吸附气欠饱和储层煤心真实解吸过程和损失气量、解吸气量、残余气量特征。目前,含气量现场测试手段很难达到对饱和煤心含气量的准确测试和估算,希望通过数值模拟为含气饱和煤心含气量分析提供思路。

3. 结 语

1)构建的吸附气欠饱和煤心解吸数值模型计算的损失气量、解吸气量和残余气量与现场测试相应结果接近(误差<10.12%),可近似反映吸附气欠饱和储层煤心含气量构成。

2)对于构建的含气饱和储层煤心数值模型,损失气时间与解吸时间和的平方根与解吸初期累计解吸气量的回归分析法预测损失气量误差较大。饱和煤心损失气时间解吸-扩散规律较为复杂,常规回归分析可能难以实现对损失气的准确估算。

3)相同损失气时间条件下,本例饱和煤心损失气总含气量占比(18.64%)高于吸附气欠饱和煤心损失气占比(11.95%),饱和煤心解吸气占比(80.90%)低于吸附气欠饱和煤心解吸气占比(87.32%),饱和煤心残余气占比(0.46%)低于吸附气欠饱和煤心残余气占比(0.63%)。

-

表 1 模型微观参数

Table 1 Microscopic parameters of the model

微观参数 描述 标定值 Rmin/mm 模型最小颗粒半径 0.500 Rmin/Rmax 粒径比 1.660 Ec/GPa 颗粒接触模量 13.200 k* 颗粒刚度比 0.500 μ 摩擦因数 0.577 Ec/GPa 平行黏结模量 13.200 $ \bar k^* $ 平行黏结刚度比 0.500 σc/MPa 平行黏结抗拉强度 35.200 c/MPa 平行黏结黏聚力 45.300 φ/(°) 摩擦角 35.000 -

[1] 潘俊锋,康红普,闫耀东,等. 顶板“人造解放层”防治冲击地压方法、机理及应用[J]. 煤炭学报,2023,48(2):636−648. PAN Junfeng, KANG Hongpu, YAN Yaodong, et al. The method, mechanism and application of preventing rock burst by artificial liberation layer of roof[J]. Journal of China Coal Society, 2023, 48(2): 636−648.

[2] 郑志涛,徐颖,李德生,等. 多孔线性控制套筒致裂效果影响因素分析[J]. 实验力学,2016,31(4):564−572. doi: 10.7520/1001-4888-15-150 ZHENG Zhitao, XU Ying, LI Desheng, et al. Analysis of influencing factors of fracture effect on porous linear control sleeve[J]. Journal of Experimental Mechanics, 2016, 31(4): 564−572. doi: 10.7520/1001-4888-15-150

[3] 冯彦军,康红普. 定向水力压裂控制煤矿坚硬难垮顶板试验[J]. 岩石力学与工程学报,2012,31(6):1148−1155. doi: 10.3969/j.issn.1000-6915.2012.06.008 FENG Yanjun, KANG Hongpu. Test on hard and stable roof control by means of directional hydraulic fracturing in coal mine[J]. Chinese Journal of Rock Mechanics and Engineering, 2012, 31(6): 1148−1155. doi: 10.3969/j.issn.1000-6915.2012.06.008

[4] 杜建,左建平,吴根水,等. 产气具弱化坚硬顶板力学机制及损伤特征分析[J]. 岩石力学与工程学报,2023,42(9):2224−2236. DU Jian, ZUO Jianping, WU Genshui, et al. Analysis of mechanical mechanism and damage characteristics of new fracturing device gas producing tool weakening hard roof[J]. Chinese Journal of Rock Mechanics and Engineering, 2023, 42(9): 2224−2236.

[5] 赵志鹏,欧阳烽,何富连,等. 切顶沿空留巷双向聚能爆破关键参数研究[J]. 煤矿安全,2022,53(2):226−233. ZHAO Zhipeng, OUYANG Feng, HE Fulian, et al. Study on key parameters of bidirectional shaped charge blasting for gob side entry retaining with roof cutting and pressure relief[J]. Safety in Coal Mines, 2022, 53(2): 226−233.

[6] 牛同会. 分段水力压裂弱化采场坚硬顶板围岩控制技术研究[J]. 煤炭科学技术,2022,50(8):50−59. NIU Tonghui. Study on surrounding rock control technology for weakened hard roof of stope by staged hydraulic fracturing[J]. Coal Science and Technology, 2022, 50(8): 50−59.

[7] 李团结,牟文辉,易瑞强,等. 双孔膨胀致裂坚硬岩体裂隙扩展演化试验研究[J]. 煤矿安全,2021,52(10):70−78. LI Tuanjie, MOU Wenhui, YI Ruiqiang, et al. Evolution and extension of fissures in hard rocks under double-hole expansion fracturing[J]. Safety in Coal Mines, 2021, 52(10): 70−78.

[8] 张嘉勇,崔啸,周凤增,等. 煤层钻孔静态爆破致裂半径数值模拟[J]. 煤矿安全,2017,48(12):146−149. ZHANG Jiayong, CUI Xiao, ZHOU Fengzeng, et al. Numerical simulation on crack radius of coal seam drilling by static blasting[J]. Safety in Coal Mines, 2017, 48(12): 146−149.

[9] 谢雄刚,陈学习,刘锦伟. 静态膨胀生裂增透作用原理及影响因素研究[J]. 煤矿安全,2015,46(2):21−24. XIE Xionggang, CHEN Xuexi, LIU Jinwei. Research on active principle and effect factors by static expansion and crack to increase permeability[J]. Safety in Coal Mines, 2015, 46(2): 21−24.

[10] 王金贵,张苏. 煤岩静爆致裂微震活动规律及频谱演变特征[J]. 煤炭学报,2017,42(7):1706−1713. WANG Jingui, ZHANG Su. Characteristics of microseismic signals and its frequency-spectrum evolvement rule during the static cracking of coal[J]. Journal of China Coal Society, 2017, 42(7): 1706−1713.

[11] ZHAI Cheng, XU Jizhao, LIU Shimin, et al. Fracturing mechanism of coal-like rock specimens under the effect of non-explosive expansion[J]. International Journal of Rock Mechanics and Mining Sciences, 2018, 103: 145−154. doi: 10.1016/j.ijrmms.2018.01.037

[12] 谢益盛,杨光辉,黄小朋. 静态破碎剂膨胀力学性能试验研究[J]. 煤矿安全,2019,50(3):9−12. XIE Yisheng, YANG Guanghui, HUANG Xiaopeng. Experimental research on mechanical properties of static breaking agents[J]. Safety in Coal Mines, 2019, 50(3): 9−12.

[13] HUANG Bingxiang, LIU Jiangwei, ZHANG Quan. The reasonable breaking location of overhanging hard roof for directional hydraulic fracturing to control strong strata behaviors of gob-side entry[J]. International Journal of Rock Mechanics and Mining Sciences, 2018, 103: 1−11. doi: 10.1016/j.ijrmms.2018.01.013

[14] 唐铁吾,刘大安,崔振东,等. 煤矿顶板致裂水压力的断裂力学评估[J]. 煤炭学报,2020,45(S2):727−735. TANG Tiewu, LIU Daan, CUI Zhendong, et al. Initiation pressure evaluation of coal mine roof hydraulic fracturing based on fracture mechanics[J]. Journal of China Coal Society, 2020, 45(S2): 727−735.

[15] 康红普,冯彦军,张震,等. 煤矿井下定向钻孔水力压裂岩层控制技术及应用[J]. 煤炭科学技术,2023,51(1):31−44. KANG Hongpu, FENG Yanjun, ZHANG Zhen, et al. Hydraulic fracturing technology with directional boreholes for strata control in underground coal mines and its application[J]. Coal Science and Technology, 2023, 51(1): 31−44.

[16] 夏永学,陆闯,杨光宇,等. 坚硬顶板孔内磨砂射流轴向切缝及压裂试验研究[J]. 采矿与岩层控制工程学报,2020,2(3):56−62. XIA Yongxue, LU Chuang, YANG Guangyu, et al. Experimental study on axial fracture cutting and fracturing of abrasive jet in boreholes within hard rock roofs[J]. Journal of Mining and Strata Control Engineering, 2020, 2(3): 56−62.

[17] 许红杰. “钻−切−压”定向水力压裂顶煤弱化技术应用研究[J]. 煤炭工程,2021,53(6):73−76. XU Hongjie. Application of drilling-cutting-fracturing directional hydraulic fracturing technology for top-coal weakening[J]. Coal Engineering, 2021, 53(6): 73−76.

[18] 马召辉,耿进军. 不同导向槽对静态破碎剂弱化煤层顶板效果研究[J]. 煤炭科学技术,2020,48(S1):46−50. MA Zhaohui, GENG Jinjun. Study on effect of weakening coal seam roof by static cracking agent with different guide grooves[J]. Coal Science and Technology, 2020, 48(S1): 46−50.

[19] 张超,林柏泉,周延,等. 本煤层深孔定向静态破碎卸压增透技术研究与应用[J]. 采矿与安全工程学报,2013,30(4):600−604. ZHANG Chao, LIN Baiquan, ZHOU Yan. et al. Deep-hole directional static cracking technique for pressure relief and permeability improvement in mining-coal bed[J]. Journal of Mining & Safety Engineering, 2013, 30(4): 600−604.

[20] 叶义成,陈常钊,姚囝,等. 膨胀型浆体的膨胀材料若干问题研究进展[J]. 金属矿山,2021(1):71−93. YE Yicheng, CHEN Changzhao, YAO Nan, et al. Research progress on several problems of expansive materials for expansive slurry[J]. Metal Mine, 2021(1): 71−93.

[21] 李英杰,倪婷,左建平,等. 坚硬顶板定向水力压裂裂纹起裂机制及影响因素分析[J]. 岩石力学与工程学报,2022,41(10):2015−2029. LI Yingjie, NI Ting, ZUO Jianping, et al. Analysis of crack initiation mechanism and influencing factors of hard roofs due to directional hydraulic fracturing[J]. Chinese Journal of Rock Mechanics and Engineering, 2022, 41(10): 2015−2029.

[22] 胡善超,韩金明,黄俊鸿,等. 套筒压裂作用下岩石细观裂隙与能量演化规律探究[J]. 煤炭科学技术,2024,52(2):79−91. doi: 10.12438/cst.2023-1438 HU Shanchao, HAN Jinming, HUANG Junhong, et al. Study on meso-fracture and energy evolution law of rock under sleeve fracturing[J]. Coal Science and Technology, 2024, 52(2): 79−91. doi: 10.12438/cst.2023-1438

[23] 谭云亮. 矿山压力与岩层控制[M]. 北京:煤炭工业出版社,2014:15−20.

下载:

下载: