Dynamic stress characteristics of isolated coal by fault cutting and collaborative pressure relief technology

-

摘要:

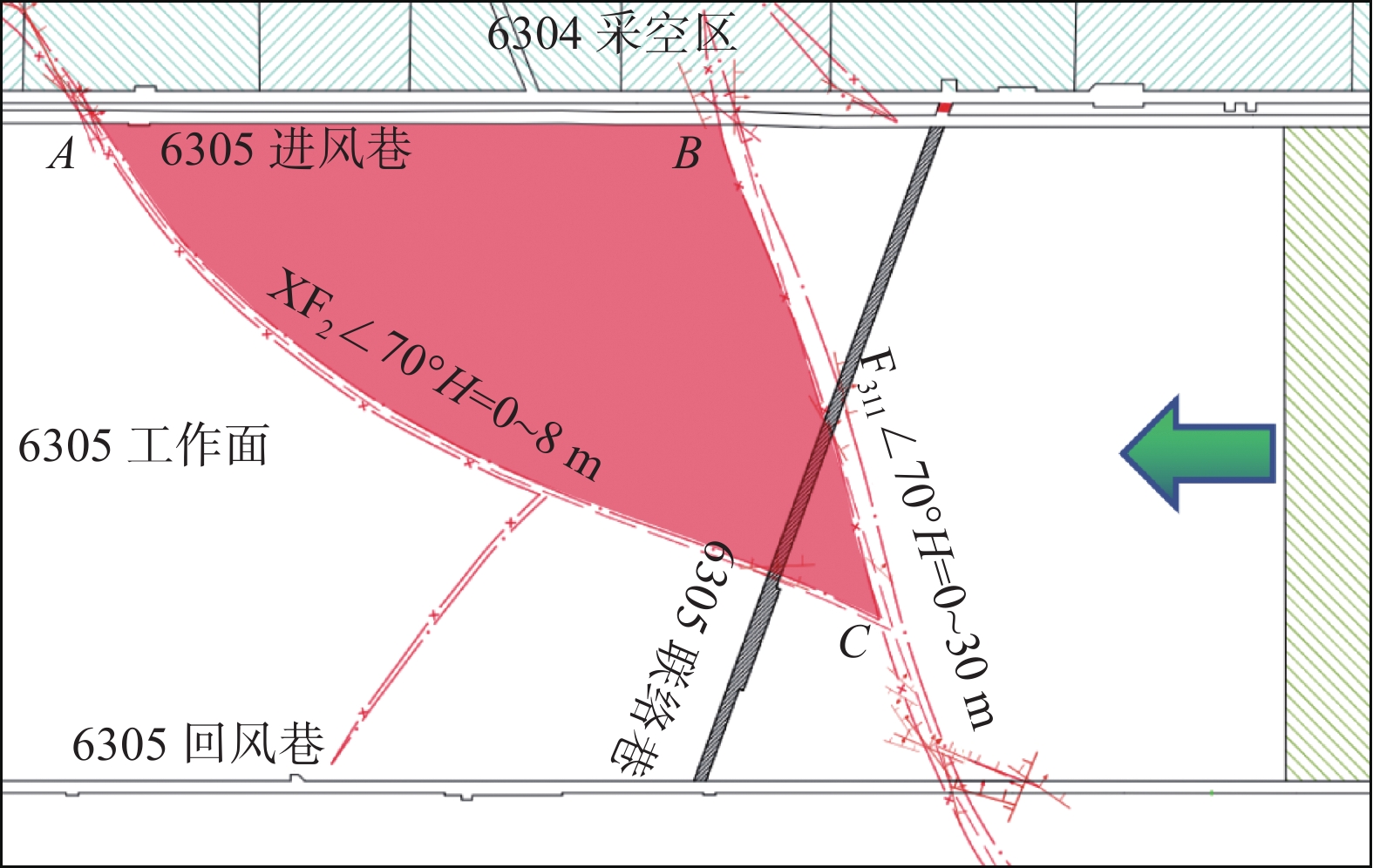

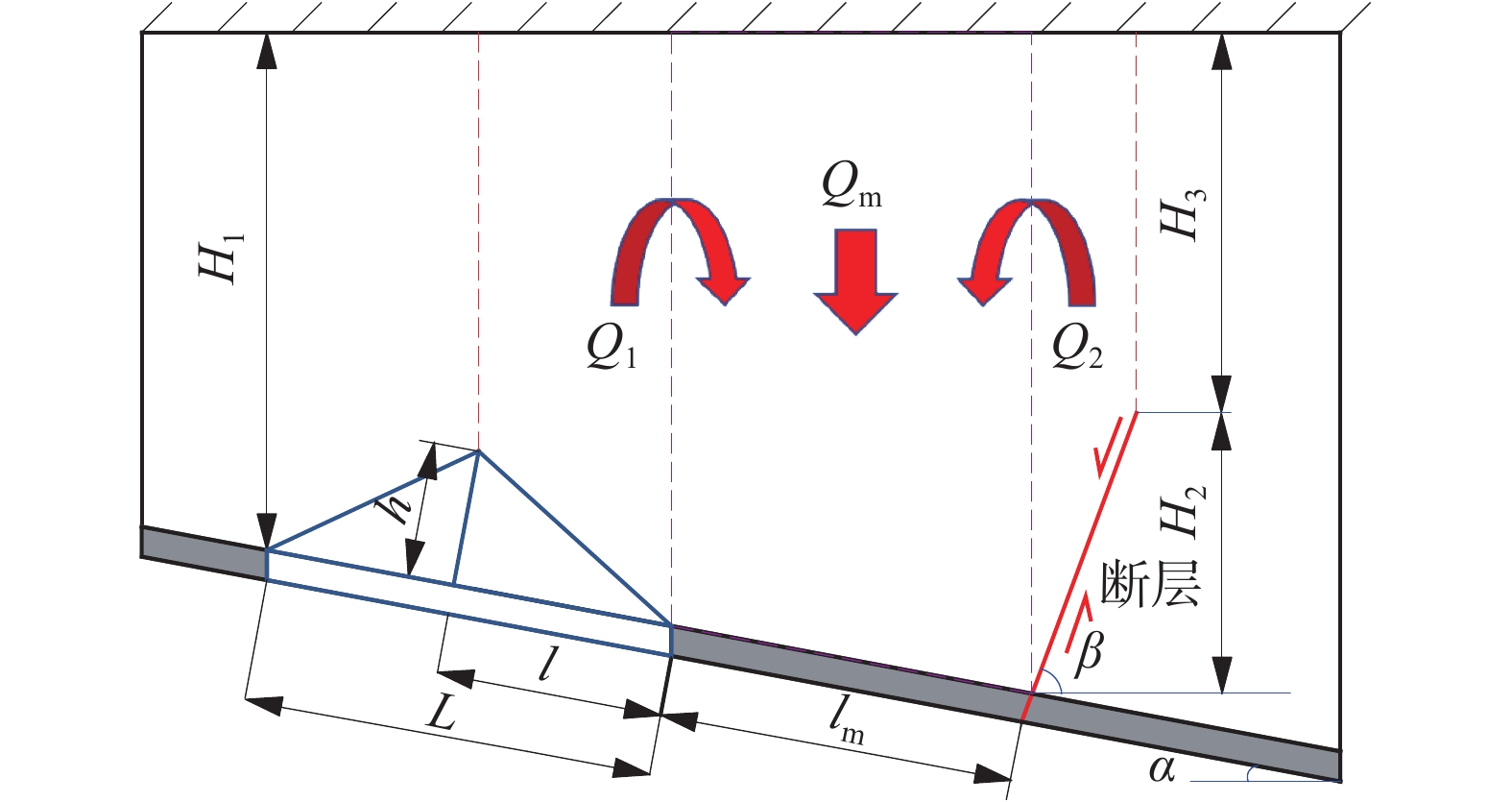

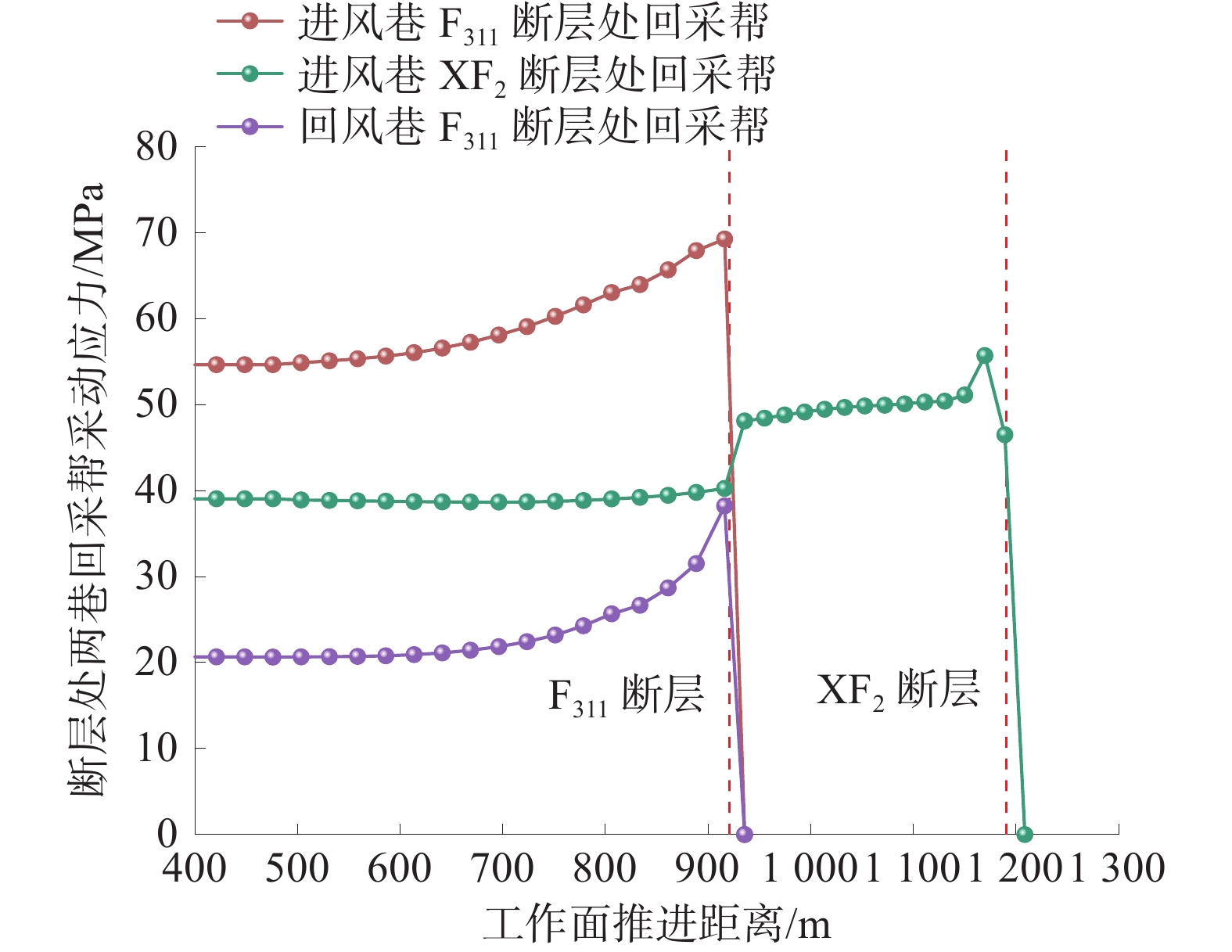

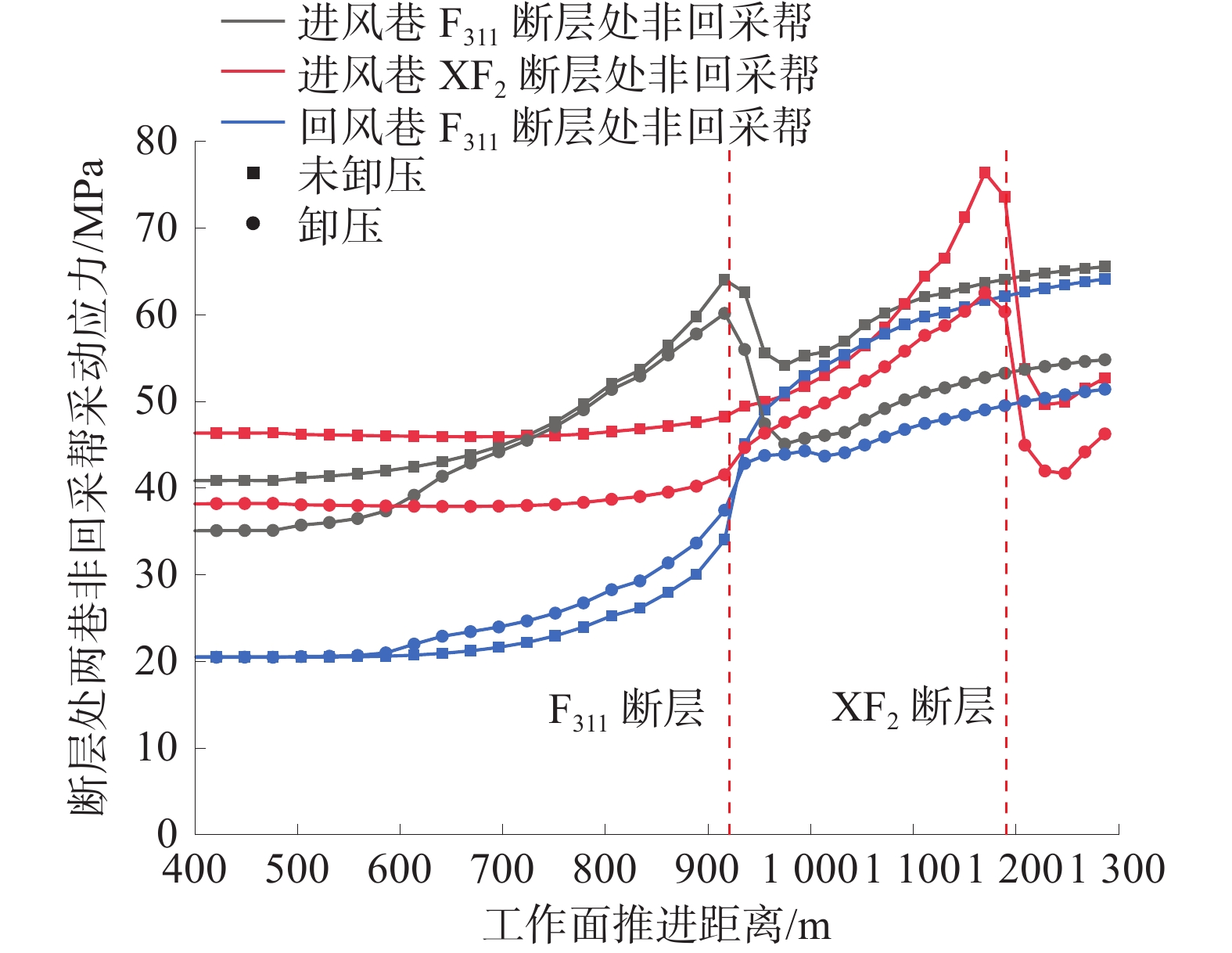

为了研究由断层切割形成的孤立煤体应力特征,防止孤立煤体应力集中区域在工作面回采期间发生冲击危险;以新巨龙煤矿6305工作面为例,建立了孤立煤体受力估算模型,得到冲击危险性指数Ic;提出了针对孤立煤体区域两侧巷道实施的“大直径钻孔卸压+爆破切顶卸压”协同卸压技术,并通过FLAC3D模拟协同卸压前后孤立煤体应力动态特征。结果表明:冲击危险性指数Ic=2.6>1.5,即孤立煤体平均支承压力超过临界冲击阈值易发生冲击;卸压前过F311断层后XF2断层处回采帮采动应力突增7.85 MPa,冲击危险程度升高;卸压后孤立煤体突出部位回采帮应力平均降低25.3%,非回采帮应力平均降低12.5%,卸压区域无大能量微震事件发生,钻屑量正常,卸压效果良好。

Abstract:In order to study the stress characteristics of isolated coal body formed by fault cutting, the stress concentration area of isolated coal body can be prevented from impact risk during the mining of the working face. Taking the 6305 working face of Xinjulong Coal Mine as an example, the force estimation model of isolated coal body is established, and the impact risk index Ic is obtained. The collaborative pressure relief technology of “large-diameter drilling pressure relief + blasting cutting roof and pressure relief” is proposed for both sides of the isolated coal body area, and the dynamic stress characteristics of isolated coal body before and after collaborative pressure relief are simulated by FLAC3D. The results show that the impact risk index Ic=2.6>1.5, that is, the average abutment pressure of isolated coal is more than the critical impact threshold. After passing the F311 fault before pressure relief, the mining stress at the XF2 fault side suddenly increases 7.85 MPa, and the impact risk degree increases. After pressure relief, the stress on the mining side of isolated coal body outburst area is reduced by 25.3% on average, and the stress on the non-mining side is reduced by 12.5% on average. There is no large energy microseismic event in the pressure relief area, and the amount of drilling cuttings is normal.

-

Keywords:

- fault cutting /

- isolated coal /

- mining stress /

- microseisms /

- coordinated pressure relief

-

煤炭资源是我国主体能源,而超过20%煤炭资源储存于位于西部急倾斜煤层[1-2],其地质、应力和开采条件等与缓倾斜/倾斜煤层差异巨大,向深部开采过程中冲击地压等煤岩动力灾害的防治形势日趋严峻。冲击地压致灾因素辨识是采取针对性防治措施的前提,能大大提高防冲措施的施加效能并降低成本。曹民远等[2-3]基于数据统计的方法分析发现上覆遗留煤柱是近直立煤层冲击地压显现的主要致灾因素,采掘扰动等是冲击地压显现的影响因素;杜涛涛等[4]利用微震监测系统对近直立煤层的“高阶段”区域和围岩进行探测,发现煤体高应力集中和诱冲关键层是冲击地压的主要致灾因素;李兵[5]通过开展不同区域冲击倾向性鉴定、不同尺度冲击危险性评价以及利用微震系统,从微震能量分布与历史矿压显现规律,分析得到了矿井冲击隐蔽致灾因素;李振武等[6]采用理论分析和数值模拟方法,研究了工作面推进过程中覆岩运动及矿压显现规律,辨识工作面冲击地压的诱发因素;荣海等[7]利用地质动力区划方法发现急倾斜特厚煤层的冲击地压事件主要发生于断裂带以及应力梯度区和高应力区的煤岩体中;张冬阳[8]采用层次分析法确定了大屯矿区冲击致灾因素并定量化确定了断层构造等因素的影响权重;陈凡等[9]分析了煤层厚度、倾角、开采深度及采掘干扰等与矿震事件分布的相关性,利用层次分析法(AHP)确定冲击主控因素及对应权重;乔中栋等[10]根据某工作面回采期间全部冲击事件,辨识对冲击事件影响较大的4个致灾因素,并利用层次分析法,计算不同条件下各因素的影响权重,总结其演化规律,为矿井冲击地压防治提供可靠的统计分析结果。此外,还有大量学者[11-15]从地质条件、开采技术和环境因素等方面对井下冲击地压的主控因素进行了辨识。

然而,冲击地压本身是多因素共同作用的结果,不同致灾因素之间存在复杂的非线性关系,目前已有的致灾因素辨识多基于专家经验分析和复杂力学计算,难以及时适应井下多变的地质环境,导致冲击地压的防治缺乏针对性[16]。微震监测系统具有数据连续性、自动监测等优点,主要通过采集顶板破碎或煤岩体断裂产生的震动波信号以判断顶板的运移和煤岩体的破裂从而实现矿井大范围内震动场、应力场等监测[17-18]。利用现场微震监测数据可以辅助相关人员进行动态、实时的主控因素辨识。为此,以乌东煤矿作为工程背景,从时间和空间角度研究其历次冲击地压事件前后微震监测数据的分布信息,辨识冲击地压的主要致灾因素,并分析其随采深增加的演化规律,为冲击地压的高效、精准防治提供理论依据。

1. 工程概况

1.1 工作面背景

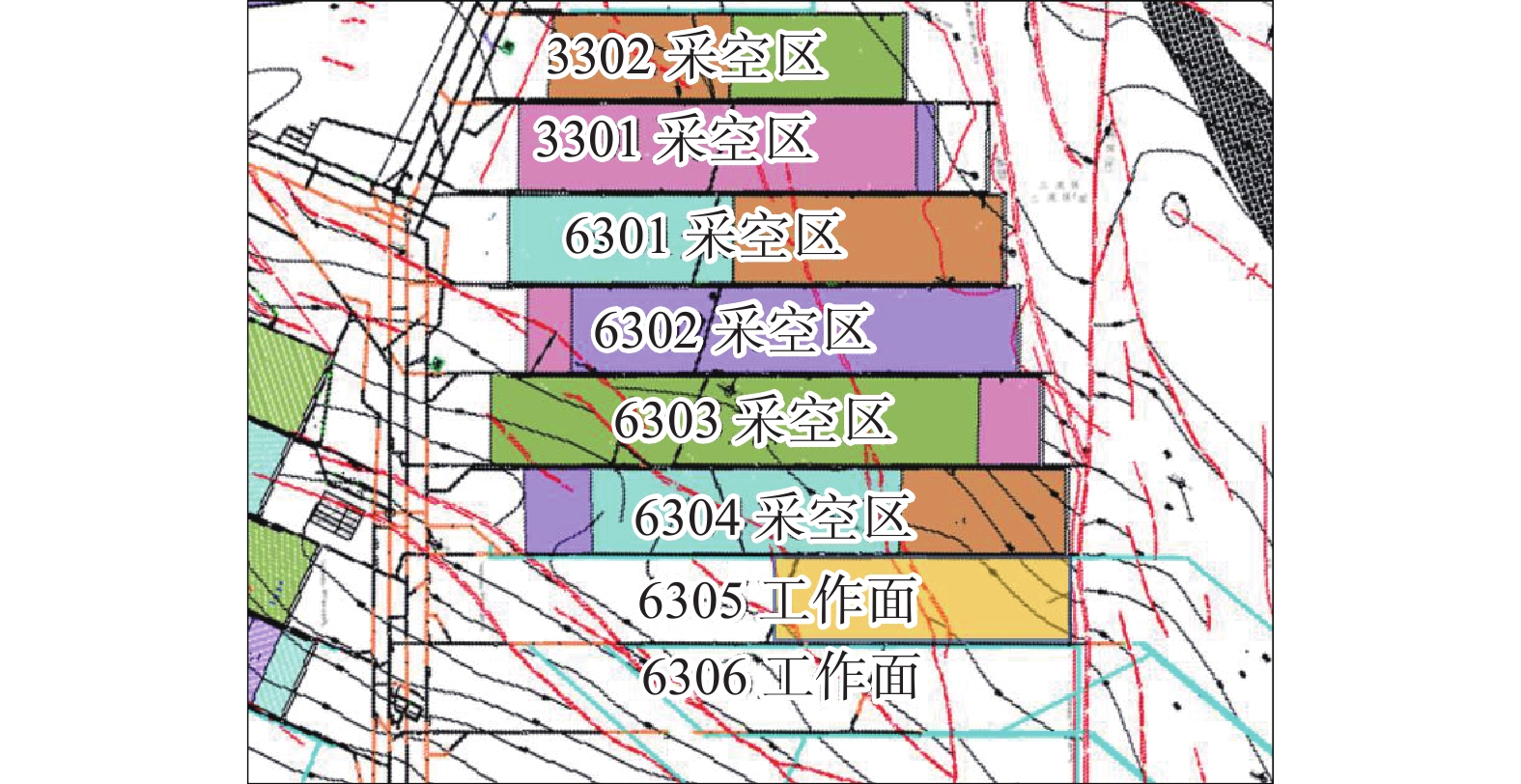

乌东煤矿受早期地质构造运动影响形成典型近直立特厚煤层,目前该矿主要开采南采区B3-6和B1+2煤层,工作面示意图如图1所示。

乌东煤矿南采区煤层平均倾角达87°,两煤层之间由厚度为70~101 m的近直立悬空岩柱分隔。经实验室测定,B3-6、B1+2煤层具有弱冲击倾向性,单轴抗压强度分别为19.801、18.317 MPa,顶底板则以砂岩、粉砂岩和砂质泥岩为主,质地坚硬[1]。该矿采用水平分段综放开采技术开采,阶段开采高度达25 m,各工作面采深跨度较大,随着浅部煤炭资源的枯竭,开采深度的增加导致冲击地压发生频率迅速增高[19]。

1.2 工作面冲击地压事件概述

乌东煤矿南采区历史上共发生6次严重冲击地压事件,全部集中于先开采的B3-6煤层,分别为[19]:发生在+500 m B3-6工作面的“2·27”和“7·2”冲击事件(2013年),+475 m B3-6工作面的“3·13”冲击事件(2015年)和+450 m B3-6工作面的“11·24”(2016年)、“2·1”和“4·26”冲击事件(2017年)。由于+500 m B3-6工作面微震监测数据不全,故本文主要研究其它冲击事件,各事件的冲击破坏区域及震源位置如图2所示。

由图2可知:历次冲击地压事件的破坏区域主要位于上覆原五一煤矿历史开采区、大红沟煤矿历史开采区及防洪渠煤柱区,显现位置主要以回采巷道为主且集中于超前工作面;冲击事件破坏程度不一,破坏形式以底鼓、帮鼓、顶板下沉、肩窝下沉为主,且在+500 m开采水平呈现由北(N)帮向南(S)帮、从上到下的方向性,在+475 m和+450 m开采水平呈现由南(S)帮向北(N)帮的方向性。说明乌东煤矿不同开采水平的冲击地压事件主控因素不同,而冲击地压的主控因素辨识是对其进行有效防治的关键,因此有必要研究各冲击事件主控因素并分析其随采深增加的演化规律。

2. 近直立煤层冲击地压致灾因素分析

微震事件的时空分布与矿井应力场、震动场等具有强相关关系,因此从时间和空间多维度对不同开采水平的微震监测数据进行深入分析,可有效辅助冲击地压的致灾因素辨识。

2.1 微震空间维度分析

2.1.1 震动场空间分布规律

利用Python中matplotlib第三方库绘制B3-6煤层不同采深工作面回采全过程微震的能量密度云图(图3),分析不同位置煤岩体单位面积的能量释放大小。

由图3可知:红色矿震高能区随采深增加由纵向分布且集中于岩柱侧转变为横向分布于顶板和岩柱侧,即在浅部开采时中间岩柱受水平构造应力和自重应力对煤岩体产生的“撬动”作用是导致煤岩体失稳破坏的主要因素,而进入深部开采后由于采空区黄土的变形与下沉,B6顶板悬空面积逐渐增大并发生弯曲变形,对工作面产生“挤压”作用,其内部储存的弹性能瞬间释放从而诱发大能量矿震事件,也就是说悬空顶板与中间岩柱对煤岩体的“压+撬”共同作用是B3-6煤层冲击地压的主要致灾因素之一[20]。

2.1.2 应力场空间分布规律

研究表明煤岩体内部纵波波速随承载应力的增加而增加,因此,利用震动波层析成像技术绘制冲击地压发生前波速异常云图,以“4·26”冲击地压事件为例,绘制的结果如图4所示。

由图4(a)可知:高波速区域主要集中在B3-6煤层和中间岩柱,表明上述区域应力集中,同时在工作面走向位置的高波速区有向B3-6煤体延伸的趋势,这意味着随着采空区的不断增加,中间岩柱可能发生大规模断裂,从而对工作面施加动态载荷。由图4(b)可知:高波速区集中于中间岩柱和悬空顶板,相比前1 d该区域聚集程度更高且最大波速上升至6.0 m/s,应力集中程度加剧,这表明该区域一旦受到强动载扰动则极易诱发冲击地压,现场实测结果也显示此次冲击地压的震源位于工作面前方的中间岩柱中。由图4(c)可知:冲击发生后工作面周围的波速异常程度减小的则显示在冲击地压发生后,工作面附近小范围内的波速异常程度减小,应力集中区远离中间岩柱破裂带向深部转移,这是由于中间岩柱破裂产生的能量突然释放导致的,表明此次冲击地压的主要致灾因素为中间岩柱。

通过微震能量场和震动场的空间演化规律,揭示出近直立层间岩柱和悬空顶板对煤体撬动和挤压产生的高应力集中以及岩柱破裂产生的动载荷为乌东煤矿的主要诱冲因素之一。

2.2 微震时序维度分析

通过对乌东煤矿南采区B3-6煤层发生的冲击地压事故前后微震监测数据进行统计分析,重点研究日推进度、开采深度等冲击地压致灾因素与冲击事故之间的关联以确定主要致冲因素。

2.2.1 日推进度关联分析

井下开采活动不仅对煤岩体施加连续不断地动载扰动,并破坏了其内部的应力平衡,开采活动的强度对于围岩活动性程度具有重要影响。以“4·26”事件前后2个月的微震监测数据为例,绘制的日推进度与微震日总能量、频次的时序演化曲线如图5所示。

由图5可以看出:自4月1日至10日,乌东煤矿日推进度由0 m/d迅速上升至6 m/d,产生了较大的波动,在4月14日该矿出现了1次能量大于105 J的大能量矿震事件但并未造成明显破坏;之后继续以4 m/d左右的推进度开采,但在4月23日后日推进度迅速由5 m/d降为0 m/d,紧接着发生了“4·26”冲击地压事件。表明开采强度与冲击地压的发生具有明显正相关关系,开采活动的剧烈变化会使煤岩体内部积聚的弹性能以较大的速率释放出来,从而增加冲击地压的发生概率[21],因此,开采强度的波动程度为冲击地压的致灾因素之一。

2.2.2 上覆遗留煤柱关联分析

遗留煤柱的存在会造成附近区域的应力分布不均衡,煤岩体内部积聚弹性能至储能极限后会导致冲击地压的发生。乌东煤矿南采区上覆有防洪渠保护煤柱、大红沟煤矿和原五一煤矿历史开采区遗留煤柱,工作面开采至下方时受其影响冲击危险程度增大。+450 m B3-6工作面为例,绘制的全工作面微震日总能量、频次的时序演化曲线如图6所示,其中①、②、③分别表示开采防洪渠煤柱区、大红沟煤矿历史开采区和原五一煤矿历史开采区期间,④表示停产。

由图6可知:当工作面位置由正常开采区进入遗留煤柱影响区时,日总能量和频次出现剧烈上升,同时微震整体能级也出现明显升高,特别在+450 m B3-6工作面过②、③区域时该现象最为显著;而在工作面出遗留煤柱影响区后,微震能量和频次较之前出现明显下降。同时,图2中也可以看出+450 m B3-6工作面历次冲击地压事件震源位置都集中于②、③遗留煤柱影响区,这表明遗留煤柱是乌东煤矿冲击地压的致灾因素之一,并且受特殊地质条件及开采方式影响,该矿上覆遗留煤柱在经过多分层开采后仍对冲击地压存在明显影响。

2.2.3 开采深度关联分析

乌东煤矿采用水平分段综放开采技术开采,阶段开采高度达25 m,各工作面采深跨度较大,且不同采深工作面几乎都发生过严重冲击地压事件,因此需研究不同采深对冲击地压事件的影响。以B3-6煤层各开采水平工作面微震监测数据为研究对象,绘制各能级微震事件的能量、频次占比分布图的B3~6煤层各水平如图7所示。

由图7可知:随着开采深度的增加,1×104 J及以上能级的微震事件占开采全过程释放总能量的比例越来越高,而其发生频次的占比却降低了,其形式逐渐由“低能高频”转化为“高能低频”,说明进入深部开采阶段后,煤岩体内部微裂隙扩展至宏观断裂面的过程缩短,其内部积聚的高弹性应变能由阶段性耗散逐渐转变为瞬间释放,更容易造成煤岩体突然、剧烈的破坏,围岩冲击危险程度增加、工作面发生冲击危险的概率及破坏程度也随之增加,因此,开采深度也是影响冲击地压事故的一项重要影响因素。

综上,通过微震的时空演化信息,得到了乌东煤矿应力场、震动场等分布特征,得出近直立煤层冲击地压主要致灾因素包括悬空顶板和层间岩柱的“压+撬”作用、各历史开采区的遗留煤柱导致的应力集中和动静载扰动以及矿井开采强度和采深,对以上因素进行针对性防治是降低近直立煤层开采过程冲击地压危险的关键。

3. 近直立煤层致冲因素定量辨识

根据历次冲击地压事件的发生情况,对不同开采水平下各致灾因素进行定量辨识。目前,很多学者采用层次分析法对冲击地压的主控因素进行权重量化,但是,在对各指标因素的重要程度进行对比的时候,常规的 AHP 方法往往使用1~9标记法来构建判断矩阵,但是这样会使得矩阵比较主观盲目,不能体现出人们评估思路的模糊特性。用三角模糊数来代表专家对指标重要程度的判断,从而建立了1个模糊判断矩阵,进而来确定评估指标的权重。可以有效避免这一情况的发生。

3.1 基于三角模糊数改进AHP的权重分析方法

1)根据得到的影响近直立煤层冲击危险的因素,使用一种单层次的模型结构,该模型结构包含1个决策目标C和1层准则层,该准则层是隶属于目标C的n个因素(A1,A2,A3,$\cdots $,An)。

2)对准则层各影响因素两两对比进行重要性判断,得到结果为$ a_{i j}=\left(l_{ij}, m_{i j}, p_{ij}\right) $,$ a_{i j} $为因素 i 比j的相对重要程度,$ l_{ij} $为重要程度的下限,$ p_{ij} $为重要程度的上限,$ m_{{ij}} $为重要程度的最大可能值,$ a_{ji}=\left(1 / l_{i j}, 1 / m_{ij}, 1 / p_{ij}\right) $。

3)构建模糊中值矩阵$ {\boldsymbol{M}}=\left(m_{ij}\right)_{n \times n} $,并进行一致性检验。

$$ \boldsymbol{M}=\left[\begin{array}{cccc} m_{11} & m_{12} & \cdots & m_{1 n} \\ m_{21} & m_{22} & \cdots & m_{2 n} \\ \vdots & \vdots & \vdots & \vdots \\ m_{n 1} & m_{n 2} & \cdots & m_{n n} \end{array}\right] $$ 4)生成模糊判断因子矩阵E:

$$ {\boldsymbol{E}}=\left[\begin{array}{cccc} 1 & 1+s_{12} & \cdots & 1+s_{1 n} \\ 1+s_{21} & 1 & \cdots & 1+s_{2 n} \\ \vdots & \vdots & \vdots & \vdots \\ 1+s_{n 1} & 1+s_{n 2} & \cdots & 1 \end{array}\right] $$ 式中:$ s_{i j}=\left(p_{i j}-l_{i j}\right) /\left(2 m_{i j}\right) $,$ s_{ij} $为专家评价的标准偏差,数值较大,表示该评价具有较强的模糊性和较低的可信度;数值较低,说明了该方法的可靠性较高,且具有较低的模糊性。所以,它所组成的模糊判定因素矩阵 E本质上就是1个专家判定的可信度矩阵。

5)构造1个调整判断矩阵Q,其中Q = M × E,同时,把Q转化成对角线为1的矩阵Q’。

$$ Q^{\prime}=\left[\begin{array}{cccc} 1 & \delta_{12} & \cdots & \delta_{1 n} \\ \delta_{21} & 1 & \cdots & \delta_{2 n} \\ \vdots & \vdots & \vdots & \vdots \\ \delta_{n 1} & \delta_{n 2} & \cdots & 1 \end{array}\right] $$ 6)权重计算。用特征值法对上述矩阵Q’ 进行计算,得到因素 i 的权重,同时归一化处理得到各个因素的权重ω。

3.2 冲击地压事件影响因素权重量化

根据近直立煤层冲击地压主要致灾因素:顶板和岩柱(A1)、历史遗留煤柱(A2)、开采强度(A3)、开采深度(A4),建立单层次模型。进行乌东煤矿B3-6煤层发生的各冲击地压事件的主控因素进行权重量化分析。

以B3-6煤层+500 m开水水平发生的“2·27”冲击事故为例进行详细的权重计算。此事件的影响因素重要程度判断结果见表1。对模糊中值矩阵$ {\boldsymbol{M}}=\left(m_{ij}\right)_{n \times n} $进行一致性检验。计算得其随机一致性比率CR=0.072<0.1,满足要求。

表 1 “2·27”冲击事故影响因素重要程度判断结果Table 1. Determination results of the importance of factors affecting the “2-27” rock burst accident顶板和岩柱 遗留煤柱 开采强度 开采深度 顶板和岩柱 (1,1,1) (1.74,3.92,8.12) (1.54,2.15,7.56) (0.89,1.76,4.09) 遗留煤柱 (0.09,0.84,0.57) (1,1,1) (0.87,1.65,4.45) (0.19,0.47,3.37) 开采强度 (0.13,0.46,0.69) (0.23,0.65,1.12) (1,1,1) (0.19,0.35,0.88) 开采深度 (0.15,0.34,1.1 ) (0.20,2.34,4.13) (1.23,2.23,4.76) (1,1,1) 生成模糊判断因子矩阵:

$$ {\boldsymbol{E}}=\left[\begin{array}{cccc} 1.00 & 3.92 & 2.15 & 1.76 \\ 0.84 & 1.00 & 1.65 & 0.47 \\ 0.46 & 0.65 & 1.00 & 0.35 \\ 0.34 & 2.34 & 2.23 & 1.00 \end{array}\right] $$ 计算调节矩阵:

$$ {\boldsymbol{Q}}={\boldsymbol{M}} \times {\boldsymbol{E}}=\left[\begin{array}{rrrr} 13.74 & 11.53 & 15.86 & 25.05 \\ 5.91 & 5.34 & 6.60 & 9.69 \\ 3.74 & 3.31 & 4.09 & 6.04 \\ 9.35 & 7.45 & 9.71 & 16.27 \end{array}\right] $$ 转化为对角线为1的矩阵:

$$ {\boldsymbol{Q}}^{\prime}=\left[\begin{array}{cccc} 1.00 & 2.15 & 3.88 & 1.54 \\ 0.43 & 1.00 & 1.61 & 0.60 \\ 0.27 & 0.62 & 1.00 & 0.37 \\ 0.68 & 1.39 & 2.37 & 1.00 \end{array}\right] $$ 利用特征值法求得的顶板和岩柱、遗留煤柱、开采强度、开采深度的权重矩阵为:W=[0.428 4,0.181 3,0.113 2,0.277 1]。

可知造成该事故的最大权重因素为顶板和岩柱,即主控因素为顶板和岩柱,其次是开采深度,可见开采深度对冲击的影响相当大。除此之外,在对不同开采水平历次冲击地压事件的致灾因素进行权重量化后可知,在矿井由浅部到深部开采过程中,顶板和岩柱、开采深度的影响逐渐增大,其产生的动静载和“压撬”作用导致的应力集中成为诱发冲击地压的主控因素;遗留煤柱、开采强度的影响逐渐减小。

4. 结 语

1)基于微震空间震动场及应力场分布信息,得出:乌东矿近直立煤层冲击地压主要由悬空顶板和中间岩柱对工作面产生的应力集中以及岩体破裂产生的动载扰动诱发的。

2)通过分析日推进度、开采深度及遗留煤柱等冲击地压致灾因素与冲击事故之间的关联性,得出上述因素与冲击事件具有强相关关系,是近直立煤层的主要致灾因素。

3)乌东煤矿历次冲击地压事件的破坏程度、破坏形式不一,冲击地压主控因素随采深增加发生较大变化,在浅部受遗留煤柱应力集中影响大于深部,并且在经过多分层开采后遗留煤柱应力作用仍存在。

4)近直立煤层不同开采深度下冲击地压的致灾因素的演变规律为:浅部开采时中间岩柱受水平构造应力和自重应力对煤岩体产生的“撬动”作用是导致煤岩体失稳破坏的主要因素,而深部开采则叠加了顶板的“挤压”作用,冲击致灾因素转变为顶板和岩柱的“压+撬”共同作用。

-

表 1 岩层模拟参数表

Table 1 Rock layer simulation parameters table

岩层名称 密度/

(kg·m−3)体积模量/

GPa剪切模量/

GPa黏聚力/

MPa内摩擦角/

(°)抗拉强度/

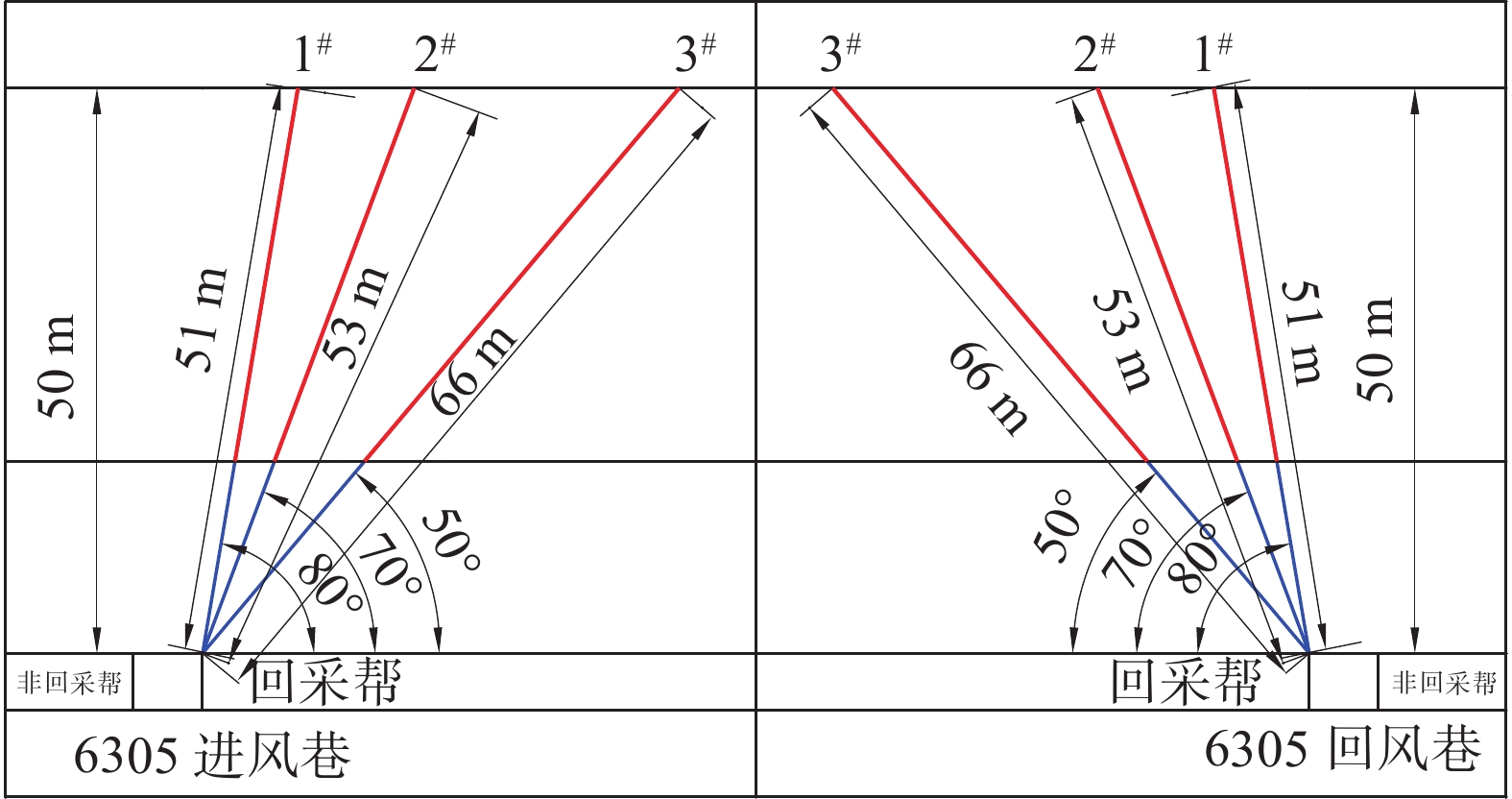

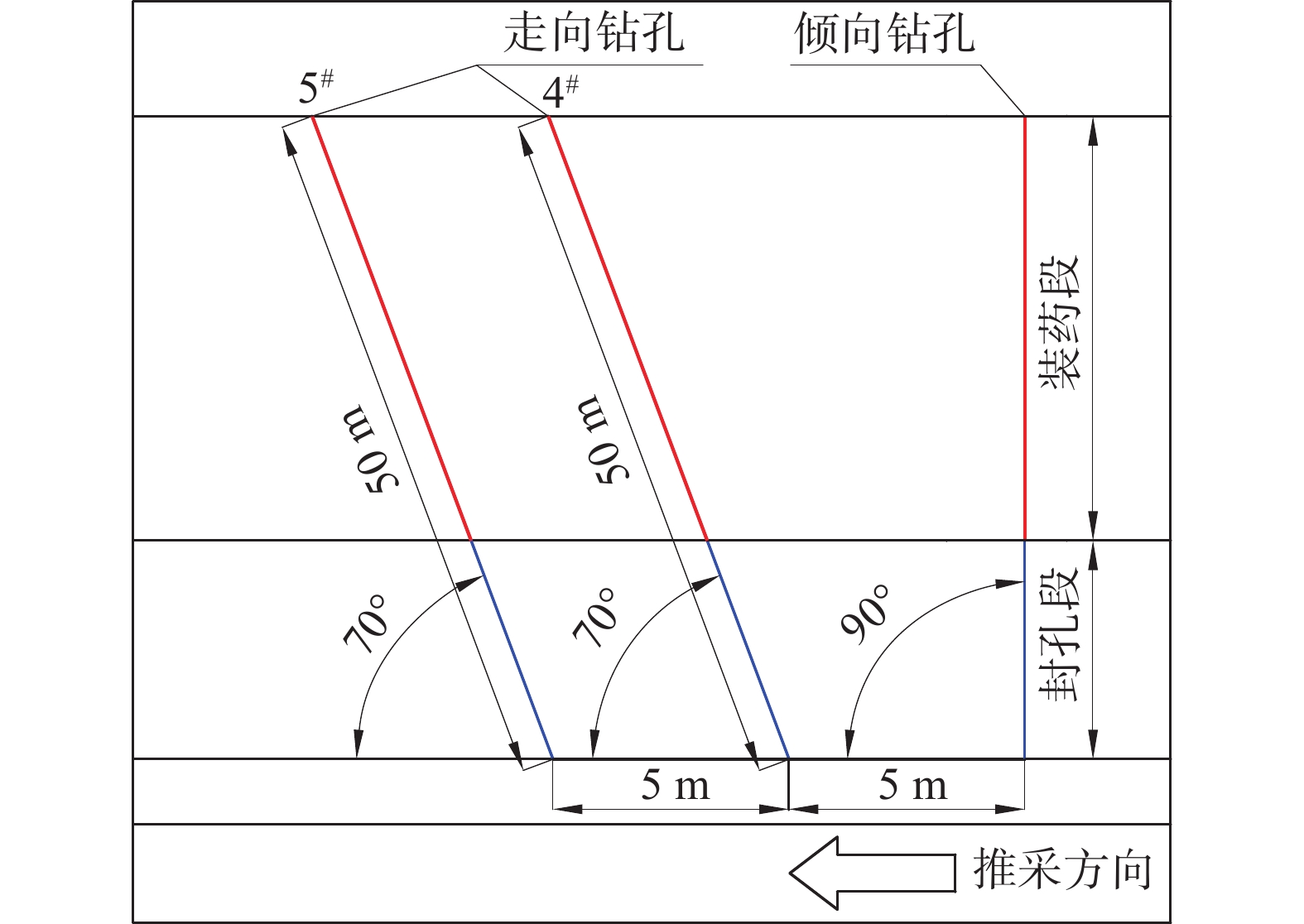

MPa中砂岩 2650 1.33 0.80 3.00 33 0.74 细砂岩 2650 2.67 1.60 3.00 36 0.79 粉砂岩 2540 1.20 0.72 2.60 34 0.65 砂质泥岩 2500 1.00 0.60 2.40 30 0.55 煤层 1400 1.00 0.46 2.20 28 0.49 泥岩 2400 1.25 0.58 2.40 28 0.53 黏土层 2400 1.33 0.44 1.80 26 0.38 表 2 进风巷、回风巷预裂爆破钻孔参数

Table 2 Borehole parameters of pre-splitting blasting in intake airway and return laneway

钻孔编号 炮孔总长度/

m与水平仰角/

(°)装药量/

kg钻孔直径/

mm1 51 80 75 89 2 53 70 77 89 3 66 50 99 89 4 50 70 75 89 5 50 70 75 89 -

[1] 窦林名,田鑫元,曹安业,等. 我国煤矿冲击地压防治现状与难题[J]. 煤炭学报,2022,47(1):152−171. DOU Linming, TIAN Xinyuan, CAO Anye, et al. Pres-ent situation and problems of coal mine rock burstprevention and control in China[J]. Journal of China Coal Society, 2022, 47(1): 152−171.

[2] 张修峰,陈洋. 煤柱型冲击地压类型、发生机理与防治对策研究[J]. 煤炭科学技术,2023,51(10):1−11 ZHANG Xiufeng, CHEN Yang. Research on the type and occurrence mechanism and prevention of coal pillar rockbursts[J]. Coal Science and Technology, 2023, 51(10): 1−11.

[3] 潘俊锋,齐庆新,刘少虹,等. 我国煤炭深部开采冲击地压特征、类型及分源防控技术[J]. 煤炭学报,2020,45(1):111−121. PAN Junfeng, QI Qingxin, LIU Shaohong, et al. Chara-cteristics, types and prevention and control technology of rockburst in deep coal mining in China[J]. Journal of China Coal Society, 2020, 45(1): 111−121.

[4] 谢和平,高峰,鞠杨. 深部岩体力学研究与探索[J]. 岩石力学与工程学报,2015,34(11):2161−2178. XIE Heping, GAO Feng, JU Yang. Research and dev-elopment of rock mechanics in deep ground engineering[J]. Chinese Journal of Rock Mechanics and Engineering, 2015, 34(11): 2161−2178.

[5] 杨伟利,林强,魏全德,等. 深井不等宽断层煤柱诱发冲击地压机理研究[J]. 煤炭工程,2020,52(7):112−116. YANG Weili, LIN Qiang, WEI Quande, et al. Mechani-sm of rockburst induced by fault coal pillars with different widths in deep shaft[J]. Coal Engineering, 2020, 52(7): 112−116.

[6] 胡昌硕,李东,周法乐,等. 多因素耦合诱发孤立煤体冲击地压机理研究[J]. 山东科技大学学报(自然科学版),2022,41(5):40−50. HU Changshuo, LI Dong, ZHOU Fale, et al. Research on mechanism of rock burst induced by multi-factor coupling in isolated coal body[J]. Journal of Shandong University of Science and Technology (Natural Science), 2022, 41(5): 40−50.

[7] 王高昂,朱斯陶,姜福兴,等. 千米深井大巷孤立煤体整体失稳冲击机理及防治研究[J]. 采矿与安全工程学报,2019,36(5):968−976. WANG Gaoang, ZHU Sitao, JIANG Fuxing, et al. Me-chanism of rock burst induced by overall instability of isolated coal and its prevention in large well at thousands-kilometer underground[J]. Journal of Mining & Safety Engineering, 2019, 36(5): 968−976.

[8] 朱广安,窦林名,刘阳,等. 深埋复杂不规则孤岛工作面冲击矿压机制研究[J]. 采矿与安全工程学报,2016,33(4):630−635. ZHU Guangan, DOU Linming, LIU Yang, et al. Rock burst mechanism analysis on deep irregular island face[J]. Journal of Mining & Safety Engineering, 2016, 33(4): 630−635.

[9] 曹明辉,刘钒,王同旭. 断层活化过程及煤柱失稳机理的数值模拟研究[J]. 山东科技大学学报(自然科学版),2020,39(2):61−68. CAO Minghui, LIU Fan, WANG Tongxu. Numerical simulation study of fault activation process and coal pillar instability mechanism[J]. Journal of Shandong University of Science and Technology (Natural Science), 2020, 39(2): 61−68.

[10] 李俊平,胡文强,张浩. 断层切割围岩的巷道稳定性数值分析[J]. 地下空间与工程学报,2018,14(S2):925−929. LI Junping, HU Wenqiang, ZHANG Hao. Numerical analysis on roadway stability by fault cutting surrounding rock[J]. Chinese Journal of Underground Space and Engineering, 2018, 14(S2): 925−929.

[11] 张世平,赵健,李士栋,等. 深井厚煤层大巷孤立煤体冲击危险性评价研究[J]. 中国安全生产科学技术,2022,18(6):70−77. ZHANG Shiping, ZHAO Jian, LI Shidong, et al. Study on impact risk assessment of isolated coal mass in roadway of thick coal seam in deep mine[J]. Journal of Safety Science and Technology, 2022, 18(6): 70−77.

[12] 王高昂,朱斯陶,左二宁,等. 超深井厚煤层下山孤立煤体冲击机理研究[J]. 煤矿安全,2019,50(8):63−66. WANG Gaoang, ZHU Sitao, ZUO Erning, et al. Study on rock burst mechanism of isolated downhill coal body in thick coal seam of ultra deep well[J]. Safety in Coal Mines, 2019, 50(8): 63−66.

[13] 薛成春,曹安业,牛风卫,等. 深部不规则孤岛煤柱区冲击地压机理及防治[J]. 采矿与安全工程学报,2021,38(3):479−486. XUE Chengchun, CAO Anye, NIU Fengwei, et al. Me-chanism and prevention of rock burst in deep irregular isolated coal pillar[J]. Journal of Mining & Safety Engineering, 2021, 38(3): 479−486.

[14] 宋艳芳,潘一山,李忠华,等. 孤立煤柱冲击地压蠕变失稳研究[J]. 煤矿安全,2018,49(5):47−50. SONG Yanfang, PAN Yishan, LI Zhonghua, et al. Creep instability of isolated coal pillar under rock burst[J]. Safety in Coal Mines, 2018, 49(5): 47−50.

[15] 曹安业,王常彬,窦林名,等. 临近断层孤岛面开采动力显现机理与震动波CT动态预警[J]. 采矿与安全工程学报,2017,34(3):411−417. CAO Anye, WANG Changbin, DOU Linming, et al. D-ynamic manifestation mechanism of mining on the island coalface along fault and dynamic pre-warning of seismic waves with seismic tomography[J]. Journal of Mining & Safety Engineering, 2017, 34(3): 411−417.

[16] 姜福兴,成功,冯宇,等. 两侧不规则采空区孤岛工作面煤体整体冲击失稳研究[J]. 岩石力学与工程学报,2015,34(S2):4164−4170. JIANG Fuxing, CHENG Gong, FENG Yu, et al. Resea-rch on coal overall instability of isolated working face with irregular gobs on both sides[J]. Chinese Journal of Rock Mechanics and Engineering, 2015, 34(S2): 4164−4170.

[17] 杨洋,郝生雷,秦瑞. 基于不规则煤柱应力场特征的冲击地压防治研究[J]. 煤炭工程,2023,55(5):111−115. YANG Yang, HAO Shenglei, QIN Rui. Prevention and control of rock burst based on stress field characteristics of irregular coal pillars[J]. Coal Engineering, 2023, 55(5): 111−115.

[18] 蒋金泉,武泉林,曲华. 硬厚覆岩正断层附近采动应力演化特征[J]. 采矿与安全工程学报,2014,31(6):881−887. JIANG Jinquan, WU Quanlin, QU Hua. Evolutionary characteristics of mining stress near the hard-thick overburden normal faults[J]. Journal of Mining & Safety Engineering, 2014, 31(6): 881−887.

[19] 龙军,于秋鸽. 基于应力波理论的断层对覆岩移动变形和应力传递阻隔效应研究[J]. 煤炭工程,2022,54(3):105−111. LONG Jun, YU Qiuge. Blocking effect of fault on overburden deformation and stress transfer based on stress wave theory[J]. Coal Engineering, 2022, 54(3): 105−111.

[20] 姜福兴,苗小虎,王存文,等. 构造控制型冲击地压的微地震监测预警研究与实践[J]. 煤炭学报,2010,35(6):900−903. JIANG Fuxing, MIAO Xiaohu, WANG Cunwen, et al. Predicting research and practice of tectonic-controlled coal burst by microseismic monitoring[J]. Journal of China Coal Society, 2010, 35(6): 900−903.

下载:

下载: