Study on the impact of microscopic characteristics of loess at different depths on mining subsidence

-

摘要:

为了探究厚黄土层下开采黄土微观特性对地表移动变形的影响,以山西某矿为例,采用物理实验与数值模拟相结合的方法,分析了不同深度黄土颗粒组成及微观结构特征,建立了厚黄土层分层模型,研究了不同黄土层厚度下的地表变形特征,揭示了黄土微观结构变化对地表移动变形的影响。研究表明:随着黄土深度增加,粉粒含量不断减少,黏粒及胶粒含量升高,微观结构由似柱状堆砌到似球状镶嵌最后形成胶结凝块结构,孔隙空间由贯穿可压缩孔隙到镶嵌孔隙最后形成微孔隙空间;该矿150 m厚黄土层下开采,地表最大下沉及水平移动值分别为4.112、1.327,20 m黄土层移动变形低于地表黄土,黄土压缩量约占地表最大下沉值的12.4%且主要表现在地表浅层处;随着土岩比不断增大,地表下沉量及水平移动呈先增大后减小特征,两者分别于土岩比1.33、1.67达到转折点;黄土层随着深度的增加,其微观结构变化对于地表宏观沉陷具有缓冲作用。

Abstract:In order to investigate the impact of loess micro characteristics on surface movement and deformation during the mining of thick loess layers, a case study was conducted in a mine in Shanxi Province. A combined approach of physical experiment and numerical simulation was used to analyze the particle composition and microstructural characteristics of loess at different depth conditions. A layered model of thick loess layers was established to study the deformation characteristics of the surface under different loess layer thickness conditions. The research revealed the influence of variations in loess microstructure on surface movement and deformation. Research has shown that: with the increase of loess depth, the content of silt particles decreases continuously, while the content of clay and colloidal particles increases. The microstructure changes from a columnar-like arrangement to a spherical-like embedding, ultimately forming a cemented agglomerate structure. The pore space transitions from interconnected compressible pores to embedded pores, eventually forming micropore spaces; the mining of the 150-meter thick loess layer in the mine resulted in a maximum surface subsidence of 4.112 m and a maximum horizontal displacement of 1.327 m. The movement and deformation of the 20 m loess layer were lower than those of the surface loess. The compression of the loess accounted for approximately 12.4% of the maximum surface subsidence, mainly occurring in shallow layers of the surface; as the soil-rock ratio increases, the surface subsidence and horizontal displacement exhibit a first-increase-then-decrease trend. The turning points occur at soil-rock ratios of 1.33 and 1.67, respectively. The variation of loess microstructure with depth has a buffering effect on the macroscopic subsidence of the surface.

-

随着我国中东部煤炭可采储量的不断减少,晋陕蒙宁等西部煤炭基地开采变得尤为重要[1],截至2022年底,晋陕蒙宁煤炭资源储量为1 239.47亿t,占全国煤炭储量的59.87%[2],其与中东部矿区最大区别为厚黄土层与沟壑地貌特征,黄土覆盖地区占西部矿井开采面积的60%以上[3],黄土层厚度占开采深度30%~70%[4],在采动过程中极易产生附加变形造成严重的地表沉陷与损害。“十四五”规划提出实现黄河流域的生态保护和高质量发展,推动资源与环境的协调开发利用[1],如何安全高效的开采厚黄土层下压覆的煤炭资源成为我国资源合理发展的重要一环。

针对厚黄土层下开采地表移动变形规律,学者对其进行了分层研究:汤伏全[5]将西部矿区上覆地层分为基岩层和黄土层2种介质,利用随机介质理论建立了黄土覆盖矿区开采沉陷的双层介质模型;顾伟等[6]基于覆岩和松散层表土移动方式,建立了土岩双层介质开采沉陷模型;宋世杰等[7]以覆岩层状结构关键特征为基础,构建了厚黄土层下开采沉陷分层介质预测模型,并通过工程实例进行了验证。学者还利用模拟及现场实测等方法对地表下沉变形规律进行了研究:刘义新等[8]采用相似材料模拟对厚松散层下采煤岩土体的沉陷规律进行研究,发现松散土体移动因自身压缩表现为沉陷渐增,土体附加压缩量约占地表最大下沉量的25%;郭文兵等[9]通过现场实测对厚黄土层下综放开采地表移动特征进行研究,得到了动态地表移动参数与地表下沉变形特点;穆驰等[10]利用FLAC模拟对韩家湾煤矿不同边坡角度地表滑坡灾害形成机理进行研究,发现当坡角小于30°时,滑坡灾害发生可能性较小。关于厚黄土开采地表裂缝及宏观沉陷研究方面:秦喜文等[11]对王家岭煤矿黄土沟壑地貌下开采矿压显现特征进行研究,发现地层浅部原岩应力会受黄土沟壑地貌的影响;赵兵朝等[12]针对黄土沟壑下地表岩移参数进行研究,发现地表岩移参数受黄土坡体稳定性及滑移附加量的影响;王双明等[13]研究了黄土沟谷区浅埋煤层开采地表非连续性损害产生机理及演化规律,阐明了覆岩破坏块体对地表非连续损害的控制效应;苗彦平等[14]采用动态监测及数值模拟相结合的方法,对黄土地表浅埋煤层开采地表裂缝发育规律及机理进行了研究,得到裂缝发育与黄土地表移动变形的相关关系;徐祝贺等[15]根据地表沉陷区移动变形特点将其分为三向移动变形区、双向移动变形区及单向移动区,建立了地表沉陷区全断面及分区预测模型。

关于厚黄土层下开采移动变形规律的研究主要集中在开采变形破坏的宏观理论研究[16]及黄土沟壑特殊地貌下地表移动变形规律[17],上述研究成果对厚黄土层条件下开采沉陷预计与控制起到了很好的指导作用,但忽略了不同深度黄土层力学性质的差异,在数值模拟[18]、相似材料模拟[19]中将厚黄土层看作一层,若不考虑黄土层深度对力学参数所带来的影响,按照均质条件对厚黄土条件下开采地表沉陷进行预计和模拟,结果与实际情况可能相差较大,因此有必要研究不同深度黄土层的微观结构变化,得到更加准确的厚黄土层下开采移动变形规律。基于此,采用扫描电镜方法,对黄土层不同深度的微观结构、粒度组成等进行研究,分析黄土层深度对微观结构变化的影响,借助UDEC数值模拟对厚黄土层进行分层模拟研究,分析黄土层深度因素下的地表移动变形特征及规律,对于促进厚黄土开采地表沉陷预测与控制,减少煤炭开采对于西部黄土矿区地表下沉具有重要意义。

1. 黄土基本理化性质

测试土样取自山西某矿原状土,以地面为水平点,自上而下采集地表及深度为0~25.0 m的黄土样品,分别利用环刀法、烘干法、比重瓶法等方法测出黄土样品的密度、含水量等参数。黄土基本理化性质参数见表1。

表 1 黄土理化性质参数Table 1. Physicochemical parameters of loess深度/

m含水率/

%密度/

(g·cm−3)干密度/

(g·cm−3)孔隙率/

%液限/

%塑限/

%饱和度/

%压缩

系数1 10.60 1.528 1.382 41.3 31.62 20.71 33.70 0.328 2 11.80 1.500 1.342 41.9 31.21 19.67 36.30 0.325 3 12.20 1.529 1.351 40.3 29.98 19.70 39.20 0.349 4 12.70 1.587 1.380 38.6 31.63 19.28 39.80 0.311 5 12.60 1.593 1.365 34.2 29.95 19.73 40.50 0.291 10 11.10 1.711 1.412 29.8 27.42 19.03 41.00 0.274 20 9.90 2.013 1.424 12.8 26.77 18.72 42.10 0.189 通过对0~20 m部分取样点黄土理化性质进行对比分析,发现随着黄土深度增加,黄土的含水率先增大后减小,黄土的饱和度、密度、干密度逐渐增大,液塑限、孔隙率、压缩系数等虽出现小幅度变化,但总体呈逐渐减少趋势,总结可得,黄土层厚度变化对其理化性质具有一定影响。

2. 黄土深度对微观特性的影响

2.1 试验方案

1) 黄土粒度分析试验。利用Master-sizer激光粒度分析仪对土样进行粒度分析,粒度测试范围为0.01 ~2 000 μm,重复测量误差小于2%,测试样品粒度组各种粒度参数。

2)电镜扫描试验 。利用Gemini Sigma电子显微镜对黄土进行扫描电镜试验,对所取土样进行固定、切割截面等预处理,将处理好的黄土样品放置在电子显微镜样品台上,并确保它在观察期间保持稳定,调节并选择合适的放大倍率和分辨率进行黄土微观结构试验。

2.2 黄土微观特性试验

2.2.1 黄土颗粒级配

黄土土样粒度组成见表2。

表 2 黄土粒度组成Table 2. Grain size composition of loess深度/m 粗粉粒/% 细粉粒/% 黏粒/% 胶粒/% 平均粒径/μm 1 13.22 49.75 13.01 5.53 3.95 2 12.03 46.32 13.19 4.88 4.13 3 9.47 43.89 13.45 5.64 3.12 4 13.13 47.81 18.59 7.13 2.57 5 9.77 43.31 16.21 6.94 2.67 10 11.72 48.79 14.89 6.75 2.73 20 6.80 58.21 20.04 7.78 2.13 由表2可以看出:黄土的粒度组成有以下特征:在深度范围为1~5 m的黄土中,平均粒径在2.57~4.13 μm之间,且具有较高的粉粒含量,最高可达62.97%,其中细粉粒是主要成分,黏粒和胶粒的含量相对较少,平均含量分别为14.89%和6.02%;在深度10 m黄土中,平均粒径为2.73 μm,粗粉粒、细粉粒、黏粒及胶粒的含量分别为11.72%、48.79%、14.89%、6.75%,与深度1~5 m平均值相接近。

绘制的不同深度黄土粒度组成含量变化曲线如图1所示。

由图1可知:10 m黄土的粒度组成含量变化曲线处于1~5 m黄土变化范围内,随深度的增加没有明显的变化规律,说明10 m黄土的颗粒级配与1~5 m黄土具有一定的相似性;在深度20 m黄土中,平均粒径仅为2.13 μm,粗粉粒的含量为6.80%,相较于1~5 m与10 m黄土平均值分别降低了4.72%、4.92%,细粉粒、黏粒和胶粒的含量与10 m黄土平均值相比分别提高了9.42%、5.15%、1.03%;随着深度的增加,20 m黄土中的粗粉粒含量降低,逐渐变化为粒径更小的颗粒,使得细粉粒、黏粒及胶粒的含量升高,可知20 m黄土与1~10 m颗粒级配具有差异性,由此说明随着黄土埋深的变化其本身的性质及组成发生了改变。

2.2.2 黄土微观结构特征

不同深度黄土电镜微观结构如图2所示。在颗粒形态方面,地表黄土颗粒以似柱状形态为主,颗粒表面附着有少许片状碎屑物与黏粒胶结形成的集粒;5 m黄土片状与似柱状形态共存,表面的黏粒集粒数量增多;10、15 m黄土外形以似球状为主,同时存在少量的片状及集粒;当深度为20、25 m时,大量片状与集粒胶结于似球状颗粒之上,使黄土颗粒表现为胶结块状形态。

在孔隙结构方面,地表黄土的骨架颗粒大,表面较干净,胶结程度很差,粒间孔隙接触处几乎见不到细粒物质,颗粒间形成的空间较大且分布较为均匀;5 m黄土骨架颗粒仍以粗骨料为主,但细粒物质开始增多,主要分布在粗骨料的表面,对孔隙间产生的胶结作用较小,颗粒间形成的空间开始收缩;10、15 m黄土的骨架颗粒表面及间隙存在黏粒及胶结物造成轮廓模糊不清,颗粒凝结成球状闭合了部分连通性孔隙,使得贯穿孔隙空间减小,主要以镶嵌孔隙为主;20、25 m黄土骨架颗粒表面完全被胶结物渗透覆盖,这些黏粒及胶结物与骨架颗粒之间相互镶嵌成凝块,骨架颗粒被嵌埋,轮廓不清,并将颗粒间孔隙填充为数量较少的微孔隙。

在黄土接触形式上,地表黄土大颗粒之间主要以点接触为主,骨架颗粒间呈堆砌形态,形成了大量的孔隙空间;5 m黄土颗粒之间仍为堆砌形态,但是以边-边、面-面的接触形式为主,一定程度上收缩了地表黄土的可压缩孔隙空间;10、15 m的黄土颗粒之间呈镶嵌结构,具有一定的孔隙空间但主要以镶嵌形成的夹角空间为主,比起地表黄土堆砌孔隙,具有较小的抗干扰能力,受到开采扰动仍会发生坍塌压缩;20、25 m的黄土颗粒之间呈胶结形态,在胶粒及深度作用下,骨架颗粒相互胶结极大压缩了孔隙空间,仅存在少量的微孔隙,抗干扰能力强。

对比发现,地表及5~15 m黄土的微观结构相似,均存在大颗粒且胶结物较少,形成了不同孔径和形态的可压缩贯穿孔隙与镶嵌孔隙,在较小的压力作用下,颗粒间的连接就会遭到破坏,造成孔隙空间的坍塌,因此地表浅层黄土结构稳定性较差;而20 m与25 m黄土颗粒在胶结物作用下凝结成块,孔隙数量少,空间小且密实,使深部黄土的稳定性明显增大,说明了黄土随着埋深的增大,其微观结构不断变化,从松散结构呈现出压实结构,这与前人关于黄土不同深度微观孔隙结构的研究结果[20-21]具有相似性。

关于黄土微观结构与地表沉陷宏观现象的关系,芦家欣等[4]提出黄土微观特征与土层特性密切相关,黄土开采沉陷的宏观表征就是一定尺度内黄土微观变形的叠加。由此分析在该矿的地质环境下,20 m以上黄土在开采影响下不仅会发生下沉变形,其自身也会发生压缩性下沉,而深度20 m以下黄土的可压缩下沉大大降低,如果不考虑可压缩下沉上的差异,在模拟及预测中可能出现黄土层越厚,附加压缩变形越大,导致地表下沉值大于实际情况,这就是黄土可压缩孔隙微观的叠加对于开采沉陷的宏观表征。因此可以将20 m作为黄土压缩下沉变形变小的转折点,对厚黄土层地表开采沉陷的宏观现象进行补充研究。

3. 黄土深度对开采沉陷的影响

3.1 数值模型建立

根据该矿1#煤层一采区实际地质钻孔及岩性资料,开采长度为500 m,煤层厚度6.5 m,开采深度为216.5 m,利用UDEC数值模拟软件建立厚黄土层下开采模型,设计模型高度为250 m,长度为1 000 m,根据模型水平及垂直方向选取合适的网格大小,在工作面走向和倾向两侧各留250 m的边界保护煤柱,模型如图3所示。数值模拟岩层物理及节理参数见表3。

表 3 数值模拟岩层物理及节理参数Table 3. Numerical simulation of rock physics and joint parameters岩层 岩层厚度/m 弹性模量/GPa 泊松比 内摩擦角/(°) 黏聚力/MPa 抗拉强度/MPa 密度/(t·m−3) 法向刚度/(GPa·m−1) 切向刚度/(GPa·m−1) 浅部黄土 20.0 0.015 0.15 15.00 0.115 0.013 1.300 1 1 深部黄土 130.0 1.000 0.20 24.00 0.650 0.300 1.630 2 1 细粒砂岩 32.0 9.000 0.26 35.50 3.000 1.900 2.250 6 6 泥岩 28.0 6.400 0.23 35.84 0.870 1.240 2.400 3 2 煤层 6.5 2.400 0.29 34.18 0.660 0.940 1.500 2 1 粉砂岩 33.5 5.000 0.23 38.00 1.200 2.120 2.300 7 7 为了研究厚黄土层下开采覆岩与黄土层的移动变形规律,以及黄土层厚度对这一规律的影响,设计2个模拟方案:①针对该矿150 m黄土层厚度条件进行数值模拟,在模拟开采过程中,记录岩层、20 m黄土层及地表的下沉与水平移动数值,探讨厚黄土层下开采对覆岩下沉及移动变形的影响;②基岩层厚度保持不变,将黄土层厚度作为建模变量,设计黄土层厚度为60、80、100、120 m时,其他因素和该矿150 m黄土层模拟设计保持一致,并与150 m黄土层进行对比,记录不同黄土层厚度条件下地表的下沉及水平移动数值,研究黄土层厚度变化对地表下沉及移动变形的影响。

3.2 该矿150 m厚黄土层开采覆岩移动变形规律

该矿150 m厚黄土层下开采过程中,上覆岩层移动变形曲线如图4所示。由图4可知:厚黄土层下煤层开采覆岩下沉和移动变形曲线与一般地质条件下的地表移动变形曲线相近,但当达到充分采动时,20 m处黄土层的下沉值却低于地表下沉值,主要是地表浅部黄土除开采扰动下沉以外,还存在大量的松散黄土压缩变形,因此地表下沉表现更为剧烈。从数值上来看,岩土交界处最大下沉量为5.734 m,20 m深部黄土最大下沉值为4.024 m,地表最大下沉值为4.122 m,通过20 m黄土层下沉推算,如不考虑黄土压缩变形,地表下沉值为3.611 m,计算可知地表浅层黄土的压缩变形量约0.511 m,占地表最大下沉量的12.4%,与学者刘义新松散层研究中[8]提到的松散层压缩变形量占地表下沉量的25%相比有所差异,主要由于考虑黄土层深部由于地质作用逐渐压实,可压缩孔隙大大减小,微观结构强度的提升也进一步降低了地表下沉量。

在煤层开采水平移动变形方面,从开采边缘到顶点处的区域,地表及20 m黄土层水平移动逐步增加随后逐渐下降,水平变形呈现正极值到负极值的上下波动变化;在采场中心位置,即最大沉降点处地表及20 m黄土层水平移动变形下降至0,此处主要发生垂直下沉,当远离最大沉降点,水平移动开始逐渐上升,并在达到负极值后逐渐下降为0,水平变形呈现负极值到正极值的波动变化。从数值上来看,岩土交界处水平移动最大值为2.454 m,20 m处黄土层水平移动最大值为1.215 m,水平变形极值为17.592、−17.823 mm/m;地表水平移动最大值为1.327 m,水平变形极值为17.212、−17.164 mm/m。地表的水平移动值高于20 m处黄土层,在水平变形上也存在着差异,由此分析地表与深部黄土之间的水平移动变形差异可能是厚黄土层下开采地表易产生裂缝的原因之一。

3.3 黄土层不同厚度对地表移动变形的影响

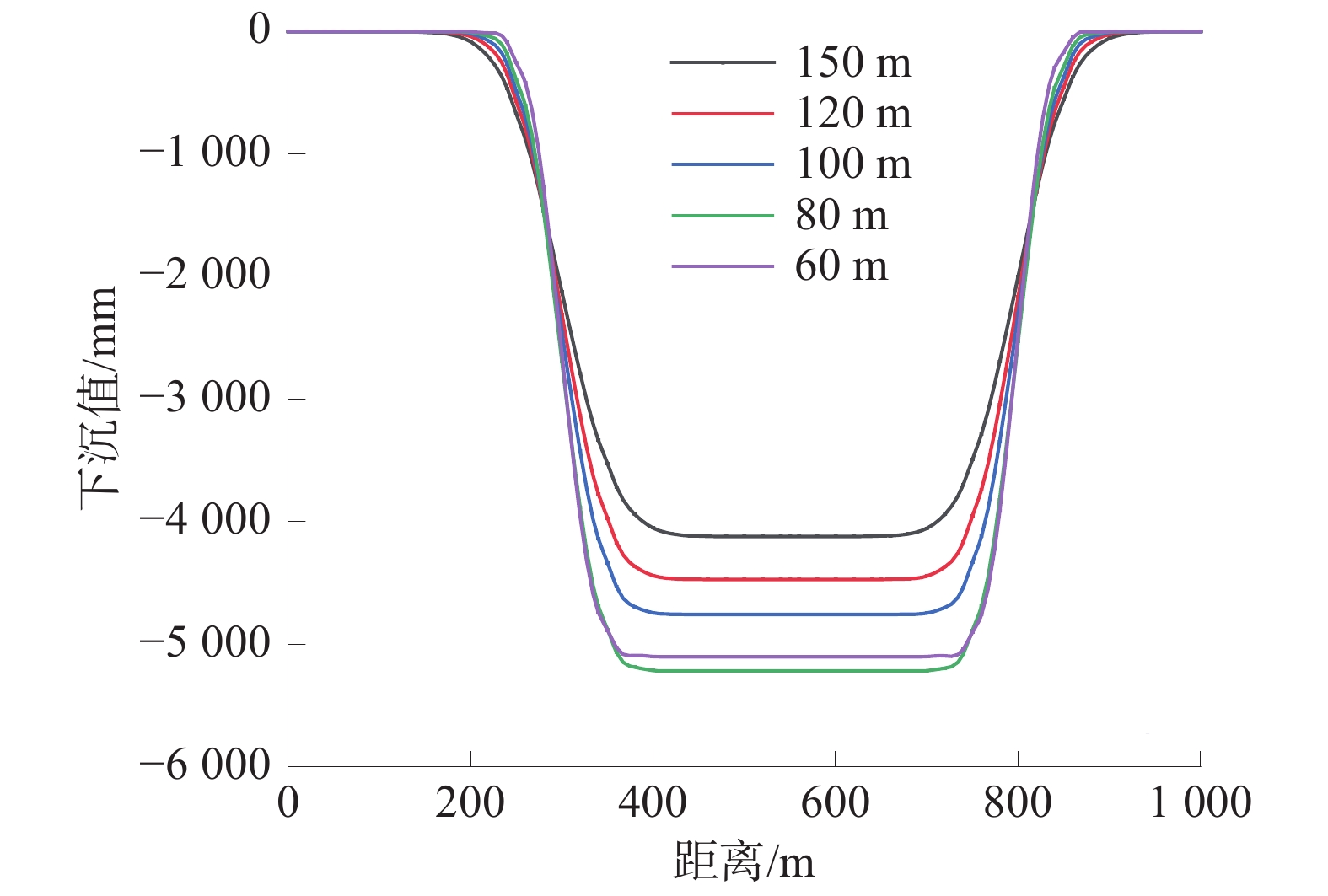

通过对方案②进行模拟计算,得到的不同黄土层厚度对地表下沉及水平移动的影响见表4,绘制的不同黄土层厚度时地表下沉和水平移动曲线如图5和图6所示。

表 4 不同厚度黄土层地表下沉与水平移动参数Table 4. Different thickness loess layer surface subsidence movement deformation parameters模拟

编号黄土层

厚度/m基岩

厚度/m黄土基

岩比下沉值/

m下沉

系数

q水平

移动/

m水平

移动

系数bTY-1 60 60 1.00 5.102 0.785 1.949 0.382 TY-2 80 60 1.33 5.221 0.803 2.068 0.396 TY-3 100 60 1.67 4.757 0.732 1.941 0.408 TY-4 120 60 2.00 4.471 0.688 1.659 0.371 TY-5 150 60 2.50 4.122 0.634 1.327 0.322 当黄土层厚度为60~80 m时,地表下沉与水平移动随着黄土层厚度的增加而增大,一方面是因为黄土层厚度的增加使得基岩层及采空区承受的荷载加大,导致采空区垮落带破碎岩石更加压实[22],基岩下沉增大,导致地表下沉增大;另一方面,松散层拱结构的形成与松散层力学特征、基岩和松散层厚度等因素有关[23]。因此尽管黄土层厚度增加,深部黄土的微观结构强度随之增大,但在开采扰动的影响下,无法形成有效的支撑拱结构来减少地表及上覆岩层的下沉,共同导致了黄土层厚度增加地表下沉增大的情况。当黄土层厚度为80~150 m时,地表下沉值与水平移动值随着黄土层厚度的增加而减小,主要是因为当黄土层厚度增加到一定值时,基岩的承载能力达到饱和状态,基岩下沉不再随着黄土层厚度的增加而增大。另外,随着黄土层厚度的增加,深部黄土层在上方逐级施加的自重荷载作用下,导致黄土微观结构不断压实,微观结构强度不断提高,厚黄土层中形成了有效的拱结构与有效支撑应力层,承担了上覆附加应力,从而降低了开采对黄土层及地表的影响,因此,深部黄土层对于地表下沉与水平移动具有缓冲作用,随着黄土层厚度的增加,地表下沉与水平移动最大值逐渐减小。

从土岩比与下沉系数、水平移动系数的关系来看,土岩比为1.00~1.33时,地表下沉系数随土岩比增大而增大,而在1.33~2.50时地表下沉系数又逐渐减小,其中当土岩比为1.33时,下沉系数最大值达到0.803,土岩比为1.67时,水平移动系数最大值达到0.408,与刘辉等[22]研究中松基比1.75 时地表下沉系数最大,松基比1.25时水平移动系数最大有所不同,下沉系数比水平移动系数更早达到拐点且土岩比值更小。这是由于黄土层随着厚度的增加,其深部黄土受到上部载荷的作用逐渐压实,在煤层开采引起地表沉降时,黄土层结构内部也会产生附加应力,提高黄土层的压实度,因此随着黄土层厚度增加,抗压强度随之提高导致下沉系数逐渐降低,在土岩比1.33时达到拐点。而水平移动引起的变形主要是黄土层内部的剪切滑动和拉伸等变形形式,随着黄土层厚度的增加,水平移动系数也会发生先增大后减小的现象,但是相比之下,黄土层抗压强度远大于抗拉强度,在受到垂直应力时表现出较高的强度,但在水平应力下表现较为脆弱,使得黄土层在受到水平拉伸作用时容易发生断裂和变形,因此下沉系数比水平移动系数应更先到达拐点。

刘辉等[22]研究中厚松散层下开采地表下沉系数出现大于1的情况;张文泉等[24]研究中提到随着松散层厚度的增加,地表下沉越来越大,地表下沉增加的部分可能是由松散层自身压缩下沉量造成的。而在上述厚黄土下开采研究中,充分考虑黄土层随深度微观压缩孔隙的变化,研究发现厚黄土层下开采地表下沉系数小于1,且当黄土层厚度达到一定值后,地表下沉值应随着黄土层厚度的增加而减小,说明对厚黄土不同深度进行微观结构研究,有利于了解黄土深部的压缩变形,理解黄土层的力学特性和变形机制,为工程设计和施工提供科学依据。同时,这些研究结果也表明了黄土层不同深度与厚度对地表下沉的影响是复杂而显著的。

4. 结 语

1)黄土颗粒组成及微观结构随着埋深的增大而变化,1~10 m黄土颗粒细粒含量73.53%,同时具有较高的粗粒含量,20 m黄土颗粒细粒含量88.03%,粗粒含量较少;地表及5 m黄土以似柱状堆砌结构为主,具有可压缩孔隙空间,10 m及15 m黄土以似球状镶嵌结构为主,具有一定的镶嵌孔隙空间,20 m及25 m黄土以胶结凝块形态为主,仅存在少量的微空隙,由此判断黄土深度20 m作为黄土压缩下沉变形变小的转折点。

2)该矿150 m厚黄土层下开采地表最大下沉值为4.112 m,20 m处黄土层的下沉值低于地表黄土下沉值,主要是由于地表浅部黄土除开采扰动下沉以外,还存在大量的松散黄土压缩变形,黄土压缩量约占地表最大下沉量的12.4%,在水平移动方面,地表的水平移动值高于20 m处黄土,水平移动变形差异可能是厚黄土层下开采地表易产生裂缝的原因之一。

3)不同厚度黄土层下开采模拟发现,随着土岩比不断增大,地表下沉量及水平移动呈明显的先增大后减小特征, 两者分别于土岩比1.33、1.67达到转折点,说明黄土层随着深度的增加,其微观结构变化对于地表宏观沉陷具有缓冲作用。

-

表 1 黄土理化性质参数

Table 1 Physicochemical parameters of loess

深度/

m含水率/

%密度/

(g·cm−3)干密度/

(g·cm−3)孔隙率/

%液限/

%塑限/

%饱和度/

%压缩

系数1 10.60 1.528 1.382 41.3 31.62 20.71 33.70 0.328 2 11.80 1.500 1.342 41.9 31.21 19.67 36.30 0.325 3 12.20 1.529 1.351 40.3 29.98 19.70 39.20 0.349 4 12.70 1.587 1.380 38.6 31.63 19.28 39.80 0.311 5 12.60 1.593 1.365 34.2 29.95 19.73 40.50 0.291 10 11.10 1.711 1.412 29.8 27.42 19.03 41.00 0.274 20 9.90 2.013 1.424 12.8 26.77 18.72 42.10 0.189 表 2 黄土粒度组成

Table 2 Grain size composition of loess

深度/m 粗粉粒/% 细粉粒/% 黏粒/% 胶粒/% 平均粒径/μm 1 13.22 49.75 13.01 5.53 3.95 2 12.03 46.32 13.19 4.88 4.13 3 9.47 43.89 13.45 5.64 3.12 4 13.13 47.81 18.59 7.13 2.57 5 9.77 43.31 16.21 6.94 2.67 10 11.72 48.79 14.89 6.75 2.73 20 6.80 58.21 20.04 7.78 2.13 表 3 数值模拟岩层物理及节理参数

Table 3 Numerical simulation of rock physics and joint parameters

岩层 岩层厚度/m 弹性模量/GPa 泊松比 内摩擦角/(°) 黏聚力/MPa 抗拉强度/MPa 密度/(t·m−3) 法向刚度/(GPa·m−1) 切向刚度/(GPa·m−1) 浅部黄土 20.0 0.015 0.15 15.00 0.115 0.013 1.300 1 1 深部黄土 130.0 1.000 0.20 24.00 0.650 0.300 1.630 2 1 细粒砂岩 32.0 9.000 0.26 35.50 3.000 1.900 2.250 6 6 泥岩 28.0 6.400 0.23 35.84 0.870 1.240 2.400 3 2 煤层 6.5 2.400 0.29 34.18 0.660 0.940 1.500 2 1 粉砂岩 33.5 5.000 0.23 38.00 1.200 2.120 2.300 7 7 表 4 不同厚度黄土层地表下沉与水平移动参数

Table 4 Different thickness loess layer surface subsidence movement deformation parameters

模拟

编号黄土层

厚度/m基岩

厚度/m黄土基

岩比下沉值/

m下沉

系数

q水平

移动/

m水平

移动

系数bTY-1 60 60 1.00 5.102 0.785 1.949 0.382 TY-2 80 60 1.33 5.221 0.803 2.068 0.396 TY-3 100 60 1.67 4.757 0.732 1.941 0.408 TY-4 120 60 2.00 4.471 0.688 1.659 0.371 TY-5 150 60 2.50 4.122 0.634 1.327 0.322 -

[1] 刘峰,曹文君,张建明,等. 我国煤炭工业科技创新进展及“十四五”发展方向[J]. 煤炭学报,2021,46(1):1−15. LIU Feng, CAO Wenjun, ZHANG Jianming, et al. Current technological innovation and development direction of the 14th Five-Year Plan period in China coal industry[J]. Journal of China Coal Society, 2021, 46(1): 1−15.

[2] 中华人民共和国自然资源部. 中国矿产资源报告2022[J]. 自然资源情报,2023(1):2. [3] 余学义,李邦帮,李瑞斌,等. 西部巨厚湿陷性黄土层开采损害程度分析[J]. 中国矿业大学学报,2008,37(1):43−47. doi: 10.3321/j.issn:1000-1964.2008.01.009 YU Xueyi, LI Bangbang, LI Ruibin, et al. Analysis of mining damage in huge thick collapsible loess of western China[J]. Journal of China University of Mining & Technology, 2008, 37(1): 43−47. doi: 10.3321/j.issn:1000-1964.2008.01.009

[4] 芦家欣,汤伏全,赵军仪,等. 黄土矿区开采沉陷与地表损害研究述评[J]. 西安科技大学学报,2019,39(5):859−866. LU Jiaxin, TANG Fuquan, ZHAO Junyi, et al. Review of study on mining subsidence and ground surface damage in loess mining area[J]. Journal of Xi’an University of Science and Technology, 2019, 39(5): 859−866.

[5] 汤伏全. 西部厚黄土层矿区开采沉陷预计模型[J]. 煤炭学报,2011,36(S1):74−78. TANG Fuquan. Prediction model of mining subsidence in western thick loess mining area[J]. Journal of China Coal Society, 2011, 36(S1): 74−78.

[6] 顾伟,谭志祥,邓喀中. 基于双重介质力学耦合相关的沉陷模型研究[J]. 采矿与安全工程学报,2013,30(4):589−594. GU Wei, TAN Zhixiang, DENG Kazhong. Study on subsidence model based on double-medium mechanics coupling[J]. Journal of Mining & Safety Engineering, 2013, 30(4): 589−594.

[7] 宋世杰,王双明,赵晓光,等. 基于覆岩层状结构特征的开采沉陷分层传递预计方法[J]. 煤炭学报,2018,43(S1):87−95. SONG Shijie, WANG Shuangming, ZHAO Xiaoguang, et al. Stratification transfer method of the mining subsidence based on the characteristics of layered structure in coal overburden[J]. Journal of China Coal Society, 2018, 43(S1): 87−95.

[8] 刘义新,戴华阳,姜耀东. 厚松散层矿区采动岩土体移动规律模拟试验研究[J]. 采矿与安全工程学报,2012,29(5):700−706. LIU Yixin, DAI Huayang, JIANG Yaodong. Model test for mining induced movement law of rock and soil mass under thick unconsolidated layers[J]. Journal of Mining & Safety Engineering, 2012, 29(5): 700−706.

[9] 郭文兵,黄成飞,陈俊杰. 厚湿陷黄土层下综放开采动态地表移动特征[J]. 煤炭学报,2010,35(S1):38−43. GUO Wenbing, HUANG Chengfei, CHEN Junjie. Dynamic surface movement characteristics of fully mechanized caving mining under thick collapsible loess layer[J]. Journal of China Coal Society, 2010, 35(S1): 38−43.

[10] 穆驰,余学义,张冬冬,等. 黄土沟壑区采动滑坡变形规律分析[J]. 煤矿安全,2021,52(8):208−217. MU Chi, YU Xueyi, ZHANG Dongdong, et al. Analysis of deformation law of mining landslide in loess gully area[J]. Safety in Coal Mines, 2021, 52(8): 208−217.

[11] 秦喜文,杨秀宇,巨文涛. 黄土沟壑地貌下综放开采覆岩结构稳定性研究[J]. 煤矿安全,2021,52(12):66−72. QIN Xiwen, YANG Xiuyu, JU Wentao. Study on stability of overlying rock structure in fully mechanized top coal caving mining under loess gully landform[J]. Safety in Coal Mines, 2021, 52(12): 66−72.

[12] 赵兵朝,刘宾,王建文,等. 柠条塔煤矿叠置开采地表岩移参数分析[J]. 煤矿安全,2016,47(9):213−216. ZHAO Bingchao, LIU Bin, WANG Jianwen, et al. Analysis of surface rock movement parameters in Ningtiaota Coal Mine Superimposed Mining[J]. Safety in Coal Mines, 2016, 47(9): 213−216.

[13] 王双明,魏江波,宋世杰,等. 黄土沟谷区浅埋煤层开采覆岩破坏与地表损伤特征研究[J]. 煤炭科学技术,2022,50(5):1−9. WANG Shuangming, WEI Jiangbo, SONG Shijie, et al. Study on overburden and surface damage characteristics of shallow-buried coal seam mining in loess gully area[J]. Coal Science and Technology, 2022, 50(5): 1−9.

[14] 苗彦平,谢晓深,陈小绳,等. 浅埋煤层开采地表裂缝发育规律及机理研究[J]. 煤矿安全,2022,53(4):209−215. MIAO Yanping, XIE Xiaoshen, CHEN Xiaosheng, et al. Development law and mechanism of surface cracks caused by shallow coal seam mining[J]. Safety in Coal Mines, 2022, 53(4): 209−215.

[15] 徐祝贺,朱润生,何文瑞,等. 厚松散层浅埋煤层大工作面开采沉陷模型研究[J]. 采矿与安全工程学报,2020,37(2):264−271. XU Zhuhe, ZHU Runsheng, HE Wenrui, et al. Subsidence model of large working face in shallow buried coal seam with thick loose layer[J]. Journal of Mining & Safety Engineering, 2020, 37(2): 264−271.

[16] 汤伏全,董龙凯,王宗良,等. 基于沉陷对称特征的近水平煤层开采InSAR三维位移反演模型[J]. 煤炭学报,2019,44(1):210−220. TANG Fuquan, DONG Longkai, WANG Zongliang, et al. InSAR three-dimensional displacement inversion model of near-horizontal coal seam mining based on subsidence symmetry characteristics[J]. Journal of China Coal Society, 2019, 44(1): 210−220.

[17] 胡海峰,廉旭刚,蔡音飞,等. 山西黄土丘陵采煤沉陷区生态环境破坏与修复研究[J]. 煤炭科学技术,2020,48(4):70−79. HU Haifeng, LIAN Xugang, CAI Yinfei, et al. Study on ecological environment damage and restoration for coal mining-subsided area in loess hilly area of Shanxi Province[J]. Coal Science and Technology, 2020, 48(4): 70−79.

[18] 关军琪,吕义清,赵国贞. 黄土沟谷区采空区充填对地表变形规律的影响研究[J]. 煤矿安全,2022,53(1):49−55. GUAN Junqi, LYU Yiqing, ZHAO Guozhen. Study on the influence of goaf filling on surface deformation in loess gully area[J]. Safety in Coal Mines, 2022, 53(1): 49−55.

[19] 徐树媛,张永波,时红,等. 厚黄土覆盖区煤炭开采对松散含水层影响的相似模拟研究[J]. 矿业安全与环保,2019,46(3):1−5. XU Shuyuan, ZHANG Yongbo, SHI Hong, et al. Analogy simulation study on the influence of coal mining on unconsolidated aquifer in the area covered by thick loess[J]. Mining Safety & Environmental Protection, 2019, 46(3): 1−5.

[20] 崔靖俞,张吾渝,解邦龙,等. 西宁地区不同深度原状黄土湿陷性及微观机理研究[J]. 岩土工程学报,2019,41(S2):249−252. doi: 10.11779/CJGE2019S2062 CUI Jingyu, ZHANG Wuyu, XIE Banglong, et al. Collapsibility and microscopic mechanism of intact loess at different depths in Xining area[J]. Chinese Journal of Geotechnical Engineering, 2019, 41(S2): 249−252. doi: 10.11779/CJGE2019S2062

[21] 方祥位,申春妮,李春海,等. 陕西蒲城黄土微观结构特征及定量分析[J]. 岩石力学与工程学报,2013,32(9):1917−1925. FANG Xiangwei, SHEN Chunni, LI Chunhai, et al. Quantitative analysis of microstructure characteristics of Pucheng loess in Shaanxi Province[J]. Chinese Journal of Rock Mechanics and Engineering, 2013, 32(9): 1917−1925.

[22] 刘辉,李玉,苏丽娟,等. 松基比对地表变形的影响及厚松散层薄基岩条件的分析与探讨[J]. 煤炭科学技术,2023,51(9):11−23. LIU Hui, LI Yu, SU Lijuan, et al. Analysis and discussion of the influence of loose foundation ratio on surface deformation and the condition of thick loose layer and thin bedrock[J]. Coal Science and Technology, 2023, 51(9): 11−23.

[23] 汪锋,陈绍杰,许家林,等. 基于松散层拱结构理论的岩层控制研究[J]. 煤炭科学技术,2020,48(9):130−138. WANG Feng, CHEN Shaojie, XU Jialin, et al. Research on ground control based on arch structure in unconsolidated layers theory[J]. Coal Science and Technology, 2020, 48(9): 130−138.

[24] 张文泉,刘海林,赵凯. 厚松散层薄基岩条带开采地表沉陷影响因素研究[J]. 采矿与安全工程学报,2016,33(6):1065−1071. ZHANG Wenquan, LIU Hailin, ZHAO Kai. Influential factors on surface subsidence in stripe mining under thick unconsolidated layers and thin bedrock[J]. Journal of Mining & Safety Engineering, 2016, 33(6): 1065−1071.

-

期刊类型引用(1)

1. 范铭今,陈军涛,古海龙,唐道增,韩港,张树强,李光强. 西部矿区可注断层破碎带注浆加固特性试验研究. 煤矿安全. 2025(01): 155-163 .  本站查看

本站查看

其他类型引用(0)

下载:

下载: