Research on preparation and performance of a new type of inorganic paste fire preventing and extinguishing filling material in Shendong Mining Area

-

摘要:

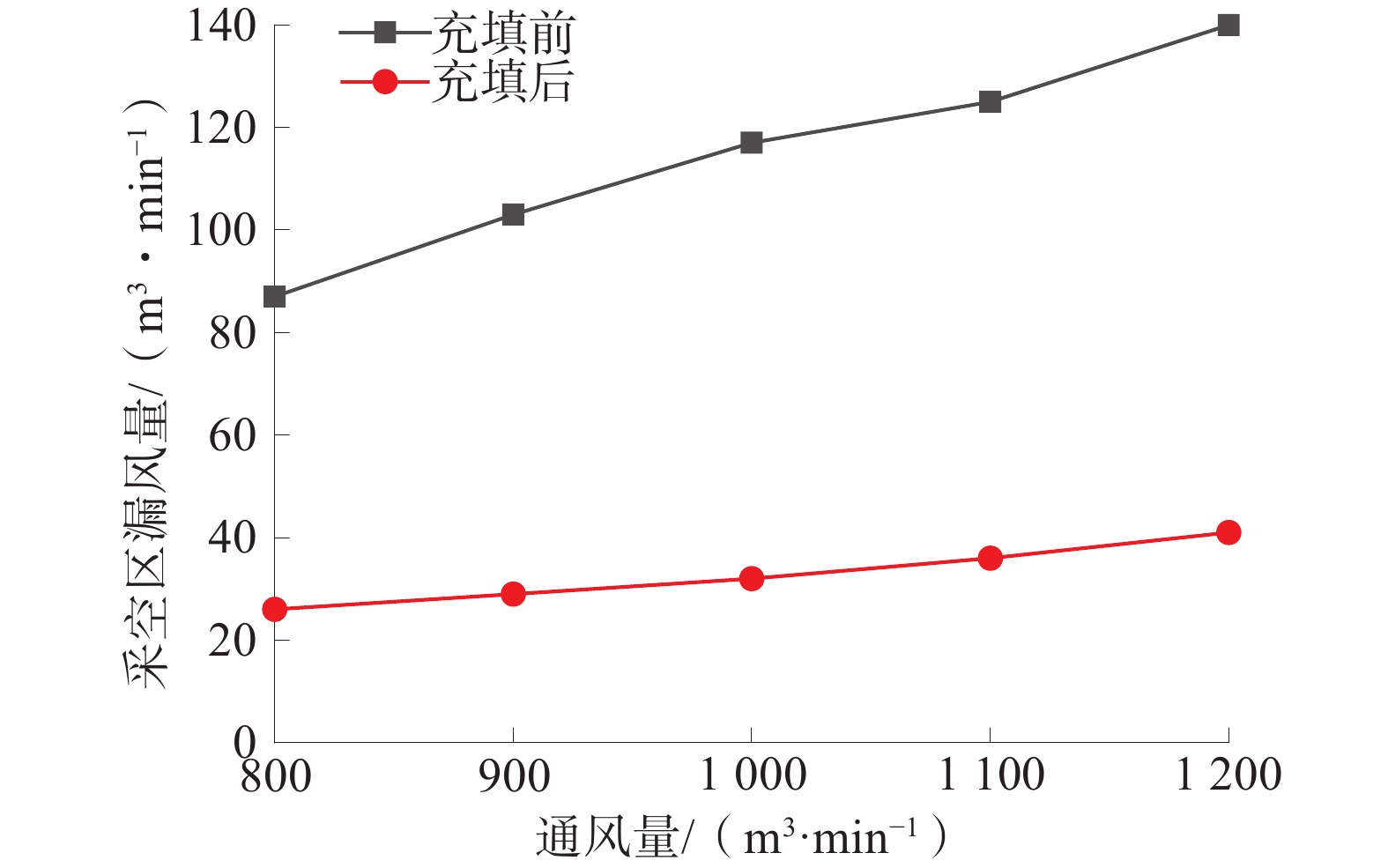

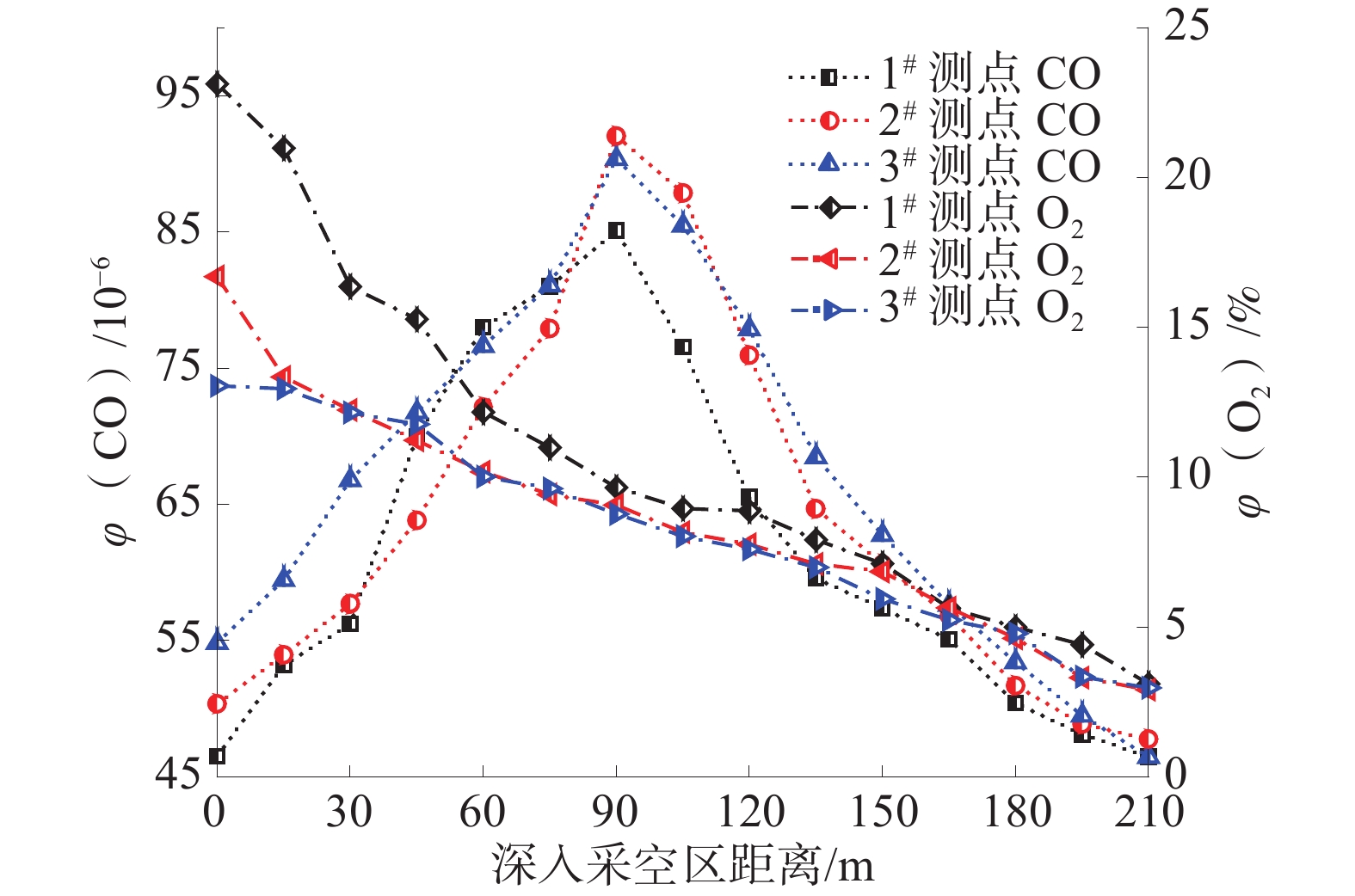

为解决神东矿区回采工作面两端巷道附近采空区遗煤多、易自燃、难封堵的难题,提出一种新型无机膏体防灭火充填材料,高效快速充填回采工作面上下隅角。采用神东矿区附近易获取的粉煤灰、炉渣和P·O·42.5硅酸盐水泥作为膏体主要原料,通过室内实验对材料的物理性质和化学成分进行研究,并通过膏体流动性、凝固特性、膨胀特性、充填体强度测试实验,确定出膏体最佳材料配比及外加剂参量。实验结果表明:炉渣基膏体具有良好自膨胀性,7 d自膨胀率可达5.6%,且初凝时间短,满足工程所需强度要求;膏体防灭火材料的最佳配比方案为水泥∶粉煤灰∶炉渣=1∶4∶20,质量分数为78%,J85型速凝剂的添加量为6%。工程应用表明:采用优选的膏体充填材料进行隅角充填封堵后,采空区漏风量整体下降至充填前的30%,CO体积分数从120×10−6降至46.5×10−6,O2体积分数在深入采空区走向长度约80 m处降至10%以下,采空区内“散热带+氧化带”的走向长度由未充填前的160 m缩短为80 m。

Abstract:In order to solve the problem of many coal remains, easy to spontaneous combustion and difficult to be sealed in the goaf near the two ends of roadway of the working face in Shendong Mining Area, this paper proposes a new type of inorganic paste fire preventing and extinguishing filling material, which can efficiently and quickly fill the upper and lower corners of the working face. Fly ash, slag and P·O·42.5 silicate cement, which are easily accessible in the vicinity of Shendong Mining Area, are used as the main raw materials of the paste, and the physical properties and chemical compositions of the materials are investigated through indoor tests, and the optimal ratio of the paste and the amount of additives are determined through the paste liquidity test, the paste solidification test, the paste expansion test and the paste filling strength test. The test results show that: the slag base paste has good self-expansion, the self-expansion rate can reach 5.6% in 7 days, and the initial setting time is short, which can meet the strength requirements of the project. The best proportioning scheme of the paste fireproofing material is cement : fly ash : slag = 1 : 4 : 20, and the mass fraction is 78%, and the addition amount of J85 accelerator is 6%. The engineering application shows that, after using the preferred paste filling material for corner filling and sealing, the air leakage in the mining airspace is reduced to 30% of that before filling, the CO volume fraction is reduced from 120×10−6 to 46.5×10−6, the O2 volume fraction is reduced to less than 10% at a point of about 80 m in depth of the strike length of the mining area, and the strike length of the dispersion zone + oxidation zone in the goaf is shortened from 160 m before filling to 80 m.

-

煤储层含气量是煤层气资源勘探测试的关键参数[1-4],也是表征煤储层开发潜力和确保矿井瓦斯安全的关键参数之一[4-11];煤储层含气量测试可为煤层气资源量、储量估算和煤层气开发设计提供重要依据[4]。煤储层含气量测值的不准确性是导致煤层气资源计算出现差异的重要原因[12]。现阶段,我国煤炭资源勘探和煤层气资源勘探开发煤层含气量测试方法主要采用GB/T19559—2021《煤层气含量测定方法》提供的解吸法及其矫正计算方法[13-17],其中损失气量计算采用最初10个地面实测解吸气量数据,由损失气时间与解吸时间和的平方根与累计解吸气量之间线性关系倒推零时间解吸气量得出。

应用上述方法,多年来我国在多个煤层气勘探开发区块获取了大量含气量数据。然而,目前煤层含气量计算仍有以下不足:吸附气欠饱和储层现场含气量测试的可靠性缺乏数值模拟验证,特别是损失气量估算的准确程度尚未有数值模型验证;另外,上述方法对含气饱和储层(吸附气、游离气均饱和,下同)含气量测试的准确性尚不清楚,饱和储层煤心含气量测试过程模拟尚未开展。基于此,选取新疆低煤化煤(本次为长焰煤)煤心为研究对象,构建了储层煤心含气量解吸-扩散数值模型,并通过模型计算分析了吸附气欠饱和与含气饱和储层煤心解吸动态,对比分析了数值模型与现场测试损失气量、解吸气量、残余气量构成的差异性,以期为我国低煤化储层煤层气勘探提供含气性分析新思路。

1. 测试方法

1.1 现场含气量相关测试

按照GB/T 19559—2021《煤层气含量测定方法》国家标准提供的方法,开展自然煤心采样,记录采样及装样时间,开展自然解吸气量连续测试和残余气测试;根据GB/T 19560—2008《煤的高压等温吸附试验方法》、GB/T 212—2008《煤的工业分析方法》等开展煤等温吸附实验和工业分析。现场煤心采样及上述相关工作开展于新疆某长焰煤储层煤层气开发先导试验区,煤心样品为长焰煤(属于低煤化度煤),且煤心对应的实测含气饱和度分别为54.77%、77.51%、99.79%。工业分析及煤岩组分分析成果见表1。

表 1 煤心工业分析及煤岩组分分析成果Table 1. Coal core industrial analysis and coal rock composition analysis results样品编号 直径/mm 长度/cm 宏观煤岩类型 平均镜质组最大反射率/% 水分/% 灰分/% 挥发分/% 镜质组组分/% 惰质组组分/% 壳质组组分/% BF-1 63.0 26.8 半亮煤 0.60 0.90 11.77 43.79 84.2 14.8 1.0 BF-2 60.1 30.0 半亮煤 0.61 0.86 22.08 40.45 79.6 19.4 1.0 BF-3 61.0 34.0 半亮煤 0.67 1.12 13.40 37.17 78.6 25.5 1.0 1.2 储层煤心含气量测试数值模拟流程

1.2.1 假设条件

煤是一种复杂的多孔介质,为了方便求解,通常对煤心样品做出以下假设:①煤屑由球形颗粒组成;②煤颗粒为均质、各向同性体;③CH4解吸-扩散遵从连续性原理;④扩散系数与浓度、时间和坐标无关;⑤煤屑瓦斯解吸为等温条件下的解吸过程;⑥煤心含气量测试过程中孔隙度不变。

1.2.2 控制方程

单位体积吸附气欠饱和储层煤心基质CH4质量可表述为(CH4全部吸附在煤基质表面,在储层压力条件下吸附解吸平衡,孔隙表面外不含游离CH4):

$$ {m}_{\mathrm{m}\mathrm{u}}={\varphi }_{\mathrm{u}\mathrm{n}}(1-{\phi }_{\mathrm{m}})\left(\dfrac{100-{M}_{\mathrm{a}\mathrm{d}}-{A}_{\mathrm{a}\mathrm{d}}}{100}\right)\dfrac{{V}_{\mathrm{L}}{p}_{\mathrm{m}}}{{p}_{\mathrm{m}}+{p}_{\mathrm{L}}}{\rho }_{\mathrm{c}\mathrm{o}\mathrm{a}\mathrm{l}}{\rho }_{\mathrm{s}\mathrm{c}} $$ 式中:mmu为单位体积煤基质中赋存的瓦斯质量,g;φun为欠饱和储层含气饱和度,%;ϕm为基质孔隙度;Mad为空气干燥基水分含量,%;Aad为空气干燥基灰分产率,%;VL为朗缪尔体积,单分子层最大的吸附量,cm3/g;pm为基质孔隙中的CH4压力,MPa;pL为朗缪尔压力,吸附量为最大吸附量1/2时间的吸附平衡压力,MPa;ρcoal为煤视密度,kg/m3;ρsc为标准状态下的CH4密度,g/cm3。

煤心解吸至大气环境控制方程:

$$\begin{array}{c} \dfrac{\partial p}{\partial t}\left({\varphi }_{{\mathrm{un}}}\left(1-{\phi }_{{\mathrm{m}}}\right)\left(\dfrac{100-{{M}}_{\mathrm{a}\mathrm{d}}-{{A}}_{\mathrm{a}\mathrm{d}}}{100}\right)\dfrac{{V}_{{\mathrm{L}}}{p}_{{\mathrm{L}}}}{{\left(p+{p}_{{\mathrm{L}}}\right)}^{2}}{\rho }_{{\mathrm{coal}}}\dfrac{{M}_{{\mathrm{c}}}}{{V}_{{\mathrm{M}}}}\right)=\\ \nabla \left(\dfrac{{M}_{{\mathrm{c}}}}{RT}D\nabla p\right) \end{array} $$ 式中:t为时间,s;p为煤心孔隙气体压力,MPa;Mc为甲烷分子摩尔质量,kg/mol;VM为CH4分子摩尔体积,m3/mol;R为理想气体常数,J/(mol·K);T为煤层温度,K;D为扩散系数,10−9 m2/s。

单位体积饱和储层煤心基质CH4质量可表述为(CH4在煤基质表面吸附饱和,且在储层压力条件下游离CH4充满孔隙):

$$ \begin{array}{c} {m}_{{\mathrm{mo}}}=(1-{\phi }_{{\mathrm{m}}})\left(\dfrac{100-{{M}}_{\mathrm{a}\mathrm{d}}-{{A}}_{\mathrm{a}\mathrm{d}}}{100}\right)\dfrac{{V}_{{\mathrm{L}}}{p}_{{\mathrm{m}}}}{{p}_{{\mathrm{m}}}+{p}_{{\mathrm{L}}}}{\rho }_{{\mathrm{coal}}}{\rho }_{{\mathrm{sc}}}+\\ {\phi }_{{\mathrm{m}}}\dfrac{{M}_{{\mathrm{c}}}}{RT}{p}_{{\mathrm{m}}} \end{array} $$ 式中:mmo为初始条件下单位体积饱和储层煤心基质CH4质量,g。

饱和储层煤心含气饱和度:

$$ {\varphi }_{{\mathrm{m}}}=\dfrac{{m}_{{\mathrm{mo}}}}{(1-{\phi }_{{\mathrm{m}}})\left(\dfrac{100-{{M}}_{\mathrm{a}\mathrm{d}}-{{A}}_{\mathrm{a}\mathrm{d}}}{100}\right)\dfrac{{V}_{{\mathrm{L}}}{p}_{0}}{{p}_{0}+{p}_{{\mathrm{L}}}}{\rho }_{{\mathrm{coal}}}{\rho }_{{\mathrm{sc}}}} $$ 煤心扩散、解吸控制方程:

$$ \begin{array}{c} \dfrac{\partial p}{\partial t}\left(\left(1 - {\phi }_{{\mathrm{m}}}\right)\left(\dfrac{100 - {{M}}_{\mathrm{a}\mathrm{d}} - {{A}}_{\mathrm{d}}}{100}\right)\dfrac{{V}_{{\mathrm{L}}}{p}_{{\mathrm{L}}}}{{\left(p + {p}_{{\mathrm{L}}}\right)}^{2}}{\rho }_{{\mathrm{coal}}}\dfrac{{M}_{{\mathrm{c}}}}{{V}_{{\mathrm{M}}}} + {\phi }_{{\mathrm{m}}}\dfrac{{M}_{{\mathrm{c}}}}{RT}\right) =\\ \nabla \left(\dfrac{{M}_{{\mathrm{c}}}}{RT}D\nabla p\right) \end{array} $$ 1.2.3 几何模型和边界条件

几何模型为实际圆柱体煤心物理模型,几何尺寸与现场测量一致;初始煤心各点孔隙压力为根据煤层气井试井储层压力推算得出,由于解吸时煤心已与大气接触,认为边界条件煤心柱面和断面表面压力为大气压力0.1 MPa。煤心几何模型如图1。

2. 结果与讨论

2.1 欠饱和储层煤心自然解吸测试与数值模拟

采用与煤心参数近似数据开展模拟并拟合解吸体积曲线,还原现场解吸参数和煤样特性参数。储层煤心参数实测值与拟合值对比见表2,煤心xy中心截面单位体积煤心含气性变化如图2。BF-1煤心累计解吸体积与解吸时间关系如图3。

表 2 储层煤心参数实测值与拟合值对比Table 2. Comparison between measured values and fitting values of coal core parameters of reservoir参数 实测值(BF1/BF2/BF3) 拟合值(BF1/BF2/BF3) 误差率/%

(BF1/BF2/BF3)储层压力/ MPa 9.88/9.25/8.96 9.88/9.25/8.96 0/0/0 兰氏压力/ MPa 1.92/2.05/1.65 1.92/2.05/1.65 0/0/0 兰氏体积/

(cm3·g−1)19.23/22.05/15.40 18.60/20.10/13.80 3.28/8.84/10.39 水分含量

(空干基)/%0.90/0.86/1.12 0.93/0.93/1.08 3.33/8.14/3.57 灰分产率

(干燥基)/%11.77/22.08/13.40 11.72/23.18/14.20 0.42/4.98/5.97 煤心密度/

(g· cm−3)1.36/1.44/1.44 1.36/1.44/1.44 0/0/0 孔隙度 0.10/0.09/0.08 0.10/0.08/0.072 0/11.1/10.0 扩散系数/

10−9(m2·s−1)4×10−9/—/— 3.70/1.00/0.80 7.50/—/— 含气

饱和度/%54.77/77.51/99.79 54.77/77.51/99.79 0/0/0 由图2可知:解吸开始24 h,含气量快速下降,各时刻煤心中心位置含气量最高而边缘最低。

由图3可知:BF-1扣除损失气时间拟合累计解吸气量(6 427.66 cm3)与现场煤心累计解吸气量(6 346.73 cm3)接近,相差2.00%;未扣损失气时间模拟累计解吸量(7 361.4 cm3)大于上述二者,显示损失气的存在;同理,BF-2和BF-3也有类似结果。

吸附气饱和储层煤心现场解吸与数值模拟含气量构成对比见表3,BF-1、BF-2、BF-3煤心损失气时间(T)与解吸时间(t)和的平方根和解吸初期累计解吸气量回归关系如图4。

表 3 吸附气饱和储层煤心现场解吸与数值模拟含气量构成对比Table 3. Comparison of adsorbed gas saturated reservoirs between on-site desorption and numerical simulation of cores样品 含气饱和度/% 含气量构成 实测体积/cm3 占比/实测/% 拟合体积/cm3 占比(拟合)/% 实测-拟合误差/% BF-1 54.77 损失气 979.43 13.28 880.26 11.95 10.12 解吸气 6 346.73 86.06 6427.66 87.32 2.00 残余气 48.43 0.66 46.24 0.63 4.52 总含气量 7 374.59 100.00 7361.40 100.00 0.18 BF-2 77.51 损失气 823.04 7.80 755.37 7.03 8.22 解吸气 9680.43 91.78 9937.60 92.52 2.66 残余气 43.88 0.42 47.89 0.45 9.14 总含气量 10290.96 100.00 10740.86 100.00 1.83 BF-3 99.79 损失气 793.71 6.36 841.77 6.75 6.06 解吸气 11638.39 93.26 11575.20 92.84 0.54 残余气 47.56 0.38 50.32 0.40 5.80 总含气量 12479.66 100.00 12467.29 100.00 0.10 对于BF-1煤心,现场测试BF-1煤心损失气量结果为979.43 cm3,与数值模拟结果前15 min解吸气量(880.26 cm3)(图4(a))接近。现场BF-1煤心解吸气量和残余气量与数值模型计算的解吸气量和残余气量也较接近。

BF-2和BF-3煤心现场测试煤心损失气量结果分别为823.04、793.71 cm3,略低于与数值模拟结果前15 min解吸气量(952.40、1015.80 cm3) (图4(b)、图4(c)),说明吸附气饱和度较高煤心解吸初期损失气量时间平方根法计算结果可能略偏小。这可能是吸附气饱和度较高,煤心内CH4浓度高,扩散作用更显著导致。用损失气时间与解吸时间和的平方根与解吸初期累计解吸气量的线性回归关系计算BF-2和BF-3煤心损失气量,发现基于数值模拟计算的损失气量结果(755.37、841.77 cm3)与基于现场实测的损失气量计算结果(832.04、793.71 cm3)较为接近。说明基于数值模拟数据利用时间平方根法计算的损失气量与实测时间平方根法估算的损失气量较为接近。

现场实测BF-1、BF-2和BF-3煤心解吸气量和残余气量与数值模型计算出的解吸气量和残余气量也较为接近,误差不超过10.12%(表3)。说明数值模型可以近似反映吸附气欠饱和储层煤心真实解吸过程和损失气量、解吸气量、残余气量特征。

2.2 饱和储层煤心含气量测试与数值模拟

以BF-1煤心为例,采用现场实测参数数据(表2),假设煤心处于饱和状态(即吸附气饱和、游离气在储层压力条件下充满孔隙也达到饱和状态),对现阶段现场含气量测试难度较大的含气饱和煤心解吸-扩散过程进行模拟。含气饱和煤心xy中心截面各位置单位体积煤心含气性变化如图5。

由图5可知:解吸前24 h煤心含气量快速下降,各时刻煤心中心位置含气量最高而煤心边缘含气量最低。

损失气时间与解吸时间和的平方根和累计解吸气量的线性回归关系如图6。饱和储层煤心解吸-扩散数值模拟含气量构成预测见表4。

表 4 饱和储层煤心解吸-扩散数值模拟含气量构成预测Table 4. Prediction of gas content composition of coal core desorption-diffusion numerical simulation in saturated core含气量构成 预测体积/cm3 占比/% 损失气 3 792.50 18.64 解吸气 16 460.70 80.90 残余气 93.51 0.46 总含气量 20 346.71 100.00 数值模拟显示,损失气时间内(15 min)假设的饱和煤心解吸-扩散气量达到4 441.3 cm3,相同损失气时间的情况下,约为相应吸附气欠饱和储层煤心此时间段解吸气量(即本例损失气量)的4倍。

损失气时间与解吸时间和的平方根与解吸初期累计解吸气量的线性回归关系截距为正数(R2=0.9988),暗示采用解吸时间平方根与解吸初期累计解吸气量线性回归方法并不适用于饱和煤心损失气量的估算;采用解吸时间平方根与解吸初期累计解吸气量多项式回归方法,计算得煤心损失气量仅为433.11 cm3(R2=0.9988),甚至小于吸附气欠饱和储层煤心损失气量估算值,说明基于时间平方根与累计解吸气量的相关性分析方法可能无法准确估算损失气量。同时测试初期时间平方根与累计解吸气量的回归关系(图6蓝色标记)和损失气时间与累计气量的回归关系(图6红色标记,实测测不出部分)也存在较大差异,说明饱和煤心损失气时间解吸-扩散规律较为复杂,常规回归分析法可能难以实现对损失气量的准确估算。

由表4可知:饱和煤心损失气、解吸气、残余气占比分别为18.64%、80.90%、0.46%,其损失气占比高于吸附气欠饱和煤心损失气占比、解吸气占比低于吸附气欠饱和煤心解吸气占比。

数值模型可以近似反映吸附气欠饱和储层煤心真实解吸过程和损失气量、解吸气量、残余气量特征。目前,含气量现场测试手段很难达到对饱和煤心含气量的准确测试和估算,希望通过数值模拟为含气饱和煤心含气量分析提供思路。

3. 结 语

1)构建的吸附气欠饱和煤心解吸数值模型计算的损失气量、解吸气量和残余气量与现场测试相应结果接近(误差<10.12%),可近似反映吸附气欠饱和储层煤心含气量构成。

2)对于构建的含气饱和储层煤心数值模型,损失气时间与解吸时间和的平方根与解吸初期累计解吸气量的回归分析法预测损失气量误差较大。饱和煤心损失气时间解吸-扩散规律较为复杂,常规回归分析可能难以实现对损失气的准确估算。

3)相同损失气时间条件下,本例饱和煤心损失气总含气量占比(18.64%)高于吸附气欠饱和煤心损失气占比(11.95%),饱和煤心解吸气占比(80.90%)低于吸附气欠饱和煤心解吸气占比(87.32%),饱和煤心残余气占比(0.46%)低于吸附气欠饱和煤心残余气占比(0.63%)。

-

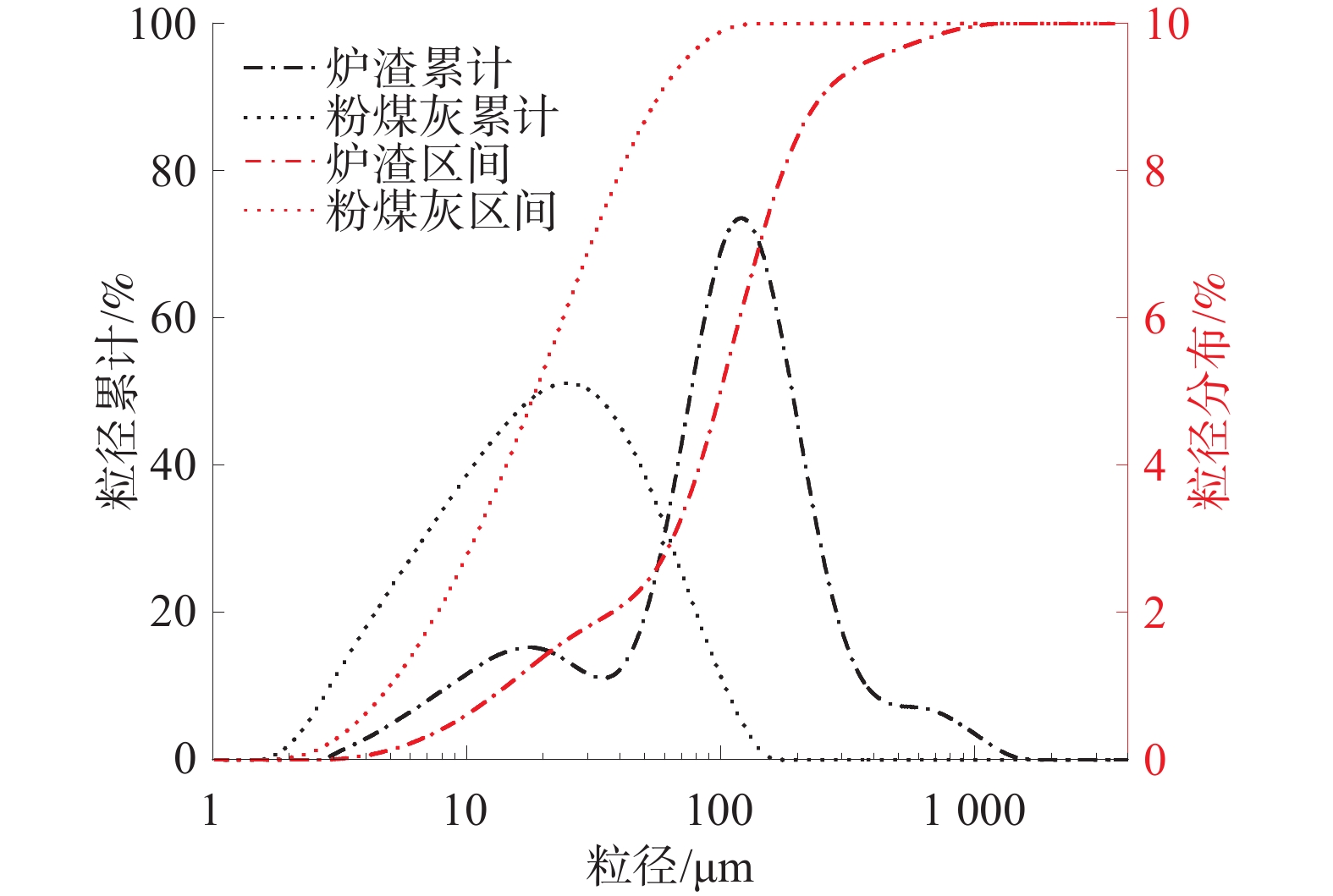

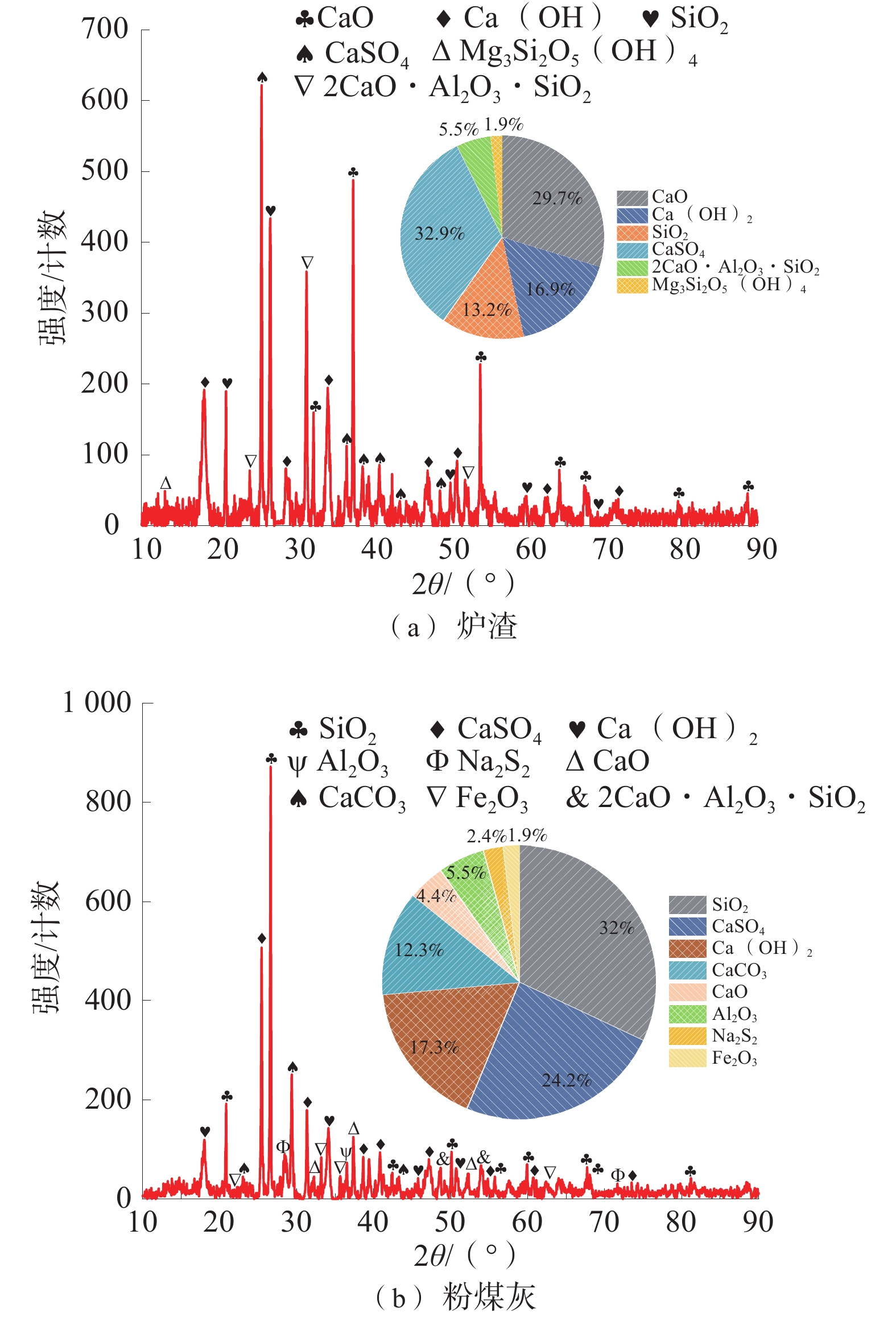

表 1 充填材料物理参数

Table 1 Physical parameters of filling materials

充填材料 含水率/% 相对质量密度 松散干密度/(g·cm−3) 孔隙率/% 炉渣 0 2.28 0.85 62.72 粉煤灰 0.50 1.95 0.80 58.97 表 2 充填材料化学成分测定结果

Table 2 Chemical composition determination results of filling materials

充填

材料化学元素含量/% O Si Al Mg Ca Fe S Pb Mn K P 炉渣 44.03 4.61 2.25 0.53 31.69 2.52 3.911 - 0.091 0.230 0.006 粉煤灰 52.78 11.24 5.19 0.58 23.26 2.82 6.393 0.003 0.066 0.559 0.020 表 3 膏体流动性实验方案

Table 3 Experiment plan for paste fluidity

编号 水泥∶粉煤灰∶

炉渣质量

分数/%编号 水泥∶粉煤灰∶

炉渣质量

分数/%A1 1∶2∶6 77.5 A9 1∶4∶15 78.0 A2 1∶2∶6 78.0 A10 1∶4∶15 78.5 A3 1∶2∶6 78.5 A11 1∶4∶15 79.0 A4 1∶2∶6 79.0 A12 1∶4∶15 79.5 A5 1∶2∶10 78.5 A13 1∶4∶20 77.5 A6 1∶2∶10 79.0 A14 1∶4∶20 78.0 A7 1∶2∶10 79.5 A15 1∶4∶20 78.5 A8 1∶2∶10 80.0 A16 1∶4∶20 79.0 表 4 膏体速凝剂选型实验方案

Table 4 Selection test plan for paste accelerating agent

编号 水泥∶粉煤灰∶

炉渣质量

分数/%速凝剂

类型速凝剂

添加量/%速凝剂成本/

(元·m−3)S1 1∶2∶6 78 不添加 0 0 S2 1∶2∶6 78 混凝土早强剂 0.5 21.56 S3 1∶2∶6 78 液体速凝剂 10.0 288.02 S4 1∶2∶6 78 混凝土速凝剂 5.0 155.22 S5 1∶2∶6 78 J85型速凝剂 6.0 24.84 注:速凝剂添加量为水泥添加量的百分比。 表 5 膏体速凝剂定量实验方案

Table 5 Quantitative test plan for paste accelerator

编号 水泥∶粉煤灰∶

炉渣质量

分数/%速凝剂

类型速凝剂

添加量/%速凝剂成本/

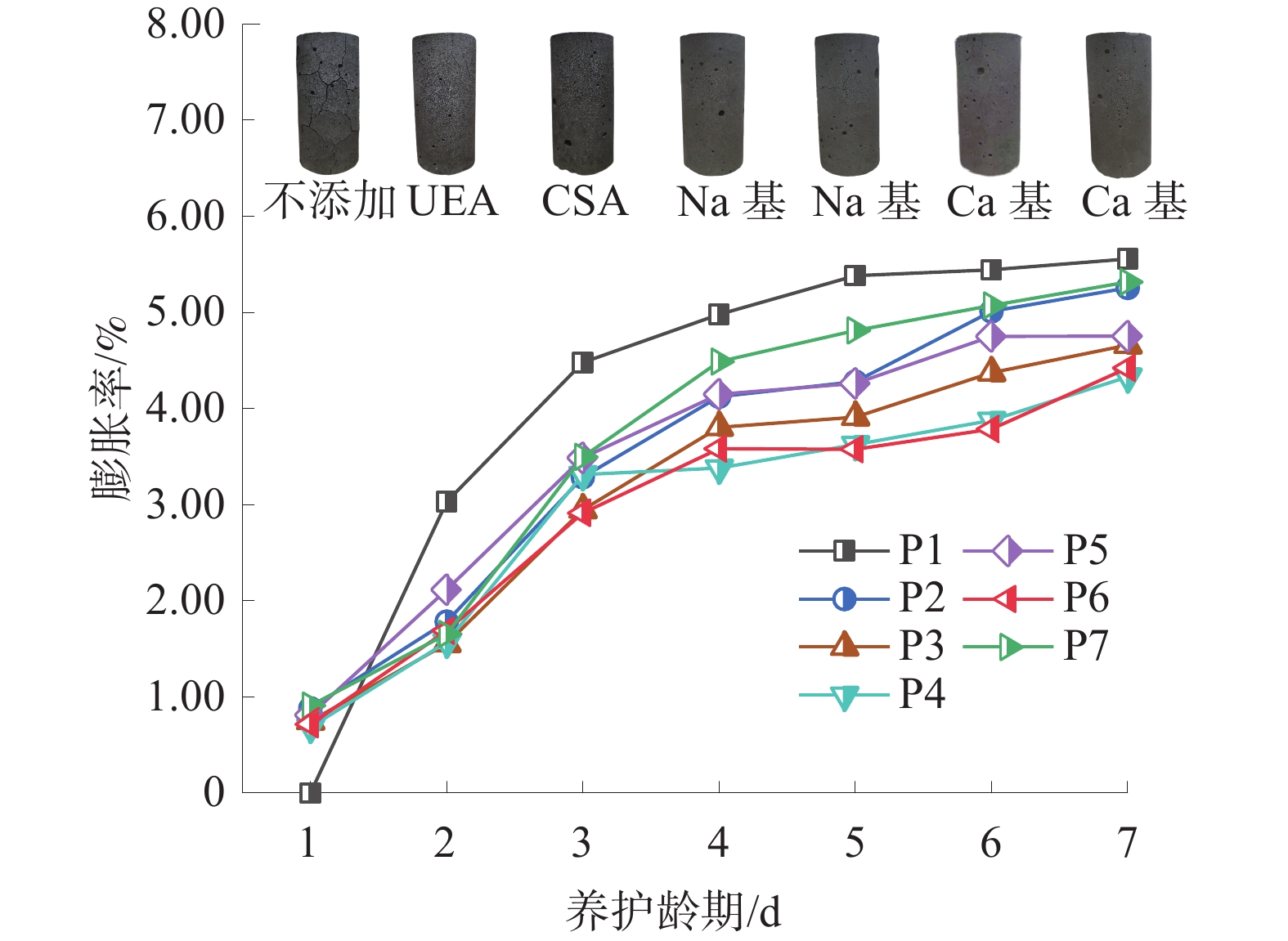

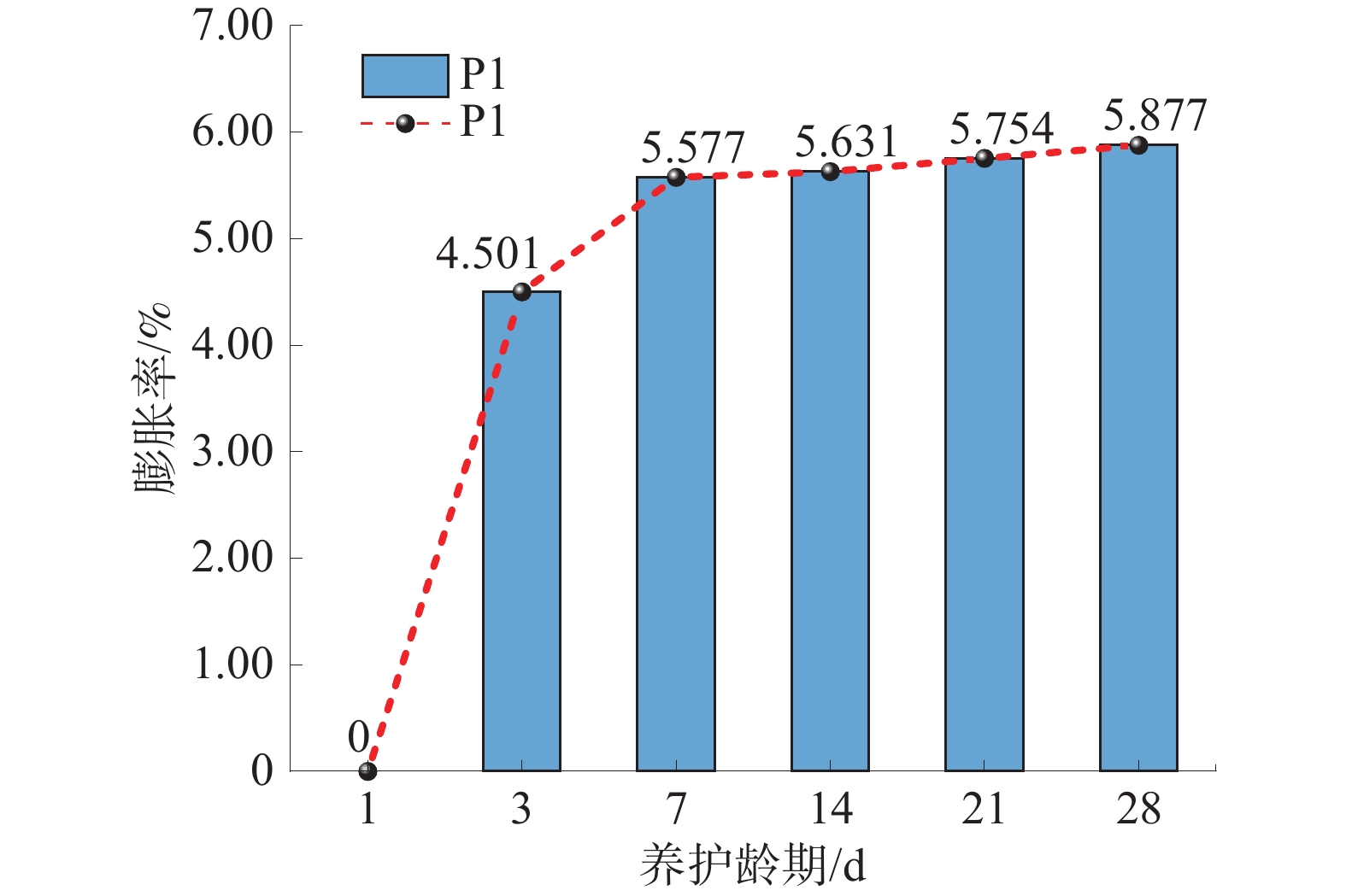

(元·m−3)B1 1∶2∶6 78 J85型速凝剂 3 12.42 B2 1∶2∶6 78 J85型速凝剂 6 24.84 B3 1∶2∶6 78 J85型速凝剂 9 37.25 B4 1∶2∶6 78 J85型速凝剂 12 49.67 B5 1∶2∶10 79 J85型速凝剂 3 8.99 B6 1∶2∶10 79 J85型速凝剂 6 17.97 B7 1∶2∶10 79 J85型速凝剂 9 26.96 B8 1∶2∶10 79 J85型速凝剂 12 35.94 B9 1∶4∶15 78 J85型速凝剂 3 5.70 B10 1∶4∶15 78 J85型速凝剂 6 11.40 B11 1∶4∶15 78 J85型速凝剂 9 17.10 B12 1∶4∶15 78 J85型速凝剂 12 22.80 B13 1∶4∶20 78 J85型速凝剂 3 4.58 B14 1∶4∶20 78 J85型速凝剂 6 9.17 B15 1∶4∶20 78 J85型速凝剂 9 13.75 B16 1∶4∶20 78 J85型速凝剂 12 18.33 注:速凝剂添加量为水泥添加量的百分比。 表 6 炉渣基膏体膨胀剂选型实验方案

Table 6 Selection test plan for paste expansion agent

编号 水泥∶

粉煤灰∶

炉渣质量

分数/

%速凝剂

类型速凝剂

添加量/%膨胀剂

类型膨胀剂

添加量/%膨胀剂

添加成本/

(元·m−3)P1 1∶4∶20 78 J85型

速凝剂6 不添加 0 0 P2 1∶4∶20 78 J85型

速凝剂6 UEA型

膨胀剂0.5 5.73 P3 1∶4∶20 78 J85型

速凝剂6 CSA型

膨胀剂10.0 63.65 P4 1∶4∶20 78 J85型

速凝剂6 钠基

膨润土10.0 330.97 P5 1∶4∶20 78 J85型

速凝剂6 钠基

膨润土15.0 496.45 P6 1∶4∶20 78 J85型

速凝剂6 钙基

膨润土10.0 318.24 P7 1∶4∶20 78 J85型

速凝剂6 钙基

膨润土15.0 477.36 注:外加剂添加量均为水泥添加量的百分比。 表 7 炉渣基膏体充填配比实验结果

Table 7 Experiment results of filling ratio of paste

配比 龄期/

d抗压强度/

MPa抗拉强度/

MPa弹性模量/

MPa水泥∶粉煤灰∶炉渣=

1∶4∶203 0.65 0.031 51.14 7 1.42 0.072 185.16 14 1.99 0.172 332.83 28 4.06 0.401 388.33 表 8 神东矿区回采工作面隅角充填推荐配比

Table 8 Recommended ratio of corner filling in the mining face of Shendong Mining Area

配比 质量

分数/

%速凝剂

类型及

添加量膨胀剂

类型及

添加量密度/

(t·m−3)3 d

强度/

MPa7 d

强度/

MPa14 d

强度/

MPa28 d

强度/

MPa水泥∶粉煤灰∶炉渣

(1∶4∶20)78 J85(6%) - 2.026 0.65 1.42 1.99 4.06 注:外加剂添加量均为水泥添加量的百分比。 -

[1] 梁运涛,侯贤军,罗海珠,等. 我国煤矿火灾防治现状及发展对策[J]. 煤炭科学技术,2016,44(6):1−6. LIANG Yuntao, HOU Xianjun, LUO Haizhu, et al. Development countermeasures and current situation of coal mine fire prevention & extinguishing in China[J]. Coal Science and Technology, 2016, 44(6): 1−6.

[2] XIA T, ZHOU F, GAO F, et al. Simulation of coal self-heating processes in underground methane-rich coal seams[J]. International Journal of Coal Geology, 2015, 141: 1−12.

[3] KONG B, LI Z H, YANG Y L, et al. A review on the mechanism, risk evaluation, and prevention of coal spontaneous combustion in China[J]. Environmental Science and Pollution Research International, 2017, 24(30): 23453−23470. doi: 10.1007/s11356-017-0209-6

[4] 郭志国. 惰性气体抑制煤自燃氧化升温机理的实验研究[D]. 北京:中国矿业大学(北京),2017. [5] 梁运涛,罗海珠. 中国煤矿火灾防治技术现状与趋势[J]. 煤炭学报,2008,33(2):126−130. LIANG Yuntao, LUO Haizhu. Current situation and development trend for coal mine fire prevention & extinguishing techniques in China[J]. Journal of China Coal Society, 2008, 33(2): 126−130.

[6] 蒋仲安,杜翠凤,何理,等. 石灰凝胶阻化剂防灭火技术在高硫矿的应用研究[J]. 中国安全科学学报,2003,13(10):31−33. JIANG Zhongan, DU Cuifeng, HE Li, et al. Study on application of fireproofing and fire-extinguishing technology using fire-retardant lime-gel in coal mine of high sulfur content[J]. China Safety Science Journal, 2003, 13(10): 31−33.

[7] 任万兴,郭庆,左兵召,等. 近距离易自燃煤层群工作面回撤期均压防灭火技术[J]. 煤炭科学技术,2016,44(10):48−52. REN Wanxing, GUO Qing, ZUO Bingzhao, et al. Pressure balanced fire prevention and control technology during equipment withdrawing period of coal mining face in easy spontaneous combustion contiguous seams group[J]. Coal Science and Technology, 2016, 44(10): 48−52.

[8] 秦波涛,王德明. 防治煤炭自燃的三相泡沫新技术及应用[C]// 第3届全国煤炭工业生产一线青年技术创新文集. 北京:煤炭工业出版社,2008:291-298. [9] 焦淑华. 注氮防灭火系统在宽沟煤矿的应用[J]. 河北煤炭,2009(5):20−21. JIAO Shuhua. Application of the fire extinguishing system of injected nitrogen in Kuan Gou mine[J]. Hebei Coal, 2009(5): 20−21.

[10] LU Wei, ZHANG X D, YUAN Y, et al. Study on the characteristics and mechanism of a new type of antioxidant gel foam for coal spontaneous combustion prevention[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2021, 628:DOI: 10.1016/j.colsurfa.2021.127254.

[11] WANG L, LIU Z Y, YANG H Y, et al. A novel biomass thermoresponsive konjac glucomannan composite gel developed to control the coal spontaneous combustion: Fire prevention and extinguishing properties[J]. Fuel, 2021, 306: 121757. doi: 10.1016/j.fuel.2021.121757

[12] 郭旭东,范智海,司俊鸿,等. 综放采空区矸石堵漏充填防灭火技术[J]. 陕西煤炭,2016,35(2):82−86. GUO Xudong, FAN Zhihai, SI Junhong, et al. Technology of fire prevention with gangue backfilling in the fully-mechanized caving goaf[J]. Shaanxi Coal, 2016, 35(2): 82−86

[13] 陈庆丰. 近距离缓倾斜煤层群开采工作面自燃防治技术[J]. 煤矿安全,2021,52(2):78−82. CHEN Qingfeng. Prevention and control technology of spontaneous combustion in mining face of closely inclined coal seam group[J]. Safety in Coal Mines, 2021, 52(2): 78−82.

[14] 秦波涛,王德明. 矿井防灭火技术现状及研究进展[J]. 中国安全科学学报,2007,17(12):80−85. doi: 10.3969/j.issn.1003-3033.2007.12.014 QIN Botao, WANG Deming. Present situation and development of mine fire control technology[J]. China Safety Science Journal, 2007, 17(12): 80−85. doi: 10.3969/j.issn.1003-3033.2007.12.014

[15] 赵先科. 煤泥灌浆防灭火技术研究[D]. 西安:西安科技大学,2016. [16] 阮国强. 鲍店煤矿粉煤灰胶体防灭火技术研究[D]. 西安:西安科技大学,2006. [17] ANGLE C, BERKOWITZ N. Distribution of oxygen forms in Alberta low rank coals[J]. Fuel, 1991, 70(7): 891−896. doi: 10.1016/0016-2361(91)90201-K

[18] JONES J C. Steady behaviour of long duration in the spontaneous heating of a bituminous coal[J]. Journal of fire sciences, 1996, 14(2): 159−166. doi: 10.1177/073490419601400208

[19] 张义顺,何小芳,朱伶俐,等. 水泥-粉煤灰注浆材料的研发与应用[J]. 河南理工大学学报(自然科学版),2010,29(5):674−679. ZHANG Yishun, HE Xiaofang, ZHU Lingli, et al. Study and application of cement-fly ash grouting material[J]. Journal of Henan Polytechnic University(Natural Science), 2010, 29(5): 674−679.

[20] 轩召军,常庆粮. 膏体充填开采底板破坏机理及分区治理技术[J]. 煤矿安全,2022,53(8):210−217. XUAN Zhaojun, CHANG Qingliang. Study on floor failure mechanism of paste backfill mining and division area control technology[J]. Safety in Coal Mines, 2022, 53(8): 210−217.

[21] 王超,简勇,张延旭,等. 煤矿膏体充填材料电阻率的测定试验研究[J]. 煤矿安全,2021,52(4):66−71. WANG Chao, JIAN Yong, ZHANG Yanxu, et al. Experimental study on determination of resistivity of coal mine paste filling material[J]. Safety in Coal Mines, 2021, 52(4): 66−71.

[22] PRABHU R S, ANURADHA R, JUDEA B. Understanding the mining waste as resources in self-compacting concrete: A numerical study on sustainable construction[J]. Resources Policy, 2022, 78: 102806. doi: 10.1016/j.resourpol.2022.102806

[23] TAN H B, DU Chao, HE X Y, et al. Enhancement of compressive strength of high-volume fly ash cement paste by wet grinded cement: Towards low carbon cementitious materials[J]. Construction and Building Materials., 2022, 323: 126458. doi: 10.1016/j.conbuildmat.2022.126458

[24] SUN Y, LI L H, LIAO J, et al. Dry shrinkage performance of cement-stabilized reclaimed lime-fly ash macadam[J]. Construction and Building Materials., 2022, 331: 127332. doi: 10.1016/j.conbuildmat.2022.127332

[25] BEHERA S K, GHOSH C N, MISHRA D P, et al. Strength development and microstructural investigation of lead-zinc mill tailings based paste backfill with fly ash as alternative binder[J]. Cement and Concrete Composites, 2020, 109: 103553. doi: 10.1016/j.cemconcomp.2020.103553

[26] MOHANA R, LEELA BHARATHI S M. Sustainable utilization of pre-treated and nano fly ash powder for the development of durable geopolymer mortars[J]. Advanced Powder Technology, 2022, 33: 103696. doi: 10.1016/j.apt.2022.103696

[27] 张勇,王启庆,张育宝,等. 粉煤灰煤矸石混合浆液性能试验研究[J]. 煤矿安全,2023,54(3):140−146. ZHANG Yong, WANG Qiqing, ZHANG Yubao, et al. Experimental study on performance of fly ash and coal gangue mixed slurry[J]. Safety in Coal Mines, 2023, 54(3): 140−146.

[28] JIANG Y, LI B, HE J, et al. Properties and microstructure of packing-optimised recycled aggregate concrete with different cement paste or sand contents[J]. Construction and Building Materials., 2022, 344: 128178. doi: 10.1016/j.conbuildmat.2022.128178

[29] ZHAO H T, XIANG Y, LIU J P, et al. Effects of reinforcement on autogenous deformation of early-age concrete containing CaO-based expansion agent[J]. Construction and Building Materials, 2022, 320: 126197. doi: 10.1016/j.conbuildmat.2021.126197

[30] GUO J J, ZHANG S W, QI C G, et al. Effect of calcium sulfoaluminate and MgO expansive agent on the mechanical strength and crack resistance of concrete[J]. Construction and Building Materials, 2021, 299: 123833. doi: 10.1016/j.conbuildmat.2021.123833

下载:

下载: