Creep-seepage evolution of coal under different temperatures, confining pressures, and gas pressures

-

摘要:

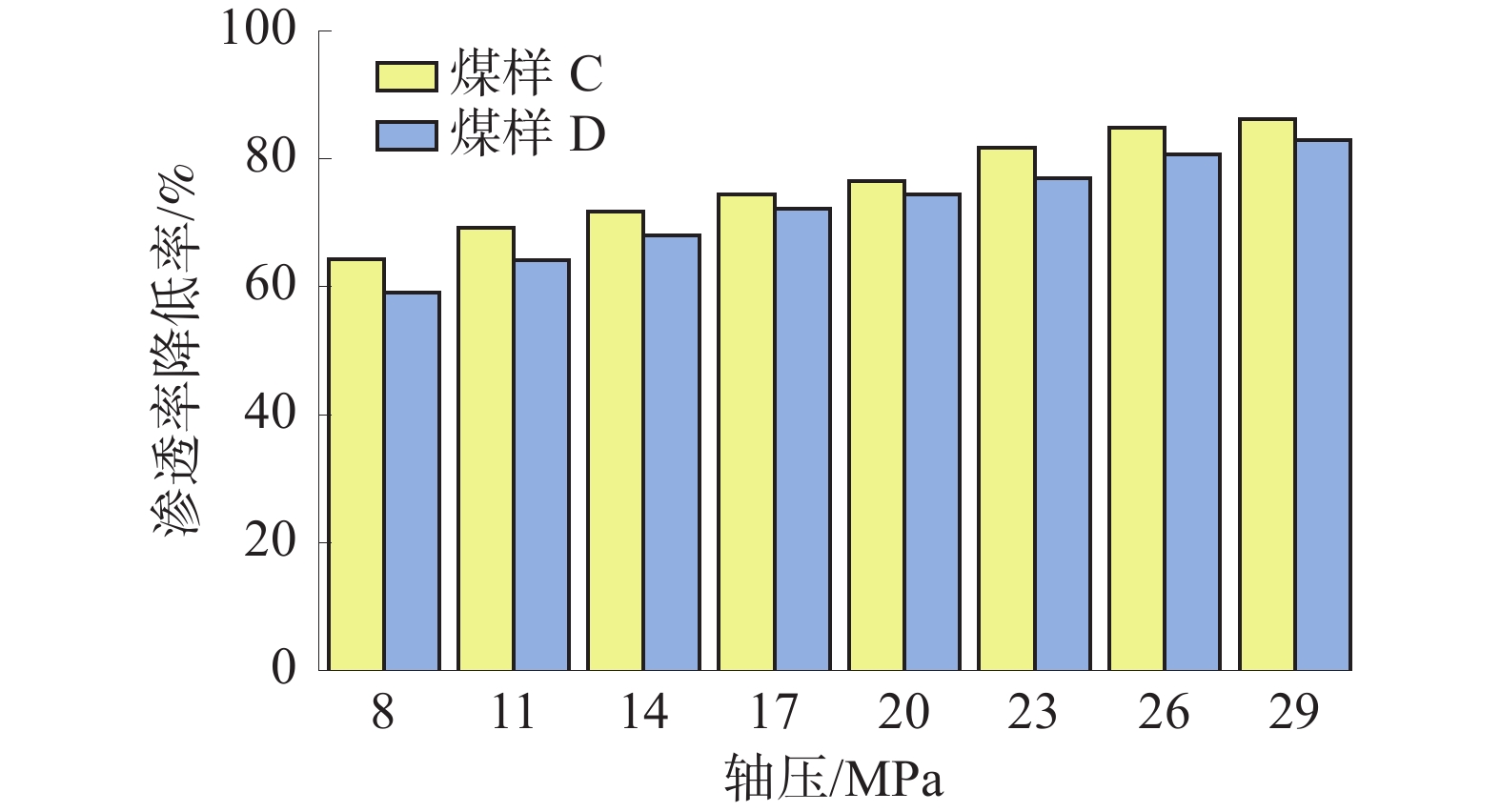

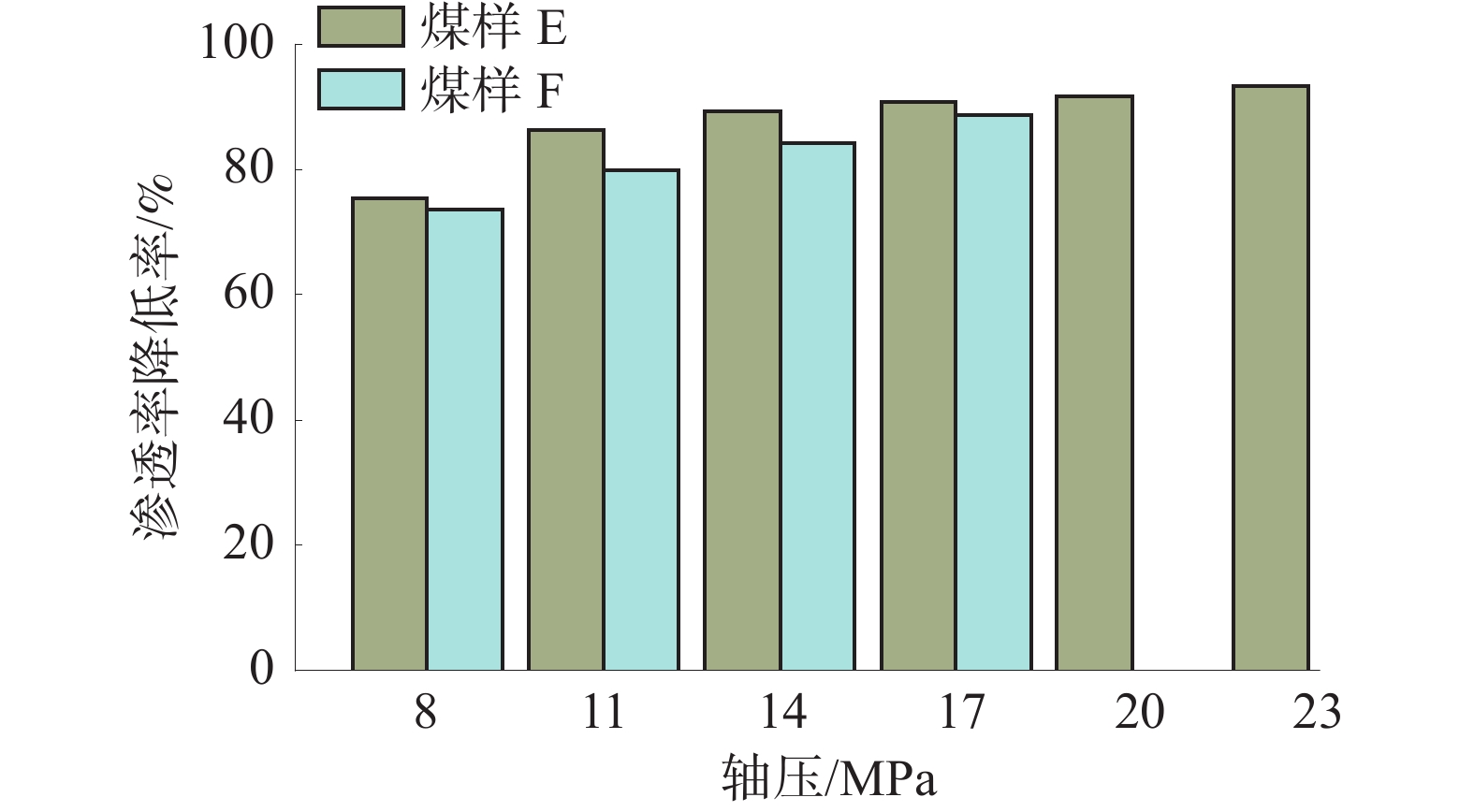

为实现深部煤层气的高效开采,通过研究不同温度、围压和气体压力下煤体蠕变变形和渗透率演化规律,得到多因素作用下煤体蠕变-渗流耦合关系;采用自行设计的岩石三轴蠕变-渗流装置,对焦煤进行多因素变量下的压缩蠕变-渗流试验。结果表明:温度与煤样的蠕变呈正相关性,随温度的增加焦煤煤样径向和轴向应变变化速率增大且高温(110 ℃)下这种变化会一直持续直至煤样破裂;围压强度3 MPa与4 MPa的焦煤煤样在温度30、70、110 ℃下其气体渗透率降低率最大和最小差值分别为7.8%、5.2%、6.5%和4.2%、2.1%、1.9%;焦煤煤样的渗透率最大降低率随着温度水平升高而增大,试验温度110、70、30 ℃下的焦煤煤样的气体渗透率最大降低率均值依次为91%、84.6%、73.25%。

-

关键词:

- 煤层气抽采 /

- 煤体蠕变变形 /

- 煤体渗透率 /

- 煤体蠕变-渗流耦合 /

- 三轴压缩蠕变-渗流试验

Abstract:In order to realize the efficient mining of deep coalbed methane, through studying the creep deformation and permeability evolution laws of coal mass under different temperatures, confining pressures and gas pressures, we obtain the coupling relationship between creep and seepage of coal mass under the action of multiple factors. A self-designed rock triaxial creep and seep device was used to carry out a compressive creep and seepage experiment on coking coal under multi-factor variables. The results show that: temperature is positively correlated with the creep of coal sample: the change rate of radial and axial strain of coking coal sample increases with the increase of temperature, and the change will continue until the coal sample cracks at high temperature (110 ℃). The maximum and minimum difference of gas permeability reduction rates of coke coal samples with confining pressures of 3 MPa and 4 MPa at temperatures of 30 ℃, 70 ℃,110 ℃ are 7.8%, 5.2%, 6.5% and 4.2%, 2.1%, 1.9%, respectively. The maximum reduction rate of permeability of coking coal sample increases with the increase of temperature. The average maximum reduction rates of permeability of coke coal samples at 110 ℃, 70 ℃ and 30 ℃ are 91%, 84.6% and 73.25%, successively.

-

我国金属矿、煤矿等主要依靠井工开采,当发生冒顶、透水等井下灾害事故造成人员被困时,由于巷道坍塌严重,次生灾害频发,导致井下救援受限[1-3]。地面救援是一种首先施工大直径应急救援井,然后以提升舱为载体,使用提升设备将被困人员从井下提升至地面的救援方式,具有速度快、可保证救援人员安全等特点,在国内外已有多个成功应用实例[4-5]。国外矿难救援的成功,特别是2010年智利矿难救援的壮举,给予我国矿山救援装备制造企业很大的启发,国内外先后生产了不同规格型号的救援提升舱[6-8],但普遍存在功能单一、对被救人员和设备的保护性不足、缺乏指导救援系统及方法等问题。

中煤科工西安研究院(集团)有限公司在“十三五”国家重点研发计划课题“地面应急救援井安全提升装备”的资助下,研制了多功能柔性救援提升舱,从救援指挥系统、柔性转动、导向、缓冲、钢丝绳与舱体分动、断绳保护、救援提升方法等多方面提出了解决方案,以加强对人员和设备的保护,提高地面大直径钻孔提升救援的成功率、安全性、规范性。

1. 柔性救援能提升舱总体方案

经过充分调研,对煤矿巷道结构进行实地考察,并根据人机工程学原理,确定了救生舱的设计参数。矿用应急救援提升舱外径550 mm,内部净高1 930 mm,每次可载1名人员,要求舱体对钻孔的适应性、通过性强,同时实现空气监测、二次逃生、实时通信等功能,二次逃生高度800 m。提升舱主要包括上导向、上舱段、柔性转动装置、人员舱、下舱段、下导向、分动装置、断绳保护装置、上侧缓冲、下侧缓冲、底部缓冲、救援指挥系统等方面。柔性救援提升舱总体方案如图1所示。

提升舱整体结构为“子弹形”,从上到下的连接顺序为上导向、上舱段、柔性转动装置、人员舱、下舱段、下导向。分动装置安装于上导向与上舱段的结合面,上侧缓冲和断绳保护装置安装于上舱段内部,下侧缓冲安装于下舱段内部,底部缓冲安装于下舱段与下导向的结合面。上导向、下导向均为锥形结构,有利于提升舱下放和提升时进入救援孔[9]。救援钢丝绳同时具备提升舱体和救援指挥系统通信2方面的功能。

柔性救援提升舱实现可视化救援指挥、救生舱柔性转动、通信钢丝绳防扭转等功能,以加强提升舱的通过性和对人员和设备的保护,提高地面大直径钻孔提升救援的成功率、安全性、规范性。

2. 分动装置

分动装置实现了通信钢丝绳与提升舱的分动,避免救援过程中提升舱带动通信钢丝绳旋转,干扰内部信号传输,损坏钢丝绳编织结构。不同于普通电信号滑环的分动结构[10],分动装置实现了通信钢丝绳与提升舱转动分动的同时,承受钢丝绳轴向拉力,进而实现了通信钢丝绳提升和通信的双重功能。分动装置结构图如图2所示。

悬挂轴为阶梯式通轴结构,轴内部为中空,上部加工有紧固螺纹,悬挂轴下端法兰安装于上导向和上舱段的结合面,悬挂轴上端小直径段与上导向的固定板配合安装(悬挂轴安装时应从上导向底部向上安装);垫板1安装在悬挂台肩上,止推轴承1的2个端面分别与垫板1和接头下凹槽端面接触,止推轴承2的2个端面分别与接头上凹槽端面和垫板2接触;锁紧螺母通过悬挂轴上的紧固螺纹将止推轴承、止推轴承、垫板1、垫板2、接头压紧至悬挂轴台肩上,实现接头与悬挂轴的分动(一方不随另一方转动)。滑环安装座固定在悬挂轴上端面,防爆滑环安装在滑环安装座中,滑环下部导线通过悬挂轴中空孔引至上舱段中的信号转换器,防爆滑环的上部导线通过拉板固定在接头上,滑环上部与下部通过防爆电刷分动;防爆滑环上部导线与通信钢丝绳内部电缆连接,将提升舱内的电信号通过通信钢丝绳传输至地面终端;销轴安装在接头上。通信钢丝绳通过锁具与销轴连接,实现提升舱的提升和下放。防爆滑环出线连接救援指挥系统在救生舱上安装的部分,实现通信系统的连通。

3. 柔性转动装置

地面大直径钻孔过程中,可能会出现钻孔偏斜、弯曲等情况,提升舱面临无法通过的风险[11]。通过在上舱段和人员舱中间设计柔性转动装置,使提升舱遭遇钻孔偏斜、弯曲时转动一定角度,增加其钻孔适应性和通过性。舱体小角度弯曲示意图如图3所示,柔性转动装置结构图如图4所示。

柔性转动装置包括柔性旋转座、旋转体、限转块、油杯。柔性旋转内部加工为球形面,旋转体外部加工为球形面,两者球形面的直径相同,柔性旋转座与旋转体通过内外球面配合,两者可绕球心在任意方向转动。柔性旋转座与上舱段连接,旋转体穿过柔性旋转座后通过可拆卸方式与人员舱连接;柔性旋转座圆周方向对称加工有2个方形凹台,限转块安装于凹台之上,限制柔性旋转与旋转体之间绕球心旋转的角度,避免提升舱过渡弯曲及旋转过程中剪断下舱段底部监控器的通信电缆,同时可根据钻孔轴线弯曲程度,安装不同大小的限转块,达到改变提升舱柔性角度α。

柔性转动装置通过油杯注射润滑液体,通过旋转体上的润滑孔道进入柔性旋转座与旋转体的配合球面,实现润滑。

柔性转动装置不同于机器人及仿生结构的柔性结构,主要承受轴向拉力的作用,且内部大直径中空,实现上舱段和下舱段的大空间连通。

提升救援过程中提升舱主要受力来源于旋转体及以下舱段的设备和人员质量,旋转体承受向下拉力,旋转座为壳体结构,可能出现外扩变形,导致旋转体滑落,出现人员坠落的二次事故,故重点对柔性旋转座与旋转体之间的接触球面进行受力分析。柔性转动装置应变云图如图5所示。

通过Workbench有限元分析可以看出,在静态加载10 000 N(人员质量及设备质量的6倍)情况下,最大变形量为0.024 mm,出现在内球铰体与下舱体连接块连接部位,远小于旋转件外直径与设备舱壳体内直径之间的距离,柔性旋转座与旋转体之间的接触球面强度满足迁都要求。

4. 缓冲装置

缓冲装置主要分为上侧缓冲、下侧缓冲、底部缓冲3个部分。上部缓冲安装于上舱段内部,下侧缓冲安装于下舱段内部,底部缓冲安装于下舱段与下导向的结合面。

上、下侧缓冲装置结构图如图6所示。上侧缓冲和下侧缓冲结构相同,均由6组缓冲体组成,在上舱段圆周方向均布,缓冲体由底座、弹簧、滚轮组成,自然状态下缓冲体的弹簧为伸长状态,6个滚轮外圆周构成的圆形直径大于救援钻孔直径;在提升舱下放、提升过程中,滚轮压缩弹簧,使6个滚轮外圆周构成的圆形直径等于救援钻孔直径,弹簧反作用力将滚轮压紧在救援钻孔孔壁上,通过弹簧压缩量随救援钻孔直径的变化而变化,由此达到下放、提升过程中对于救生舱和舱内人员的缓冲保护效果。

底部缓冲装置结构图如图7所示。底部缓冲由4组弹簧、套筒、导向销、底板组成,导向销穿过下导向底板的导向孔,一端与底板固定,底板和导向销整体可沿导向孔轴线上下自由滑动,上套筒、弹簧安装在导向销上,弹簧自然状态的长度大于套筒长度,提升舱到达人员被困巷道或提升至地面接触地面的过程中,底板最先接触地面压缩弹簧,至套筒支撑底板,实现提升舱着陆缓冲。其中,套筒长度应大于下舱段底部监控器的外露长度,避免着陆过程中底板损坏下舱段底部监控器。

5. 救援指挥系统

救援指挥系统如图8所示。救援指挥系统的上舱段顶部监控器、人员舱内部监控器、下舱段底部监控器分别对提升舱上部救援钻孔情况、提升舱内部人员情况、提升舱下部救援钻孔情况进行监控,气体浓度监测仪对舱内气体浓度进行监控,人员舱内部语音对讲器实现地面与舱内人员实时双向联系,气体浓度信号、监控视频和语音信号均通过信号转换器经通信钢丝绳传输至地面终端。地面终端通过通信监测软件界面对所有通信信号进行集中显示和指挥控制[12-15]。

6. 提升舱人机工程分析

提升救援过程中,人员舱内的人员在一定程度上会受到灾害带来的影响而受伤,从而出现行动不便和无力支撑等情况。因此,获救人员进入人员舱内,需要提供一定的身体支撑,对人员舱内部结构进行人机工程分析也是必不可少。

6.1 入舱情况分析

对人员入舱情况进行分析,根据救生舱结构尺寸,入舱门槛高600 mm,对人员入舱有阻碍,尤其对人体尺寸百分位数为P50以下的人群入舱行为产生明显的障碍。

为了解决被救人员入舱阻碍的问题,需要在人员舱舱门内部设置入舱扶手,人员入舱扶手高度应该设置在离地1 400~1 800 mm处,这样可对人体尺寸百分位数为P5~P95的人群给予借力的帮助,也方便被救人员顺利进入舱内。人员舱入舱扶手高度图如图9所示,

6.2 人员姿态情况分析

在被救人员入舱后,对其在人员舱内的姿态进行分析,加装一些舱内辅助人机工程组件,保障被救人员在人员舱内能够处于一个比较舒适的姿态。依、靠、扶、握可使保持的姿态省力、放松,也有助于抵抗救生舱舱体在救援提升过程中由于舱体晃动产生的心理不安因素,帮助安抚受救人员的紧张情绪。

一般人员舱内被救人员的舱内姿态分为靠坐握和站趴扶2种形式,舱内人员靠坐握姿态分析图如图10所示,舱内人员站趴扶姿态分析图如图11所示。

由图10可以看出,靠坐握姿态的舒适度高(绿色),可保持姿态较长时间而不会疲劳,可预测为被救援人员较长时间保持的姿态。由图11可以看出,站趴扶姿态舒适度略低(黄色),长时间坚持会产生肌肉疲劳,可预测为被救援人员暂时变换姿态短暂使用。

根据对人员舱内被救人员的姿态分析,选取靠坐握姿态为主要姿态依据,设计人机工程组件。需要在被救人员的臀部部位设计坐姿的支点,提供尺寸合适的坐姿点和扶手,应以人体尺寸百分位数为P50的人体模型双膝微屈姿态为基础原型,支点的高度740 mm,宽5 mm,形态圆润,防止碰撞对人体造成伤害,并且扶手高度应设置为890~1 160 mm。人员坐姿支点设计图如如图12所示。

当人员舱内被救人员坐姿调整为站立姿态时,提供尺寸合适的立姿扶手,应以人体尺寸百分位数为P50的人体模型身体前倾为基础原型,手扶舱壁的高度确定为1 515 mm,外形圆润,也要防止碰撞对人体造成伤害。人员立姿扶手支点设计图如图13所示。

6.3 安全防护情况分析

舱内需设置防撞装置,从而避免在救援提升过程中,被救人员在舱内发生碰撞造成伤害。防撞装置主要针对头部进行设置,沿舱壁设置橡胶条防撞,尺寸下线以人体尺寸百分位数为P5的人体尺寸模型坐姿状态下,受到晃动后头部撞击舱壁的位置为确定高度,上限以人体尺寸百分位数为P99的人体模型立姿头顶位置为确定高度。

舱体内壁需要设置安全挂钩,可将被救人员身上的安全带固定在安全挂钩上,也能起到在舱体碰撞过程中固定被救人员避免冲撞的危险。安全挂钩的安装高度应该以人体尺寸百分位数为P99的人体模型尺寸加上鞋与安全帽的修正尺寸为依据,确定为1 920 mm。安全挂钩安装示意图如图14所示。

7. 测试及试验

柔性救援提升舱与救援提升车共同构成了提升救援成套装备,在室内和施工现场分别对舱体弯曲角度和综合性能进行了测试和试验。

1)弯曲角度测试。将提升舱顶端吊起,底端着地,保持上下舱体弯曲至最大值,利用数显倾角仪测量上下舱体倾角度数得到舱体相对的弯曲角度。上下舱体2次测量的相对弯曲角度分别为2.2°和2.6°,均大于2°的指标,满足设计指标要求。

2)现场综合试验。通过宁夏梅花井矿施工的大直径救援井,对提升救援成套装备进行了综合检验。通过空载、重载、载人登试验验证了提升舱的综合性能。具体为:①提升舱内径满足人员正常或辅助站立,上下舱体间可摆动,配备有井径测量、气体测量和音视频通讯装置,能在580 mm以上的井筒内顺利通过,视频音频清晰度高,能清晰看到救援舱内和井壁内的运行变化,内壁圆整,套管与裸井段接缝处无明显凸起,提升舱可顺利通过井下通道;②在线气体测量功能正常,能实时显示气体浓度,从现场软件记录数据来看,测试孔段CO、H2S 2种气体体积分数为0,O2体积分数在20%~21.2%之间、CH4体积分数在0.2%~0.3%之间、CO2体积分数在0.01%~0.02%之间变化,大气压差在107~110 Pa 之间变化,温度在30~34 ℃之间变化;③提升舱在运行速度突变及载重情况下,结构稳固,音视频数据传输正常,试验验证了提升舱重载条件下的可靠性。

8. 结 语

研制了多功能矿用救援柔性提升舱。多功能救援柔性提升舱从救援指挥系统、柔性转动、导向、缓冲、钢丝绳与舱体分动等多方面提出了解决手段。实现了可视化救援指挥、通信钢丝绳防扭转、救生舱柔性转动等功能,提高地面大直径钻孔提升救援的成功率、安全性、规范性。

1)分动装置实现了通信钢丝绳与提升舱的分动,避免救援过程中提升舱带动通信钢丝绳旋转,干扰内部信号传输,损坏钢丝绳编织结构,为实现通信钢丝绳提升和通信的双重功能提供了技术支撑。

2)柔性转动装置实现了上下舱体的弯曲,增强了提升舱体对曲率较大、有局部凸起等复杂井壁的适应性,以加强提升舱的通过性。

3)通过人机工程学相关理论和技术,开发了人员舱内辅助入舱、靠坐握姿态等人机工程组件,对被救人员进行全方位保护。

4)基于井径测量、气体测量和音视频通讯装置的通信系统则从监测井壁、气体及环境参数、被救人员等多方面实现可视化救援,保证救援过程的安全。

-

表 1 试验方案

Table 1 Experimental schemes

试验组 温度/

℃瓦斯压

力/MPa围压/

MPa轴压/MPa 1 30.0 1.0 3.0 8、11、14、17、20、23、26、29 2 30.0 1.5 4.0 8、11、14、17、20、23、26、29 3 70.0 0.5 3.0 8、11、14、17、20、23、26、29 4 70.0 1.0 4.0 8、11、14、17、20、23、26、29 5 110.0 1.0 3.0 8、11、14、17、20、23、26、29 6 110.0 1.0 4.0 8、11、14、17、20、23、26、29 表 2 不同围压下煤样的蠕变起始强度和极限破坏强度

Table 2 Creep initial strength and ultimate failure strength of coal samples under different confining pressures

煤样 温度/℃ 围压/MPa 蠕变起始强度/MPa 破坏应力强度/MPa A 30 3 8 无破坏 B 30 4 11 无破坏 C 70 3 8 29 D 70 4 11 无破坏 E 110 3 8 23 F 110 4 11 20 -

[1] 谢和平,高峰,鞠杨,等. 深地煤炭资源流态化开采理论与技术构想[J]. 煤炭学报,2017,42(3):547−556. XIE Heping, GAO Feng, JU Yang, et al. Theoretical and technological conception of the fluidization mining for deep coal resources[J]. Journal of China Coal Society, 2017, 42(3): 547−556.

[2] 黄中伟,李国富,杨睿月,等. 我国煤层气开发技术现状与发展趋势[J]. 煤炭学报,2022,47(9):3212−3238. HUANG Zhongwei, LI Guofu, YANG Ruiyue, et al. Review and development trends of coalbed methane exploitation technology in China[J]. Journal of China Coal Society, 2022, 47(9): 3212−3238.

[3] 申建. 我国主要盆地深部煤层气资源量预测[D]. 徐州:中国矿业大学,2021. [4] 何满潮. 深部建井力学研究进展[J]. 煤炭学报,2021,46(3):726−746. HE Manchao. Research progress of deep shaft construction mechanics[J]. Journal of China Coal Society, 2021, 46(3): 726−746.

[5] 王路军,周宏伟,荣腾龙,等. 深部煤体非线性蠕变本构模型及实验研究[J]. 煤炭学报,2018,43(8):2196−2202. WANG Lujun, ZHOU Hongwei, RONG Tenglong, et al. Research on experimental and nonlinear creep constitutive model of coal at depth[J]. Journal of China Coal Society, 2018, 43(8): 2196−2202.

[6] 谢生荣,王恩,陈冬冬,等. 深部强采动大断面煤巷围岩外锚-内卸协同控制技术[J]. 煤炭学报,2022,47(5):1946−1957. XIE Shengrong, WANG En, CHEN Dongdong, et al. Cooperative control technology of external anchor-internal unloading of surrounding rock in deep large-section coal roadway under strong mining influence[J]. Journal of China Coal Society, 2022, 47(5): 1946−1957.

[7] 李祥春,张良,赵艺良. 常规三轴压力下含瓦斯煤蠕变-渗流演化规律[J]. 工程科学与技术,2018,50(4):55−62. LI Xiangchun, ZHANG Liang, ZHAO Yiliang. Evolution of gas-filled coal greep-seepage under conventional triaxial compression[J]. Advanced Engineering Sciences, 2018, 50(4): 55−62.

[8] XU Weiya, WANG Rubin, WANG Wei, et al. Creep properties and permeability evolution in triaxial rheological tests of hard rock in dam foundation[J]. Journal of Central South University, 2012, 19(1): 252−261. doi: 10.1007/s11771-012-0999-0

[9] 何峰,王来贵,王振伟,等. 煤岩蠕变-渗流耦合规律实验研究[J]. 煤炭学报,2011,36(6):930−933. HE Feng, WANG Laigui, WANG Zhenwei, et al. Experimental study on creep-seepage coupling law of coal (rock)[J]. Journal of China Coal Society, 2011, 36(6): 930−933.

[10] 蔡婷婷,冯增朝,姜玉龙,等. 不同温度应力下煤体蠕变中的渗流规律研究[J]. 岩石力学与工程学报,2018,37(S2):3898−3904. CAI Tingting, FENG Zengchao, JIANG Yulong, et al. Seepage evolution in coal creep under different temperatures and different stresses[J]. Chinese Journal of Rock Mechanics and Engineering, 2018, 37(S2): 3898−3904.

[11] 曹亚军,王伟,徐卫亚,等. 低渗透岩石流变过程渗透演化规律试验研究[J]. 岩石力学与工程学报,2015(S2):3822−3829. CAO Yajun, WANG Wei, XU Weiya, et al. Permeability evolution of low-permeability rocks in triaxial creep tests[J]. Chinese Journal of Rock Mechanics and Engineering, 2015(S2): 3822−3829.

[12] 江宗斌,姜谙男,李宏,等. 加卸载条件下石英岩蠕变-渗流耦合规律试验研究[J]. 岩土工程学报,2017,39(10):1832−1841. doi: 10.11779/CJGE201710011 JIANG Zongbin, JIANG Annan, LI Hong, et al. Creep-seepage coupling laws of quartzite under cyclic loading-unloading conditions[J]. Chinese Journal of Geotechnical Engineering, 2017, 39(10): 1832−1841. doi: 10.11779/CJGE201710011

[13] ZHOU H W, WANG L J, RONG T L, et al. Creep-based permeability evolution in deep coal under unloading confining pressure[J]. Journal of Natural Gas Science and Engineering, 2019, 65: 185−196. doi: 10.1016/j.jngse.2019.03.010

[14] 张雷,周宏伟,王向宇,等. 考虑蠕变影响的深部煤体分数阶渗透率模型研究[J]. 岩土工程学报,2020,42(8):1516−1524. ZHANG Lei, ZHOU Hongwei, WANG Xiangyu, et al. Fractional permeability model for deep coal considering creep effect[J]. Chinese Journal of Geotechnical Engineering, 2020, 42(8): 1516−1524.

[15] ZHOU H W, ZHANG L, WANG X Y, et al. Effects of matrix-fracture interaction and creep deformation on permeability evolution of deep coal[J]. International Journal of Rock Mechanics and Mining Sciences, 2020, 127(2): 104236.

[16] 赵建会,许鸿忆. 不同含水率孔周煤岩体蠕变试验及蠕变模型研究[J]. 煤矿安全,2022,53(12):35−41. ZHAO Jianhui, XU Hongyi. Research on creep damage model of coal and rock mass around hole with different moisture contents[J]. Safety in Coal Mines, 2022, 53(12): 35−41.

[17] 郭泽雄,张东峰,王开,等. 分级加载速率对无烟煤蠕变特性的影响规律试验研究[J]. 煤矿安全,2022,53(8):1−7. GUO Zexiong, ZHANG Dongfeng, WANG Kai, et al. Experimental study on effect of graded loading rate on creep characteristics of anthracite[J]. Safety in Coal Mines, 2022, 53(8): 1−7.

[18] 杨玉良,蒋金虎,刘闯,等. 温度-应力耦合作用下无烟煤的蠕变特性与本构关系研究[J]. 煤矿安全,2020,51(5):61−65. YANG Yuliang, JIANG Jinhu, LIU Chuang, et al. Creep properties and constitutive relation of anthracite under temperature-stress coupling[J]. Safety in Coal Mines, 2020, 51(5): 61−65.

下载:

下载: