Experimental study and field application of charge induction law in coal rock deformation and failure

-

摘要:

准确掌握岩体受载破坏过程电荷感应规律,对于冲击地压等动力灾害预测具有重要意义。在电荷监测仪采集精准度优化提升基础上,对砂岩试样单轴压缩受载破坏电荷感应规律进行了实验室监测试验,并进行井下监测试验,详细分析了不同加载速率下砂岩电荷感应与应力降以及裂纹扩展的关系和超前工作面支承压力影响区电荷感应特征。结果表明:岩样受载破坏过程中裂纹的多次形成、发育与扩展均伴随着电荷感应信号,前兆电荷信号的产生早于岩样受载破裂出现的应力降;在0.005、0.015、0.020 mm/s 3种加载速率条件下,岩样破坏过程的电荷信号规律随加载速率的变化显现出差异性,主要表现为加载速率越大,电荷信号越丰富,超前应力突变前兆电荷信号越发提前出现;现场各测点平均感应电荷量最大值均位于超前支承压力影响区内,且平均感应电荷量大小与工作面超前支承压力分布趋势一致。

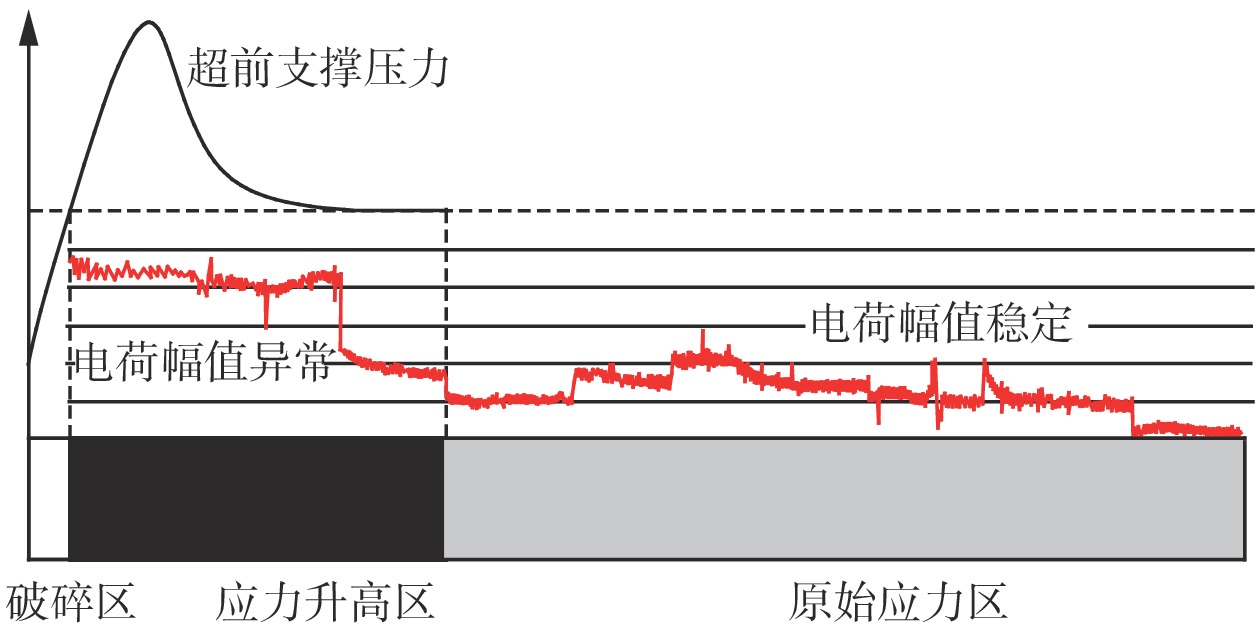

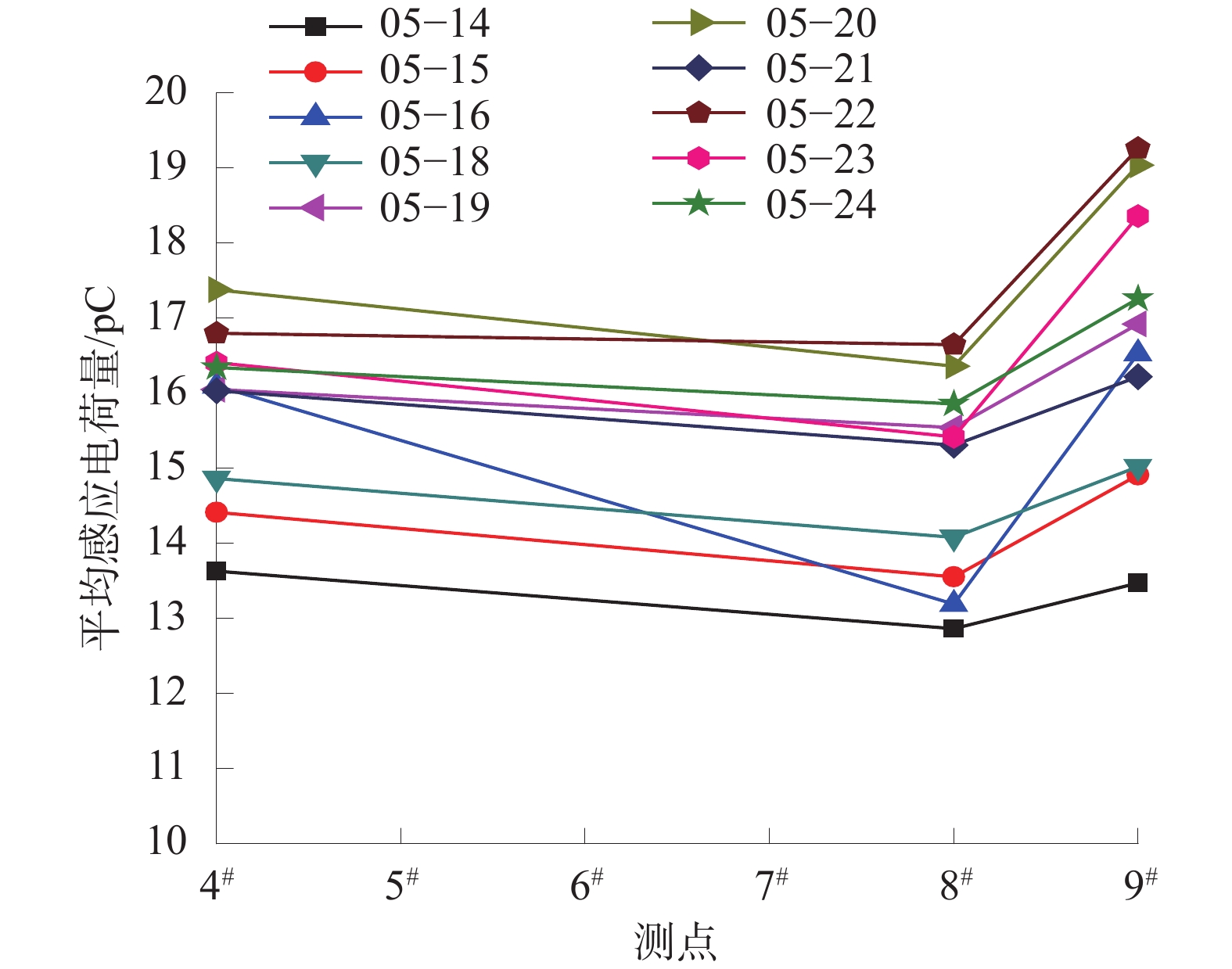

Abstract:It is of great significance to accurately grasp the charge induction law of rock mass during load failure process for the prediction of dynamic disasters such as rock burst. On the basis of optimizing and improving the acquisition accuracy of charge monitor, laboratory monitoring tests were carried out on the charge induction rule of sandstone samples under uniaxial compression failure under load, and underground monitoring tests were carried out. The relationship between charge induction, stress drop and crack growth of sandstone samples under different loading rates and the charge induction characteristics in the area affected by abutment pressure of advanced working face were analyzed in detail. The research shows that: the formation, development and propagation of cracks are accompanied by charge induction signals during the process of loading failure, and the generation of precursor charge signals is earlier than the stress drop caused by loading failure. Under the loading rates of 0.005 mm/s, 0.015 mm/s and 0.020 mm/s, the law of charge signal in the failure process of rock samples varies with the loading rate. The higher the loading rate is, the richer the charge signal is, and the precursory charge signal appears more early. Field monitoring found that the maximum value of the average induced charge at each measuring point was located in the influence area of the advanced abutment pressure, and the average induced charge was consistent with the distribution trend of the advanced abutment pressure on the working face.

-

矿井火灾是影响矿井安全生产的主要灾害之一[1-2] ,煤自燃是诱发矿井火灾的主要因素之一,采空区煤自燃事故数量占矿井火灾事故数量的90%以上[3]。煤炭自燃导致浪费大量的煤炭资源,而且会产生大量CO、SOx等有毒有害气体,严重威胁一线井下工人的生命财产安全。根据《煤矿安全规程》提出的“安全第一,预防为主,综合治理”的指导方针,在开采容易自燃和自燃煤层时,必须开展煤自然发火监测工作,建立煤自然发火监测系统,确定煤层自然发火标志气体及临界值,健全煤自然发火预测预报及管理制度[4]。而现有的煤自然发火预警体系多基于束管监测系统及监测监控系统测试的单一或多个单一气体指标来搭建的,其测试结果受仪器设备精度因素和环境因素。马文龙[5]提出了一种多传感器信息融合方法,利用BP神经网络、ELM极限学习机和D-S证据理论算法实现了多传感器数据在特征级和决策级的信息融合,并将该方法应用到火灾预测领域,大大提高了火灾预测的准确率;罗招贤等[6]对传统BP神经网络提出了改进,建立了一种具有离线学习和在线校正的双模式BP神经网络模型,提高了神经网络对煤自燃预测的准确性;LEI等[7]基于随机森林算法建立了采空区煤自燃预警方法,并将预测结果与支持向量机和BP神经网络的预测结果进行对比,验证了随机森林算法的稳定性与适用性;刘奇[8]提出了一套基于LVQ神经网络的煤层自然发火预报系统,该系统能有效克服标志气体浓度数据难以采取复杂数学建模的问题,提高了煤自燃预测的准确率;贾彭涛等[9]针对传统煤自燃预测模型泛化性不强、鲁棒性较差的问题,提出一种基于粒子群优化SVR的煤自燃预测模型,并将其预测结果与SVR、RF和BP进行对比,得出了粒子群优化SVR模型具有良好的泛化性和鲁棒性的结论;温荣岩[10]提出了一种基于改进粒子群算法的小波神经网络进行多传感器煤自燃信号的融合,结果表明改进粒子群小波神经网络实际的分类精度最高,同时训练速度最快,明显提高了煤自燃预测的速度和精度,对煤自燃预测的研究有一定的应用价值;王民华等[11]针对采空区遗煤自燃预测泛化能力不强等问题,对实测数据集特征进行重构增强,以提高模型预测性能;翟小伟等[12]针对标志气体浓度受人为或仪器影响易缺失的问题,分别将K近邻,随机森林,决策树等算法应用于缺失值插补中,以提高缺失数据下煤自燃温度预测准确率;周旭等[13]采用极限梯度提升树算法(Extreme Gradient Boosting,XGBoost)建立了煤自燃温度预测模型,并利用粒子群优化算法(PSO)对 XGBoost 模型的随机采 样率和最小叶子节点样本权重进行优化,实现了煤自燃温度的准确预测;邓军等[14]利用采空区实测数据 建立了基于随机森林(Random Forest,RF)方法的煤自燃预测模型,在不同矿井进行煤自燃温度预测,均具有良好的应用效果;郑学召等[15]将随机森林算法应用到煤自燃温度预测问题,相较于支持向量机、神经网络,其预测精度得到了较大的提升;雷昌奎等[16]引入灰色综合关联分析方法,对上限漏风强度因素进行了相关性分析,并通过改进的粒子群算法对支持向量回归模型进行了极限参数预测,提高了模型精度。

以上研究表明,我国已经利用机器学习的方法对煤自燃进行预测预警研究,并取得相应成果,证明利用神经网络算法对煤自燃进行预测具有良好可行性。但在国内外学者的研究中,对煤自然发火的预测往往基于传统的预测手段,预测指标较为单一。基于深度学习的煤自然发火预测的研究大部分仍停留在风险分级预警的定性预测阶段,而对煤自燃温度直接进行预测的定量预测方法鲜有报道。为此,采用实验室试验、理论分析、构建模型等方法,选取砚北煤矿250203下采煤工作面的煤样,通过煤氧化升温实验获取实验数据,结合多源数据预处理方法建立煤自燃温度预测指标体系;并构建基于神经网络算法的采空区煤自燃温度预测模型,该模型可为采空区内部最高温度的准确预测提供一定参考。

1. 煤自燃温度预测指标实验分析

1.1 煤氧化升温实验实验分析

1.1.1 煤样选取制备

对采自砚北煤矿的长焰煤进行氧化升温实验,首先将大块煤样敲碎成碎煤块,随后用颚式破碎机进行破碎处理形成煤粉,并倒入筛分器,筛选出粒径为60~80目(0.18~0.25 mm)的煤颗粒,制备1 kg的实验煤样,制备好的煤样经过标号、密封处理后待用。

1.1.2 实验方法及过程

煤氧化升温实验过程中,通过气泵将空气输送至煤样罐,确保进气量恒定。煤样罐的上下部分各设有1个温度传感器,用于收集煤样的温度数据。采用的空气式煤程序升温氧化实验系统原理图如图1所示。

基本参数设定如下:温度测量时间,在煤样达到105 ℃前,升温过程持续10 min,升温过程中温度共升高10 ℃,然后恒温保持40 min;煤样达到105 ℃后,升温过程持续15 min,升温过程中温度共升高15 ℃,然后保持恒温40 min。煤样罐高20 cm,半径2.25 cm。实验步骤如下:

1)实验开始前,首先需要将气室和管内残留气体排出,并正确安装实验设备。将处理好的煤样装入煤样罐中,并将煤样罐固定在空气加热炉内。

2)将经过干燥处理的空气泵入煤样罐中,使煤样发生氧化反应。将反应产生的气体通过煤样罐上的导气管送入气相色谱仪中,进行成分和浓度分析。开启气泵和流量计,将空气泵入混气室,控制空气流量为60 mL/min,清空气室和管道内残留气体,使用气相色谱仪对混气室排放的气体进行分析,直到检测到排放气体中氧气体积分数稳定后,再将空气导入煤样罐中。

3)启动升温装置后,以1 ℃/min的速度升高温度,然后保持温度40 min。在这段时间里,如果煤样罐内的温度在5 min内上下波动不超过0.5 ℃,则表明煤样温度已经稳定。此时,需要使用气相色谱仪检测各气体产物的成分和体积分数值,接着进入下1个升温阶段。重复以上操作,直到煤温升至约200 ℃时结束煤氧化升温实验。

1.2 实验结果分析

1.2.1 单一指标

根据实验得到的各气体数据绘制出的气体产物体积分数与煤温间的对应关系曲线如图2所示。

由图2可以看出:

1)随着温度的升高,O2消耗量呈现上升趋势,起初O2消耗量的上升速度缓慢,当温度在120~175 ℃范围内时,O2消耗量的上升速度显著加快,最后曲线的上升的趋势回复平缓。O2消耗量随煤自燃温度的变化有较强的规律性,故O2消耗量可以作为煤自燃温度预测指标。

2)随着温度的升高,CO2体积分数呈现上升趋势,起初CO2体积分数的上升速度缓慢,当温度在76~110 ℃范围内时,CO2体积分数的上升速度显著加快,最后曲线的上升的趋势回复平缓。CO2体积分数随煤自燃温度的变化有较强的规律性,故CO2体积分数可以作为煤自燃温度预测指标。

3)CO体积分数随温度升高而不断升高,当温度达到91 ℃后,CO体积分数的上升速度迅速加快,随着温度升高,CO体积分数呈现出近似指数的上升趋势。CO体积分数随煤自燃温度的变化有较强的规律性,故CO体积分数可以作为煤自燃温度预测指标。

4)随着温度的升高,CH4体积分数呈现上升趋势。在温度范围为35~110 ℃时,CH4的上升趋势较为平缓,当温度达到110 ℃时,CH4体积分数的上升速度迅速加快,随着温度升高,CH4体积分数呈现出近似指数的上升趋势。CH4体积分数随煤自燃温度的变化有较强的规律性,故CH4体积分数可以作为煤自燃温度预测指标。

5)C2H6和C2H4变化趋势相似,在温度较低时,无气体产生,102 ℃左右时开始生成C2H6,122 ℃左右时开始生成C2H4,气体体积分数随温度的升高呈近似指数趋势上升,有较好的规律性,故C2H6和C2H4体积分数可作为煤自燃温度预测指标。

因此,可以将O2消耗量、CO2、CO、CH4、C2H6、C2H4的体积分数作为煤自燃温度预测指标。

1.2.2 复合指标

矿井下的现场生产环境较为复杂,在生产现场监测得到的标志气体浓度会受井下空气流通等因素的影响,其监测浓度往往会随风量的改变而变化,故在煤自燃温度预测过程中使用单一指标会导致难以判明煤自燃氧化高温点的实际温度,所以结合复合指标,能够达到更为良好的效果。

复合指标主要包括碳氧化物比(即CO与CO2体积分数的比值、CO体积分数与O2消耗量百分比的比值)、链烷比、烯烷比。复合指标随煤温变化关系曲线如图3所示。

由图3可以发现:

1)φ(CO)/φ(CO2)、φ(CO)/φ(CH4)随煤自燃温度的变化较为复杂,不满足单调变化性原则,故暂不考虑作为煤自燃温度预测的预测指标。

2)φ(CO)/φ(O2)随着温度的升高呈现上升趋势,在温度范围为35~115 ℃时曲线的上升趋势较为平缓,当温度达到115 ℃后,φ(CO)/φ(O2)的上升速度迅速加快,φ(CO)/φ(O2)随温度的升高呈近似指数趋势上升有较强的规律性,可以作为煤自燃温度预测的预测指标。

3)在链烷比和烯烷比中(φ(C2H6)/φ(CH4)、φ(C2H4)/φ(CH4)、φ(C2H4)/φ(C2H6)),在煤样氧化升温初期无C2H6和C2H4生成,故在煤样氧化升温初期各比值均为0,达到一定温度之后开始出现C2H6和C2H4,φ(C2H6)/φ(CH4)随温度的升高而迅速上升,随着温度的进一步升高,φ(C2H6)/φ(CH4)的上升速度有所下降,曲线的上升的趋势回复平缓。φ(C2H4)/φ(CH4)随温度的升高呈近似指数趋势上升,φ(C2H4)/φ(C2H6)随温度的升高数值不断升高,可知链烷比和烯烷比随煤自燃温度的变化有较强的规律性,因此链烷比和烯烷比可以作为煤自燃温度预测的预测指标。

2. 煤自燃温度预测指标研究

2.1 数据处理

由于实验指标数据会受到人员,设备,条件等多方面因素的影响,因此在确定煤自燃温度预测指标后,需要利用多源数据处理方法,对上一节分析的预测指标进行数据清洗,以消除数据中的异常值与缺失值。同时为进一步确保预测模型的精确性,对预测指标进行灰色关联度分析,最终建立煤自燃温度预测模型指标体系。

2.1.1 异常值处理

利用库克距离(Cook’s Distance)法对样本数据集进行分析,库克距离法根据各预测指标与煤自燃温度之间的相关性,计算预测指标数据与煤自燃温度数据间的库克距离,故当某数值的库克距离过大,可以认为该数值偏离了回归模型,定义该数据为离群点,视为异常值[17]。通过库克距离法所筛选出的异常值较为合理,在筛选煤自燃温度预测的错误数据时更加精准。处理样本数据集的异常值时,可将异常值视为缺失值,按照处理缺失值的方式对异常值进行替换。

2.1.2 缺失值处理

采用多重插补法对煤自燃温度预测指标的缺失值进行补充。但若某一指标的数据完整度少于50%,则无法对该数据进行插补,考虑直接剔除该预测指标。

使用灰色关联度分析法(GRA)对煤自燃温度预测指标进行分析,建立煤自燃温度预测指标体系[18],灰色关联度分析法的示意图如图4所示。

将各预测指标的灰色关联度按由大到小顺序排列,该排序既为各预测指标与煤自燃温度之间关联程度的排名,排名越靠前,说明该预测指标与煤自燃温度之间的关联程度越高,越适合用于煤自燃温度预测。剔除排名靠后的预测指标,根据情况保留前6~8个预测指标,建立煤自燃温度预测指标体系。

将各预测指标的灰色关联度按由大到小顺序排列,该排序既为各预测指标与煤自燃温度之间关联程度的排名,排名越靠前,说明该预测指标与煤自燃温度之间的关联程度越高,越适合用于煤自燃温度预测。剔除排名靠后的预测指标,根据情况保留前6~8个预测指标,建立煤自燃温度预测指标体系。灰色关联度与关联度排名见表1。

表 1 灰色关联度与关联度排名Table 1. Grey relational degree and ranking指标 O2 CO2 CO CH4 C2H6 C2H4 φ(CO)/φ(O2) φ(C2H6)/φ(CH4) φ(C2H4)/φ(CH4) φ(C2H4)/φ(C2H6) 关联度 0.88 0.94 0.90 0.89 0.881 0.86 0.87 0.92 0.86 0.86 关联度排名 5 1 3 4 6 9 7 2 8 10 经过上述数据处理后,最终保留灰色关联度排名前6的预测指标(φ(CO2)、φ(C2H6)/φ(CH4)、φ(CO)/φ(O2)、φ(CO)、φ(CH4)、O2消耗量、φ(C2H6))建立煤自燃温度预测指标体系,为下文煤自燃温度预测模型的建立以及煤自燃温度预测可视化平台的开发奠定了基础。

2.2 基于Elman煤自燃温度回归预测模型

建立的煤自燃温度递归神经网络预测模型将输入的数据集通划分为训练集和验证集;然后建立递归神经网络的网络结构,确定递归神经网络的网络超参数;最后建立Elman煤自燃温度预测模型并选取验证集对预测模型进行验证,得到预测精度理想的预测模型。

2.2.1 神经网络模型的建立与超参数确定

1)模型数据集。Elman神经网络回归预测模型中训练集的数量取决于样本数据集的数量。根据3∶1的比值划分训练集与测试集,模型的输出即预测结果为煤自燃温度。

2)Elman层数。Elman神经网络的层数即神经网络结构中隐含层与承接层的数量。Elman层数对神经网络的预测效果起到十分直接的影响。测试采用控制变量法,在保持其他超参数不变的条件下比较不同Elman层数预测模型的预测效果,确定最佳的Elman层数为1。

3)神经元个数。Elman神经网络中神经元数量会对神经网络的预测效果起到直接影响。神经元数量越多,隐含层所能处理的信息也就越多,但也可能造成信息的重叠与冗余;但神经元过少,会造成神经网络在训练过程中丢失数据中的部分关键信息,导致预测结果准确度下降,因此模型的神经元数量应取15。

4)其余参数。对采取经验原则,选取Elman神经网络默认激活函数Tanh函数作为激活函数,选取神经网络最常用的MSE函数(均方误差)作为损失值的计算方式。选用SGDM作为优化函数。初始学习率主要用于控制优化函数对网络权重更新的速率,选取初始学习率为0.01。

2.2.2 煤自燃温度预测模型性能分析

为证明建立的Elman神经网络模型在煤自燃温度预测方面的可靠性与适用性,分别与BP神经网络与RBF神经网络进行精度分析。不同神经网络模型预测结果如图5所示,预测误差表见表2。

表 2 预测误差表Table 2. Prediction error table预测模型 均方根误差 最大绝对误差 Elman 2.710 7.103 BP 6.754 20.390 RBF 4.626 10.299 由图5和表2可知:Elman神经网络模型的预测输出的曲线贴近期望输出曲线,在输出结果偏大或偏小时,Elman神经网络模型的表现更加突出。Elman神经网络模型的2种误差值相对较小,说明Elman神经网络模型的预测效果较好,并且与BP神经网络及RBF神经网络进行对比,Elman神经网络模型的预测效果最优,建立的煤自燃温度预测模型有较好的可靠性与适用性。

3. 结 语

1)通过实验室实验、理论分析、模型构建等方法,开展砚北矿煤自燃温度预测研究,通过煤氧化升温实验得到煤样在氧化升温过程中的温度以及气体产物成分和体积分数。

2)分析了各预测指标与煤自燃温度之间的相关性,然后基于多源数据预处理方法,建立了煤自燃温度预测指标体系。

3)以煤自燃温度预测指标体系为基础,并结合Elman神经网络模型,确定Elman神经网络的Elman层数、神经元个数、激活函数、损失函数、优化函数、初始学习率等模型超参数,建立了基于Elman的煤自燃温度预测模型。

4)对该模型的预测结果进行性能分析,结果表明:Elman温度预测模型的预测均方根误差仅为2.710,最大绝对误差为7.103,相比于其他温度预测模型,误差较小,预测效果较好。基于Elman的煤自燃温度预测模型有较好的可靠性与适用性,在煤自燃灾害预测方面具有推广价值。

-

-

[1] 潘一山,李忠华,章梦涛. 我国冲击地压分布、类型、机理及防治研究[J]. 岩石力学与工程学报,2003(11):1844−1851. doi: 10.3321/j.issn:1000-6915.2003.11.019 PAN Yishan, LI Zhonghua, ZHANG Mengtao. Distribution, type, mechanism and prevention of rockbrust in China[J]. Chinese Journal of Rock Mechanics and Engineering, 2003(11): 1844−1851. doi: 10.3321/j.issn:1000-6915.2003.11.019

[2] 孙光裕,杨付领,乞朝欣. 贵州省煤矿安全现状分析及对策研究[J]. 煤矿安全,2021,52(9):245−249. SUN Guangyu, YANG Fuling, QI Chaoxin. Analysis and countermeasures of coal mine safety in Guizhou Province[J]. Safety in Coal Mines, 2021, 52(9): 245−249.

[3] 方书昊,霍雨佳,郭晋麟,等. 不同动载对煤岩块的破坏作用数值模拟[J]. 煤矿安全,2021,52(1):184−188. FANG Shuhao, HUO Yujia, GUO Jinlin, et al. Numerical simulation of failure of coal and rock blocks under different dynamic loads[J]. Safety in Coal Mines, 2021, 52(1): 184−188.

[4] 徐雪战. 矿井防突信息预测装备体系与应用效果[J]. 煤矿安全,2020,51(12):100−104. XU Xuezhan. Mine outburst prevention lnformation prediction equipment system and lts application effect[J]. Safety in Coal Mines, 2020, 51(12): 100−104.

[5] 尹智鹏. 瓦斯管理三级预警机制的建立及应用[J]. 煤矿安全,2020,51(12):292−295. YIN Zhipeng. Establishment and application of three-level warning mechanism for gas management[J]. Safety in Coal Mines, 2020, 51(12): 292−295.

[6] 牟义. 综采工作面带压区域电磁波CT探测小构造技术[J]. 煤矿安全,2019,50(12):69−75. MU Yi. Technique of detecting small structure with electromagnetic wave CT in pressure zone of fully mechanized mining face[J]. Safety in Coal Mines, 2019, 50(12): 69−75.

[7] 潘一山,罗浩,肖晓春,等. 三轴条件下含瓦斯煤力电感应规律的试验研究[J]. 煤炭学报,2012,37(6):918−922. PAN Yishan, LUO Hao, XIAO Xiaocun, et al. Experimental study on mechanical-charge induction law of coal containing gas under triaxial compression[J]. Journal of China Coal Society, 2012, 37(6): 918−922.

[8] 潘一山,赵扬锋,李国臻. 冲击地压预测的电荷感应技术及其应用[J]. 岩石力学与工程学报,2012,31(S2):3988−3993. PAN Yishan, ZHAO Yangfeng, LI Guozheng. Charge-induced technique of rockburst prediction and its application[J]. Chinese Journal of Rock Mechanics and Engineering, 2012, 31(S2): 3988−3993.

[9] 杜涛涛. 冲击地压煤矿井上下微震联合监测技术[J]. 煤矿安全,2022,53(7):92−98. DU Taotao. Joint monitoring of surface and underground micro-seismic monitoring technology in rockburst coalmine[J]. Safety in Coal Mines, 2022, 53(7): 92−98.

[10] 王恩元,何学秋,刘贞堂,等. 受载岩石电磁辐射特性及其应用研究[J]. 岩石力学与工程学报,2002(10):1473−1477. doi: 10.3321/j.issn:1000-6915.2002.10.008 WANG Enyuan, HE Xueqiu, LIU Zhentang. Study on electromagnetic emission characteristics of loaded rock and its applications[J]. Chinese Journal of Rock Mechanics and Engineering, 2002(10): 1473−1477. doi: 10.3321/j.issn:1000-6915.2002.10.008

[11] 何学秋,刘明举. 含瓦斯煤岩破坏电磁动力学[M]. 徐州:中国矿业大学出版社,1995. [12] 王恩元,何学秋,聂百胜,等. 电磁辐射法预测煤与瓦斯突出原理[J]. 中国矿业大学学报,2000(3):225−229. doi: 10.3321/j.issn:1000-1964.2000.03.001 WANG Enyuan, HE Xueqiu, NIE Baisheng, et al. Principle of predicting coal and gas outburst using electromagnetic emission[J]. Journal of China University of Mining & Technology, 2000(3): 225−229. doi: 10.3321/j.issn:1000-1964.2000.03.001

[13] Воларович, ПарxоменкоЭИ. Пьезоэлектрически ифектго рныхпород[J]. ДАН СССР, 1954, 99(2): 239.

[14] Nitson U. Electromagnetic emission accompanying fracture of quartz-bearing rocks[J]. Geophysical Research Letters, 1977, 4(8): 333−336. doi: 10.1029/GL004i008p00333

[15] 徐为民,童芜生,王自成. 单轴压缩下岩样破坏过程中的发光现象[J]. 地震,1984(1):8−10. [16] 赵扬锋,潘一山. 单轴压缩下花岗岩电磁信号的实验研究[J]. 中国地质灾害与防治学报,2009,20(3):132−137. ZHAO Yangfeng, PAN Yishan. Study on the charge and magnetic signals of granite samples under uniaxial compression[J]. The Chinese Journal of Geological Hazard and Control, 2009, 20(3): 132−137.

[17] 赵扬锋,潘一山,李国臻,等. 岩石变形破裂过程中电荷感应信号的检测[J]. 防灾减灾工程学报,2010,30(3):252−256. ZHAO Yangfeng, PAN Yishan, LI Guozheng, et al. Measuring of the charge-induced signal of rock during the deformation and fracture process[J]. Journal of Disaster Prevention and Mitigation Engineering, 2010, 30(3): 252−256.

[18] 王恩元,何学秋,刘贞堂,等. 煤岩动力灾害电磁辐射监测仪及其应用[J]. 煤炭学报,2003(4):366−369. WANG Enyuan, HE Xueqiu, LIU Zhentang, et al. Electromagnetic radiation detector of coal or rock dynamic disasters and its application[J]. Journal of China Coal Society, 2003(4): 366−369.

[19] 窦林名,何学秋,王恩元. 冲击矿压预测的电磁辐射技术及应用[J]. 煤炭学报,2004(4):396−399. DOU Linming, HE Xueqiu, WANG Enyuan. Electromagnetic emission technique of monitoring rock burst and its application[J]. Journal of China Coal Society, 2004(4): 396−399.

[20] Шевцов Г И, Мигунов Н И и др. Электризацияполе выхшта-повпридефформациии разру-шении[J]. ДАНСССР, 1975, 225(2): 313−315.

[21] 王丽华,孙正江,陈化然. 岩石样品破裂时带电现象的研究[C]//八十年代中国地球物理学进展. 北京:学术书刊出版社,1989:204-209. [22] 潘一山,唐治,李忠华,等. 不同加载速率下煤岩单轴压缩电荷感应规律研究[J]. 地球物理学报,2013,56(3):1043−1048. PAN Yishan, TANG Zhi, LI Zhonghua, et al. Research on the charge inducing regularity of coal rock at different loading rate in uniaxial compression tests[J]. Chinese Journal of Geophysics, 2013, 56(3): 1043−1048.

-

期刊类型引用(2)

1. 孙吉平. 基于SF_6质量浓度变化特征的煤矿火灾状态识别分析. 山西煤炭. 2025(01): 42-49 .  百度学术

百度学术

2. 王银辉. 基于ReaxFF的不黏煤燃烧过程中自由基及主要燃烧产物生成规律研究. 矿业安全与环保. 2024(04): 80-89 .  百度学术

百度学术

其他类型引用(0)

下载:

下载: