Preparation of Mg-Al hydrotalcite foam retardant and its inhibition characteristics study

-

摘要:

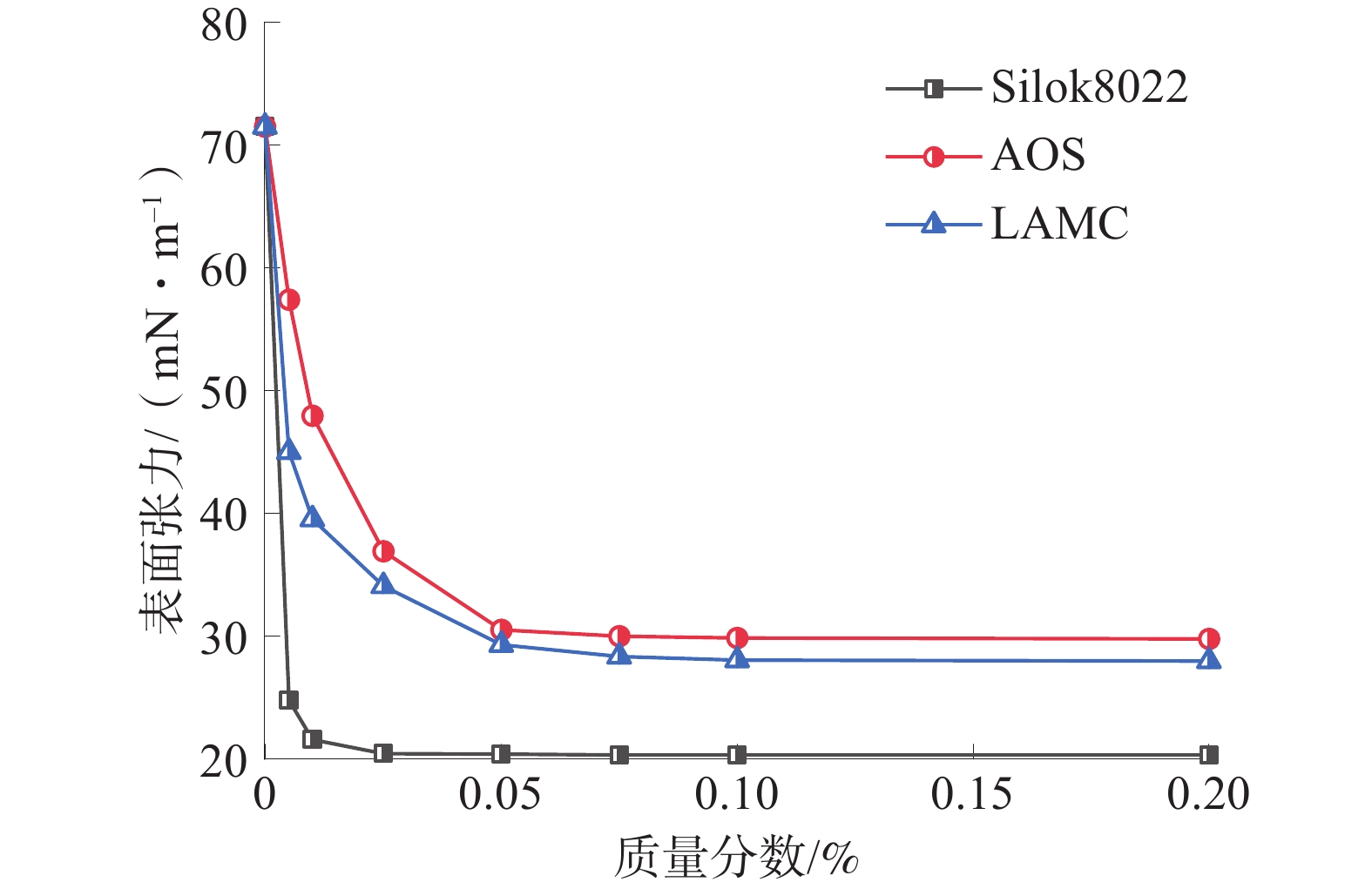

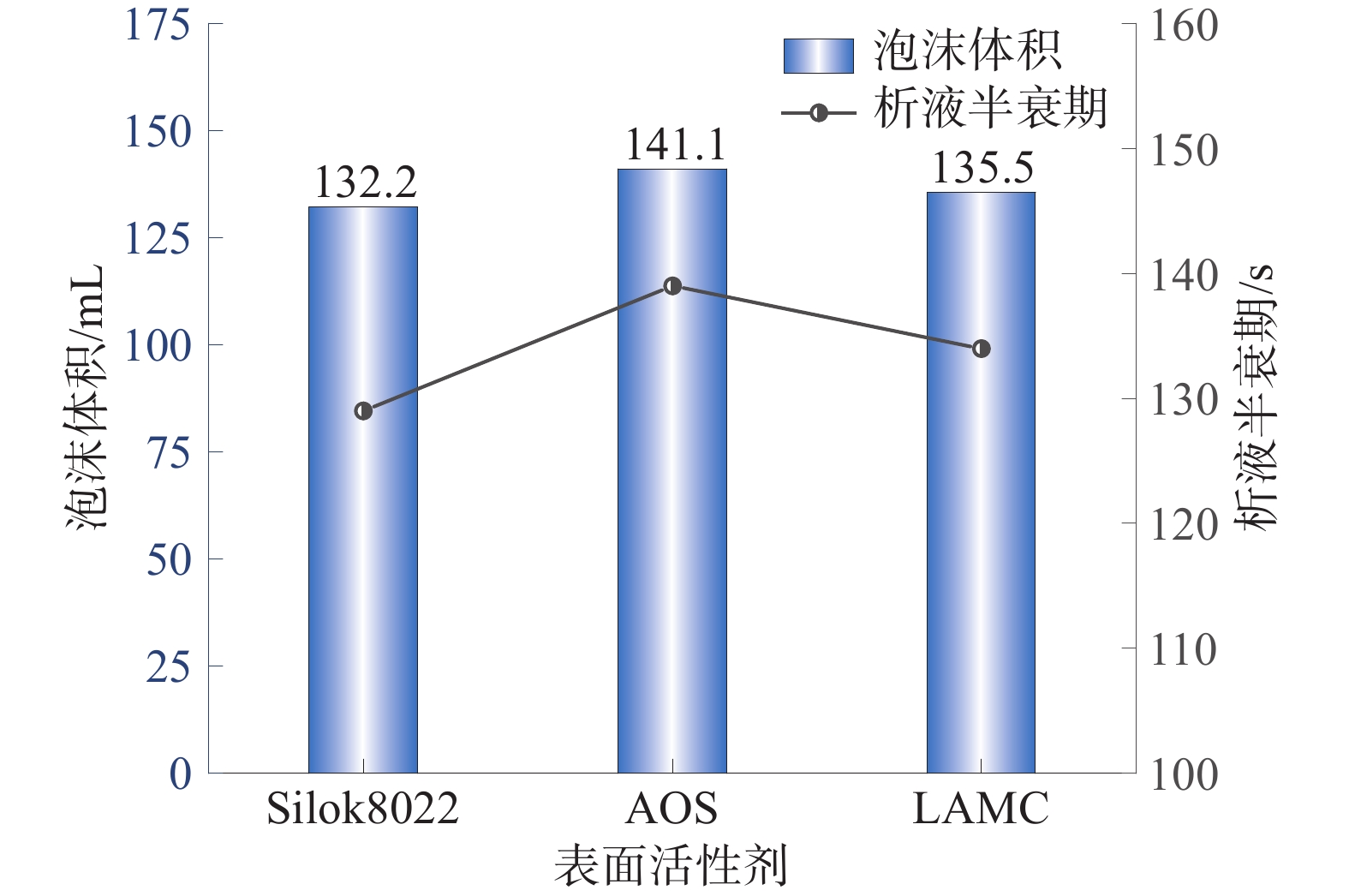

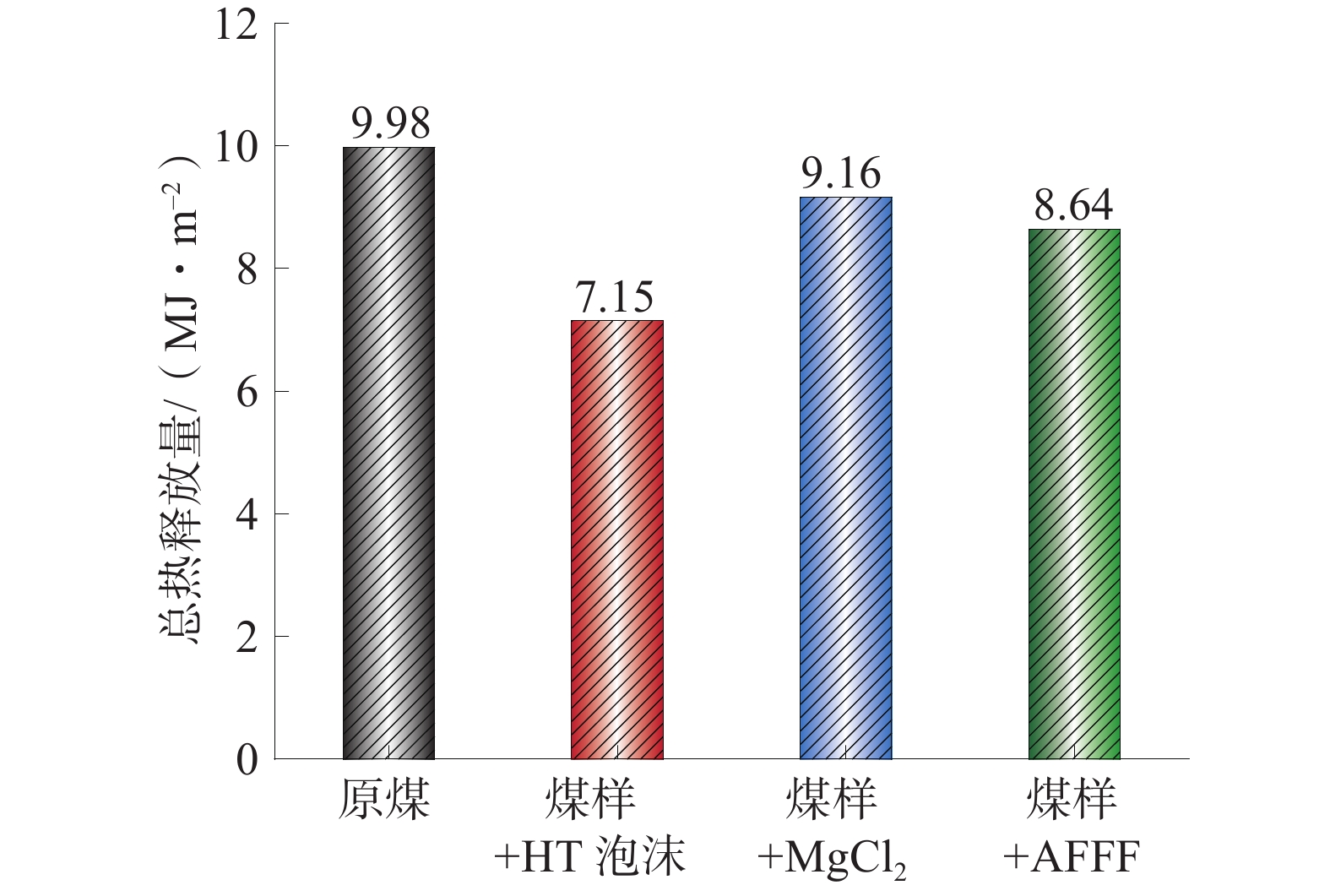

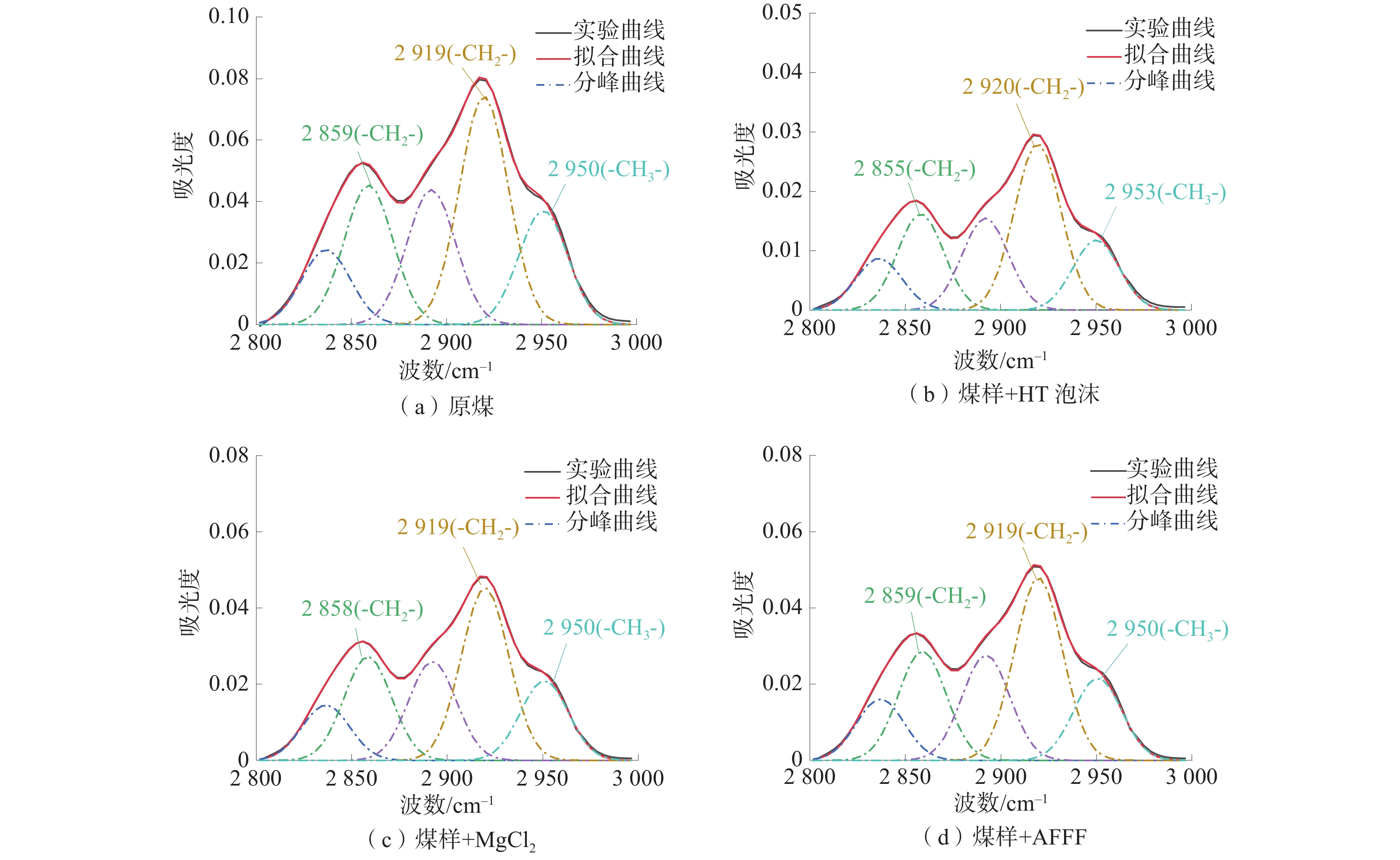

为防治煤自燃,采用表面活性剂、稳泡剂和镁铝水滑石(HT)按一定比例配制出稳定性高、阻燃效果好的镁铝水滑石泡沫,通过正交试验和Waring-Blender法确定了镁铝水滑石泡沫的最佳配方,通过程序升温装置和锥形量热实验测试其阻化特性。结果表明:当表面活性剂Silok8022质量分数为0.03%、AOS质量分数为0.1%、LAMC质量分数为0.075%,稳泡剂HEC质量分数为0.05%,阻燃剂HT质量分数为1%时,镁铝水滑石泡沫的性能最好;在低温阻化方面,HT泡沫的阻化率达到68.4%,200℃时添加HT泡沫的煤样CO体积分数较原煤降低了36.9%;在高温燃烧方面,HT泡沫处理的煤样热释放速率峰值从74.59 kW/m2下降至43.48 kW/m2,总热释放量从9.98 MJ/m2下降至7.15 MJ/m2,相比MgCl2和AFFF,HT泡沫对煤表现出优异的阻燃效果;添加HT泡沫的煤样脂肪烃和含氧官能团含量均显著降低,表明HT泡沫对煤自燃具有较强的抑制能力。

Abstract:In order to prevent coal spontaneous combustion, Mg-Al hydrotalcite foam with high stability and good flame retardant effect was prepared by using surfactant, foam stabilizer and Mg-Al hydrotalcite(HT) in a certain proportion. The optimum formula of Mg-Al hydrotalcite foam was determined by orthogonal test and Waring-Blender method. The inhibition characteristics were tested by temperature programmed device and cone calorimeter test. The results show that when the mass fraction of surfactant Silok8022 is 0.03%, the mass fraction of AOS is 0.1%, the mass fraction of LAMC is 0.075%, the mass fraction of foam stabilizer HEC is 0.05%, the mass fraction of flame retardant HT is 1%, the performance of Mg-Al hydrotalcite foam is the best. In terms of low temperature inhibition, the inhibition rate of HT foam reached 68.4%, and the CO volume fraction of coal samples added with HT foam at 200 °C was 36.9% lower than that of raw coal. In terms of high temperature combustion, the peak heat release rate of coal samples treated with HT foam decreased from 74.59 kW/m2 to 43.48 kW/m2, and the total heat release decreased from 9.98 MJ/m2 to 7.15 MJ/m2. Compared with MgCl2 and AFFF, HT foam showed excellent flame retardant effect on coal. It was found that the content of aliphatic hydrocarbons and oxygen-containing functional groups in coal samples with HT foam was significantly reduced, indicating that HT foam had a strong inhibitory effect on coal spontaneous combustion.

-

为贯彻党中央国务院关于人工智能的决策部署,推动智能化技术与煤炭产业融合发展,提升煤矿智能化水平,促进我国煤炭工业高质量发展。2020年3月,由国家发展改革委等8部委联合印发了《关于加快煤矿智能化发展的指导意见》,《意见》明确指出“冲击地压、煤与瓦斯突出等灾害严重的矿井,优先开展智能化采掘(剥)和危险岗位的机器人替代,建设一批智能化示范煤矿,凝练出可复制的智能化开采模式、技术装备、管理经验等,向类似条件煤矿进行推广应用”。2023年,中国科协发布的重大科学问题、工程技术难题和产业与技术问题中,将“如何实现冲击地压煤层智能安全高效开采?”列为十大产业技术问题,再次将冲击地压矿井的智能化问题推向了一个新的高度[1-3]。

国内外专家学者针对冲击地压煤层的智能安全高效开采问题已经开展了探索性研究。齐庆新等[4-5]、程建远等[6]、王世斌等[7]开展了煤矿精细化建模研究,形成了具有各自特色的模型构建方法;陈结等[8]、何生全等[9]、史志红等[10]、贺勇亮等[11]、崔峰等[12]、丁震等[13]开展了冲击地压智能预警研究,建立了一系列智能预警模型,指导了现场冲击地压防治工作;韩刚等[14]、刘耀琪等[15]应用图像识别、深度学习等技术,对冲击危险区和冲击危险性进行了预测,并实现了软件化;魏立科等[16]针对冲击地压监管难度大的一系列问题,开展了冲击地压灾害风险监察智能分析系统研究,对接入的海量监测数据的有效信息进行深度挖掘;祁和刚等[17]、秦子晗等[18]根据冲击地压智能化的需要,开展了冲击地压智能防控初步探索,形成了思想架构和技术体系。

综上,国内外专家学者对冲击地压煤层智能安全高效开采的认识和理解逐步加深,促进了这类矿井智能化水平的提高。煤炭科学技术研究院冲击地压团队作为国内最早实现“理论−技术−装备−工程”一体化、全链条研究的团队,结合40年来的理论研究和工程实践,提出了“数字孪生地质模型−工程活动推演−全息监测感知−AI智能决策−采掘与防治工程联动”为核心思想的冲击地压煤层智能安全高效开采系统架构,为冲击地压矿井实现全面智能化提供了一种创新路径和技术支撑。

1. 冲击地压矿井智能安全高效开采现状

1.1 冲击地压矿井现状

我国煤矿冲击地压灾害最早发生于1933年,20世纪80年代以来,随着煤矿技术和装备飞速提升,冲击地压矿井数量逐年增长。我国冲击地压矿井开采深度约为270~1 200 m,自有统计数据以来,埋深小于600 m的矿井共发生冲击地压85次,埋深介于600~1 000 m之间的矿井共发生冲击地压145次,埋深大于1 000 m的矿井共发生冲击地压14次[1]。通过统计分析可以看出,冲击地压的发生和开采深度和强度关系密切。我国历年冲击地压矿井数量如图1所示。

据统计,我国煤矿开采深度以每年10~25 m的速度向深部延伸[19]。随着我国煤炭资源开发战略逐渐向西部转移,西部地区近年来出现了一批冲击地压矿井,且数量具有明显上升趋势。西部4省区冲击地压矿井数量近10年变化趋势如图2所示。

总体上,东部的山东省和黑龙江省为我国冲击地压的重灾区;西部的陕西省和内蒙古自治区不断有新的冲击地压矿井出现。特别是彬长矿区和鄂尔多斯深部矿区,尽管开发历史不长,但冲击地压已成为这些矿区影响最大的典型灾害,多数矿井受到冲击地压的影响。由于我国东西部冲击地压矿井地质条件差异大、机理尚未摸清,冲击地压灾害时有发生,冲击地压煤层智能安全高效开采将成为解决这一难题的主要途径之一。

1.2 冲击地压煤层智能安全高效开采面临的挑战

我国煤矿冲击地压具有明显的地区差异性,东部冲击地压矿井以开采深度大、采动影响因素复杂、煤层赋存多样、处于充分采动阶段为显著特点;西部冲击地压矿井以高强度开采、厚硬岩层、超长推进度、处于非充分采动阶段为显著特点。东部地区以山东巨野和兖州煤田为代表,西部地区则以鄂尔多斯深部煤田和彬长煤田为代表[20]。这就给冲击地压煤层智能安全高效开采带来了诸多挑战:

1)冲击地压机理仍有待于深入研究。虽然国内外学者相继提出了强度理论[21]、刚度理论[22]、能量理论[23]、冲击倾向性理论[24]、变形系统失稳理论[25]、“三准则”理论[26]、“三因素”机理[27]、应力控制理论[28]、扰动响应失稳理论[29]、动静载叠加原理[30]、冲击启动理论[31]等一系列理论、模型和假说,但由于我国东西部矿井差异,难以通过一套理论来揭示冲击地压发生机理。已有研究关注冲击地压形成过程的复杂性而忽略了其系统性,缺乏从源头统筹防控的科学理念。

2)冲击地压矿井产能与防治工程间的矛盾日益凸显。2019年5月,原国家煤矿安全监察局印发《关于加强煤矿冲击地压防治工作的通知》,规定冲击地压矿井生产能力不得超过800万t/a。由于目前冲击地压矿井智能化建设中,缺乏采掘工程和防治工程间的协同联动,无法准确给出采掘工作面在特定措施落实情况下的安全推进速度。为避免冲击地压事故发生,只能采取限制产能、降低采掘速度的措施,特别是在西部地区,许多矿井设计产能均在1 000万t/a以上,均无法发挥出全部生产能力。

3)冲击地压监测数据与采掘、防治工程脱节。经过10多年的技术发展与推广,特别是2018年《防治煤矿冲击地压细则》出台后,微震监测系统、采动应力监测系统等几乎应用于全国所有冲击地压矿井。目前,已监测得到了大量的数据,但是对数据挖掘的深度明显不足,难以实时、动态划分冲击危险区,精准指导采掘活动和防治工程。矿井往往采取多种防治措施,其效果到底如何,尚难以定量评价。

4)冲击地压防治措施设计缺乏有力依据。目前冲击地压防治存在严重依赖经验、参数设计不够科学合理等问题。尤其是新建矿井未从初步设计阶段考虑冲击地压防治问题,导致后期冲击地压防治难度和成本加大,大量的防治工程施工,增加了井下一线工人的安全风险,同时,也增大了矿井的资金投入,降低了生产效率。

5)防治工程量与限员管理不匹配。《关于加强煤矿冲击地压防治工作的通知》中规定“冲击地压煤层的掘进工作面200米范围内进入人员不得超过9人,回采工作面及两巷超前支护范围内进入人员生产班不得超过16人、检修班不得超过40人”,这也就要求进一步提高冲击地压矿井智能化水平,最终达到减员、减人的目的。

2. 冲击地压煤层智能安全高效开采系统架构

2.1 总体架构

从我国煤炭开发形势来看,东部地区浅部煤炭资源面临枯竭,特别是在我国煤种全但分布不均的资源形势下,浅部的煤炭资源已难以满足经济发展需要。目前我国最大开采深度已达到1 500 m,根据我国第二次全国煤田预测结果,1 500 m以深的煤炭资源占比达到28.1%,未来开发1 500 m以深煤炭资源是大势所趋。开采深度的增加势必加剧冲击地压对安全生产的影响。因此,开展1 500 m以深远景开采冲击地压防治探索性研究,将为我国煤炭资源稳定开发提供一定的支撑。西部地区矿井开采强度较大,由于工作面推进速度与冲击地压密切相关,开展工作面长度、推进速度与冲击地压防治的协调研究,对解放冲击地压矿井产能具有重要作用,通过智能化之路解决这一问题,对国家稳定的能源供应具有重要战略意义。

结合当今科技发展趋势及冲击地压智能化需求,提出的冲击地压煤层智能安全高效开采的总体架构图3所示。

首先,应用数字孪生技术开展数字建模,精细化探测、探查矿井所处区域构造信息,实测区域地应力场特征和煤岩物理力学性质,依托算法进行地层变化信息的工程展布,实现地质信息“透明化”;其次,在模型中依据矿井开采设计,开掘井筒、巷道、工作面,同时,根据井上、井下各类监测系统的数据,实时在矿井数字模型上进行计算、更新,既可实现对以往工程效应的回放,又可实现对未来工程活动的推演;再次,应用深度学习、AI等技术,使计算机自主学习矿井全息数据,根据监测数据和工程活动的变化,自主决策开采和防治工程活动,同时形成标准化通信技术,实现矿井万物互联;最后,开发智能化采煤装备控制模块,在计算机智能决策指令下,智能控制全矿井的各类设备动作,自主调节采煤和卸压解危间的时效,控制采煤、运输、提升等设备速度,全面实现冲击地压煤层智能开采。

2.2 感知层系统功能架构

冲击地压归根到底是一个复杂的工程问题,既然是工程问题,那么冲击地压的发生一定是一个动态过程,这就提出了对煤岩体所处环境感知的要求。因此,感知层系统的主要功能是通过震动场和应力场的实时、动态监测,反映出煤岩体的应力状态以及采场上覆岩层结构。感知层系统架构如图4所示。

在结构感知方面,通过在地面和井下联合布设高、中、低频震动传感器,形成井上下联合监测系统,通过监测数据分析,反演上覆岩层结构演化,精准识别影响煤岩体应力的关键目标层。

在应力感知方面,通过地面或井下地应力实测获取原岩应力状态,研发高频、高精度应力传感器,监测采掘活动导致煤岩体的应力变化,研究应力场反演算法,结合各测点实测应力值以及震动场的波速变化,推测煤岩体整体的应力状态,实现应力监测由点到面的转变。

2.3 数据库系统功能架构

数据库系统功能架构如图5所示。数据库系统的主要功能是存储、建模和数据处理。

存储功能包括地层信息、地质构造、采掘设计等静态数据,以及存储感知层监测得到的动态数据、采掘进尺、防冲工程进尺等;建模功能是应用数字孪生技术,将数据库中的地层信息、构造信息及采掘设计数据提取出来,生成矿井数字模型;数据处理功能是自动化、智能化的处理监测得到的动态数据,并进行数据清洗,保留有效、高质量的数据,为决策层的功能实现提供支撑。

2.4 决策层系统功能架构

决策层系统功能架构如图6所示。决策层是实现冲击地压煤层智能安全高效开采最关键的环节,智能决策将打通监测、防冲和采掘等3大系统,实现真正意义上的“物联”。

基于数字孪生矿井模型,并加以数值运算技术,根据采掘及防冲工程设计开展超前推演,在数字模型中可直观显示煤岩体应力和上覆岩层结构的变化;开发具有自主学习功能的AI算法,智能分析采掘工程和防冲工程是否匹配,动态调整采掘工程和防冲工程参数,生成执行层的动作指令。

2.5 执行层系统功能架构

执行层系统功能架构如图7所示。执行层是落实冲击地压煤层智能安全高效开采的最终环节。

通过接收决策层发出的指令,自动进行工程活动,同时,感知层不断监测震动场和应力场数据变化,传输反馈至决策层,决策层根据监测数据自动分析、动态评价当前工程活动的冲击危险性。通过3个层级的循环往复、不断计算,动态调节采掘速度和防冲工程量,实现采掘工程与防冲工程的动态协调,最大限度释放冲击地压矿井产能。

3. 冲击地压煤层智能安全高效开采关键技术

3.1 感知层关键技术

1)原岩应力测试技术。基于水力压裂地应力测量原理,研究团队自主研制了适用于小孔径(ϕ31 mm和ϕ42 mm)的地应力测试装置(图8),并配套了数据采集仪、测量软件。随着煤炭逐步向深部开采,越来越多的矿井在初步设计前就需要摸清其所处区域的原岩应力特征,在现有技术的基础上,将继续研制基于水力压裂原理的煤矿地面地应力测试系统,为新建矿井冲击地压智能防控提供支撑。

2)井上下联合震动场−应力场一体化监测技术。基于研究团队自主研发的KJ768自震式微震监测系统和KJ29采动应力监测系统,深入开发集高、中、低、频震动传感器为一体的宽频广域震动场监测系统,集成实现微震、地音和矿震监测功能,并可反演工作面直至地表范围的覆岩结构;同时,在井上和井下分别布置高频应力传感器,覆盖矿井采掘区域。特别是对于新建矿井而言,在矿井建设期间就完成监测系统的布设,投产后就能掌握第一手数据,服务于矿井全生命周期。井上下联合震动场-应力场一体化监测技术示意图如图9所示。

3)钻屑法智能检测技术。煤矿用钻屑法智能检测系统主要由采集器、控制器、动力总成、行走履带等部分组成;该系统具备煤粉自动称量、动力现象智能判识、远程控制、数据实时采集与动态分析展示等多项功能;系统集精准识别、智能高效、实时预警、数据管理于一体,实现了“钻−采−测−录”的一键式作业;检测结果可实时上传至各类综合预警平台,对冲击地压矿井智能化开采具有重要意义。

3.2 数据库关键技术

1)矿井复杂模型构建技术。通过对钻孔资料进行整理,确定目标矿井主要发育的煤岩层由地表向下依次分布顺序和特征,在建模过程中将各煤层或岩层边界作为标志层进行模型搭建,并拟合成曲面,且模型一直模拟到地表。由于煤系地层的特殊性,煤矿数字模型中应包含大量不连续结构,现有建模技术可以实现对褶曲构造的孪生,但尚难以实现断层构造的孪生。对于断层构造的数字孪生将是下一步重点攻克的主要难题之一。

2)开采信息识别技术。矿井数字模型构建后,需要进一步将开采信息输入系统,矿井开采设计是较为复杂的系统工程,特别是对于倾斜煤层、多水平开采,其巷道的复杂程度不言而喻,因此,通过读取矿井采掘工程平面图中的高程数据,以及应用图像识别技术,在水平面上圈定工作面及巷道范围,即可实现对开采信息的获取。

3.3 决策层关键技术

1)应力反演技术。应用井上下震动场和应力场一体化监测得到的数据,开发应力反演算法,修正测区波速场模型,从而得到采掘区域的应力云图,通过对高应力区的智能识别,即可确定冲击危险区。应力反演云图的示意图如图10所示。

2)覆岩结构反演技术。同理利用监测得到的数据,基于波速场反演方法,推测上覆岩层结构,得出覆岩结构波速场云图。结合图像智能识别技术,自主分析高应力区域与覆岩结构间的关系,为下一步进行开采和防治工程决策提供支撑。覆岩结构波速场反演云图示意图如图11所示。

3)采掘与防冲工程智能决策技术。基于上述云图智能分析结论,已明确冲击危险区位置及冲击危险源的位置。进一步开发采掘与防冲工程智能决策AI算法,自主决策采掘工作面推进速度、防治技术选择以及参数确定;通过通信模块与采掘设备和防冲施工设备相连接,发出行动指令,采掘设备系统、监测设备系统、防冲设备系统有机联动,最终全面实现冲击地压煤层智能安全高效开采。

4. 结 语

1)系统分析了当前冲击地压矿井智能安全高效开采现状,研究团队认为实现冲击地压矿井智能安全高效开采面临“冲击地压机理仍有待于深入研究、冲击地压矿井产能与防治工程间的矛盾日益凸显、冲击地压监测数据与采掘、防治工程脱节、冲击地压防治措施设计缺乏有力依据、防治工程量与限员管理不匹配”等5大挑战。

2)结合40年来的理论研究和工程实践,提出了“数字孪生地质模型−工程活动推演−全息监测感知−AI智能决策−采掘与防治工程联动”为核心思想的冲击地压煤层智能安全高效开采系统架构。

3)通过分析现有感知层、数据库和决策层关键技术,明确了冲击地压煤层智能安全高效开采存在的问题,梳理了未来技术研究与开发的主要方向,为进一步开展研究工作奠定了基础。

-

表 1 正交试验水平因素设计表

Table 1 Design table of orthogonal experiment horizontal factor

水平 A质量分数/% B质量分数/% C质量分数/% 1 a1(0.02) b1(0.050) c1(0.050) 2 a2(0.03) b2(0.075) c2(0.075) 3 a3(0.04) b3(0.100) c3(0.100) 表 2 正交试验结果

Table 2 Orthogonal test results

组别 A B C 泡沫体积/mL 析液半衰期/s 1 a1 b1 c1 140 147 2 a1 b2 c3 153 151 3 a1 b3 c2 152 143 4 a2 b1 c3 148 149 5 a2 b2 c2 153 147 6 a2 b3 c1 154 139 7 a3 b1 c2 151 138 8 a3 b2 c1 150 145 9 a3 b3 c3 153 142 表 3 鼓气120 s泡沫体积极差分析结果

Table 3 Results of positive difference analysis of foam with bubbling for 120 s

组别 A B C 泡沫体积 k1 148.33 146.33 148.00 k2 151.67 152.00 152.00 k3 151.33 153.00 151.33 极差R 3.33 6.67 4.00 主次因素 AOS>LAMC>Silok8022 最优组合 A2B3C2 注:k1、k2、k3为各因素在相应水平下评价指标的均值。 表 4 析液半衰期极差分析结果

Table 4 Results of range analysis of liquid half-life

组别 A B C 半衰期 k1 147.00 144.67 143.67 k2 145.00 147.67 142.67 k3 141.67 141.33 147.33 极差R 5.33 6.33 4.67 主次因素 AOS>Silok8022>LAMC 最优组合 A1B2C3 表 5 原煤与阻化煤样的点燃时间

Table 5 Ignition time of raw coal and inhibited coal samples

煤样 原煤 煤样+HT泡沫 煤样+MgCl2 煤样+AFFF 点燃时间/s 26 64 39 48 -

[1] 李宗翔,张明乾,杨志斌,等. 断层构造对煤结构及氧化自燃特性的影响[J]. 煤炭学报,2023,48(3):1246−1254. LI Zongxiang, ZHANG Mingqian, YANG Zhibin, et al. Effect of fault structure on the structure and oxidative spontaneous combustion characteristics of coal[J]. Journal of China Coal Society, 2023, 48(3): 1246−1254.

[2] 王建国,赵思蕊,王康. 松散煤堆自燃高温区时空演化规律仿真研究[J]. 矿业安全与环保,2023,50(3):37−41. WANG Jianguo, ZHAO Sirui, WANG Kang. Simulation research on spatio-temporal evolution of high temperature zone of spontaneous combustion of loose coal pile[J]. Mining Safety & Environmental Protection, 2023, 50(3): 37−41.

[3] ZHANG Y, LIU Y, SHI X, et al. Risk evaluation of coal spontaneous combustion on the basis of auto-ignition temperature[J]. Fuel, 2018, 233: 68−76. doi: 10.1016/j.fuel.2018.06.052

[4] PAN D, HONG K, FU H, et al. Influence characteristics and mechanism of fragmental size of broken coal mass on the injection regularity of silicasol grouting[J]. Construction and Building Materials, 2021, 269: 121251. doi: 10.1016/j.conbuildmat.2020.121251

[5] XU Y, QIN B, SHI Q, et al. Study on the adsorption of cement particles on surfactant and its effect on the characteristics of inorganic curing foam for prevention of coal spontaneous combustion in a goaf[J]. Fuel, 2023, 333: 126407. doi: 10.1016/j.fuel.2022.126407

[6] 邓军,杨囡囡,王彩萍,等. 采空区煤自燃“防-抑-灭”协同防灭火关键技术[J]. 煤矿安全,2022,53(9):1−8. DENG Jun, YANG Nannan, WANG Caiping, et al. Key technology of “preventing-suppressing-extinguishing” coordinated fire preventing and extinguishing for coal spontaneous combustion in goaf[J]. Safety in Coal Mines, 2022, 53(9): 1−8.

[7] 秦波涛,仲晓星,王德明,等. 煤自燃过程特性及防治技术研究进展[J]. 煤炭科学技术,2021,49(1):66−99. QIN Botao, ZHONG Xiaoxing, WANG Deming, et al. Research progress of coal spontaneous combustion process characteristics and prevention technology[J]. Coal Science and Technology, 2021, 49(1): 66−99.

[8] 舒森辉,张雷林. 基于茶多酚的阻化泡沫制备及阻燃性能研究[J]. 煤矿安全,2022,53(8):50−55. SHU Senhui, ZHANG Leilin. Preparation of retarding foam based on tea polyphenols and its flame retardancy[J]. Safety in Coal Mines, 2022, 53(8): 50−55.

[9] 秦波涛,蒋文婕,史全林,等. 矿井粉煤灰基防灭火技术研究进展[J]. 煤炭科学技术,2023,51(1):329−342. QIN Botao, JIANG Wenjie, SHI Quanlin, et al. Research progress on fly ash foundation technology to prevent and control spontaneous combustion of coal in mines[J]. Coal Science and Technology, 2023, 51(1): 329−342.

[10] 秦波涛,高远,史全林,等. 近距离煤层复合采空区煤自燃综合防治技术[J]. 工矿自动化,2021,47(9):1−6. QIN Botao, GAO Yuan, SHI Quanlin, et al. Comprehensive prevention and control technology of coal spontaneous combustion in compound goaf of close distance coal seam[J]. Industry and Mine Automation, 2021, 47(9): 1−6.

[11] ZHANG B, QIN Y, SHEN H, et al. Constructing fibrous-like skeleton by simulated sea mud to improve three-phase foam for stability and fire-extinguishing performance[J]. Journal of Dispersion Science and Technology, 2023, 44(12): 2311−2321. doi: 10.1080/01932691.2022.2072872

[12] LU W, ZHANG X, YUAN Y, et al. Study on the characteristics and mechanism of a new type of antioxidant gel foam for coal spontaneous combustion prevention[J]. Colloids and Surfaces A:Physicochemical and Engineering Aspects, 2021, 628: 127254. doi: 10.1016/j.colsurfa.2021.127254

[13] 史全林,杨红旗,李洪彪. 成膜型胶体泡沫的制备及灭火降温特性研究[J]. 中国安全科学学报,2022,32(10):121−126. SHI Quanlin, YANG Hongqi, LI Hongbiao. Research on preparation of film-forming colloidal foam and its fire extinguishing and cooling characteristics[J]. China Safety Science Journal, 2022, 32(10): 121−126.

[14] 吴青山,赵鹏程,刘志启,等. 镁铝水滑石的制备与应用研究[J]. 材料导报,2022,36(S1):149−156. WU Qingshan, ZHAO Pengcheng, LIU Zhiqi, et al. Preparation and application of magnesium-aluminum hydrotalcite[J]. Materials Reports, 2022, 36(S1): 149−156.

[15] 王丽丽,徐佳. 改性钴镁铝类水滑石对乙烯-醋酸乙烯共聚物阻燃和力学性能的影响[J]. 高分子材料科学与工程,2018,34(12):52−58. WANG Lili, XU Jia. Effect of modified CoMgAl-LDHs on flame retardance and mechanical properties of EVA[J]. Polymer Materials Science and Engineering, 2018, 34(12): 52−58.

[16] SHU P, ZHANG Y, DENG J, et al. Characteristics and mechanism of modified hydrotalcite for coal spontaneous combustion preventing[J]. Energy, 2023, 265: 126353. doi: 10.1016/j.energy.2022.126353

[17] 张馨新,李治刚,高超,等. 微生物表面活性剂强化煤层注水润湿特性研究[J]. 中国安全生产科学技术,2023,19(7):77−84. ZHANG Xinxin, LI Zhigang, GAO Chao, et al. Study on wetting characteristics of enhancing coal seam water infusion by microbial surfactant[J]. Journal of Safety Science and Technology, 2023, 19(7): 77−84.

[18] GAN J, WANG D, XIAO Z, et al. Synthesis and performance of a novel high-efficiency coal dust suppressant based on biopolysaccharide-xanthan gum[J]. Fuel, 2022, 329: 125442. doi: 10.1016/j.fuel.2022.125442

[19] YEKEEN N, IDRIS K A, A MANAN M, et al. Bulk and bubble-scale experimental studies of influence of nanoparticles on foam stability[J]. Chinese Journal of Chemical Engineering, 2017, 25(3): 347−357. doi: 10.1016/j.cjche.2016.08.012

[20] 高鹏永,石必明,张雷林,等. 不同含水率煤的燃烧特性实验[J]. 工矿自动化,2021,47(7):120−124. GAO Pengyong, SHI Biming, ZHANG Leilin, et al. Combustion characteristics experiments of coal with different moisture content[J]. Industry and Mine Automation, 2021, 47(7): 120−124.

[21] 吕志广,徐永亮,刘泽健,等. 不同气体环境长焰煤氧化进程基团演化特性[J]. 煤矿安全,2022,53(2):46−52. LYU Zhiguang, XU Yongliang, LIU Zejian, et al. Groups evolution of long-flame coal oxidation process under various air ambience[J]. Safety in Coal Mines, 2022, 53(2): 46−52.

下载:

下载: