Influence of outlet parameters of wall attached air duct on dust control effect in heading face

-

摘要:

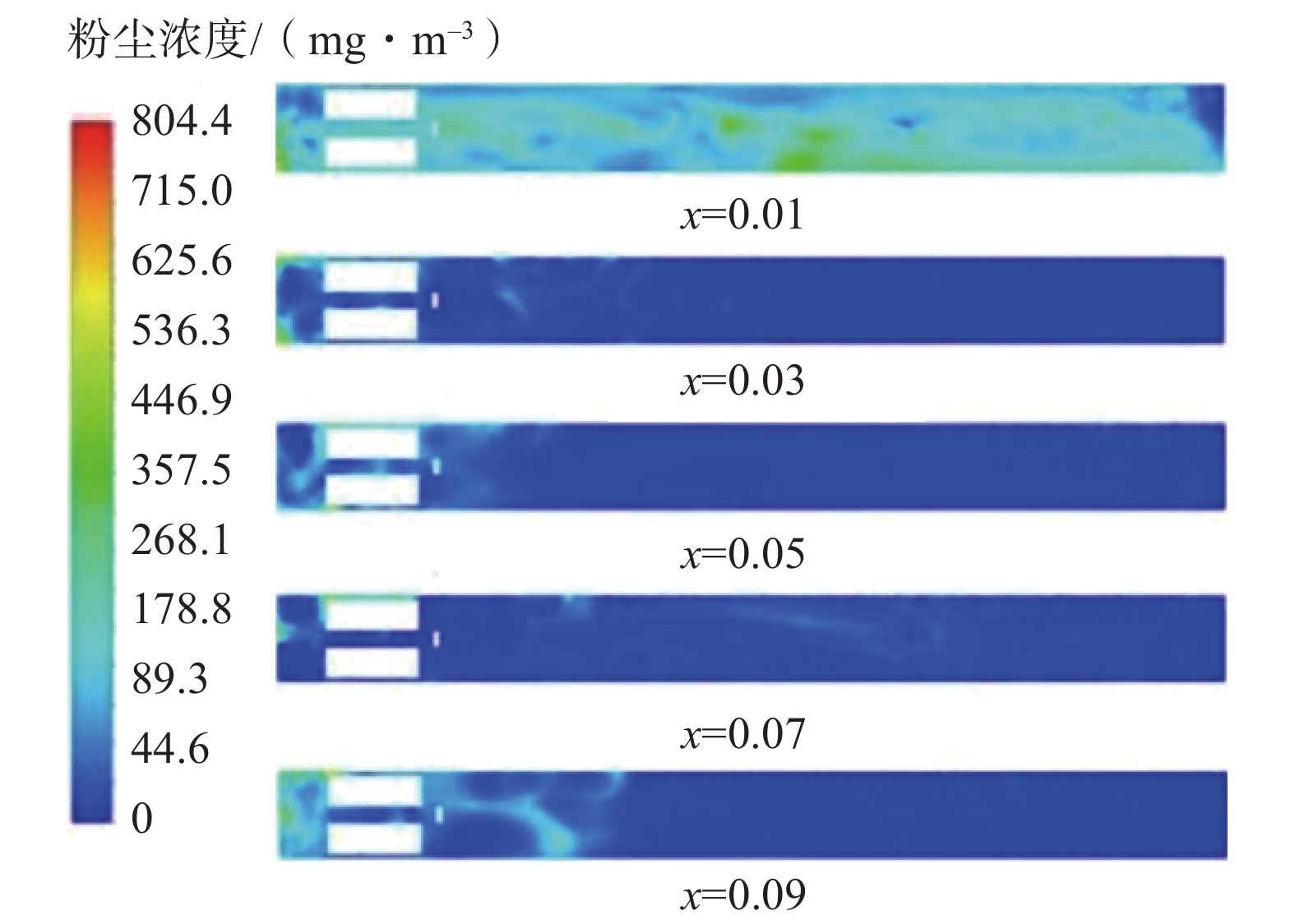

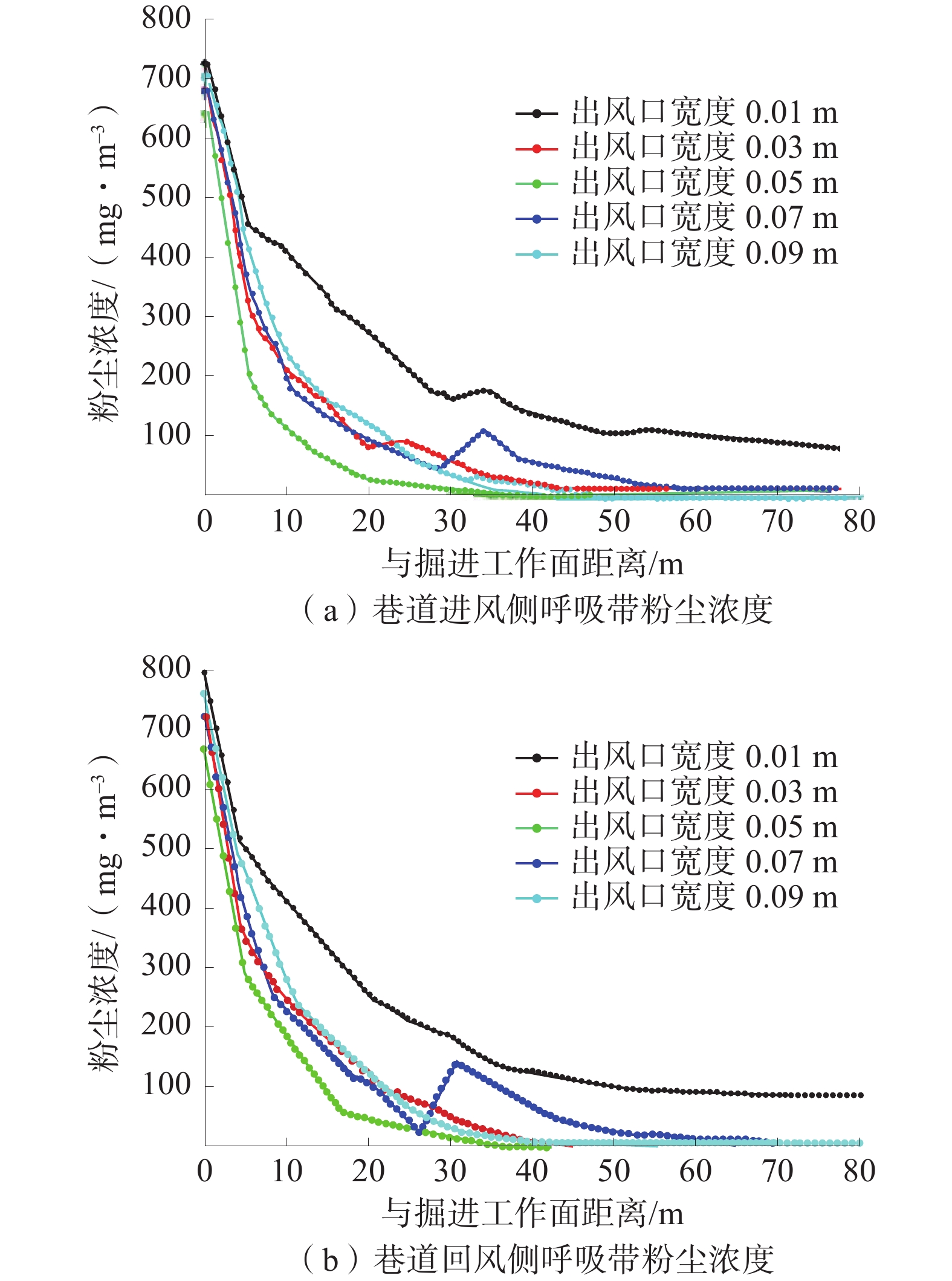

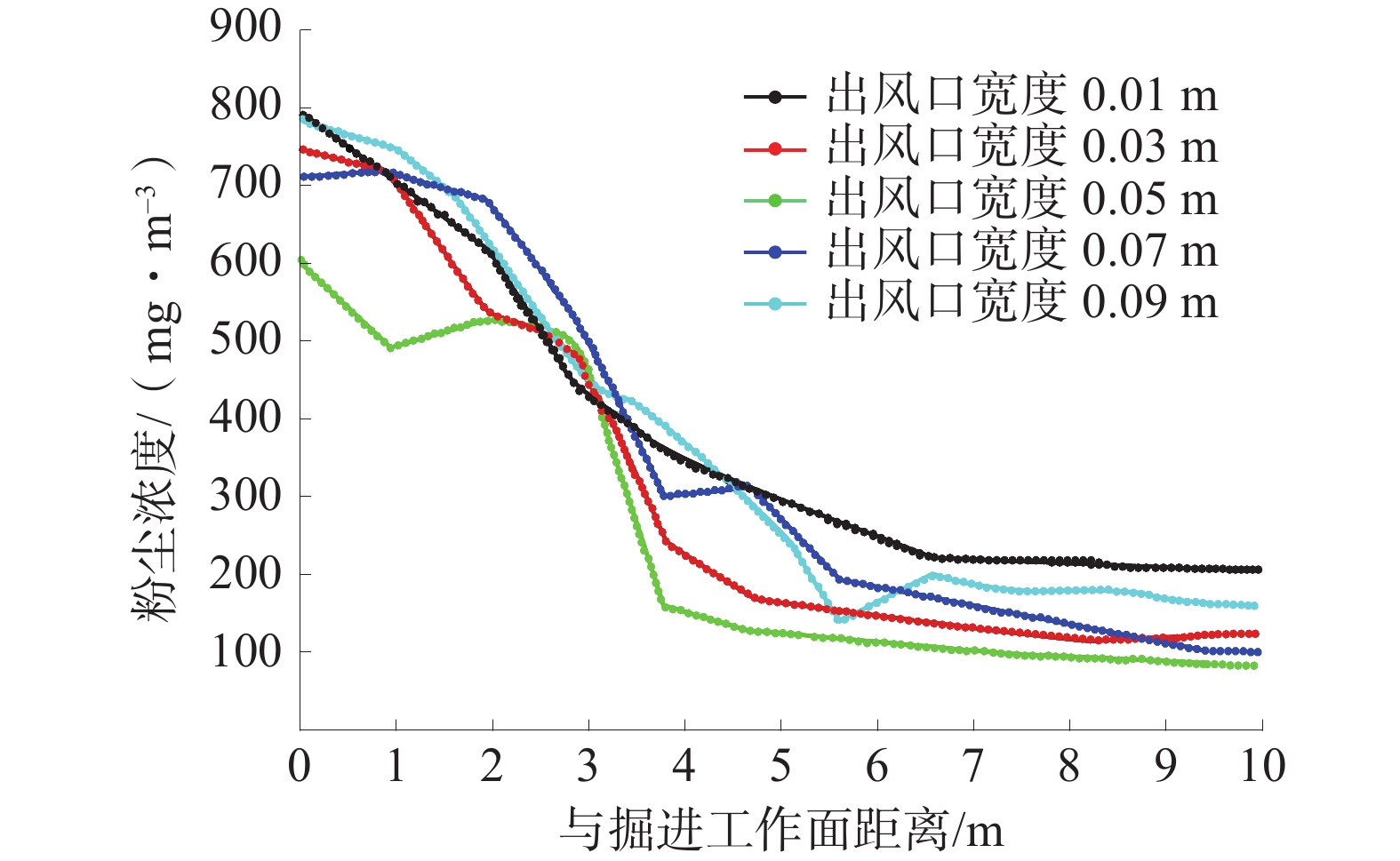

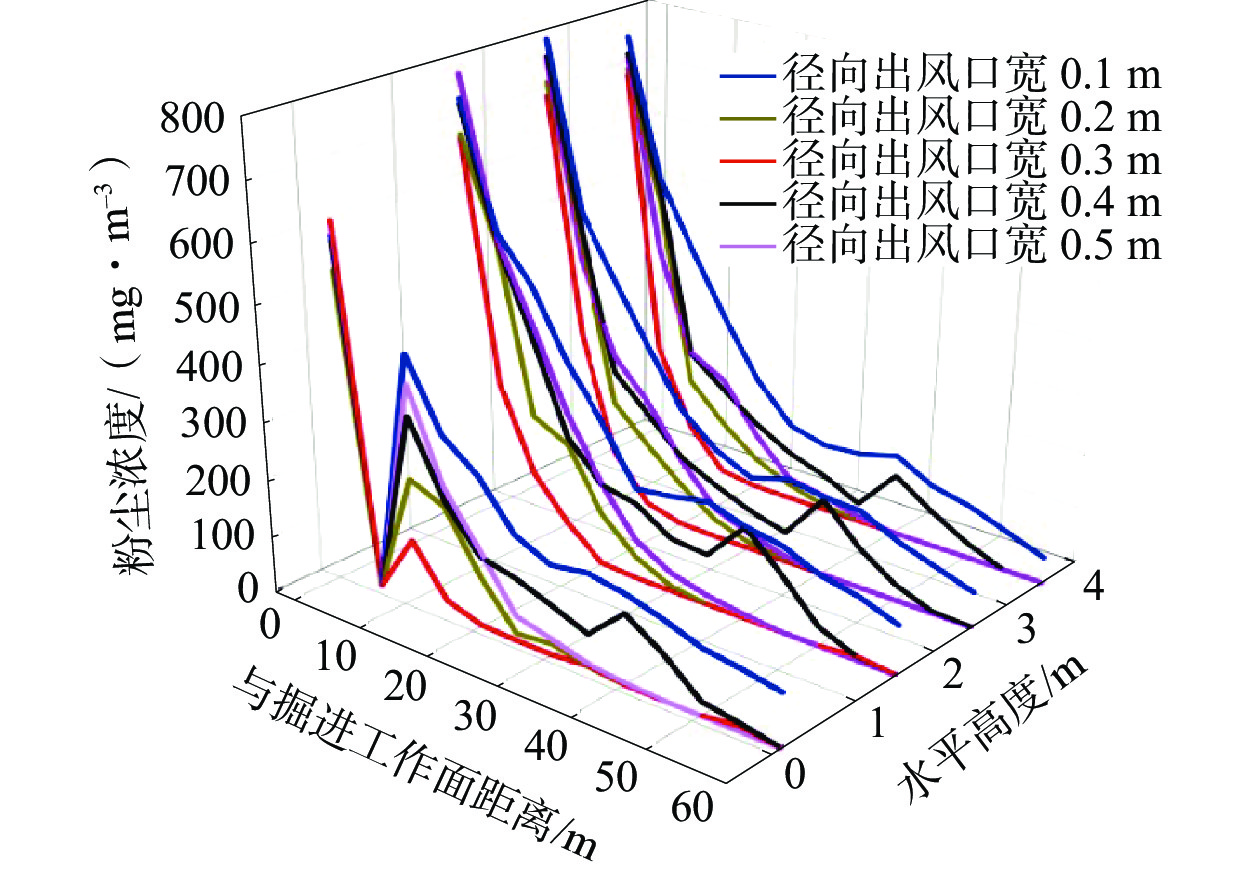

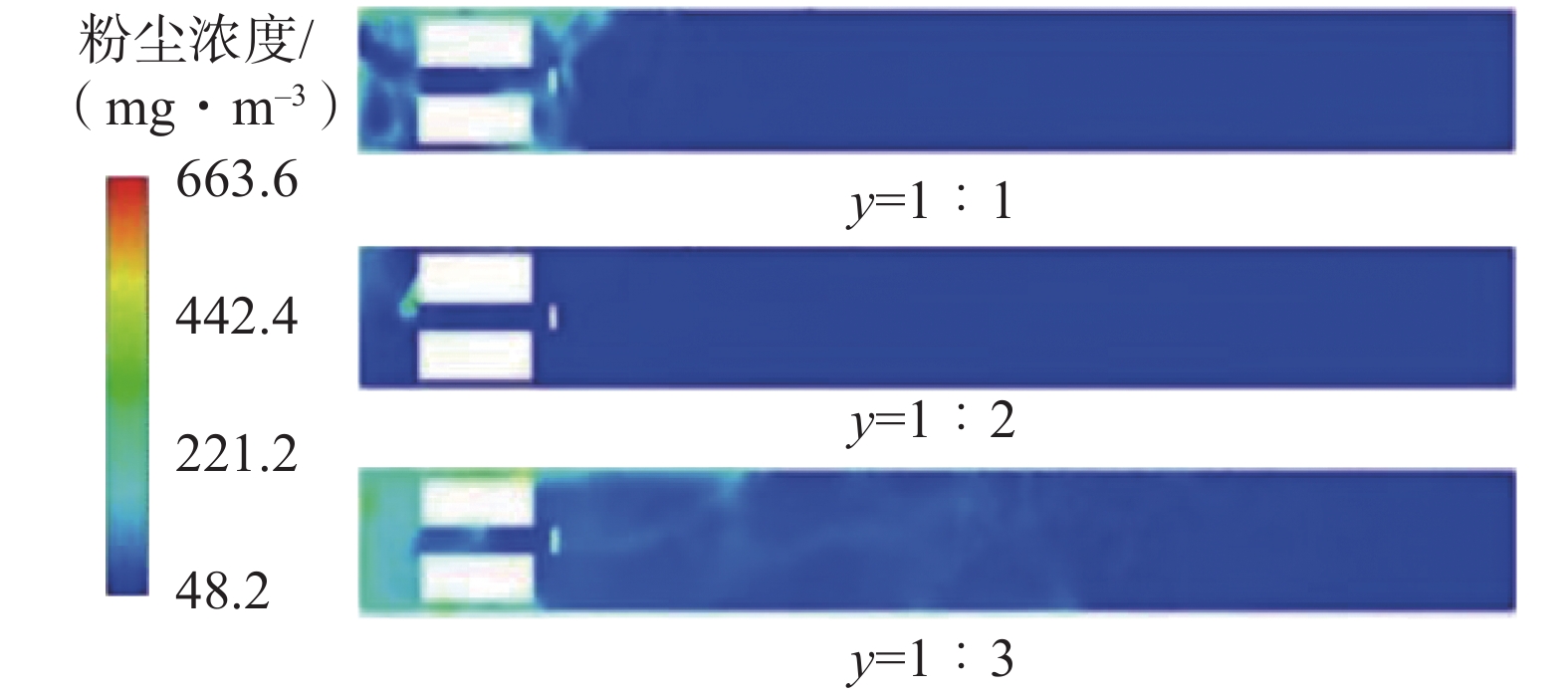

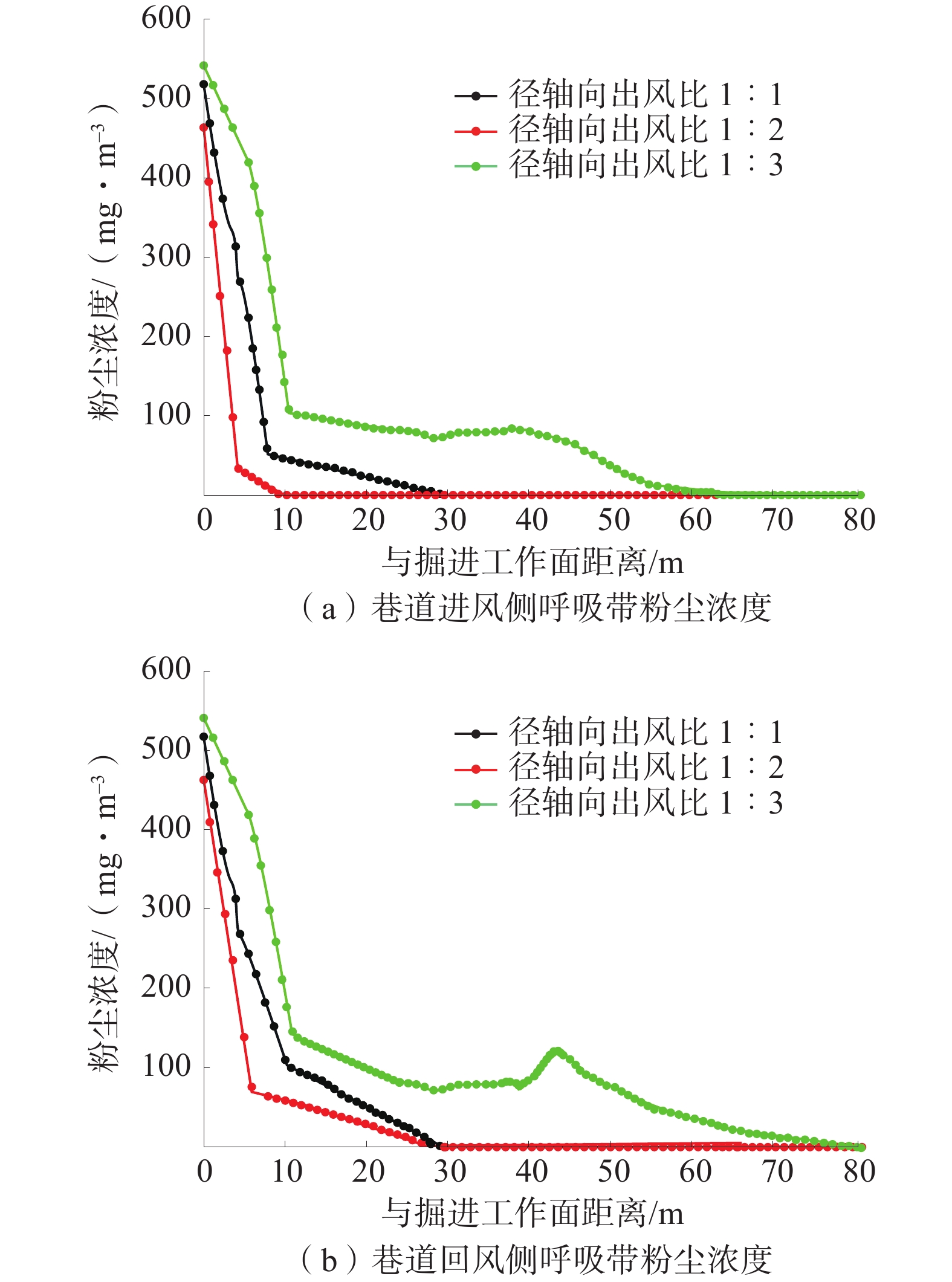

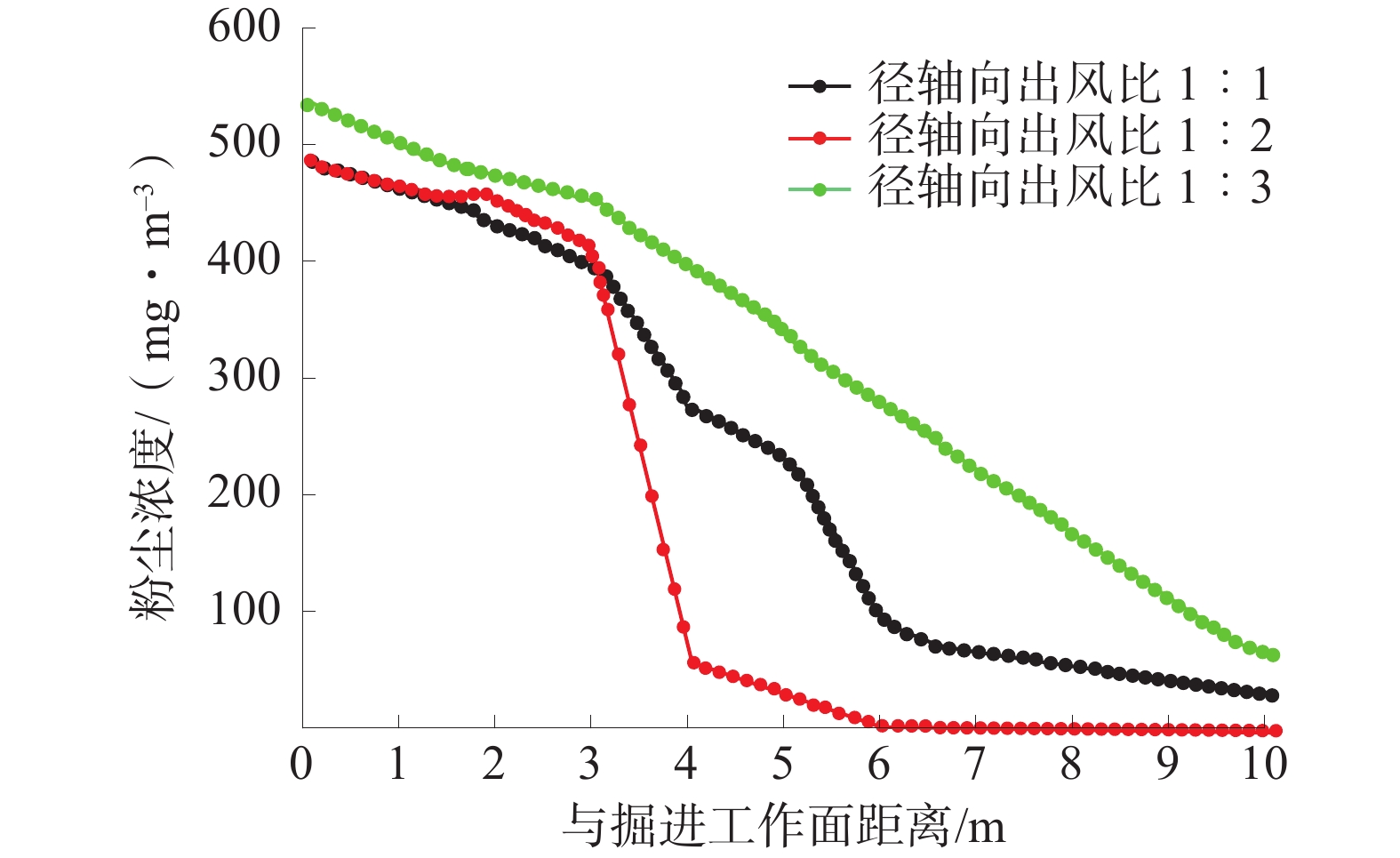

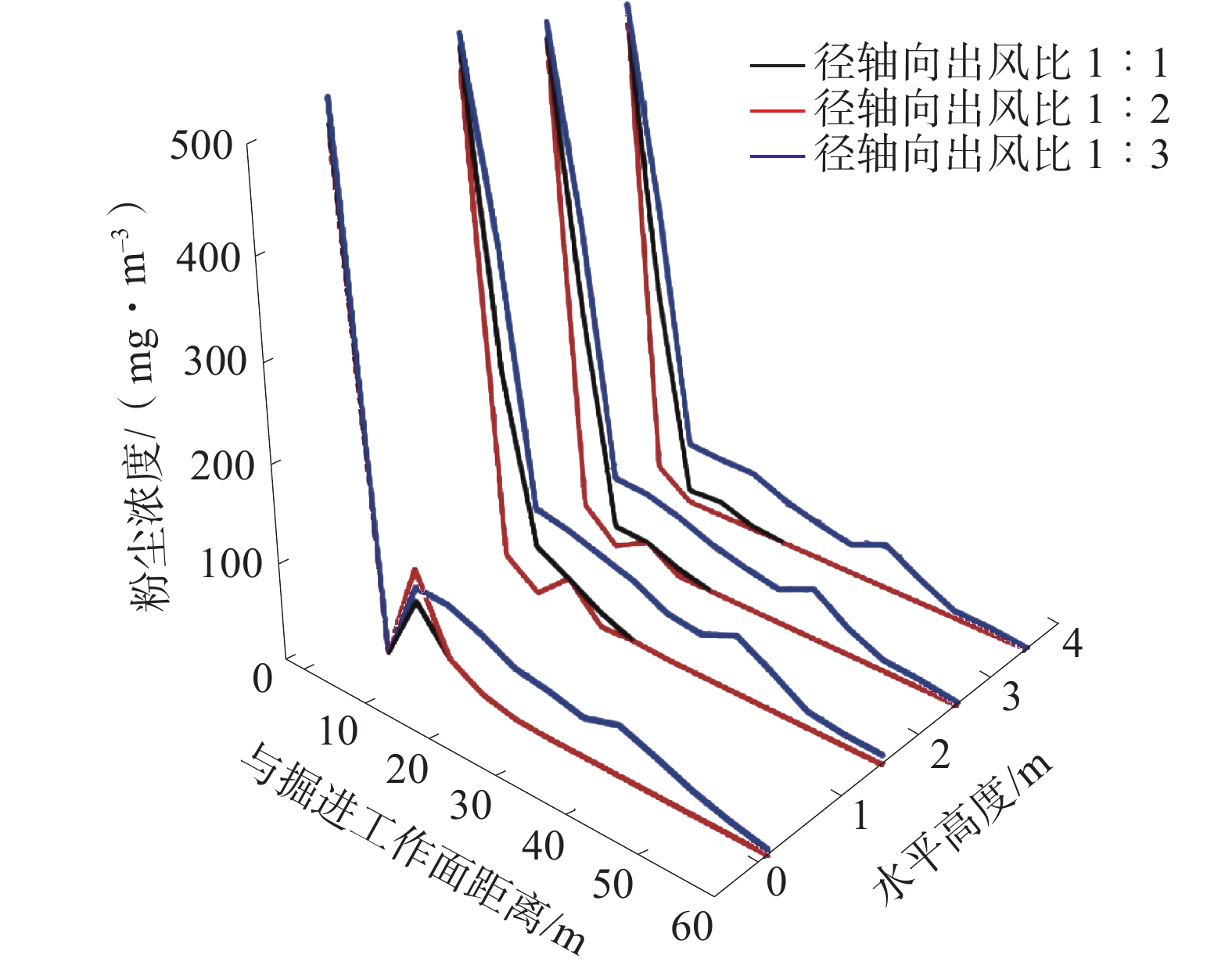

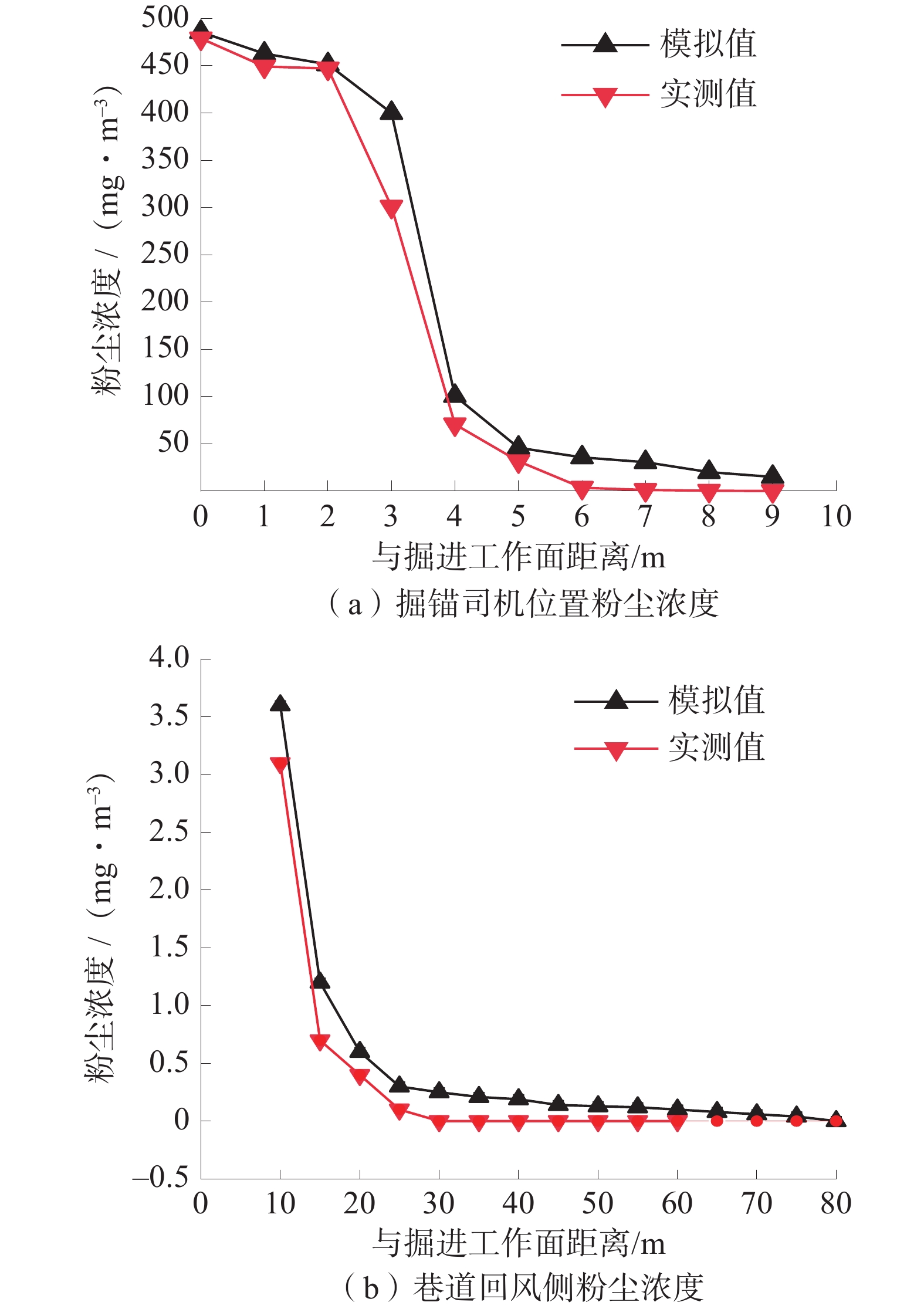

为明确径向出风式附壁风筒出风口宽度、径轴向出风比对综掘工作面控尘效果的影响,以冯家塔煤矿某综掘工作面为原型,运用FLUENT软件,对建立的长压短抽式通风综掘巷道模型进行数值模拟,并对模拟结果进行现场验证。结果表明:保持压抽比为1.3,径向出风口长为0.8 m时,随着出风口宽度增加,巷道空间内的粉尘浓度先减小随后增大,改变出风口宽度,当出风口宽度为0.05 m时,司机处粉尘浓度降至100 mg/m3,距掘进工作面20 m巷道内基本无粉尘,控尘效果最佳;保持最佳出风口宽度为0.05 m,随着径轴向出风比变小,巷道内粉尘浓度先减小后增大,当径向轴向出风比为1∶2时,粉尘被集中控制在负压抽吸区,掘锚机司机位置处粉尘浓度降至1.2 mg/m3,此时径向出风式附壁风筒控尘效果最佳。

Abstract:In order to clarify the influence of the air outlet width and the ratio of radial and axial air outlet of the wall attached air duct on the dust control effect of the fully mechanized face, taking a fully mechanized face in Fengjiata Coal Mine as the prototype, the numerical simulation of the long pressure and short extraction ventilation roadway model is carried out by using FLUENT software, and the simulation results are verified on the spot. The results show that when the pressure extraction ratio is kept at 1.3 and the length of the radial air outlet is 0.8 m, with the increase of the width of the air outlet, the dust concentration in the roadway space first decreases and then increases, and the width of the air outlet is changed. When the width of the air outlet is 0.05 m, the dust concentration at the driver is reduced to 100 mg/m3, 20 m away from the heading face, there is basically no dust in the roadway, and the dust control effect is the best. Keeping the optimal outlet width of 0.05 m. As the radial and axial air outlet ratio decreases, the dust concentration in the roadway first decreases and then increases, when the radial and axial air outlet ratio is 1∶2, the dust is centrally controlled in the negative pressure suction area, and the dust concentration at the driver’s position of the anchor digger decreases to 1.2 mg/m3. At this time, the radial outlet wall attached air duct has the best dust control effect.

-

自2020年2月8部委联合发布《关于加快煤矿智能化发展的指导意见》以来,国内掀起了煤矿智能化建设的浪潮[1-3]。辅助运输作为煤矿生产的准备环节,担负着全矿井生产所需人员、物资及设备的中转和运输,其智能化对提供矿井生产效率和确保矿井安全有着重要意义[4]。2021年12月,国家能源局发布了《智能化示范煤矿验收管理办法(试行)》,明确了智能化示范建设煤矿的验收流程、技术要求及评分办法,为验收评审提供了依据[5]。在办法中规定I类煤矿无轨胶轮车运输须具有车辆运行状态参数监测(超速、路径偏离报警、运动轨迹等)功能。由此可见,采用无轨胶轮车运输时,路径偏离报警作为车辆运行状态参数监测指标之一,是智能化煤矿建设验收的硬性指标。

路径偏离报警数据常被应用于车辆智能调度系统运输效能分析模块,用以提升车辆运输效率。许多学者对此开展了研究。常凯等[6]提出根据井下所有机车和车辆运行信息及作业需求,快速自动规划车辆运行路线,并自动调度车辆出发时间、会车地点,此方法充分体现了智能化,但是对车辆运行状态参数监测有所缺失,无法对分析模块提供数据支撑;刘宏杰等[7]提出采用多系统融合技术将煤矿井下无轨胶轮车运行相关有效数据充分筛选,实现车辆运行流程全数字化管控,实现了运力大数据分析、司机工时分析、交通效率分析等各式各样数据报表,此系统虽然提供了多维度的报表信息,但未考虑验收标准中的路径偏离元素;刘文涛[8]提出通过无线通信链路将采集数据传送至监控中心并进行显示,同时监控中心对数据进行分析,此方法仅上传了动态位置、运行时间、运行参数和故障参数等,检测的手段已无法满足验收标准的需要。

针对上述问题,设计了一种基于UWB技术[9]的无轨胶轮车路径偏离报警方法。首先,该方法基于图论理论,利用巷道中线点之间的邻接关系,对井下路网信息结构化;其次,车辆行进过程中定位数据应呈现线性关系的物理特征,对UWB定位基站输出的车辆定位数据执行滑动窗口滤波,以屏蔽定位数据中的噪声点,提高方法整体的鲁棒性;再次,利用已构建的井下路网结构化信息,根据运输任务中设定的运输出发地和目的地,按照路线优、节能佳、安全性高的原则,采用A*搜索算法[10]对运输路径进行规划,并在搜索算法的估价函数中新增权重函数和判断因子,以提高规划的智能性;最后,对车辆当前位置的偏离情况进行实时判断,当出现偏离时,将结果实时反馈至车载交互终端中。采用此方法的应用系统在新疆伊犁一矿有限公司进行验证,证明所提方法的可行性和有效性。

1. 系统架构

系统由硬件装置和软件模块2个部分组成。硬件装置主要负责采集无轨胶轮车实时位置;软件模块根据车辆实时位置与规划好的运输路径做比对,得出是否偏离结果,并将结果推送至车载终端中,给驾驶员提示。

1.1 硬件装置

硬件装置分为井上和井下2个部分,硬件装置示意图如图1。

井上部分为辅助运输系统服务器,主要是承载软件模块。井下部分主要由UWB定位基站和无轨胶轮车组成:UWB定位基站一般安装在巷道壁一侧,2根天线分别朝向2个不同方向固定在巷道上;车辆标识卡固定在无轨胶轮车的顶部,用以减少防爆结构对标识卡的信号干扰;车载终端固定在驾驶员侧,用于人机交互。UWB定位基站通过光缆接入井下环网,车载终端通过4G/WIFI接入环网。

当车辆经过基站时,UWB定位基站的天线会侦测到车辆标识卡信号并实时计算出位置信息,同时传输至位于井上的辅助运输系统服务器内,交由软件模块做逻辑判断。

1.2 软件模块

软件部分主要由构建井下路网、车辆位置滤波、运输路径规划和偏离报警判断组成。软件模块处理流程如图2。

1)构建井下路网。巷道中线是由具有三维地理空间坐标的中线点组成的,基于图论理论,构建中线点数据结构,形成具有邻接关系的邻接矩阵,从而构建井下路网地图。

2)车辆位置滤波。利用车辆行进过程中定位数据应呈现线性关系的物理特征,对定位数据中的噪声点进行识别并执行滑动窗口滤波,以获得较为平滑且符合运动规律的定位数据,避免因干扰因素造成的误判,提高方法整体的鲁棒性。

3)运输路径规划。利用已构建的井下路网结构化信息,根据运输任务中设定的运输出发地和目的地,按照路线优、节能佳、安全性高的原则,采用基于图的A*搜索方法对运输路径进行规划,快速合理地规划出线路。

4)偏离报警判断。将车辆当前位置与运输路径的关系抽象为点与线段的位置关系判断,当点远离线段时,代表偏离。反之则代表不偏离。当出现偏离时,将结果实时反馈至车载交互终端中。

2. 功能实现

2.1 构建井下路网

井下路网数据模型示意图如图3,

井下巷道是由离散中线点和中线点间的连通关系所组成,进而形成路网结构。该结构采用图G=(V,E)描述,式中:V为顶点集合;E为边集合。E=(Vi, Vj)表示顶点i和顶点j之间的连线。中线点形成的顶点集合为{1,2,3$,\cdots , $7},中线点间连通关系采用边来描述,因连通关系具有方向性,故此图为有向图。顶点间的距离作为边的权重。

采用邻接矩阵表达上述数据模型,其构建流程如下:

1)存储中线点数据,并进行顶点唯一性编号;同时,构建顶点数组队列。中线点数据结构如图4,顶点数组如图5。

2)G-(V, E)的邻接矩阵由1个|V|×|V|的矩阵A=aij予以表示,该矩阵满足下述条件:

$$ {a}_{ij}=\left\{\begin{array}{l}{\rm{dist}},\;若(i,j)\in E\\ 0,\;其他\end{array}\right. $$ (1) 式中:aij为矩阵存储值;dist为顶点i到顶点j的欧几里得距离,距离不可达到时,为∞。

通过上述步骤循环遍历操作井下巷道各中线点数据,最终得到井下路网邻接矩阵,形成井下路网结构。井下路网邻接矩阵如图6。

2.2 车辆位置滤波

根据井下车辆单向行驶特性,从UWB定位数据角度来看,理论上定位数据应该呈现V字形分布特征,定位数据理论与实际情况如图7。

车辆第1次进入基站信号覆盖范围时,此时距离值为最远。随着行进时间的推移,当接近基站时,距离值趋于0。当驶离基站时,距离值再次变大,直至信号消失,进入下1个基站的信号覆盖范围。但是现实情况是,受巷道环境恶劣、空间狭小;存在信号干扰、遮挡、反射;以及车辆行进中的抖动等多重因素影响,定位数据存在一定的漂移,也就是噪声点。这些噪声点会被上位机处理单元识别为车辆在频繁调头,但是井下物理环境已经确定车辆无法如此操作。为了避免此种噪声点对路径偏离报警方法的准确性产生影响,因此采用局部滑动窗口滤波思路对定位数据执行滤波处理。滑动窗口处理原理及数据结构如图8。

设定滑动窗口为5 s,当识别出噪声点时,基于滑动窗口内的距离值和数据时间得出预估车速,再根据预估车速和当前的数据时间,利用式(2)得出估算距离。

$$ s=v\times \Delta t $$ (2) 式中:s为估算距离;v为预估车速;Δt为当前数据时间与上一次数据时间差。

车辆位置滤波工作流程如图9。

第1步:滑动窗口队列初始化,获取当前位置和数据时间依据数据结构入队列。

第2步:判断当前位置数据所处定位基站位置,存在2种情况:①进入/驶离阶段:将当前位置数据与上2次位置数据做比对,判断是否具有线性关系,若具有,代表不是噪声点,启动正常处理子流程,反之,代表属于噪声点,进入滤波子流程;②接近基站阶段:默认为正常数据,按正常流程处理。

滤波子流程:首先,根据当前位置的数据时间对滑动窗口队列过滤,排除非法值;其次,根据滑动窗口内的距离值和数据时间,计算出估算车速;最后,估算车速×时间得出估算距离。

正常处理子流程:判断数据时间是否在滑动窗口期内,若是,就加入队列;反之,丢弃。

按照上述步骤,完成车辆位置滤波处理。

2.3 运输路径规划

基于已构建的井下路网结构,根据运输任务运输起始点和目的地,按照路线优、节能佳、安全性高的原则,采用全局路径规划算法,快速合理地规划出线路。由于业务中的起始点和目的地大概率不是巷道中线点(即路网结构中的节点),故起始点和目的地间的路径关系分为可以直连和无法直连2种情况,无法直连是指2点之间需要借助其他节点才能够到达。2种情况的处理方式存在差异,因此以下分情况进行讨论。

2.3.1 可以直连路径规划

直接连通场景如图10。图中:S为起始点;E为目的地;a、b为中线点。

起始点和目的地同处于同一段巷道内,根据观察可得:2点可直接通行,此时可直接返回规划路线集合为:{S,E}。

2.3.2 无法直连路径规划

无法直连场景如图11。图中:S为起始点;E为目的地;a、b、c、d为中线点;a→c、b→c、a→d、b→d之间存在{0,1,2$,\cdots , $n}条路径可能。

起始点和目的地处于不同巷道内,需要经过中间点才能够到达,根据观察可得:S点行至E点存在4条路径,分别为:

$$ \left\{\begin{array}{c}S\to a\to \cdots \to c\to E\\ S\to a\to \cdots \to d\to E\\ S\to b\to \cdots \to c\to E\\ S\to b\to \cdots \to d\to E\end{array}\right. $$ 分别计算这4条路径距离,取其中代价最少的路径作为最终规划路径。2坐标之间的距离d12计算公式为:

$$ d=\sqrt{{\left({x}_{1}-{x}_{2}\right)}^{2}+{\left({y}_{1}-{y}_{2}\right)}^{2}+{\left({z}_{1}-{z}_{2}\right)}^{2}} $$ (3) 式中:(x1, y1, z1)$ d $为1#坐标;(x2, y2, z2)$ d $为2#坐标。

由于a$\to \cdots \to $c、a$\to \cdots \to $d、b$\to \cdots \to $c、b$\to \cdots \to $d的路径存在0~n种可能性,因此采用A*搜索算法做全局路径规划。A*算法是经典的启发式搜索算法,它是在经典单源路径算法Dijkstra算法的基础上改进而来。其最显著的特点就是,通过在搜索过程中给定启发函数来减少搜索节点,从而提高路径搜索效率。A*算法的估价函数f (n)表示为:

$$ f(n)=g(n)+h(n)$$ (4) 式中:f (n)为起始点至目标点的预估消耗;g(n)为起始点至当前节点的实际消耗;h(n)为当前节点至目标点的估计消耗,也称为启发函数。

A*算法搜索路径过程是:先对每一个将要访问的节点使用估价函数f(n)进行评估计算,然后选择具有最小代价估算值的节点作为下一步要到达的路径节点,再不断迭代更新搜索,直至寻找到最优路线,达到目标节点。A*算法的搜索方向是根据估价函数f(n)来确定,在搜索过程中,不用遍历地图中的所有节点。A*搜索算法工作流程如图12。

整个工作流程如下:①第1步:起点入OPEN列表;②第2步:检索相邻可达到且不在CLOSE列表中的节点,分别加入CLOSE列表并计算总代价;③第3步:代价是否最小,若最小,证明下1个节点寻找成功,将它从OPEN列表移动至CLOSE列表中,若不是最小,则直接将该点存入CLOSE列表中;④第4步:比较上一步选出的节点是否为目标点,若是就结束搜索,若不是则跳至第2步进行循环检索。

其中,OPEN列表存储未被访问过的节点;CLOSE列表存储已被访问过的节点。

A*算法的核心是估价函数f(n)的设计。在实际情况下,车辆路径规划须满足以下2个应用条件:①规划路径满足车辆行车条件:井下存在部分无法行车的巷道,如部分的运输巷、回风巷、水仓等地方,须在路径搜索算法中给予排除;②同一时段、同一路段,限制车辆进入数量:应避免规划原因导致道路拥堵,进而引发其他安全风险,实现车辆智能规划调度。

因此,常规的最短路径并不一定是运输路径最优解。对式(4)的估价函数进行改进,在其中增加权重函数和行车判断因子,得到优化后的估价函数:

$$ f\left(n\right)=g\left(n\right)\times \alpha \times \beta +h\left(n\right) $$ (5) 式中:α为权重函数;β为道路是否满足行车条件的判断因子。

$$ \alpha =\left\{\begin{array}{l}1,\;{\rm{vechile}}\_{\rm{num}}\leqslant 2\\ {\rm{vechile}}\_{\rm{num}} \div 2,\;{\rm{vechile}}\_{\rm{num}} > 2\end{array}\right. $$ (6) 式中:vechile_num为当前依据运输任务已规划出的该路段在5 min内将经过的车辆数。

表达式vechile_num≤2时,代表该路段为空闲状态,可以规划行车,此时权重值为1;反之,代表该路段为繁忙状态,应避免规划。

满足行车条件的判断因子条件为:

$$ \beta =\left\{\begin{array}{l}\infty ,\;路段不可行车\\ 1,\;路径可行车\end{array}\right. $$ (7) h(n)采用曼哈顿距离进行计算,计算公式为:

$$ h(n)=\left|x_1-x_2\right|+\left|y_1-y_2\right|+\left|z_1-z_2\right| $$ (8) 2.4 偏离报警判断

车辆实时位置与运输路径比较,最终得出车辆是否偏离预定路线的结果。比较过程可以抽象为点、线的关系,从分析来看,存在3种情况。点、线关系如图13。图13(a)~图13(c)中:A、B为规划路径的2个端点;C为车辆实时位置;D点为C点在AB线段的投影;CD线段的模为C点到AB线段的距离值。

根据图13观察可得:可通过计算${\overrightarrow{AD}} $在$\overrightarrow{AB} $的占比,从而判断出C点在线段AB的位置。计算公式为:

$$ r=\frac{\overrightarrow{AC}\cdot \overrightarrow{AB}}{{\left|\overrightarrow{AB}\right|}^{2}} $$ (9) 式中:r为占比;$\overrightarrow{AC} $为线段AC向量;$\overrightarrow{AB} $为线段AB向量;$|\overrightarrow{AB}| $为线段AB的模长。

结果值存在5种情况,分别为:

$$ r=\left\{\begin{array}{l}0,\;C=A\\ 1,\;C=B\\ < 0,\;C在AB左边\\ > 1,\;C在AB右边\\ > 0\;{\rm{and}}\; < 1,\;C在AB中间\end{array}\right. $$ (10) r=0为C在AB左边的特殊情况;r=1为C在AB右边的特殊情况;当r=0或者r=1时,处于路径内;当r<0或者r>1,不在线段AB内,继续判断其他线段;0<r<1,C点在线段AB中,需要通过公式计算出D点坐标,计算公式为:

$$ \left\{\begin{array}{c}{x}_{{\rm{d}}}={x}_{{\rm{a}}}+({x}_{{\rm{b}}}-{x}_{{\rm{a}}})\times r\\ {y}_{{\rm{d}}}={y}_{{\rm{a}}}+({y}_{{\rm{b}}}-{y}_{{\rm{a}}})\times r\\ {z}_{{\rm{d}}}={z}_{{\rm{a}}}+({z}_{{\rm{b}}}-{z}_{{\rm{a}}})\times r\end{array}\right. $$ (11) 式中:(xd,yd,zd)为D点坐标;(xa,ya,za)为A点坐标;(xb,yb,zb)为B点坐标。

最终,通过计算点C和点D 2点间的距离,获得点C距离线段AB的距离。根据这个距离值进行最终判断。

3. 试验分析

新疆伊犁能源伊犁一矿使用无轨胶轮车执行井下运输任务,井下路网是由109条巷道,总计452个中线点组成;UWB定位基站65个,已基本实现重点路段UWB信号全覆盖;在册车辆数为35辆。

3.1 车辆位置滤波试验

一般情况,弯道处的UWB定位基站容易受煤璧反射信号的影响,而出现定位数据偏差的情况。为了验证滤波效果,故选取车流量大,且位于弯道处的上、下井均需要经过的“26-缓坡斜口600 m”UWB定位基站作为试验对象。车辆位置滤波试验环境如图14。

以车牌号为新KY0060为例,持续观察车辆经过该UWB定位基站时定位数据的变化情况。通过观察车辆位置原始值与滤波值可得:滤波函数可识别出噪声点数据,并对其进行滤波,滤波后的轨迹数据更符合现实运动规律。

为了验证滤波函数是否对正常数据产生影响,在图14中选择“22-缓坡井口200 m”UWB定位基站作为试验对象,该定位基站位于巷道中部,天线正负方向与巷道方向水平,信号干扰少。再次以新YK0060为例,观察车辆经过定位基站时定位数据的变化情况。观察可得:滤波值与原始值曲线重合,证明滤波函数不会对正常数据产生影响。

3.2 运输路径规划试验

在车辆调度模块中,选取“59-1506W下巷口”作为用车申请的出发地,“99-1503联络巷上巷交叉口”作为目的地。路径规划实验环境如图15。

出发地至目的地存在2条路径可选,路线Ⅰ为:出发地→1503进风巷→1506W回风巷→辅运大巷→1503E至辅运联络巷→目的地路径距离为639.68 m;路线Ⅱ为:出发地→1506W回风巷→1506W回风巷外段→1503E联络巷→目的地,路径距离为659.15 m。在用车申请中选择不同的用车时间,观察路径规划逻辑的正确性。试验方法如下:

1)用车时间选择为当前时刻,此时系统中仅存在1条该时刻的用车申请,由于路径Ⅰ的代价为639.68 m,小于路径Ⅱ的代价(659.15 m),根据代价最小的策略,系统规划出的路径为路径1。

2)再次提交相同时刻的用车申请,此时系统中存在2条该时刻的相同出发地和目的地的用车申请,由于路径Ⅰ在相同时段经过的车辆数为2,经过式(6)计算,路径Ⅰ的权重为1,因此路径Ⅰ的总代价仍为639.68 m,小于路径Ⅱ的代价,因此系统规划出的路径为路径Ⅰ。

3)参照方法2,提交相同时刻的用车申请,此时系统中存在3条该时刻相同出发地和目的地的用车申请,在此时,由于路径Ⅰ在相同时段经过的车辆数为3,经过式(6)计算,路径Ⅰ的权重值为1.5,因此路径Ⅰ的总代价为639.68×1.5×1=959.52 m,远超过路径Ⅱ的代价,因此系统规划出的路径为路径Ⅱ。

4)最后,提交不同时刻的用车申请,此时系统中仅存在1条该时刻的用车申请,因此路径Ⅰ的权重值为1,其总代价小于路径Ⅱ,因此系统规划出的路径为路径Ⅰ。

经过上述4种方法试验结果表明:预期理论值与程序逻辑一致,路径规划准确性得到验证。

3.3 偏离报警判断试验

以试验现场为例,在判断函数前后增加性能监听函数,经过一段时间的运行,累计记录1 243次性能记录,其中运行最大耗时为50 ms,最小耗时为13 ms,平均耗时约为25 ms。

试验结果表明:此判断计算方法可满足于现场应用要求。

4. 结 语

为满足《智能化示范煤矿验收管理办法(试行)》中针对I类煤矿无轨胶轮车运输的验收指标要求,设计了一种基于UWB定位技术的无轨胶轮车路径偏离报警方法。该方法通过井下路网构建、车辆位置滤波、运输路径规划和偏离报警4个步骤实现。方法在新疆伊犁一矿现场试验结果表明:①滤波函数可有效过滤定位数据中的噪声点,提高系统的鲁棒性;②运输路径规划中在估价函数中增加权重函数和判断因子参数,使得路径规划可结合巷道内行车拥堵情况,同时可避开某些无法行车的道路,实现了运输路径的智能规划和车辆调度;③偏离报警判断平均逻辑响应时间约为25 ms,可满足现场应用要求。法具有2项优势:①实用性:通过试验验证,方法性能稳定、运行时效性高,可满足验收指标要求;②低成本:整套技术方案无需额外加装硬件装置,完全借助软件实现,具有低成本的优势。

-

表 1 边界条件参数设置

Table 1 Boundary condition parameters setting

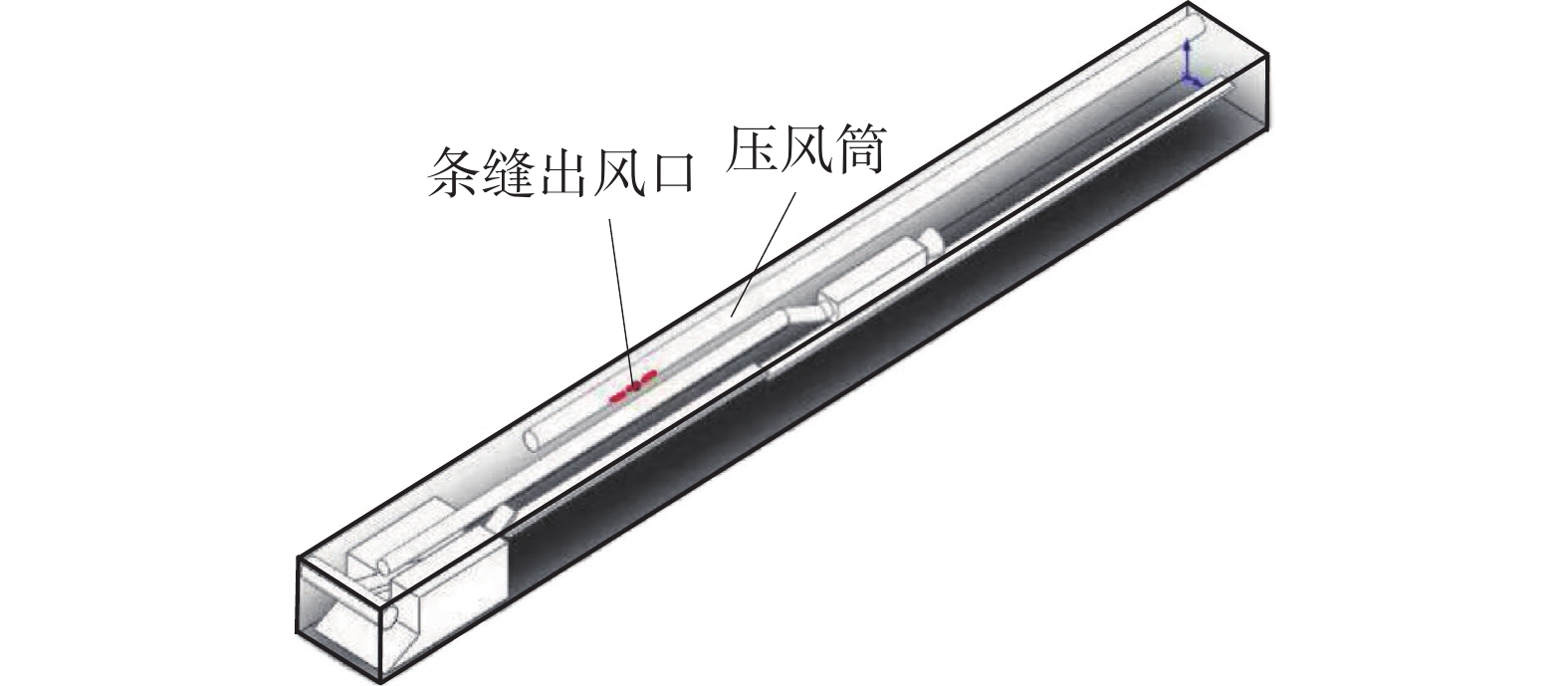

边界条件 设置 空气密度/(kg·s−3) 1.225 壁面粗糙度/m 0.02 动力黏度/(kg·s−1·m−1) 1.81×10−5 压风筒风速/(m·s−1) 12.1 压风筒水力直径/m 1 压风筒湍流强度/% 2.92 抽风筒风速/(m·s−1) −16.59 抽风筒水力直径/m 0.8 抽风筒湍流强度/% 2.8 除尘器出流风速/(m·s−1) 5.42 除尘器出流水力直径/m 1.4 除尘器出流湍流强度/% 3.09 巷道出口边界类型 自由出流 附壁风筒出风口长度/m 0.8 附壁风筒出风口间距/m 0.2 附壁风筒风速/(m·s−1) 6.1 出风口壁面类型 Velocity-inlet DPM Reflect类型 -

[1] 丁翠. 掘进巷道粉尘运移扩散规律研究进展[J]. 煤矿安全,2018,49(9):219−222. DING Cui. Research progress of dust movement and diffusion laws in excavation roadway[J]. Safety in Coal Mines, 2018, 49(9): 219−222.

[2] 罗振敏, 刘荣玮, 程方明, 等. 煤尘爆炸的研究现状及发展趋势[J]. 矿业安全与环保, 2020, 47(2): 94-98. LUO Zhenmin, LIU Rongwei, CHENG Fangming, et al. Research status and development trend of coal dust explosion[J]. Mining Safety & Environmental Protection, 2020, 47(2): 94-98.

[3] 李雨成,刘宗桃,刘蓉蒸,等. 综掘工作面风幕控尘装置设计及试验研究[J]. 煤炭科学技术,2017,45(10):66−71. LI Yucheng, LIU Zongtao, LIU Rongzheng, et al. Design and experiment study on air curtain dust control device of mine fully-mechanized heading face[J]. Coal Science and Technology, 2017, 45(10): 66−71.

[4] HUA Y, NIE W, LIU Q, et al. The development and application of a novel multi-radial-vortex-based ventilation system for dust removal in a fully mechanized tunnelling face[J]. Tunnelling and Underground Space Technology, 2020, 98: 103253. doi: 10.1016/j.tust.2019.103253

[5] 侯树宏,郝军,李腾龙,等. 综掘工作面通风控尘参数匹配关系研究及应用[J]. 煤炭技术,2022,41(1):166−169. doi: 10.13301/j.cnki.ct.2022.01.038 HOU Shuhong, HAO Jun, LI Tenglong, et al. Research and application of ventilation and dust control parameters matching in fully mechanized driving face[J]. Coal Technology, 2022, 41(1): 166−169. doi: 10.13301/j.cnki.ct.2022.01.038

[6] 邹常富. 岩巷产尘规律及控风除尘技术研究[J]. 煤炭技术,2021,40(4):77−79. ZOU Changfu. Research on dust generation law of rock drift and wind control and dust removal technology[J]. Coal Technology, 2021, 40(4): 77−79.

[7] 荔军. 基于附壁风筒的综掘工作面除尘技术研究进展[J]. 煤炭科学技术,2020,48(11):52−59. LI Jun. Research progress of dust removal technology based on wall-mounted duct in fully-mechanized driving face[J]. Coal Science and Technology, 2020, 48(11): 52−59.

[8] 王建国,王康,樊亦洋. 附壁风筒条缝参数对综掘工作面控尘效果的影响[J]. 煤矿安全,2021,52(6):206−210. WANG Jianguo, WANG Kang, FAN Yiyang. Influence of slot parameters of wall-attached air duct on dust control effect of fully mechanized mining face[J]. Safety in Coal Mines, 2021, 52(6): 206−210.

[9] 杨俊磊. 附壁风筒轴径向出风比与出风距离对控尘效果的影响[J]. 黑龙江科技大学学报,2022,32(2):180−184. doi: 10.3969/j.issn.2095-7262.2022.02.008 YANG Junlei. Influence of ratio of axail and radial air and distance of axial and radial wind on dust control effect[J]. Journal of Heilongjiang University of Science & Technology, 2022, 32(2): 180−184. doi: 10.3969/j.issn.2095-7262.2022.02.008

[10] 王康. 快速掘进工作面粉尘分布规律及综合防治技术研究[D]. 西安: 西安科技大学, 2021. [11] 杨泽安,王义亮. 综掘工作面湿式除尘条件下尘雾耦合数值模拟[J]. 煤矿安全,2021,52(11):170−175. YANG Zean, WANG Yiliang. Numerical simulation of dust and spray coupling under wet dust removal conditionin fully mechanized excavation face[J]. Safety in Coal Mines, 2021, 52(11): 170−175.

[12] 蒋仲安,杨斌,张国梁,等. 高原矿井掘进工作面截割粉尘污染效应及通风控尘参数分析[J]. 煤炭学报,2021,46(7):2146−2157. JIANG Zhongan, YANG Bin, ZHANG Guoliang, et al. Analysis of dust pollution effect of cutting dust and ventilation control parameters at the heading face in plateau mines[J]. Journal of China Coal Society, 2021, 46(7): 2146−2157.

[13] 樊亦洋. 综掘面风幕抽吸控尘系统参数优化的数值模拟研究[D]. 西安: 西安科技大学, 2020. -

期刊类型引用(4)

1. 唐维东,张九通,廖明亮,吴达科,蒋猛. 基于ZigBee的工厂化堆沤有机肥监控系统设计. 西南大学学报(自然科学版). 2024(05): 216-228 .  百度学术

百度学术

2. 袁建文. 基于TDOA/TOF混合技术的井下人员及车辆定位. 工矿自动化. 2024(S1): 39-42 .  百度学术

百度学术

3. 郝永强. 无轨胶轮车在煤矿井下辅助运输中的应用分析. 能源与节能. 2024(11): 259-261 .  百度学术

百度学术

4. 韩燕南,高文,贺耀宜. 基于精确定位技术的煤矿井下小型车避让预警方法. 煤矿安全. 2024(12): 243-249 .  本站查看

本站查看

其他类型引用(0)

下载:

下载: