Application of pneumatic directional and efficient pore-forming technology for crushed soft coalbed methane in Wangpo Coal Mine

-

摘要:

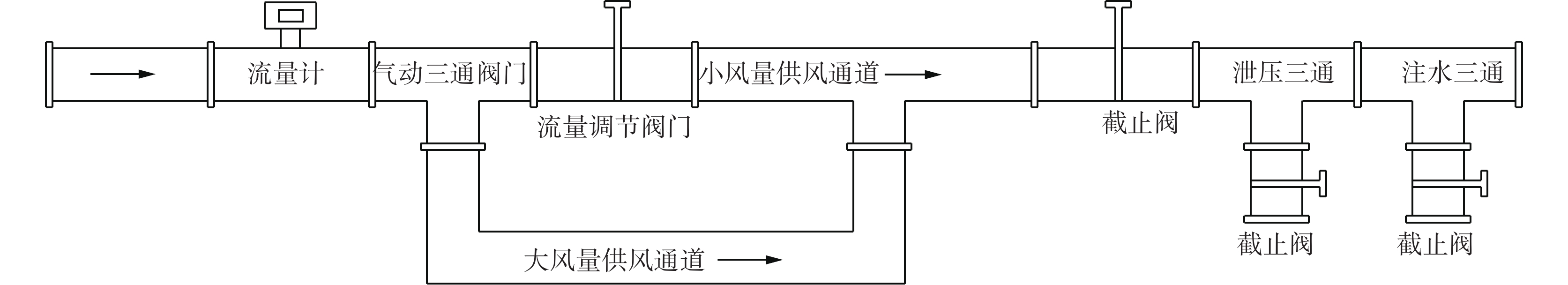

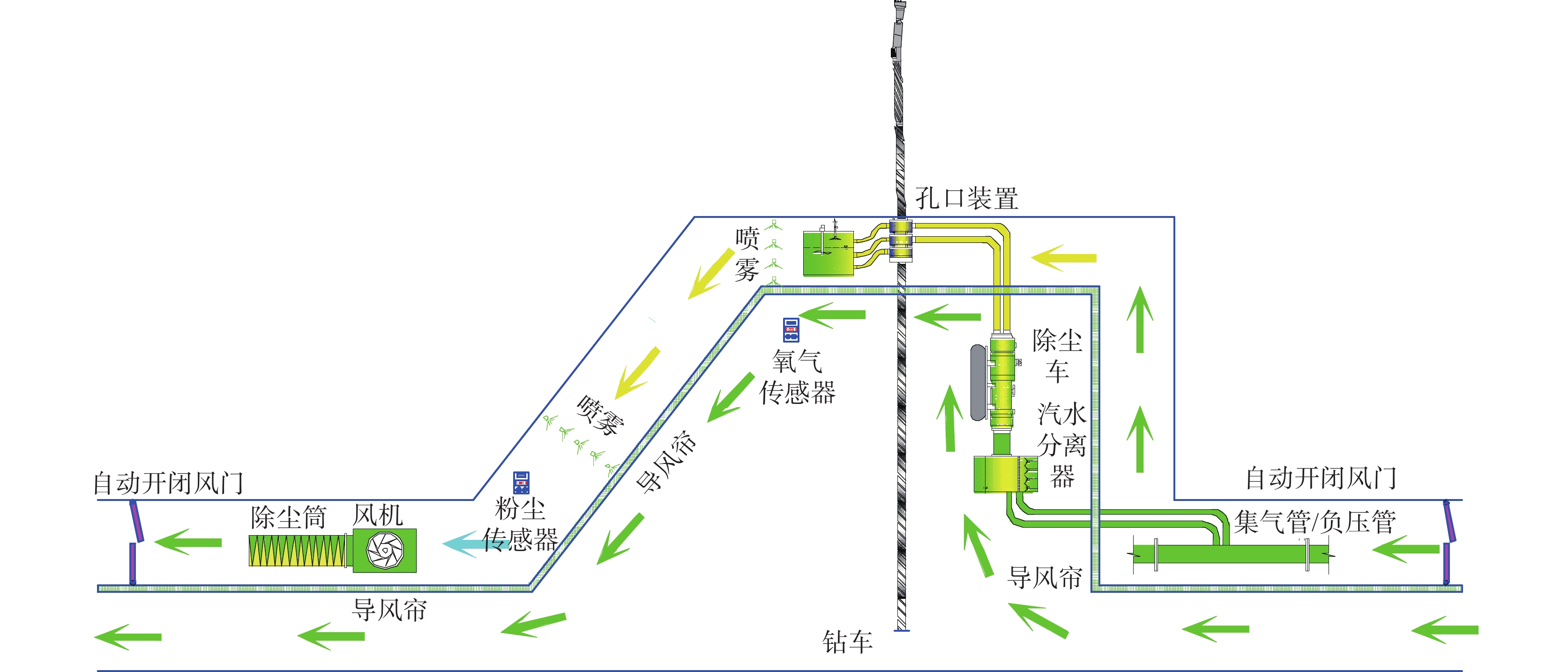

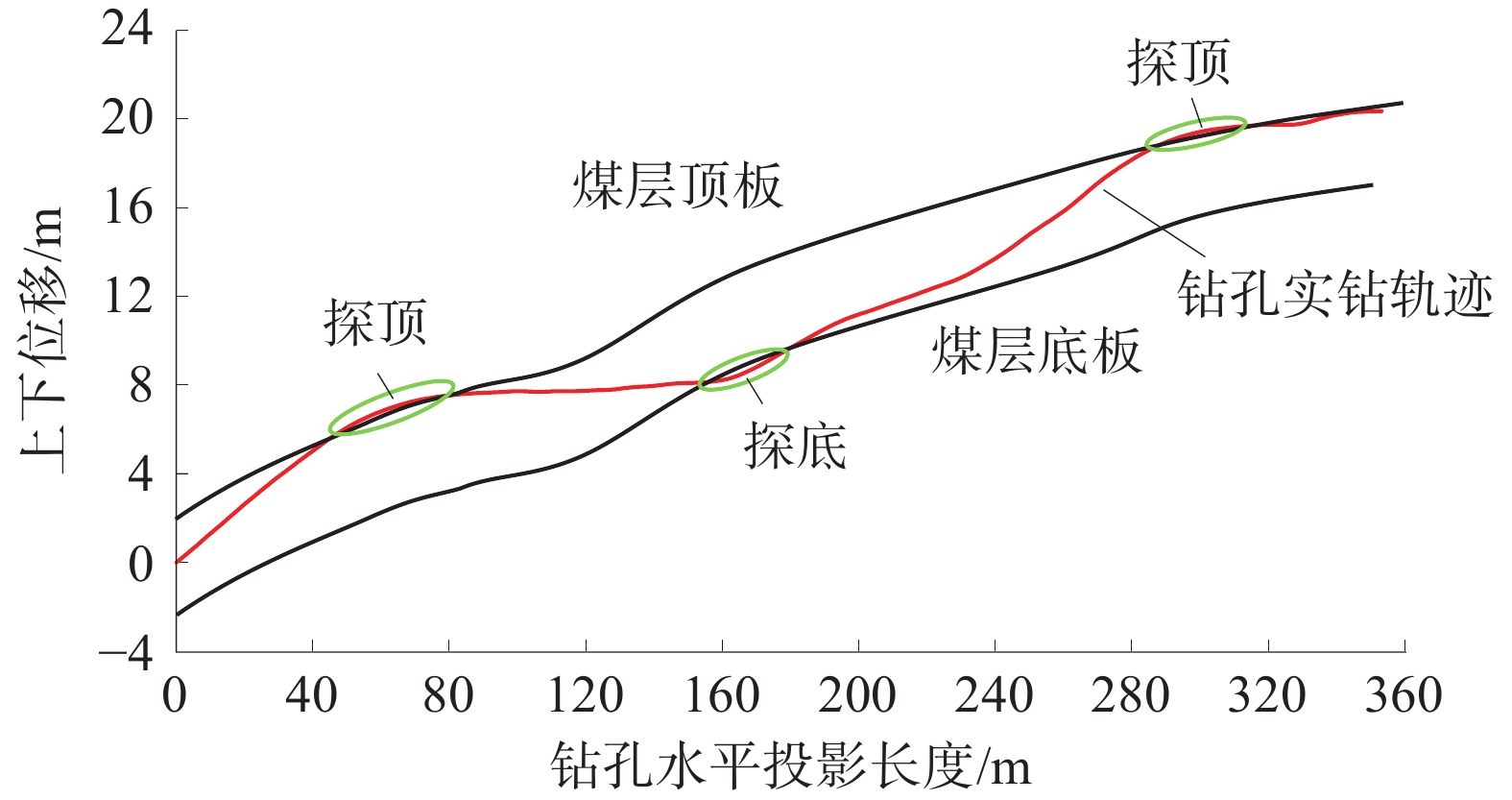

针对王坡煤矿碎软煤层区域瓦斯治理的需求,对现有气动定向钻进工艺及装备进行优化升级。通过对气动螺杆钻具升级改造,将额定扭矩提升至450 N·m以上;研制的89 mm低风阻螺旋通缆钻杆配套有线通缆测量系统,施工孔深提升至300 m以上;基于“波浪式”精准探测煤层顶底板钻孔轨迹工艺,从侧钻开分支原理出发,改进钻具造斜强度实现快速开分支;系统性分析气动定向工艺在不同地层钻进时轨迹变化特点,形成精准轨迹控制技术,大幅提升施工效率。现场试验期间,共计完成34个主孔,49个分支孔,总进尺17287 m,平均成孔深度350 m,平均日进尺103 m/d,最高154 m/d,钻孔平均瓦斯抽采体积分数60%以上,百米钻孔抽采纯量是邻近区域普通钻孔2.7倍。

Abstract:According to the demand of regional gas control in Wangpo Coal Mine crushed soft coal seam area, the pneumatic directional drilling technology was introduced to optimize the existing pneumatic directional drilling process and equipment. Through upgrading the pneumatic screw drilling tool, the rated torque was increased to more than 450 N·m. The 89 mm spiral cable drilling pipe with low wind resistance was developed to realize the construction hole depth of the connected cable measuring system of pneumatic directional drilling to more than 300 m. Based on the tecnique of the “wave type” accurate detection of coal seam top and bottom trajectory, from the principle of directional drilling and branching, the technology of rapid branching is realized by improving the strength of drilling tool. We systematically analyzed pneumatic directional drilling in different strata trajectory variation characteristics, summed up the precise trajectory control technology, and the pneumatic directional drilling process construction efficiency is greatly improved. During the field test, a total of 34 main holes and 49 branch holes were constructed, with a total footage of 17 287 m, an average hole depth of 305 m, an average daily footage of 103 m/d and a maximum of 154 m/d. The average extraction concentration of the borehole was above 60%, and the pure extraction volume of the 100-meter borehole was 2.7 times that of the ordinary borehole in the adjacent area.

-

煤炭在我国能源利用体系中仍占据50%以上,2023年全国矿山安全生产工作会议表示我国煤矿行业总体死亡率仍然高于部分发达国家。煤矿重大事故统计数据显示,人因事故占事故总数90%以上[1],当工人未能及时注意并正确理解安全标志的内容时,他们无法迅速采取保护措施避免事故[2]。安全标志是煤矿安全管理的重要方式[2]。井下环境复杂,矿工的行为受到心理和环境的支配[3],煤矿综采工作面照明环境差是近年来事故多发的重要因素之一[4]。作业人员在井下作业时,认知能力受到环境因素的综合影响导致下降,使作业人员无法正常的工作。1979 年,喻柏林等[5]分析了照度变化对视觉辨认的影响,发现了照明“收效递减律”现象。照度影响人的反应时间、情绪和警觉性[4]。SMOLDERS等 [6]发现光照时长对认知绩效有重要影响,还发现在照明不良时,操作者视觉疲劳,降低操作可靠性;景国勋等[4]发现随着光照水平和操作难度的降低,被试注意力水平受到影响,视觉疲劳度迅速增加,反应急速减慢,反应时间与光照时间呈二次函数关系。视觉注意与危险识别和安全行为密切相关,提高工人视觉注意水平至关重要[7]。近年来,各学者使用眼动仪器对安全标识设计属性的研究多集中在有无信号词、位置特征、排列顺序[8]、视觉特征[9](形状、颜色、背景对比色等)等属性特征方面,上述属性特征结合光照水平的研究目前大多集中在有无信号词[10-11]、视觉特征[12]对安全标志的有效性、显著性、视觉注意和理解等方面,安全标志设计属性主要包括视觉特征和认知特征,对于认知特征混合光照条件下对安全标志识别影响的研究有所欠缺,目前大多集中于可理解性的影响研究[2],研究的安全标志认知特征是基于CHAN等[13]建立的安全标志认知模型,他们将认知特征分为熟悉度、具体性、简单性、富有意义度、语义接近度,熟悉性、简单性和富有意义度认知特征被选中研究。熟悉度的定义是根据遇到矿井安全标志频率来定义的;简单性的定义是如果煤矿安全标志包含大量细节或错综复杂,则视为复杂,如果包含少量元素或细节,则视为简单;富有意义度的定义是指你认为煤矿安全标志有多大意义。

1. 提出假设

安全标志从出现到信息释放,对应人信息处理过程的感觉、认识、再到行为响应,安全标志包含多种认知要素,在注意这些标要素传达的视觉信息时,会通过大脑视觉神经的加工形成相应的认知。所以基于特征整合理论和视觉信息加工理论结合认知信息加工理论中的信号探测理论(signal detection theories),运用实验法对矿工在光照和认知特征水平混合条件下对安全标志识别加工过程进行定量研究,通过内在加工过程对应的各项指标变化特征的影响,使用眼动技术研究视觉注意效果。基于以下假设构建理论模型:H1不同光照下被试者对高、低简单度的安全标志认知程度存在显著差异;H2不同光照下被试者对高、低熟悉度的安全标志认知程度存在显著差异;H3不同光照下被试者对高、低富有意义度的安全标志认知程度存在显著差异。

2. 试验设计及过程

2.1 实验目的和实验对象

1)实验目的。①探究不同熟悉程度和光线程度下的煤矿安全标志的眼动指标是否存在显著差异;②探究不同简单程度和光线程度下的煤矿安全标志的眼动指标是否存在显著差异;③探究不同富有意义度和光线程度下的煤矿安全标志的眼动指标是否存在显著差异。

2)实验对象。为保证实验数据合理性和样本统一性,实验被试选取了22名煤矿专业及相近专业的在校研究生作为实验被试者。基于煤炭企业行业的特殊性质,被试均为男性,平均年龄(25.2±1.10)岁,BMI (20.9±2.24) kg/m2。研究人员承诺,所有来自受试者的实验数据都将是隐私和匿名的,数据仅用于学术研究。他们被要求在眼动实验的前1 d好好休息,避免疲劳、压力和饮酒。参与者的视力或矫正视力是正常的,他们没有散光、斜视或色盲。

2.2 实验设备和实验材料

1)实验设备。Tobii Pro Nano60眼动仪,采样率60 Hz,准确度0.3°,精确度0.10°RMS,头动范围35 cm×30 cm;可以自动记录被试者在观察刺激材料时注视、眼跳、眨眼等指标的相关数据,数据传感到眼动数据采集系统上;眼动数据采集系统为ErgoLab 3.17版本。

2)实验材料。实验选取30张的煤矿安全标志作为实验刺激材料。选用GB2894—2008《安全标志及其使用导则》现行安全标志,通过李克特五级量表法选出30张煤矿安全标志,刺激材料共分为3组,分别为高、低熟悉度安全标志12张,高、低简单度煤矿安全标志10张、高、低富有意义度10张,每组安全标志包括禁止标志、警告标志、指令标志、提示标志至少1张,处理为同等大小及像素,已控制图片物理参数对被试认知效果的影响,满足实验要求,从而进行眼动实验。将刺激材料置于屏幕正中央,并分别调节屏幕亮度和室内亮度从而形成光线程度对比。

2.3 实验步骤

实验是在实验室环境下进行的。控制温度和噪声因素以最大限度减少影响。实验中只允许1名受试者进入,其他人禁止说话。实验步骤如下:

1)向被试宣读实验内容和注意事项,介绍实验材料和过程,解释认知特征。

2)参与者填写人口学特征量表,包括年龄、性别、专业、安全知识水平等信息。

3)研究人员调整被试与屏幕的距离为0.6 m处,所成视角为5°×5°,在被试机上采用5点校准法进行校准。

4)每位被试先进行测试实验,休息10 min后在高光线程度下分别测试3组实验,每组结束后休息2 min再测下1组。每组图片随机播放,先呈现1张正中央有“+”的空白图片2000 ms矫正视线,实验素材呈现时长3000 ms,后插入1000 ms空白屏;为避免上1张图片的影响,再呈现1张正中央有“+”的空白图片2000 ms,后呈现3000 ms的实验素材,以此循环直到该组试验结束。被试需要在实验过程中判断图片对应下方呈现的哪个意思,按下前面的序号。所有图片观察完成即本组实验结束。

5)被试做完高光照实验后休息5 min,再在低光照下进行相同的实验。

6)实验完成。

3. 结果与分析

研究分别从注视维度来分析对视觉行为的影响,选取AOI兴趣区3个注视维度指标首次注视时间、首次注视持续时间、注视次数。通过ErgoLab 3.17系统对采集到的数据进行基线与片段划分,在进行批量处理后导出数据,使用SPSS 22.0进行双因素方差分析。

3.1 熟悉程度与视觉注意关系的验证结果

对高、低光照和高、低熟悉度水平下的首次注视时间、首次注视持续时间、注视次数进行双因素方差分析,熟悉程度与视觉注意关系混合试验下AOI的双因素方差分析见表1。

表 1 熟悉程度与视觉注意关系混合试验下AOI的双因素方差分析Table 1. Two-factor ANOVA for AOI under mixed test of familiarity and visual attention指标 因子 低熟悉度 高熟悉度 总数 F P 低光照 0.853±0.604 0.816±0.335 0.835±0.471 1.828 0.177 高光照 0.665 ±0.544 0.623±0.328 0.644±0.436 2.404 0.122 首次注视时间 总数 0.759±0.574 0.719±0.332 — 4.212 0.041 F 46.956 49.494 96.436 — — P <0.001 <0.001 <0.001 0.019 0.890 低光照 0.276±0.378 0.262±0.290 0.269±0.334 2.736 0.099 高光照 0.218 ±0.289 0.211±0.221 0.214±0.255 0.821 0.366 首次注视持续时间 总数 0.247±0.334 0.236±0.256 — 3.258 0.072 F 47.558 38.103 85.400 — — P <0.001 <0.001 <0.001 0.262 0.609 低光照 2.340±1.095 1.431±0.966 1.886±1.031 56.330 <0.001 高光照 1.532 ±1.039 1.22±0.973 1.294±1.006 5.364 <0.001 注视次数 总数 1.936±1.061 1.244±0.969 — 65.265 <0.001 F 47.769 8.916 47.607 — — P <0.001 0.003 <0.001 6.428 0.012 由表1可知:

1)首次注视时间交互效应不显著(检验F=0.019, 概率P=0.890);光照环境(F=96.436, P<0.001)和熟悉度水平(F=4.212, P=0.041)下的首次注视时间主效应均显著,且低水平下数据显著大于高水平下数据;高(F=49.494,P<0.001)、低(F=46.956,P<0.001)熟悉度下,低光照的数据显著大于高光照的;高(F=2.404,P=0.122)、低(F=1.828,P=0.177)光照下,低熟悉度的均值都大于高熟悉度的,但差异不显著。

2)首次注视持续时间的交互效应不显著(F=0.262,P=0.609)。光照环境的主效应显著(F=85.4,P<0.001),熟悉度的主效应不显著(F=3.258,P=0.072),高光照数据显著小于低光照,高(F=38.103,P<0.001)、低(F=47.558,P<0.001)熟悉度水平下,低光照数据显著大于高光照;高、低光照数据都随着熟悉度的升高而降低,但无显著性差异,且低熟悉度的首次注视持续时间平均值大于高熟悉度。

3)注视次数的交互效应显著(F1=6.428,P1=0.012;F2=47.607,P2<0.001;F3=65.265,P3<0.001);F1、P1为交互效应系数;F2、P2为光照环境系数;F3、P3为熟悉度水平系数。高(F=5.364,P<0.001)、低(F=56.330,P<0.001)光照下,低熟悉度数据都显著大于高熟悉度;高(F=8.916,P=0.003)、低(F=47.769,P<0.001)熟悉度下,低光照环境的注视次数显著大于高光照环境的注视次数。

3.2 简单性水平与视觉注意关系的验证结果

对高、低光照和高、低简单性水平下的首次注视时间、首次注视持续时间、注视次数进行双因素方差分析,简单性水平与视觉注意关系混合试验下AOI的双因素方差分析见表2。

表 2 简单性水平与视觉注意关系混合试验下AOI的双因素方差分析Table 2. Two-factor ANOVA for AOI under mixed test of simplicity and visual attention指标 因子 低简单性 高简单性 总数 F P 低光照 1.015±0.430 0.988±0.434 1.001±0.432 1.262 0.262 高光照 0.943 ±0.446 0.933±0.357 0.938±0.407 0.200 0.655 首次注视时间 总数 0.979±0.438 0.960±0.396 — 1.371 0.217 F 9.023 5.322 13.430 — — P 0.003 0.021 <0.001 0.233 0.730 低光照 0.231±0.716 0.216±0.230 0.223±0.473 3.707 0.055 高光照 0.188 ±0.259 0.176±0.234 0.182±0.247 2.180 0.141 首次注视持续时间 总数 0.210±0.488 0.196±0.232 — 5.002 0.016 F 24.587 23.243 51.910 — — P <0.001 <0.001 <0.001 0.118 0.713 低光照 1.909±1.048 1.718±0.938 1.814±0.993 2.953 0.086 高光照 1.482 ±0.955 1.355±0.908 1.418±0.932 1.312 0.253 注视次数 总数 1.695±1.002 1.536±0.919 — 4.101 0.043 F 14.790 10.713 25.339 — — P <0.001 0.001 <0.001 0.164 0.686 由表2可知:

1)首次注视时间的交互效应不显著(F=0.233, P=0.730);光照环境(F=13.43, P<0.001)主效应显著,简单性水平(F=1.371, P=0.217)主效应不显著,高(F=5.322,P=0.021 )、低(F=9.023,P=0.003)简单性下,低光照数据显著大于高光照,且高、低光照的首次注视时间随简单性水平的升高降低,高(F=0.200,P=0.655)、低(F=1.262,P=0.262)光照下,低简单性的均值大于高简单性。

2)首次注视持续时间交互效应不显著(F=0.118, P=0.713);光照环境(F=51.910, P<0.001)和简单性水平(F=5.002, P=0.016)主效应均显著,高(F=23.243,P<0.001)、低(F=24.587,P<0.001)简单性下,简单效应均显著,低光照数据均显著大于高光照,低简单性的数据显著大于高简单性,高(F=2.180,P=0.141)和低(F=3.707,P=0.055)光照环境,差异均不显著,但是低光照均值大于高光照。

3)注视次数交互效应不显著(F=0.164, P=0.686);光照环境(F=25.339, P<0.001)和简单性(F=4.101, P=0.043)主效应显著,低光照的注视次数显著低于高光照的,低简单性数据显著高于高简单性;高(F=10.713,P<0.001)、低简单性(F=14.790,P=0.001)下,低光照数据显著低于高光照;高(F=1.312,P=0.253)、低(F=2.953,P=0.086)光照环境下,低简单性水平的注视次数平均值大于高简单性水平。

3.3 富有意义度与视觉注意关系的验证结果

对高、低光照和高、低富有意义度水平下的首次注视时间、首次注视持续时间、注视次数进行双因素方差分析。富有意义度与视觉注意关系混合试验下AOI的双因素方差分析见表3。

表 3 富有意义度与视觉注意关系混合试验下AOI的双因素方差分析Table 3. Two-factor ANOVA for AOI under mixed test of significance and visual attention指标 因子 低富有意义度 高富有意义度 总数 F P 低光照 1.123±0.430 1.103±0.434 1.113±0.432 0.885 0.347 高光照 1.008 ±0.446 0.980±0.357 0.994±0.402 1.527 0.186 首次注视时间 总数 1.066±0.438 1.041±0.396 — 2.314 0.110 F 25.542 31.931 45.633 — — P <0.001 <0.001 <0.001 0.073 0.787 低光照 0.315±0.378 0.205±0.286 0.260±0.332 142.114 <0.001 高光照 0.206 ±0.289 0.180±0.191 0.193±0.240 7.526 0.006 首次注视持续时间 总数 0.261±0.334 0.193±0.239 — 70.528 <0.001 F 130.170 6.820 103.528 — — P <0.001 0.009 <0.001 41.500 <0.001 低光照 1.8±0.842 1.591±0.981 1.695±0.548 3.787 0.052 高光照 1.482 ±0.935 1.355±0.843 1.418±0.472 1.403 0.237 注视次数 总数 1.641±0.889 1.473±0.912 — 4.190 0.026 F 8.210 4.240 14.130 — — P 0.003 0.027 <0.001 0.210 0.521 1)首次注视时间的交互效应不显著(F=0.073 , P=0.787);光照环境(F=45.633, P<0.001)主效应显著,富有意义度水平的(F=2.14, P=0.110)主效应不显著,高(F=31.931,P<0.001)、低富有意义度水平(F=25.542,P<0.001)下,低光照显著高于高光照,高、低光照环境的时间随富有意义度升高而降低,无显著差异,且低富有意义度下的平均值高于高富有意义度下的。

2)首次注视持续时间的交互效应显著(F=41.500, P<0.001);光照环境(F=70.528, P<0.001)和富有意义度(F=103.528, P<0.001)的主效应均显著,高(F=6.82,P=0.009)、低(F=130.17,P<0.001)富有意义度下,低光照时间都显著高于高光照;高(F=7.526,P=0.006)、低(F=142.114,P<0.001)光照环境,高富有意义度首次注视持续时间都显著低于低富有意义度。

3)注视次数的交互效应不显著(F=0.210, P=0.521);光照环境(F=14.13, P<0.001)和富有意义度水平(F=4.19, P=0.026)主效应显著,高(F=4.240,P=0.027)、低(F=8.210,P=0.003)富有意义度,低光照显著高于高光照,低富有意义度显著高于高富有意义度;高(F=1.403,P=0.237)、低(F=3.787,P=0.052)光照下,注视次数随着富有意义度的降低而升高,差异都不显著。

4. 结 语

1)光照和熟悉度混合条件下,低光照和低熟悉度均会使矿工识别煤矿安全标志时认知负荷增加,不利于矿工快速识别并正确判断安全标志躲避危险。企业应注意增强井下照明环境,加强对矿工的安全培训,提高矿工对安全标志的熟悉程度。光照和简单性混合条件下,低光照环境下对各指标具有显著性影响,低简单性对各指标不具有显著性影响,简单性在一定能程度上影响被试认知负荷。

2)光照和富有意义度混合条件下,高富有意义度一定程度上降低首次注视的认知负荷,提高视觉注意效果。从危险识别的内在加工机制出发,富有意义度和光照混合对危险识别过程的前注意阶段产生显著影响,为光照和认知特征对安全标志识别的影响提供更加充分的证据,人机工程学家需要关注煤矿安全标志的图案设计,它应该与我们的日常生活有明显和直接的联系。

3)光照对低水平的认知特征影响更大,建议企业多关注工人由于光照带来的视觉疲劳增加的困扰,增强工人对安全标志防护的安全意识;定期检查光环境是否符合标准。企业有必要通过培训和危险演练增强矿工的风险意识,提高对矿井安全标志重要性的认识。

4)构建了安全标志识别内在加工机制模型,揭示了认知特征对安全标志识别的影响机制,客观呈现识别行为背后的眼动规律,为煤矿企业照度防治和矿山安全生产管理提供一定的科学依据;对煤矿安全标志的认知特征提出了改进措施,为降低煤矿工人的认知困难,提高工作场所的安全绩效提供了实践支持。

-

表 1 气动螺杆钻具参数表

Table 1 Pneumatic screw drill parameters table

规格 级数 长度/

mm排量/

(m3·min−1)压降/

MPa转速/

(r·min−1)扭矩/

(N·m)ϕ82 mm 1 4200 5~8 0.4 165 ≥200 ϕ89 mm 2 4200 5~10 0.8 100~200 ≥450 表 2 YHD2-1000 (A)随钻测量装置主要技术参数

Table 2 Main technical parameters of YHD2-1000 (A) MWD device

项目 测量范围/(°) 允许误差/(°) 限制条件 倾角 ±90 ±0.2 — 方位角 0~360 ±1.5 倾角±30° 工具面向角 0~360 ±1.5 倾角±30° 表 3 煤层顶底板情况表

Table 3 Roof-floor of coal seam

顶底板 岩石类别 厚度/m 岩性特征 基本顶 石英砂岩 5.89 灰白色细粒长石石英砂岩,有时相变为粉砂岩或泥质粉砂岩,交错层理发育 直接顶 砂质泥岩 10.68 黑色泥岩,局部含粉砂,含植物化石,局部见炭质泥岩 伪顶 炭质泥岩 0.30 黑色,质软,含植物化石,随采掘脱落 直接底 泥岩 9.16 灰黑色-黑色泥岩,夹薄层粉砂质泥岩,上部含植物化石,底部偶见4号煤,不可采,平均厚0.01 m 基本底 石英砂岩 2.03 灰白色中细粒长石石英砂岩,硅质胶结 -

[1] 李泉新,许超,刘建林,等. 煤矿井下全域化瓦斯抽采定向钻进关键技术与工程实践[J]. 煤炭学报,2022,47(8):3108−3116. LI Quanxin, XU Chao, LIU Jianlin, et al. Key technology and practice of directional drilling for gas drainage in all the mining time and space in underground coal mine[J]. Journal of China Coal Society, 2022, 47(8): 3108−3116.

[2] 袁晨瀚,张壮路,袁晨鑫. 煤矿井下碎软煤层定向钻进技术及应用[J]. 煤炭技术,2021,40(6):45−48. YUAN Chenhan, ZHANG Zhuanglu, YUAN Chenxin. Directional drilling technology and application of broken soft coal seam in coal mine[J]. Coal Technology, 2021, 40(6): 45−48.

[3] 姚宁平,王毅,姚亚峰,等. 我国煤矿井下复杂地质条件下钻探技术与装备进展[J]. 煤田地质与勘探,2020,48(2):1−7. YAO Ningping, WANG Yi, YAO Yafeng, et al. Progress of drilling technologies and equipments for complicated geological conditions in underground coal mines in China[J]. Coal Geology & Exploration, 2020, 48(2): 1−7.

[4] 姚克,田宏亮,姚宁平,等. 煤矿井下钻探装备技术现状及展望[J]. 煤田地质与勘探,2019,47(1):1−5. YAO Ke, TIAN Hongliang, YAO Ningping, et al. Present situation and prospect of drilling equipment technology in coal mine[J]. Coal Geology & Exploration, 2019, 47(1): 1−5.

[5] 李泉新,石智军,田宏亮,等. 我国煤矿区钻探技术装备研究进展[J]. 煤田地质与勘探,2019,47(2):1−6. LI Quanxin, SHI Zhijun, TIAN Hongliang, et al. Progress in the research on drilling technology and equipment in coal mining areas of China[J]. Coal Geology & Exploration, 2019, 47(2): 1−6.

[6] 田宏亮,陈建,张杰,等. 淮南矿区软煤气动定向钻进技术与装备研究及应用[J]. 煤田地质与勘探,2022,50(10):151−158. doi: 10.12363/issn.1001-1986.22.01.0014 TIAN Hongliang, CHEN Jian, ZHANG Jie, et al. Air-driven directional technology and equipment in soft coal seam of Huainan mining ares[J]. Coal Geology & Exploration, 2022, 50(10): 151−158. doi: 10.12363/issn.1001-1986.22.01.0014

[7] 张杰. 气动定向钻进技术在松软煤层条带瓦斯预抽中的应用[J]. 煤田地质与勘探,2021,49(3):256−261. doi: 10.3969/j.issn.1001-1986.2021.03.033 ZHANG Jie. The application of pneumatic directional drilling technology in gas pre-drainage of strips in soft coal seam[J]. Coal Geology & Exploration, 2021, 49(3): 256−261. doi: 10.3969/j.issn.1001-1986.2021.03.033

[8] 张杰,王毅,黄寒静. 软煤气动螺杆钻具定向钻进技术与装备[J]. 煤田地质与勘探,2020,48(2):36−41. doi: 10.3969/j.issn.1001-1986.2020.02.007 ZHANG Jie, WANG Yi, HUANG Hanjing. Directional drilling technology and equipment of pneumatic screw motor in soft seam[J]. Coal Geology & Exploration, 2020, 48(2): 36−41. doi: 10.3969/j.issn.1001-1986.2020.02.007

[9] 孔庆军,褚志伟. 碎软煤层气动定向钻进技术在青龙煤矿的应用[J]. 工矿自动化,2020,46(10):14−18. KONG Qingjun, CHU Zhiwei. Application of pneumatic directional drilling technology for soft-fragmentized coal seam in Qinglong coal mine[J]. Industry and Mine Automation, 2020, 46(10): 14−18.

[10] 聂超,王毅,姚亚峰,等. 碎软煤层气动双管定向钻进排粉特性分析及应用[J]. 煤田地质与勘探,2022,50(5):159−166. NIE Chao, WANG Yi, YAO Yafeng, et al. Powder discharge characteristics of pneumatic double pipe directional drilling in broken soft coal seams and its application[J]. Coal Geology & Exploration, 2022, 50(5): 159−166.

[11] 聂超. 碎软煤层双管定向钻进携粉模拟及成孔工艺研究[D]. 北京:煤炭科学研究总院,2022. [12] 孙永新,张杰,马强,等. 王坡煤矿碎软煤层高压氮气定向钻进试验研究[J]. 煤矿安全,2022,53(7):64−69. SUN Yongxin, ZHANG Jie, MA Qiang, et al. Experimental study on directional drilling with high pressure nitrogen in soft-fragmentized coal seam of Wangpo Coal Mine[J]. Safety in Coal Mine, 2022, 53(7): 64−69.

[13] 王岚. ϕ63.5 mm螺旋钻杆随钻定向测量系统[J]. 煤矿安全,2019,50(11):128−131. WANG Lan. Directional measurement system for auger pipe with an outer diameter of 63.5 mm[J]. Safety in Coal Mines, 2019, 50(11): 128−131.

[14] 燕南飞. 矿用中心通缆式钻杆关键技术研究[J]. 煤炭工程,2016,48(4):129−131. YAN Nanfei. Research on key technology of central cable drill pipe in coal mine[J]. Coal Engineering, 2016, 48(4): 129−131.

[15] 吕晋军. 煤矿井下用千米定向钻机通缆钻杆的研究[J]. 煤炭技术,2021,40(8):175−177. LYU Jinjun. Research on cable drilling pipe of 1000 m directional drilling machine used in coal mine[J]. Coal Technology, 2021, 40(8): 175−177.

[16] 王松. 高效制氮工艺研究应用[J]. 化工设备与管道,2019,56(5):43−46. WANG Song. Study and application of high efficiency nitrogen generating process[J]. Process Equipment & Piping, 2019, 56(5): 43−46.

-

期刊类型引用(0)

其他类型引用(1)

下载:

下载: